|

市场调查报告书

商品编码

1683406

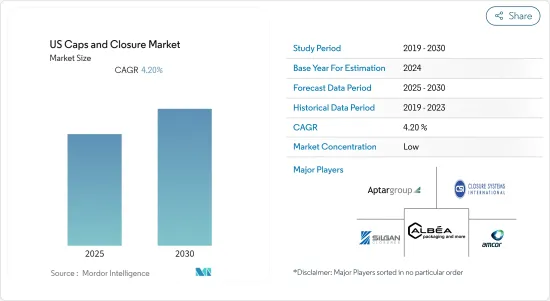

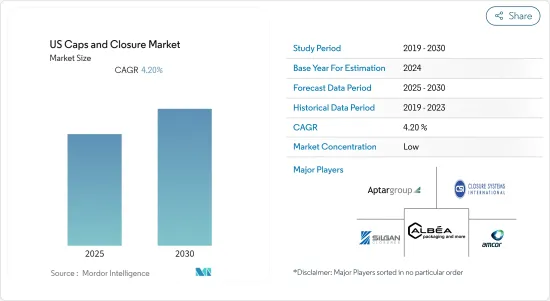

美国瓶盖和封盖市场:市场占有率分析、行业趋势、统计数据和成长预测(2025-2030 年)US Caps and Closure - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

价格

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

简介目录

预计美国瓶盖和封口市场在预测期内的复合年增长率将达到 4.2%

关键亮点

- 各类终端用户对创新解决方案的需求不断增加,推动市场的发展。除了气密性、易封闭性和阻隔性等传统要求外,客户的期望也极高。因此,创新已成为包装产业满足不断变化的消费者需求和社会需求的决定性特征。儿童防护瓶盖和封口方面也有了重大创新。例如,2018年8月,Comar推出了其新型Secure Cap QuarterLoc儿童防护封盖。这是一体式推转式瓶盖,只需旋转四分之一圈即可盖上或取下。

- 然而,针对涉及环境恶化的製造商的严格监管正在限制市场。塑胶法规的日益严格以及包装产品课税的增加对市场的成长构成了挑战。在加州,政府已颁布法令,禁止使用可拆卸的宝特瓶瓶盖。根据第 2779 号议会法案,瓶装公司将决定是否使用加州特有的繫带瓶盖宝特瓶,还是使用非加州的宝特瓶来销售给美国其他市场。

美国瓶盖与封盖市场趋势

塑胶高成长

- 根据美国工业理事会的数据,2018年对塑胶树脂的投资为378亿美元,其中249亿美元用于塑胶製品,显示各种产品对塑胶包装的需求很大。食品和饮料行业是美国瓶盖和封口市场的主要贡献者之一。大多数生产的食品都采用 PET 容器包装,其中大多数都采用塑胶外壳包裹以防止污染。由于 PET 已获得食品药物管理局(FDA) 和其他卫生安全机构的核准,可以安全接触食品和饮料 (F&B),因此 PET 瓶盖和封口越来越多地用于乳製品、简便食品和其他食品服务应用。

- 聚丙烯 (PP) 具有良好的抗拉强度、对酸、碱和溶剂的惰性等固有特性,并且比其他热塑性聚合物具有成本优势。这些特性使得PP能够广泛应用于大批量生产的消费品中。

- 透过研究和开发,业界中的一些知名参与企业致力于进一步创新其产品并推出下一代随机聚丙烯 (PP) 产品开发。例如,2019 年 10 月,北欧化工宣布推出商业性其专有 Borstar 成核技术 (BNT) 的 BorPure RF777MO。 BorPure RF777MO 专为翻盖瓶盖设计,这种新树脂可协助製造商缩短某些瓶盖应用的循环时间。

- 高密度聚苯乙烯(HDPE) 和 LDPE 是具有良好衝击强度、刚度和低应力白化敏感性组合的最佳选择。根据Borealis介绍,HDPE瓶盖和封盖的成长主要是由于玻璃瓶上的金属瓶盖被PET取代,以及软性饮料被装在小瓶中消费所导致的消费模式的改变。

