|

市场调查报告书

商品编码

1683181

策略性矿物材料市场:市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Strategic Mineral Materials - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

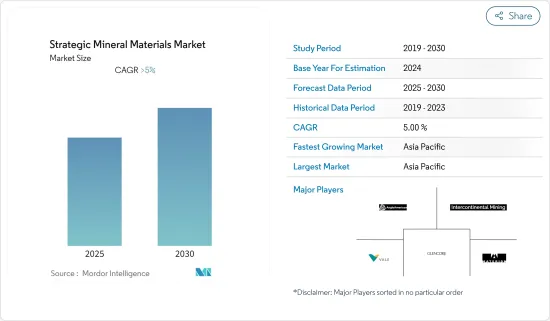

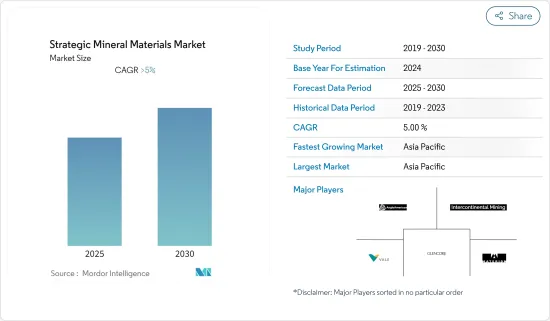

预测期内,策略性矿产市场预计将以超过 5% 的复合年增长率成长

关键亮点

- 然而,COVID-19 疫情的影响和对采矿作业日益增长的环境担忧预计将阻碍市场成长。

- 各种策略性矿产的使用基础不断增加预计将成为未来的一个机会。

- 亚太地区占据市场主导地位,其中中国是最大的消费国,其次是印度、韩国和日本。

战略矿物材料市场趋势

钢铁应用占铌市场主导地位

- 一般来说,钢的性能取决于钢的碳、锰、磷、硅、合金元素和细合金元素等化学成分以及加工条件。一般来说,提高钢强度最简单的方法就是增加碳含量。然而,这会对其他所需性能(如可焊性、韧性和成形性)产生不利影响。

- 但由于铌与碳的亲和性较大,能形成碳化物和碳氮化物,因此,常以铌铁的形式添加到钢和不銹钢中,以保持平衡的性能。最终的产品被称为微合金钢,通常含有约0.1%重量的铌,通常与钛和/或钒结合。

- 在 HSLA 钢中,铌通常占合金总量的不到 0.1%,但其作为结晶细化剂的作用却有很大不同,可提高钢的强度、可焊性、延展性和韧性。低等级钢的强度来自于结晶尺寸,而高等级钢的强度来自于结晶晶粒尺寸和沈淀硬化的结合。

- 低等级钢的强度来自于结晶尺寸,而高级钢的强度来自于结晶尺寸和沈淀硬化的结合。由于铌和钛与碳、氮等间隙元素结合,因此这些钢被描述为无间隙钢。

- 然而,最好的结果通常是透过结合利用协同优势的精细合金来实现的。例如,在「暴露」的无机钢汽车部件上将铌与钛结合使用,这对于出色的表面品质至关重要。

- 大多数现代 HSLA 钢都属于这个「低碳」类别。全球范围内,90%的铌产品用于钢铁业。

- 铌在高强度低合金(HSLA)钢中的最大用途是汽车、石油管线和建筑。 HSLA 钢也用于核子反应炉(与锆合金製成核心元件)、风力发电机、铁路轨道和造船。 HSLA 钢消耗了每年铌产量的约 90%。

- 铌铁是钢铁业应用最广泛的产品,主要用于管道、汽车、结构钢和不銹钢四个领域。在管道产业方面,中国的应用与全球其他地区类似,但在汽车用钢、结构钢和不銹钢产业的应用有很大差异。

