|

市场调查报告书

商品编码

1683397

医疗保健积层製造(3D 列印)市场 -市场占有率分析、行业趋势和统计、成长预测(2025-2030 年)Healthcare Additive Manufacturing (3D Printing) - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

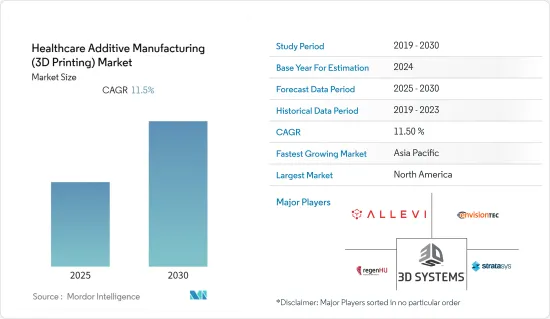

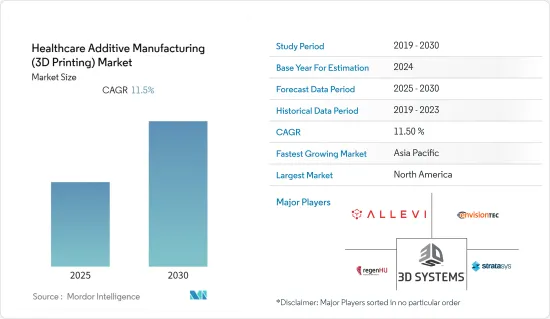

预计医疗保健积层製造市场在预测期内的复合年增长率将达到 11.5%。

3D列印,也称为积层製造,被认为是製造业的下一次工业革命,并可能提供一种经济有效的方法来实现复杂、客製化的医疗保健零件和组件,包括组织、器官、整形外科和颅骨植入以及牙科修补。定制结构对于患者来说更舒适,因此定制积层製造的需求很高。此外,专利到期将结束少数企业对市场的垄断,增加积层製造产品的市场竞争,提高产品品质。这些因素正在推动市场的成长。

然而,积层製造的成本仍然很高,导致难以承受,特别是在开发中国家和欠发达国家。操作这些机器的熟练专业人员也短缺。这些因素阻碍了市场成长。

医疗保健积层製造(3D 列印)市场趋势

聚合物可望实现高成长

聚合物及其复合材料在医疗保健领域的各种应用方面具有巨大潜力,是最广泛使用的积层製造材料之一。几十年来,基于聚合物的积层製造一直被用于製造义肢零件和医疗保健设备。这些聚合物也用于製造OK绷,这些绷带不仅可以保持结构以确保癒合,而且还很舒适,因为它们可以根据每个患者进行客製化。这是使用结合了积层製造和 3D 扫描的机器完成的,它可以在极短的时间内扫描患者的肢体并列印客自订的OK绷。

此外,聚合物也用于製造助听器、准备辅助诊断和术前规划的模型,以及准备可用于实践目的的器官和特定身体部位的模型,以演示各种精细的外科手术,如截骨术。

根据2019年世界卫生组织关于耳聋和听力损失的报告,全球有4.66亿人患有听力障碍,预计到2050年这一数字将上升到9亿以上。因此,随着听力障碍病例的增加,未来市场预计将扩大。

北美可望主导市场

美国和加拿大是北美最大的市场之一。这两个国家在医疗保健方面都投入了巨额资金。美国是医疗保健支出最高的国家之一(根据经合组织的数据,占 GDP 的 17.9%)。 2005年,美国约有2,500名新生儿出生时患有听力损失或听力障碍。 2016 年,这一数字增加到 6,300 多人。此外,根据美国人口实验室的数据,65 岁及以上美国的数量预计将增加近一倍,从 2018 年的 5,200 万人增加到 2060 年的 9,500 万人。由于老年人群更容易出现听力损失,预计对医疗保健 3D 列印助听器的需求将会增加。

医疗保健积层製造(3D 列印)产业概况

大多数医疗相关的 3D 列印结构都是由全球主要企业製造的。拥有更多研究资金和更好分销系统的市场领导已经确立了其在市场上的地位。此外,由于人们意识的增强,亚太地区正在见证规模较小的参与企业的崛起。这也推动了市场成长。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 调查结果

- 调查前提

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 市场概况

- 市场驱动因素

- 客製化积层製造的需求

- 专利到期

- 市场限制

- 积层製造的高成本

- 专业技能人才短缺

- 波特五力分析

- 新进入者的威胁

- 购买者/消费者的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争强度

第五章 市场区隔

- 依技术分类

- 立体光刻技术

- 沉淀模型

- 电子束熔炼

- 雷射烧结

- 喷射技术

- 积层製造

- 其他的

- 按应用

- 医疗植入

- 义肢

- 穿戴式装置

- 组织工程

- 其他的

- 按材质

- 金属和合金

- 聚合物

- 其他的

- 按地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 欧洲其他地区

- 亚太地区

- 中国

- 日本

- 印度

- 澳洲

- 韩国

- 其他亚太地区

- 中东和非洲

- 海湾合作委员会国家

- 南非

- 其他中东和非洲地区

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 北美洲

第六章 竞争格局

- 公司简介

- General Electric

- 3D Systems, Inc.

- EnvisionTEC GMBH

- regenHU

- Allevi, Inc.

- Eos GmbH

- Materialise NV

- Stratasys LTD.

- Nanoscribe GmbH

- GPI Prototype and Manufacturing Services, LLC.

第七章 市场机会与未来趋势

The Healthcare Additive Manufacturing Market is expected to register a CAGR of 11.5% during the forecast period.

