|

市场调查报告书

商品编码

1643088

过程仪器:市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Process Instrumentation - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

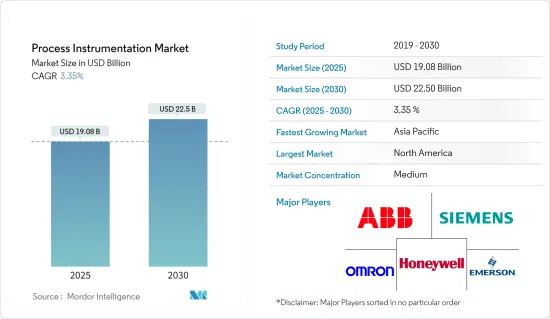

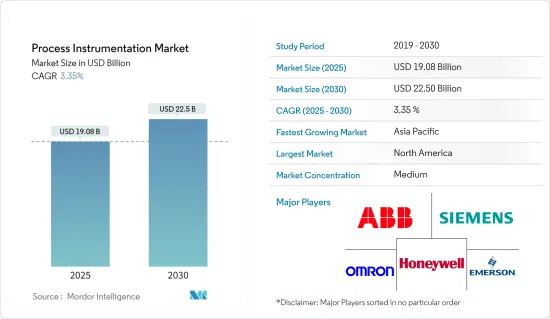

製仪器市场规模预计在 2025 年为 190.8 亿美元,预计到 2030 年将达到 225 亿美元,预测期内(2025-2030 年)的复合年增长率为 3.35%。

技术创新和对过程控制系统日益增长的需求推动着市场的发展。此外,成本效率、缩短工程时间、资产利用率和能源效率是推动製程仪器市场成长的关键因素。

关键亮点

- 许多终端行业都需要製程仪器。使用过程仪器有许多好处,包括提高产品品质、减少排放、减少人为错误和节省成本。记录、定位、测量和控制等关键参数对于製造设备的平稳运作至关重要,因此对于製程设备来说,实现关键水准的绝对可靠性、精度和准确性是重中之重,从而促进市场成长。

- 对于製程仪器解决方案供应商来说,长期合约具有显着的优势,因为它们可以提供财务保障。因此,它已成为主要企业的关键技术,尤其是在获得政府合约方面。例如,西门子于 2022 年 9 月透露,它已被选中对国有埃及电力控股公司旗下亚历山大电力配电公司 (AEDC) 的配电控製网路和增强计量网路进行现代化改造。

- 在製造业中,连网设备和感测器的激增以及 M2M通讯的实现正在产生越来越多的资料点。根据 Zebra 最新的工业视觉研究,预计到 2022 年,由物联网和 RFID 驱动的智慧资产追踪系统将取代传统的基于电子表格的方法。

- 製造业最近大力推广自动化,推动了市场的成长。这是因为业界越来越认识到自动化在上市速度、投资成本和生产品质方面的多种优势。然而,预测期内高昂的初始投资和维护成本预计将阻碍市场成长。

- 由于劳动力短缺,新冠疫情推动了对工业自动化的需求。自新冠肺炎疫情以来,企业在其生产过程中加大了对智慧机器人和技术的采用。机器人被视为提高产量的重要工具。机器人技术的大部分应用发生在工业领域,机器比人类更有效率、更可靠地执行许多手动任务。

过程仪器市场趋势

用水和污水处理预计将实现最高成长

- 製程仪器用于监测製程工厂中的各种参数,例如流量、压力、温度、pH 值、电导率、液位、浊度、速度、力、湿度以及用水和污水处理中的其他因素。

- SCADA 系统广泛用于监控和调节水和污水处理流程。这些使操作员能够监控水箱、运河、水库等的消费量、流量和内容。此外,它还提供您所处理的水的状况的资料。 SCADA 技术经常用于管理雨水排水基础设施和调节污水处理厂。

- 当前水资源供应和永续性面临的挑战主要是由于需求的大幅增加。然而,根据美国环保署(EPA)2022年5月的数据,美国家庭漏水每年浪费约9,000亿加仑的水。这相当于约1100万户家庭一年的用水量。这就需要采用流量控制阀等製程仪器,刺激市场成长。

