|

市场调查报告书

商品编码

1685904

德国工业涂料:市场占有率分析、产业趋势与统计、成长预测(2025-2030)Germany Industrial Coatings - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

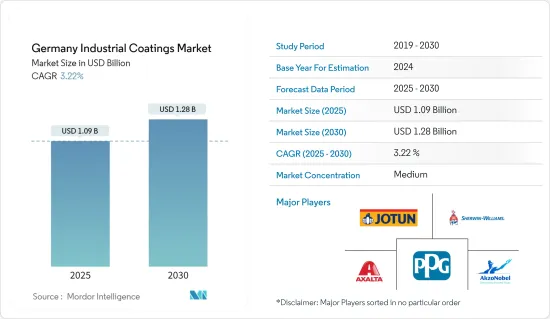

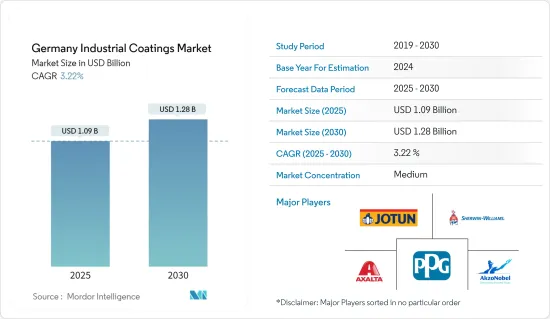

预计 2025 年德国工业涂料市场规模为 10.9 亿美元,到 2030 年将达到 12.8 亿美元,预测期内(2025-2030 年)的复合年增长率为 3.22%。

COVID-19疫情对工业涂料产业产生了负面影响。销售额受到 GDP 波动的影响。由于停工和人力短缺,大多数生产设施都已停产。这导致各生产者感到焦虑。此外,供应链限制严重阻碍了该行业的扩张。 2019-2020年,汽车业销售低迷、结构性放缓、经济疲软。然而,放鬆封锁措施以及促进经济復苏的奖励措施使该地区的汽车产业受益。预计市场将在 2021 年復苏,并在未来几年经历显着成长。

主要亮点

- 短期内,工业基础设施建设的增加以及石油天然气和石化行业的需求成长预计将推动市场成长。

- 然而,有关挥发性有机化合物(VOC)排放的严格规定预计会阻碍市场成长。

- 然而,对环保涂料产品日益增长的需求可能为所研究的市场提供丰厚的成长机会。

德国工业涂料市场趋势

蓬勃发展的石油和天然气产业推动了对防护涂料的需求

- 石油和天然气产业是防护涂料的主要终端使用者之一。由于该行业在高温环境下运行,因此需要耐热涂层。它还用于保护暴露在潮湿环境中的金属和钢骨免受腐蚀。在石油和天然气工业中,它们用于储槽、管道、阀门、泵浦等。

- 石油和天然气产业在上游和下游都使用保护涂层来防止石油和天然气在输送到精製的过程中发生腐蚀。该行业正在努力寻找降低资本成本的方法。遵守严格的环境法规的需要,加上对有效、持久的涂层系统以保护资产的需求,正在推动需求的成长。

- 海上石油和天然气生产是最苛刻的生产之一。因此,所使用的涂层系统必须能够承受这些条件。长时间暴露在穿透性的紫外线下以及不断接触波涛汹涌的海水增加了对工业涂料的需求。

- 然而,在俄乌战争爆发后,德国采取多项制裁措施,包括暂停俄罗斯对北溪2号天然气管道的认证程序,以支持乌克兰。暂停从俄罗斯进口石油及相关产品可能会影响国内市场研究。