亚太地区占市场主导地位

亚太地区占据全球市场主导地位。中国、印度、韩国和日本等国家正经历各种矿物在各种用途上的加速利用,预测期内该市场可能会显着成长。由于印度和中国等国家的高需求,亚太地区的电气和电子产业(包括半导体和通讯)近年来发展迅速。由于电子产业创新、技术进步和研发活动的快速发展,对最新电子产品的需求很高。专门生产高端产品的製造工厂和研发中心的数量也在增加。航太是战略矿物材料的另一个主要终端用户产业。随着全球对飞机的需求不断增加,航太业正在寻求实施创新解决方案来缩短生产时间并降低成本。因此,预测期内上述因素将加速战略矿物材料在各种应用上的使用。然而,由于该地区目前的 COVID-19 疫情可能继续影响经济表现和需求,因此整个 2020 年的需求可能仍会受到影响。

策略性矿产和材料产业概况

全球策略性矿物材料市场本质上是分散的,因为有许多公司经营各种矿物。市场上一些知名的公司包括洲际矿业、淡水河谷、英美资源集团、嘉能可、CBMM 和 Materion Corporation。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 调查前提条件

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 驱动程式

- 各终端用户产业的需求不断增加

- 其他驱动因素

- 限制因素

- 新冠肺炎疫情的影响

- 采矿作业的环境问题日益严重

- 产业价值链分析

- 波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章 市场区隔

- 矿物

- 锑

- 阻燃剂

- 电池

- 陶瓷和玻璃

- 催化剂

- 合金

- 重晶石

- 石油和天然气

- 其他用途(油漆、化学品製造等)

- 铍

- 电子产品

- 航太

- 车

- 活力

- 其他的

- 钴

- 电池

- 高温合金

- 硬质合金和钻石工具

- 催化剂

- 其他的

- 萤石

- 化学品

- 钢

- 铝

- 水泥

- 其他的

- 镓

- 积体电路

- 雷射二极体

- 受光元件

- 太阳能电池

- 其他的

- 鎗

- 光纤

- 红外线光学

- 催化剂

- 电气和太阳能设备

- 其他的

- 铟

- 平板显示器和触控萤幕

- 低熔点合金和焊料

- 半导体

- 透明热反射器

- 其他的

- 锰

- 铸造合金

- 包装

- 运输

- 建筑学

- 其他的

- 铌

- 钢

- 高温合金

- 超导磁铁

- 电容器

- 玻璃

- 其他的

- 铂族元素

- 自催化

- 珠宝饰品

- 电气和电子

- 化学

- 其他的

- 稀土

- 催化剂

- 电池

- 磁性合金

- 冶金

- 其他的

- 钽

- 电子产品

- 医疗

- 航太

- 车

- 其他的

- 锑

- 地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 东南亚国协

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 义大利

- 法国

- 西班牙

- 欧洲其他地区

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争格局

- 併购、合资、合作、协议

- 市场占有率/排名分析

- 主要企业策略

- 公司简介

- Anglo American plc

- CBMM

- Glencore

- Indium Corporation

- Intercontinental Mining

- Materion Corporation

- South32

- Vale

- WARRIOR GOLD INC.

第七章 市场机会与未来趋势

- 扩大各种矿物质的用途

The Strategic Mineral Materials Market is expected to register a CAGR of greater than 5% during the forecast period.

Key Highlights

- On the flipside, the impact of COVID-19 pandemic and increasing environmental concerns regarding mining operations is expected to hinder the growth of the market.

- Increasing application base for various strategic minerals is projected to act as an opportunity in the future.

- Asia-Pacific dominated the market with the largest consumption coming from China, followed by India, South Korea, and Japan.

Strategic Mineral Materials Market Trends

Steel Application to Dominate the Niobium Segment

- In general, the properties of steel depend on its chemical composition concerning carbon, manganese, phosphorus, silicon, alloying and micro-alloying elements, and processing conditions. Generally, the easiest way to increase the strength of steel is improving its carbon content. But this adversely affects other necessary properties, such as weldability, toughness, and formability.