- 由于 HDPE 瓶盖与 PET 螺纹形状高度相容,因此在 PET 瓶装的应用日益广泛。预测期内,瓶装水消费量的增加预计将推动 HDPE 瓶盖的采用。

饮料占市场成长主要份额

- 美国饮料市场随着葡萄酒和啤酒消费量的增加而成长,随着需求的发展,包装组件和材料也变得更加差异化。根据美国葡萄酒协会2019年4月发布的报告,2017年美国生产了约10亿加仑葡萄酒,美国是全球葡萄酒消费量最高的国家,占世界市场份额的15%。由于此类饮料的消费量很大,预计美国对瓶盖和封口的需求将会增加。

- 美国是世界上最大的葡萄酒消费国之一。根据 2019 年 Wines and Vines Analytics 的数据,2018 年美国葡萄酒市场的总价值为 705 亿美元。推动该市场成长的关键趋势是,人们对塑胶/人造软木塞和螺旋盖的偏好日益增加,而不再使用天然软木塞。

- 人造软木塞、技术软木塞或合成软木塞正日益取代天然软木塞,因为人造软木塞会出现软木塞污染,而且TCA(2,4,6-三氯苯甲醚)化学物质会从天然软木塞中渗入葡萄酒中,但合成软木塞也会从外部环境中吸收 TCA 污染。

- 根据SevenFifty Daily报告,为解决这个问题,全球最大的软木生产商阿莫林承诺,2020年利用最尖端科技消除软木中的TCA,并致力于生产零TCA软木。

- 此外,在美国,最常见的瓶装不含气水的包装材料是聚对苯二甲酸乙二醇酯 (PET) 塑胶。根据国际瓶装水协会(IBWA)的数据,2018年瓶装水总销售额为185亿美元,与前一年同期比较成长8.8%。美国人平均每年消耗167宝特瓶。由于该地区对包装饮用水的需求,对 PET 塑胶盖和机壳的需求尤其呈上升趋势。

- 此外,耐高温瓶盖和封口相关的创新也因其防伪性能而获得了显着的关注。

- 例如,2019 年 5 月,Guala Closures 凭藉其 e-WAK 技术赢得了 2019 年铝箔奖杯。 Guala Closures 的 e-WAK 是第一款采用新智慧技术的 NFC 铝製瓶盖,可以使每个葡萄酒瓶成为一个连网的瓶子。该晶片位于封口内,可透过相容的智慧型手机读取,为消费者提供真实性证明和丰富的产品资讯。

美国瓶盖与封盖产业概况

美国瓶盖和封盖市场高度细分。透过设计、技术和应用的创新可以获得可持续的竞争优势。过去十年,由于食品、饮料和製药行业的需求不断增长,瓶盖和封口的市场渗透率显着提高。主要参与企业包括 Albea SA、Silgan Closures 和 Amcor Plc。最近的市场趋势是-。

- 2019 年 7 月 – Aptar Food+Beverage 推出 Karma 饮料封盖。 Karma Push Cap 技术的製造商 Karma 和 Aptar 食品饮料部门联手将即溶混合技术引入专注于个人化和强化营养日益增长的趋势的细分市场。该公司预计将利用其全球影响力以及多样化的技术平台和应用经验,为 Karma 设计提供在增值便利包装领域的机会,最大限度地发挥 Karma Push Cap 的潜力。

- 2019 年 11 月-Closure Systems International 推出乳製品和非碳酸饮料的 38K-DL 瓶盖。 CSI 的 38D-KL 封盖提供了一个可持续的解决方案,并且可以使用高达 40% 的 PolyCycle(CSI 的消耗后回收 (PCR) HDPE 树脂)。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概况

- 波特五力分析

- 新进入者的威胁

- 购买者和消费者的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争强度

- 产业价值链分析

第五章 市场动态

- 市场驱动因素

- 各类最终用户对创新解决方案的需求不断增加

- 市场限制

- 对涉及环境恶化的製造商实施更严格的监管

第六章 市场细分

- 依材料类型

- 塑胶

- PET

- PP

- HDPE 与 LDPE

- 其他塑料

- 金属

- 其他的

- 塑胶

- 按最终用户产业

- 饮料(瓶装水、啤酒、乳製品、即饮饮料、葡萄酒、烈酒等)

- 食物

- 製药和医疗

- 化妆品和盥洗用品

- 其他最终用户产业(汽车清洁剂、油漆和被覆剂、化学品等)

第七章 竞争格局

- 公司简介

- Albea SA

- Silgan Closures

- Amcor Plc

- Closure Systems International

- Aptar Group Inc.