- 根据BP统计,德国2021年石油总消费量为204.5万桶/日,较2020年的204.9万桶/日下降0.2%。

- 据同一消息来源称,2021年天然气总消费量为905亿立方米,比2020年的871亿立方米增加4.2%。

- 由于上述发展,预计预测期内石油和天然气产业对防护涂料的需求将会增加。

增加环氧树脂的使用

- 环氧树脂是一种石油衍生的增强聚合物复合材料。它是环氧单元参与的反应过程的结果。这些树脂用作涂料应用中的黏合剂,以增加地板和金属应用涂料的耐久性。

- 环氧涂料具有优异的耐腐蚀、耐磨和耐候性能,适合在恶劣环境下的钢应用。它还能耐高温,适合用于储存热产品和暴露在极端高温下的罐中。

- 工业环氧涂料通常采用三层。首先,涂上底漆,例如锌底漆。然后喷洒环氧树脂。使用环氧黏合剂或聚氨酯面漆完成涂层。

- 环氧聚酰胺涂层具有优异的防潮性,环氧胶泥涂层具有优异的构造厚度,酚醛环氧涂层具有优异的耐化学性。根据应用情况,环氧树脂可用作底漆、中间漆或面漆。

- 环氧树脂经常用作工业涂料的黏合剂。这些涂层具有高附着力、高耐化学性(腐蚀性)和耐物理性,适用于船舶和化学储存槽。

- 环氧涂料因其易得性而广泛应用于众多工业领域。环氧粉末涂料用途广泛,可用于洗衣机、烘干机、白色家电、石油和天然气工业使用的钢管和配件、水管道以及混凝土加固混凝土。

- 环氧涂料有几个优点:

- 环氧涂料持久耐用、经济实惠、防水且抗衝击。

- 它可以用来提高工作安全性,因为它不像抛光混凝土那么滑。

- 环氧树脂因其光泽而具有高度可见度,并能反射光源,从而创造安全的工作环境。

- 在预测期内,上述因素可能会增加所研究市场对环氧树脂的需求。

德国工业涂料产业概况

德国工业涂料市场本质上是部分整合的。市场的主要企业包括 PPG Industries、 剪切机-Williams、AkzoNobel NV、Axalta Coating Systems 和 Jotun。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 调查前提条件

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 驱动程式

- 加大工业基础建设

- 石油、天然气和石化产业的需求不断增长

- 限制因素

- 严格控制VOC排放

- 其他阻碍因素

- 产业价值链分析

- 波特五力分析

- 供应商的议价能力

- 买家的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章市场区隔

- 树脂类型

- 环氧树脂

- 丙烯酸纤维

- 醇酸

- 聚氨酯

- 其他树脂类型

- 涂层技术

- 水性涂料

- 溶剂型涂料

- 辐射固化涂料

- 粉末涂料

- 类型

- 一般工业用途

- 保护

- 石油和天然气

- 矿业

- 力量

- 基础设施

- 其他保护措施

第六章竞争格局

- 併购、合资、合作与协议

- 市场排名分析

- 主要企业策略

- 公司简介

- AkzoNobel NV

- Axalta Coating Systems

- Beckers group

- Hempel AS

- Jotun

- MIPA SE

- PPG Industries Inc.

- RPM International Inc.

- The Sherwin-Williams Company

第七章 市场机会与未来趋势

- 对环保涂料的需求不断增加

The Germany Industrial Coatings Market size is estimated at USD 1.09 billion in 2025, and is expected to reach USD 1.28 billion by 2030, at a CAGR of 3.22% during the forecast period (2025-2030).

Due to the outbreak of COVID-19, the industrial coatings sector was negatively impacted. Sales were affected due to GDP movement. Most production units were shut down due to the lockdowns and shortage of human resources. This resulted in uncertainty among various producers. Furthermore, supply chain constraints significantly obstructed the expansion of the industry. The automotive industry showed sluggish sales, a structural slowdown, and a sputtering economy in 2019-2020. However, the easing of lockdowns, along with incentive packages to support economic revival, benefited the regional automotive industry. The market recovered in 2021 and is expected to grow at a significant rate in the coming years.

Key Highlights

- Over the short term, the increasing construction of industrial infrastructure and the growing demand from oil and gas and petrochemical industries are expected to boost the market growth.

- However, the stringent regulations for volatile organic compound (VOC) emissions are expected to hinder the market's growth.

- Nevertheless, the rising demand for eco-friendly coating products is likely to create lucrative growth opportunities for the studied market.

German Industrial Coatings Market Trends

Flourishing Oil and Gas Sector to Rise the Demand for Protective Coatings

- The oil and gas sector is one of the major end users of protective coatings. The industry requires heat-resistant coatings due to the high-temperature environment of its business operations. The coatings are also used to protect metal and steel structures from corrosion when exposed to moist and damp conditions. They are used in the oil and gas industry for tanks, pipes, valves, pumps, etc.

- The oil and gas industry uses protective coatings for both upstream and downstream segments to prevent corrosion during oil and gas transportation toward refineries. The industry has been trying to find ways to cut capital charges. Along with the need to adhere to strict environmental regulations, this has led to the demand for a coating system with a long life, which may be effective in protecting assets.