- However, niobium has a high affinity for carbon, forming carbides and carbon nitrides, therefore, it is often added to steel and stainless steel in the form of ferro-niobium to maintain a balanced package of properties, the carbon and niobium levels being carefully matched with processing conditions to achieve the desired properties. The result, known as a micro-alloyed steel product, typically contains around 0.1% niobium by weight, often in conjunction with titanium and vanadium.

- In HSLA steel niobium is often less than 0.1% of the total alloy, but its role as a grain refiner makes a significant difference by increasing strength, weldability, ductility, and toughness of the steel. Strength is generated by grain refinement for the lower grades and a combination of grain refinement and precipitation hardening for the higher grades.

- Strength is generated by grain refinement for the lower grades and a combination of grain refinement and precipitation hardening for the higher grades. These steels are described as interstitial-free, since niobium and titanium fix interstitial elements, like carbon and nitrogen.

- However, the best results are usually achieved with a combination of micro alloys that exploit synergistic benefits. An example of this is the use of niobium and titanium together in 'exposed' interstitial-free steel automobile parts where superior surface quality is essential.

- Most modern HSLA steels fall into this 'low carbon' category. Globally, 90% of the niobium products are used in the steel industry.

- The largest use for niobium in high-strength and low-alloy (HSLA) steel is for automobiles, oil pipelines, and construction. HSLA steels are also used in nuclear reactors (alloyed with zirconium to make core elements), wind turbines, railroad tracks, and in ship building. HSLA steels consume approximately 90% of the annual niobium production.

- Ferro niobium is the most widely used product in the steel industry, which is mainly applied in four fields of the pipeline, automobile, structure, and stainless steel. As for the pipeline industry, the application in China is in line with that in the other parts of the world, but the difference is significant in the application in automotive steel, structural steel, and stainless steel industries.

Asia-Pacific to Dominate the Market

Asia-Pacific dominated the global market. With accelerating usage of various minerals in different applications in countries, such as China, India, South Korea, and Japan, the market studied is likley to witness significant growth during the forecast period. The Asia-Pacific electrical and electronics industry (including semiconductors and telecommunications) grew rapidly in the recent past, owing to the high demand from countries, like India and China. There is a high demand for modern electronic products, due to the rapid pace of innovation, the advancement of technology, and R&D activities in the electronics industry. There is a growth in the number of manufacturing plants and development centers, focusing on high-end products. Aerospace is the another major end-user industry for strategic mineral materials. The demand for aircraft is increasing across the world, and the aerospace industry is aiming to introduce innovative solutions to improve the manufacturing time and save costs. Therefore, the aforementioned factors are accelerating the usage of strategic mineral materials from various applications during the forecast period. However, the demand is likely to be affected during 2020 as well, as economic performance and demand are likely to remain affected by the current COVID-19 pandemic in the region.

Strategic Mineral Materials Industry Overview

The global strategic mineral materials market is fragmented in nature with the presence of numerous players for different minerals. The prominent companies in the market includes Intercontinental Mining, Vale, Anglo American plc, Glencore, CBMM, and Materion Corporation, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Growing Demand from Various End-user Industries

- 4.1.2 Other Drivers

- 4.2 Restraints

- 4.2.1 Impact of COVID-19 Pandemic

- 4.2.2 Growing Environmental Concerns over Mining Operations

- 4.3 Industry Value-chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION

- 5.1 Mineral

- 5.1.1 Antimony

- 5.1.1.1 Flame Retardants

- 5.1.1.2 Batteries

- 5.1.1.3 Ceramics and Glass

- 5.1.1.4 Catalyst

- 5.1.1.5 Alloys

- 5.1.2 Barite

- 5.1.2.1 Oil and Gas

- 5.1.2.2 Other Applications (paints, chemical manufacturing and others)