- 此外,美国环保署(EPA)正在加快对老化水利基础设施的投资。例如,2022年11月,美国环保署核准向德克萨斯州普弗格维尔市提供5,200万美元的水基础设施融资和创新法案(WIFIA)赠款,以支持水处理厂现代化计划。利用 WIFIA 贷款,EPA 正在帮助该设施增加其可处理的饮用水量,同时使用现代化的处理和过滤设备保持水质更健康。

- 预计未来几年政府在污水处理方面加大力度的措施将促进该领域的成长。例如,2022年10月,纽约州长在布法罗鸟岛污水处理厂启动了一项耗资5,500万美元的污水升级倡议。

亚太地区成为快速成长的市场

- 由于工业活动的快速增长、成本压力和生产率的上升以及中国和印度等开发中国家政府的有利倡议,预计亚太地区将在预测期内以最快的速度增长。

- 该地区产业部门的扩张和石油和天然气使用的增加正在推动工业向前发展。例如,中国计划在2025年将其庞大的天然气管道网路扩建至163,000公里,需要投资1.9兆美元。

- 预计该地区终端用途开发的不断增加将为市场参与企业创造有利可图的机会来改善他们的足迹。 2022 年 1 月,阿达尼集团与道达尔能源的伙伴关係阿达尼道达尔天然气有限公司 (ATGL) 获得许可,在另外 14 个地区开发城市燃气发行(CGD) 基础设施,投资额为 2000 亿印度卢比(约合 2000 亿美元)。

- 石油和天然气消费量的增加必然导致新的生产设施的建立,从而增加了对製程仪器的需求。根据国际能源总署预测,到2040年,石油产量预计将超过1,500万桶/日。此外,根据IBEF的数据,到2040年天然气使用量预计将超过1.4308亿吨。因此,预计石油和天然气需求的增加将促进该地区市场的成长。

- 政府在向大众宣传技术的好处以及增加用于在工业中采用技术先进的机械的资金方面发挥积极作用,对于该地区的市场成长至关重要。预计未来几年市场将受到金属和采矿、化学品、食品和饮料以及石油和天然气等主要终端行业的强劲增长的推动。

製程仪器产业概况

过程仪器市场细分程度适中,包括全球和区域参与企业,例如霍尼韦尔国际公司、西门子股份公司、欧姆龙参与企业、ABB 有限公司和艾默生电气公司。这些主要企业正在采用各种策略,例如新产品发布、扩张、协议、合资、伙伴关係和收购,以扩大其在市场上的影响力。

2022 年 11 月,Equilibar推出了专门的一次性技术分店,以满足製药业不断变化的流体管理要求。 SDO 阀门是 Equilibar 首款可精确调整背压和流量的一次性流体控制设备。该公司声称:“SDO 是一种液体润湿的一次性阀门,在製药製造领域是独一无二的。” 2022 年 9 月,领先的工业技术和物联网 (IoT) 解决方案开发商 OleumTech 在其快速扩展的 H 系列硬连线製程仪器线中增加了智慧差压 (DP) 变送器。创新的 DP 变送器提供了石化、上游石油和天然气、电力、化学和污水等行业所需的卓越性能、可靠性和准确性。 2022 年 7 月,艾默生推出了 TESCOM Anderson Greenwood Instrumentation H2 阀门系列,该系列支援高达 15,000 psi (103.4 MPa) 的压力。这项创新技术可靠地隔离製程压力,减少逸散污染物,并提高氢气加註设施和长管拖车等高压气体操作的安全性。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 市场概况

- 市场驱动因素

- 节能生产流程的需求不断增加

- 以最小的成本实现高效率

- 市场限制

- 研发成本上升

- 引入和维护解决方案和设备的成本上升

- 价值链分析

- 波特五力模型

- 新进入者的威胁

- 买家的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争强度

第五章 市场区隔

- 测量仪器

- 发射机

- 控制阀

- 科技

- 可程式逻辑控制器 (PLC)

- 分散式控制系统(DCS)

- 监控和资料采集 (SCADA)

- 製造执行系统(MES)

- 最终用户

- 用水和污水处理

- 化学製造

- 能源公共产业

- 石油和天然气开采

- 金属和采矿

- 其他製程工业

- 地区

- 北美洲

- 欧洲

- 亚太地区

- 其他的

第六章 竞争格局

- 公司简介

- Honeywell International Inc.

- Siemens AG

- Omron Corporation

- ABB Ltd.

- Emerson Electric Company

- Rockwell Automation Inc.