- Offshore oil and gas production has some of the most demanding conditions. Therefore, the coating systems used must be equipped for these conditions. Prolonged exposure to penetrating UV rays and constant contact with rough seawater increases the need for industrial coatings.

- However, with the Russia-Ukraine war, Germany has taken steps to halt the process of certifying the Nord Stream Two gas pipeline from Russia, besides other sanctions, in support of Ukraine. The temporary halts on the imports of petroleum and allied products from Russia are likely to affect the market studied in the country.

- According to BP Stats, the total oil consumption in Germany was 2,045 thousand barrels per day in 2021, registering a decline rate of 0.2% compared to 2,049 thousand barrels per day in 2020.

- As per the same source, the total natural gas consumption in the country was 90.5 billion cubic meters in 2021, registering a growth rate of 4.2% from 87.1 billion cubic meters in 2020.

- All the above-motioned factors are expected to augment the demand for protective coatings for the oil and gas industry during the forecast period.

Rising Usage of Epoxy Resins

- Epoxy resins are reinforced polymer composites derived from petroleum sources. They are the result of a reactive process involving epoxide units. These resins are used as binders for coating applications to enhance the durability of coatings for floor and metal applications.

- Epoxy coatings are suitable for steel applications in harsh operating environments because of their resistance to corrosion, abrasion, and weathering. These coatings are also resistant to extremely high temperatures, making them suitable for use on tanks that store hot products and are exposed to extreme heat.

- Industrial epoxy coatings are commonly used in three layers. Firstly, a primer, such as zinc primer, is applied. The epoxy is then sprayed on. An epoxy binder or polyurethane topcoat is applied to complete the coating process.

- Epoxy polyamide coatings are ideal for moisture resistance, epoxy mastic coatings are used for film thickness, and phenolic epoxy coatings are excellent for chemical resistance. Depending on the application, epoxies can be used as a priming, intermediate coat, or even a topcoat.

- Epoxy resins are frequently used as binders in industrial coatings. Those coatings provide high adhesion and high chemical (corrosion) and physical resistance for use on ships and chemical storage tanks.

- Due to their availability, epoxy coatings find numerous industrial applications. Epoxy powder coatings are used on washers, dryers, white goods, steel pipes, and fittings used in the oil and gas industry, water transmission pipelines, and concrete reinforcing rebar due to their flexible applicability.

- Several advantages of epoxy coatings are:

- Epoxy coatings are long-lasting, cost-effective, waterproof, and shock-resistant.

- They are used to improve operational safety since they are not slippery like polished concrete.

- Epoxy increases visibility with its high sheen, reflecting light sources and improving visibility making for a safer working environment.

- All the above-mentioned factors may augment the demand for epoxy resins for the market studied during the forecast period.

German Industrial Coatings Industry Overview

The Germany industrial coatings market is partially consolidated in nature. Some of the major key playersin the market include PPG Industries Inc., The Sherwin-Williams Company, AkzoNobel NV, Axalta Coating Systems and Jotun.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Increasing Industrial Infrastructure Construction

- 4.1.2 Growing Demand from Oil and Gas and Petrochemical Industries

- 4.2 Restraints

- 4.2.1 Stringent Regulations for VOC Emissions

- 4.2.2 Other Restraints

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size by Value)

- 5.1 Resin Type

- 5.1.1 Epoxy

- 5.1.2 Acrylic

- 5.1.3 Alkyd

- 5.1.4 Polyurethane

- 5.1.5 Other Resin Types

- 5.2 Technology

- 5.2.1 Water-borne Coatings

- 5.2.2 Solvent-borne Coatings

- 5.2.3 Radiation-cured Coatings

- 5.2.4 Powder Coatings

- 5.3 Type

- 5.3.1 General Industrial

- 5.3.2 Protective

- 5.3.2.1 Oil and Gas

- 5.3.2.2 Mining

- 5.3.2.3 Power

- 5.3.2.4 Infrastructure

- 5.3.2.5 Other Protectives

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 AkzoNobel NV

- 6.4.2 Axalta Coating Systems

- 6.4.3 Beckers group

- 6.4.4 Hempel AS

- 6.4.5 Jotun

- 6.4.6 MIPA SE

- 6.4.7 PPG Industries Inc.

- 6.4.8 RPM International Inc.

- 6.4.9 The Sherwin-Williams Company

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Rising Demand for Eco-friendly Coatings