3D printing, also known as additive manufacturing, is regarded as the next industrial revolution in manufacturing, with high potential to provide cost-effective methods to achieve complex and customized medical parts and components, such as tissues, organs, orthopedic and cranial implants, dental prosthetics, and others. The demand for customized additive manufacturing is high as customized structures as more comfortable for patients. Moreover, patent expiration will lead to the end of monopolistic control of some companies over the market, making additive manufacturing products more competitive in the market, which will improve the quality of the product. These factors have helped the market grow.

However, the cost of additive manufacturing is still high which leads to affordability issues, especially in developing and underdeveloped countries. Also, there is a lack of skilled professionals to operate these machineries. These factors have impeded market growth.

Healthcare Additive Manufacturing (3D Printing) Market Trends

Polymers are Expected to Register a High Growth

Polymers and their composites are one of the most widely used additive manufacturing materials due to the vast potential for various applications in the healthcare. Polymer-based additive manufacturing has been used for decades in creating prosthetic limb parts as well as medical instruments. These polymers are also used to make plasters specifically for each patient that not only hold the structure to ensure healing but are also comfortable as they can be customized for each patient. This is done through the use of a machine that combines additive manufacturing with 3D scanning procedures capable of scanning a patient's limb and printing custom plasters in an incredibly short time.

Moreover, polymers are also used in crafting hearing aids, preparing models that can aid in diagnosis and preoperative planning and preparing models of organs or specific body parts that can be developed for practice purposes to demonstrate various sensitive surgical procedures such as osteotomies.

According to WHO 2019 report on "Deafness and hearing loss", There were 466 million people worldwide with hearing disability, and this number is expected to increase to over 900 million by 2050. Hence, as the number of cases of hearing disability increases the market is expected to increase in the future.

North America is Expected to Dominate the Market

United States and Canada are one of the largest markets for the North America region. Both countries spend huge amount towards its healthcare. With United States being one of the nations with high expenditure in healthcare (17.9% of GDP as per OECD). In the United States, the number of newborn babies with deafness or hearing problem was nearly 2500 in 2005. This number was found to have increased to more than 6300 in 2016. Moreover, according to the Population Reference Bureau of the United States, the number of Americans ages 65 and older is projected to nearly double from 52 million in 2018 to 95 million by 2060. As the older population is more prone to hearing loss, the demand for hearing aid devices that are manufactured using Healthcare 3D Printing is expected to increase.

Healthcare Additive Manufacturing (3D Printing) Industry Overview

Majority of the healthcare-related 3D Printing structures are being manufactured by the global established key players. Market leaders with more funds for research and better distribution system have established their position in the market. Moreover, Asia-pacific is witnessing an emergence of some small players due to the rise of awareness. This has also helped the market grow.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Deliverables

- 1.2 Study Assumptions

- 1.3 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Demand For Customized Additive Manufacturing

- 4.2.2 Patent Expiration

- 4.3 Market Restraints

- 4.3.1 High Costs Associated with Additive Manufacturing

- 4.3.2 Lack of Skilled Professionals

- 4.4 Porter's Five Force Analysis

- 4.4.1 Threat of New Entrants

- 4.4.2 Bargaining Power of Buyers/Consumers

- 4.4.3 Bargaining Power of Suppliers

- 4.4.4 Threat of Substitute Products

- 4.4.5 Intensity of Competitive Rivalry

5 MARKET SEGMENTATION

- 5.1 By Technology

- 5.1.1 Stereolithography

- 5.1.2 Deposition Modeling

- 5.1.3 Electron Beam Melting

- 5.1.4 Laser Sintering

- 5.1.5 Jetting Technology

- 5.1.6 Laminated Object Manufacturing

- 5.1.7 Other Technology

- 5.2 By Application

- 5.2.1 Medical Implants

- 5.2.2 Prosthetics

- 5.2.3 Wearable Devices

- 5.2.4 Tissue Engineering

- 5.2.5 Others

- 5.3 By Material

- 5.3.1 Metals and Alloys

- 5.3.2 Polymers

- 5.3.3 Others

- 5.4 Geography

- 5.4.1 North America

- 5.4.1.1 United States

- 5.4.1.2 Canada

- 5.4.1.3 Mexico

- 5.4.2 Europe

- 5.4.2.1 Germany

- 5.4.2.2 United Kingdom

- 5.4.2.3 France

- 5.4.2.4 Italy

- 5.4.2.5 Spain

- 5.4.2.6 Rest of Europe

- 5.4.3 Asia-Pacific

- 5.4.3.1 China

- 5.4.3.2 Japan

- 5.4.3.3 India

- 5.4.3.4 Australia

- 5.4.3.5 South Korea

- 5.4.3.6 Rest of Asia-Pacific

- 5.4.4 Middle-East and Africa

- 5.4.4.1 GCC

- 5.4.4.2 South Africa

- 5.4.4.3 Rest of Middle-East and Africa

- 5.4.5 South America

- 5.4.5.1 Brazil

- 5.4.5.2 Argentina

- 5.4.5.3 Rest of South America

- 5.4.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 General Electric

- 6.1.2 3D Systems, Inc.

- 6.1.3 EnvisionTEC GMBH

- 6.1.4 regenHU

- 6.1.5 Allevi, Inc.

- 6.1.6 Eos GmbH

- 6.1.7 Materialise N.V.

- 6.1.8 Stratasys LTD.

- 6.1.9 Nanoscribe GmbH

- 6.1.10 GPI Prototype and Manufacturing Services, LLC.