- Mitsubishi Electric Corporation

- Danaher Corporation

- Metso Corporation

- Yokogawa Electric Corporation

- Endress+Hauser AG

第七章投资分析

第八章 市场机会与未来趋势

The Process Instrumentation Market size is estimated at USD 19.08 billion in 2025, and is expected to reach USD 22.50 billion by 2030, at a CAGR of 3.35% during the forecast period (2025-2030).

The market is driven by technological innovations and increasing demands for process control systems. Moreover, cost efficiency, reduction in engineering time, asset utilization, and energy efficiency are some of the major factors driving the growth of the process instrumentation market.

Key Highlights

- Process instrumentation equipment is needed in a wide range of end-use industries. The use of process instrumentation equipment offers a host of benefits, including improvement in the quality of the product, emission reduction, reduction in human errors, and cost-savings. Significant parameters like recording, positioning, measuring, and controlling fuel the market's growth as they are essential for the smooth functioning of a manufacturing unit and are top priorities for process instruments for achieving significant levels of absolute reliability, accuracy, and precision.

- A long-term contract is a significant gain for process instrumentation solution suppliers because it ensures a steady stream of money. As a result, it is a critical technique for top companies to secure contracts, particularly from governments. Siemens, for example, revealed in September 2022 that it had been selected to modernize the distributing control network and enhanced metering network for Alexandria Electricity Distribution Company (AEDC), a part of the state-owned Egyptian Electrical Holding Company.

- The manufacturing business has seen an increase in data points created due to the widespread use of connected equipment and sensors and the enablement of M2M communication. According to Zebra's newest industrial vision research, intelligent asset tracking systems centered on IoT and RFID are predicted to outperform conventional spreadsheet-based approaches by 2022.

- The recent surge in the adoption of automation in the manufacturing sector has contributed to market growth. This is due to a greater industrialist understanding of the several advantages of automation in respect of speed to market, investment outlay, and output quality. However, high initial and maintenance investment cost is expected to hamper the market growth over the forecast period.

- The COVID-19 pandemic boosted the demand for industrial automation due to labor shortages. Post Covid-19, companies are increasingly adopting intelligent robotics and technology across the production processes. Robotics are seen as critical instruments for increasing production. The majority of robotic acceptance has happened in the industrial sector, wherein machines do numerous manual jobs more effectively and reliably than humans.

Process Instrumentation Market Trends

Water and Wastewater Treatment is Expected to Witness the Highest Growth

- Process instrumentations are used to monitor various parameters in process plants, such as flow, pressure, temperature, pH, conductivity, level, turbidity, speed, force, humidity, and other factors in water & wastewater treatment.

- SCADA systems are widely employed in monitoring and regulating water and waste treatment processes. These enable operators to monitor the consumption, flows, and contents of water tanks, canals, reservoirs, and others. Furthermore, these give data on the condition of the water being handled. SCADA technologies are frequently utilized to manage stormwater draining infrastructure and regulate wastewater purification plants.

- The current challenges of water availability and sustainability are primarily attributed to an enormous increase in demand. However, as per U.S. EPA in May 2022, Household leaks waste around 900 billion gallons of water per year in the United States. That is equivalent to roughly 11 million households' annual water use. This necessitates the adoption of process instrumentation, such as flow control valves, fueling market growth.

- Moreover, the United States Environmental Protection Agency (EPA) has accelerated investment in the nation's aging water infrastructure. For instance, in November 2022, the U.S. The EPA approved a USD 52 million Water Infrastructure Finance and Innovation Act (WIFIA) grant to the City of Pflugerville, Texas, to support the Water Treatment Plant Modernization Project. With the WIFIA loan, the EPA is assisting the facility in increasing the amount of drinking water it can process while also keeping the water healthier to consume with modern treatment and filter equipment, which in turn is expected to propel the growth of the process instrumentation market in the industry.

- Increasing government initiatives in wastewater treatment are expected to contribute to segment growth over the coming years. For instance, in October 2022 New York Governor launched a USD 55 million wastewater upgrade initiative at Buffalo's Bird Island Wastewater Processing Facility.

Asia Pacific to Emerge as the Fastest Growing Market

- Asia Pacific is expected to have the fastest growth over the forecast due to rapidly increasing industrial activities, rising cost pressure and production rate, and favorable government policies in developing nations such as China and India in this region.

- The region's expanding industrial sector and increased oil & gas usage are propelling the industry ahead. For instance, China intends to increase its massive gas pipeline networks to 163,000 kilometers by 2025, requiring a USD 1.9 trillion investment.