- Bericap Holdings

- Berry Global Inc.

- Coral Products Plc

- Crown Holdings Inc.

- Tetra Pak International Sa

- Mjs Packaging

- O. Berk Company Llc

第八章投资分析

第九章:未来市场展望

简介目录

Product Code: 68202

The US Caps and Closure Market is expected to register a CAGR of 4.2% during the forecast period.

Key Highlights

- Increased demand for innovative solutions from different end users drives the market. In addition to traditional demands, such as leak tightness, easy closing, and offering higher barrier properties, customers expectations have increased highly. Therefore, the innovation has become a characteristic to define the packaging industry's approach to cater to the vast and changing consumer demands and society's needs. Major innovations have also been made in child-proof caps and closures. For instance, in August 2018, Comar introduced the new Secure Cap QuarterLoc child resistant closure, a one-piece push-and-turn bottle closure that requires only a quarter turn to apply or remove.

- However, stringent regulation on manufacturers pertaining to environmental degradation is restraining the market. The increasing regulation against plastic and increasing taxes on packaged products poses challenges against the growth of the market. In California, the government imposed ban on removable plastic bottle caps. According to Assembly bill 2779, the bottling companies would decide if they want to have California specific plastic bottles with tethered bottle caps or different bottles for the other markets in the United States.

US Caps and Closure Market Trends

Plastic to Witness a Highest Growth

- According to American Chemistry Council, in 2018, out of USD 37.8 billion investment in plastic resins, USD 24.9 billion investment is used for plastic products, which shows the demand for plastic packaging in the overall products. The food and beverage industry is one of the major contributors to the caps and closures market in the United States. Majority of the manufactured food products are packaged in PET containers, which are mostly covered with plastic enclosures, to protect them from contamination. As PET had been approved as safe for contact with food and beverage (F&B) by the FDA and health-safety agencies, due to which PET caps and closures are increasingly being used for dairy products, convenience food, and other food service applications.

- Polypropylene (PP) has inherent properties, like excellent tensile strength, inertness toward acids, alkalis, and solvents, and has a cost advantage over other thermoplastic polymers. These properties positioned PP across a wide range of consumer products, which are manufactured by high-volume forming methods.

- Some of the prominent players in the industry through research and developments have been instrumental in further innovating their offerings and coming up with product developments with a next generation random polypropylene (PP). For instance, in October 2019, Borealis announced the commercial launch of BorPure RF777MO based on the proprietary Borstar Nucleation Technology (BNT). The BorPure RF777MO is designed for use in flip-top caps where the new resin enables the manufacturer to reduce cycle times for certain caps applications.

- Moroever to provide impact strength, combined with stiffness and a low potential for stress whitening, High-density polyethylene (HDPE) and LDPE are best suited in it. According to Borealis, the growth in the HDPE caps and closures is mainly due to the replacement of metal caps used on glass bottles (replaced by PET), and a change in the consumption pattern as more refreshments are consumed from small bottles.

- As HDPE caps are more compatible with the geometries of the PET thread, these are being increasingly used in the PET bottling. The increasing consumption of the bottled water is expected to fuel the adoption of the HDPE caps over the forecast period.

Beverage Accounted to Hold a Major Market Growth

- As the US beverage market is growing, following with higher consumption of wine and beer, the packaging components and materials are also adding value differentiation with evolving demands. According to the report by the Wine Institute of America, released in April 2019, almost 1 billion gallons of wine were produced in the United States in 2017. The United States is the highest consumer of wine, with a 15% global share. Owing to such high consumption of beverages, the demand for caps and closures is expected to increase in the United States.

- United States is one of the largest wine consuming country. According to Wines and Vines Analytics, 2019, the total dollar value of the US wine market in 2018 was USD 70.5. A key trend for the market growth that can be seen in this market is the growing preference for plastic/synthetic corks and screw caps over natural corks.