- 5.1.3 Beryllium

- 5.1.3.1 Electronics

- 5.1.3.2 Aerospace

- 5.1.3.3 Automotive

- 5.1.3.4 Energy

- 5.1.3.5 Other Applications

- 5.1.4 Cobalt

- 5.1.4.1 Batteries

- 5.1.4.2 Superalloys

- 5.1.4.3 Cemented Carbides and Diamond Tools

- 5.1.4.4 Catalysts

- 5.1.4.5 Other Applications

- 5.1.5 Fluorspar

- 5.1.5.1 Chemicals

- 5.1.5.2 Steel

- 5.1.5.3 Aluminum

- 5.1.5.4 Cement

- 5.1.5.5 Other Applications

- 5.1.6 Gallium

- 5.1.6.1 Integrated Circuits

- 5.1.6.2 Laser diodes

- 5.1.6.3 Photodetectors

- 5.1.6.4 Solar Cells

- 5.1.6.5 Other Applications

- 5.1.7 Germanium

- 5.1.7.1 Fiber Optics

- 5.1.7.2 Infrared Optics

- 5.1.7.3 Catalyst

- 5.1.7.4 Electrical and Solar Equipment

- 5.1.7.5 Other Applications

- 5.1.8 Indium

- 5.1.8.1 Flat-Panel Display Screens and Touchscreens

- 5.1.8.2 Low Melting Alloys and Solders

- 5.1.8.3 Semiconductors

- 5.1.8.4 Transparent Heat Reflectors

- 5.1.8.5 Other Applications

- 5.1.9 Manganese

- 5.1.9.1 Casting Alloys

- 5.1.9.2 Packaging

- 5.1.9.3 Transportation

- 5.1.9.4 Construction

- 5.1.9.5 Other Applications

- 5.1.10 Niobium

- 5.1.10.1 Steel

- 5.1.10.2 Super Alloys

- 5.1.10.3 Superconducting Magnets

- 5.1.10.4 Capacitors

- 5.1.10.5 Glass

- 5.1.10.6 Other Applications

- 5.1.11 Platinum Group Elements

- 5.1.11.1 Autocatalyst

- 5.1.11.2 Jewelry

- 5.1.11.3 Electrical & Electronics

- 5.1.11.4 Chemical

- 5.1.11.5 Other Applications

- 5.1.12 Rare Earth Elements

- 5.1.12.1 Catalyst

- 5.1.12.2 Batteries

- 5.1.12.3 Magnetic Alloys

- 5.1.12.4 Metallurgy

- 5.1.12.5 Other Applications

- 5.1.13 Tantalum

- 5.1.13.1 Electronics

- 5.1.13.2 Medical

- 5.1.13.3 Aerospace

- 5.1.13.4 Automotive

- 5.1.13.5 Other Applications

- 5.1.1 Antimony

- 5.2 Geography

- 5.2.1 Asia-Pacific

- 5.2.1.1 China

- 5.2.1.2 India

- 5.2.1.3 Japan

- 5.2.1.4 South Korea

- 5.2.1.5 ASEAN Countries

- 5.2.1.6 Rest of Asia-Pacific

- 5.2.2 North America

- 5.2.2.1 United States

- 5.2.2.2 Canada

- 5.2.2.3 Mexico

- 5.2.3 Europe

- 5.2.3.1 Germany

- 5.2.3.2 United Kingdom

- 5.2.3.3 Italy

- 5.2.3.4 France

- 5.2.3.5 Spain

- 5.2.3.6 Rest of Europe

- 5.2.4 South America

- 5.2.4.1 Brazil

- 5.2.4.2 Argentina

- 5.2.4.3 Rest of South America

- 5.2.5 Middle-East and Africa

- 5.2.5.1 Saudi Arabia

- 5.2.5.2 South Africa

- 5.2.5.3 Rest of Middle-East and Africa

- 5.2.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers & Acquisitions, Joint Ventures, Collaborations and Agreements

- 6.2 Market Share/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Anglo American plc

- 6.4.2 CBMM

- 6.4.3 Glencore

- 6.4.4 Indium Corporation

- 6.4.5 Intercontinental Mining

- 6.4.6 Materion Corporation

- 6.4.7 South32

- 6.4.8 Vale

- 6.4.9 WARRIOR GOLD INC.

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Increasing Application base of Various Minerals