- Increasing end-use developments in the region are expected to create lucrative opportunities for market participants to improve their footprints. In January 2022, Adani Total Gas Ltd (ATGL), a collaborative partnership among the Adani Group and TotalEnergies, secured licenses to develop its City Gas Distribution (CGD) infrastructure to 14 additional geographical regions with an INR 20,000-crore (~USD 200 Billion) investment.

- The rising consumption of oil & gas will necessitate the establishment of new production facilities, boosting the requirement for process instrumentation. According to the IEA, daily oil output is expected to exceed 15 million barrels by 2040. Further, according to the IBEF, natural gas usage is expected to surpass 143.08 million tons by 2040. Thus, increasing demand for oil & gas is expected to contribute to regional market growth.

- The active role of governments in educating the masses regarding the benefits of technology and rising funds being diverted towards adopting technologically advanced machinery in industries has been of prime importance for market growth in the region. In the next few years, the market will be driven by the thriving growth of key end-use industries such as metal and mining, chemical, food and beverages, oil & gas, and others.

Process Instrumentation Industry Overview

The process instrumentation market is moderately fragmented, with the presence of both global and regional players such as Honeywell International Inc., Siemens AG, Omron Corporation, ABB Limited, and Emerson Electric Co., among others. These key players are adopting various strategies such as new product launches, expansions, agreements, joint ventures, partnerships, acquisitions, and others to increase their footprints in the market.

In November 2022, Equilibar launched a dedicated Single Use Technology Branch to address the pharmaceutical industry's ever-changing fluid management requirements. The SDO valves are Equilibar's first single-usage fluid control device, which precisely regulates back pressures and flow. "The SDO is the unique wetted per-use valve in the pharmaceutical production area," claims the company. In September 2022, OleumTech, a leading developer of industrial technology and Internet of Things (IoT) solutions, added a Smart Differential Pressure (DP) Transmitter to its rapidly expanding H Series range of hardwired processes instrumentation. The innovative DP Transmitter provides the superior performance, dependability, and precision required by industrial industries such as petrochemical, upstream oil and gas, electricity, chemical, and wastewater. In July 2022, Emerson introduced the TESCOM Anderson Greenwood Instrumentation H2 Valve Range for hydrogen operations with pressures up to 15,000 psi (103.4 MPa). The innovative technology reliably separates process pressures in high-pressure gas operations, including hydrogen filling facilities and tube trailers, lowering fugitive pollutants and increasing safety.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing demand for energy-efficient production processes

- 4.2.2 High level of efficiency with minimum cost

- 4.3 Market Restraints

- 4.3.1 Higher cost of research and development

- 4.3.2 Higher cost of implementation and maintenance of solutions and devices

- 4.4 Value Chain Analysis

- 4.5 Porters Five Forces

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Bargaining Power of Suppliers

- 4.5.4 Threat of Substitute Products

- 4.5.5 Intensity of Competitive Rivalry

5 MARKET SEGMENTATION

- 5.1 Instrument

- 5.1.1 Transmitter

- 5.1.2 Control Valve

- 5.2 Technology

- 5.2.1 Programmable Logic Controller (PLC)

- 5.2.2 Distributed Control System (DCS)

- 5.2.3 Supervisory Control and Data Acquisition (SCADA)

- 5.2.4 Manufacturing Execution System (MES)

- 5.3 End-User

- 5.3.1 Water and Wastewater Treatment

- 5.3.2 Chemical Manufacturing

- 5.3.3 Energy & Utilities

- 5.3.4 Oil and Gas Extraction

- 5.3.5 Metals and Mining

- 5.3.6 Other Process Industries

- 5.4 Geography

- 5.4.1 North America

- 5.4.2 Europe

- 5.4.3 Asia-Pacific

- 5.4.4 Rest of the World

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 Honeywell International Inc.

- 6.1.2 Siemens AG

- 6.1.3 Omron Corporation

- 6.1.4 ABB Ltd.

- 6.1.5 Emerson Electric Company

- 6.1.6 Rockwell Automation Inc.

- 6.1.7 Mitsubishi Electric Corporation

- 6.1.8 Danaher Corporation

- 6.1.9 Metso Corporation

- 6.1.10 Yokogawa Electric Corporation

- 6.1.11 Endress+ Hauser AG