- As artificial corks, technical and synthetic corks are replacing natural corks, as it shows cork taint or TCA (2,4,6-trichloroanisole) chemical that leeches out of a natural cork into the wine, but the synthetic corks can also pick up TCA contamination from the external environment.

- To address this issue, according to SevenFifty Daily,the world's largest cork producer,Amorim, is focusing to eliminate TCA from corks by 2020, using cutting-edge technology, and it focuses to manufacture cork with zero TCA.

- Moreover, the most conventional packaging material for single-serve, non-carbonated bottled water in the United States is polyethylene terephthalate (PET) plastic. According to the International Bottled Water Association (IBWA), in 2018, the total sales of bottled water were USD 18.5 billion, an increase of 8.8% from previous years. The average American consumes 167 plastic bottles of water per year. Owing to such demand for packaged drinking water in the region, there is an increasing demand for especially PET plastic caps and enclosures.

- Furthermore, the innovation pertaining to temper resistant caps and closures is also gaining significant traction due to anti-counterfeiting properties.

- For instance, in May 2019, Guala Closures won Alufoil Trophy 2019 for its e-WAK technology; the e-WAK from Guala Closures is the first NFC aluminum closure which is based on a new smart technology that allows every bottle of wine to become a connected bottle. A chip is positioned inside the closure that can be read by enabled smartphones, providing consumers authenticity certification and extensive product information.

US Caps and Closure Industry Overview

The US caps and closures market is highly fragmented. The sustainable competitive advantage can be gained through innovation in design, technology, and application. The levels of market penetration for the caps and closure have grown significantly over the last decade, aided by growing demand from the food, beverage, and pharmaceutical industries. Key players are Albea S.A., Silgan Closures, Amcor Plc, etc. Recent developments in the market are -

- July 2019 - Aptar Food + Beverage introduced the Karma Beverage Closure. Karma,makers of the Karma Push Cap Technology, and Aptar Food & Beveragedivision formed a collaborative relationship to provide instant-mix technologyto the market segments focused on the growing trend of personalized,fortified nutrition. The company is expected to leverage its global presence,along with its diverse technology platform and application experience, tooptimize the potential of the Karma Push Cap by providing opportunities forKarma's design to be used in the value-add convenient packaging area.

- Nov 2019 - Closure Systems International introduced 38K-DL a caps for diary and non-carbonated beverages. CSI's 38D-KL closure delivers a sustainable solution and can be sourced with up to 40% PolyCycle, CSI's post-consumer recycled (PCR) HDPE resin.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Porters 5 Force Analysis

- 4.2.1 Threat of New Entrants

- 4.2.2 Bargaining Power of Buyers/Consumers

- 4.2.3 Bargaining Power of Suppliers

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 The Increased Demand for Innovative Solutions from Different End Users.

- 5.2 Market Restraints

- 5.2.1 Stringent Regulation on Manufacturers Pertaining to Environmental Degradation

6 MARKET SEGMENTATION

- 6.1 By Material Type

- 6.1.1 Plastic

- 6.1.1.1 PET

- 6.1.1.2 PP

- 6.1.1.3 HDPE and LDPE

- 6.1.1.4 Other Plastics

- 6.1.2 Metal

- 6.1.3 Other Material Types

- 6.1.1 Plastic

- 6.2 By End-User Industry

- 6.2.1 Beverage (Bottled Water, Beer, Dairy, RTD, Wine, Spirits, etc.)

- 6.2.2 Food

- 6.2.3 Pharmaceutical and Healthcare

- 6.2.4 Cosmetics and Toiletries

- 6.2.5 Other End-user Industries (Automotive Cleaners, Paints and Coatings, Chemicals, etc.)

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Albea S.A.

- 7.1.2 Silgan Closures

- 7.1.3 Amcor Plc

- 7.1.4 Closure Systems International

- 7.1.5 Aptar Group Inc.

- 7.1.6 Bericap Holdings

- 7.1.7 Berry Global Inc.

- 7.1.8 Coral Products Plc

- 7.1.9 Crown Holdings Inc.

- 7.1.10 Tetra Pak International Sa

- 7.1.11 Mjs Packaging

- 7.1.12 O. Berk Company Llc

8 INVESTMENT ANALYSIS

9 FUTURE OUTLOOK OF THE MARKET

02-2729-4219

+886-2-2729-4219