|

市场调查报告书

商品编码

1686562

硫磺:市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Sulfur - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

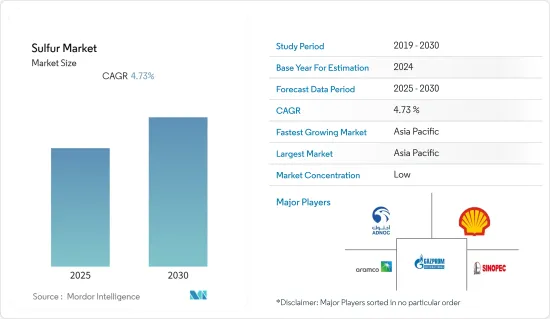

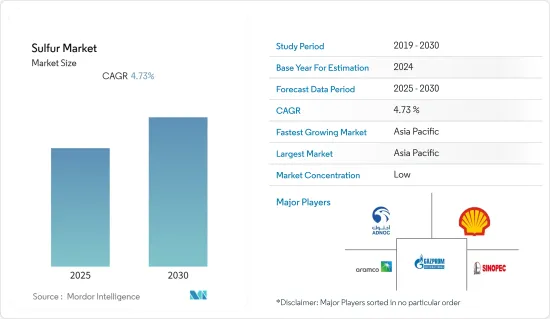

预测期内,硫磺市场预计将以 4.73% 的复合年增长率成长。

COVID-19 的影响扰乱了硫磺供应,并减少了金属製造和化学加工等多个终端用户行业的需求。此外,新冠疫情彻底扰乱了化肥的生产和供应链,这可能会在短期内阻碍市场发展。不过,预计这种情况将会改善,市场预计将在预测期后半段恢復成长轨迹。

主要亮点

- 短期内,推动硫磺市场成长的关键因素是化肥製造业的需求增加和橡胶硫化对硫磺的使用增加。

- 然而,有关排放的严格环境法规预计会阻碍市场成长。

- 预计硫在水泥聚合物混凝土中的应用将成为一个未来的机会。

- 亚太地区在全球市场占据主导地位,在消费量和消费价值方面均占有最大份额。预计预测期内市场将大幅成长。

硫磺市场趋势

肥料製造业的需求增加

- 由于硫磺经济实惠,它被广泛用于製造肥料,如硫酸钙,硫酸钙是一种众所周知的防止养分流失和土壤侵蚀的肥料。硫磺可以杀死昆虫、真菌、螨虫和囓齿动物。这就是为什么自20世纪20年代以来硫磺就被登记在美国的农药和肥料中。

- 硫肥是添加到土壤和植物中的有机或合成成分,为植物提供重要的营养,促进生长和生产。硫肥还可用于提高土壤肥力或取代先前作物从土壤中吸收的化学元素,从而提高农业产量,为植物提供额外的营养,促进植物发育。

- 此外,硫肥被认为是农业领域与磷、氮和钾并列的第四大常量营养素。硫在植物中也发挥多种功能。它的一些重要作用包括蛋白质合成和叶绿素的形成。

- 国际肥料协会称,在2021年下降2%、2022年下降5%之后,预计2023年全球肥料消费量将恢復3%至1.94亿吨(增加590万吨),略高于2019年的水准。

- 此外,有关化肥使用的环境政策、产能扩张、极端天气事件和地缘政治紧张局势都会对全球化肥料价格产生重大影响。然而,到 2035 年,中东地区的化肥产量预计将达到 5,000 万吨。

- 例如,2022 年 9 月,荷兰特种化学品公司 Nouryon 收购了 ADOB Fertilizers。此次收购为 ADOB 提供了利用大型全球组织并迈向全球成长下一阶段的机会。

- 除此之外,亚太地区政府为增加化肥产量而采取的各种措施也推动了硫磺的需求。

- 例如,据印尼化肥生产商协会(APPI)称,2023年2月,政府将全面启动Pusri 3B化肥厂计划,该项目将取代Pusri 3和4化肥厂。新计划将于 2030 年完工,化肥产能将由目前的 1,397 万吨增至 1,687 万吨。

- 因此,考虑到世界各地的成长趋势和化肥产量,化肥产业可能会主导市场,从而导致预测期内对硫的需求增加。

亚太地区占市场主导地位

- 由于中国和印度等国家对肥料和橡胶加工中硫磺的需求不断增长,亚太地区占据了市场主导地位。

- 中国是世界各类型硫磺的最大生产国。中国是世界最大的黄铁矿(原料)生产国,占各种硫磺的50%以上。中国是全球最大的硫磺进口国之一,占全球进口量的35%左右,大部分用于製造硫酸。

- 中国使用的硫酸约有三分之二用于化肥生产。在肥料工业中,钙、镁和硫被用作二次肥料。雅苒中国有限公司和Nutrien Ltd 是提供二次肥料相关产品的公司之一。

- 根据中国国家统计局的数据,预计2022年硫酸产量将创下9,505万吨的历史新高(连续第三年成长),较2021年产量增加1.3%。

- 在产量方面,根据印度化学和化肥部的数据,在 2022-23 财年 4 月至 12 月中旬,印度生产了 3.2076 亿吨化肥,为化肥供应充足做出了贡献。由于政府的优惠政策,该国的化肥生产正在受到青睐。例如,2022-23年该国对磷钾肥的补贴支出将达到5,564.8亿印度卢比(67.8亿美元)。

- 印度是亚太地区继中国之后最大的橡胶生产国和消费国之一。儘管该国是最大的橡胶生产国之一,但该国仍从各国进口大量橡胶以满足国内需求。印度拥有约 6,000 个製造单位,其中包括 30 个大型製造单位、300 家中型製造单位和约 5,600 个小型和微型製造单位。所有这些单位在全国生产超过 35,000 种橡胶产品,因此对硫磺的需求量很大。

- 全球橡胶消费量的约三分之一是泰国、印尼和马来西亚人工林生产的天然橡胶。泰国是世界上最大的天然橡胶生产国和出口国。

- 上述因素导致亚太地区硫磺消费需求增加。

硫磺行业概况

硫磺市场是一个分散的市场,有多家公司在全球和区域层面开展业务。市场的主要企业(不分先后顺序)包括中国石油化学集团公司(中石化)、俄罗斯天然气工业股份公司、阿布达比国家石油公司、壳牌公司。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 调查前提条件

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 驱动程式

- 肥料製造业的需求增加

- 橡胶硫化中硫磺的使用增加

- 精製扩建

- 限制因素

- 有关排放的严格环境法规

- 硫磺开采高成本

- 产业价值链分析

- 波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章 市场区隔

- 形式

- 固体的

- 液体

- 技术(表面处理工程)

- 颗粒

- 锭剂

- 普林林

- 最终用户产业

- 肥料

- 化学处理

- 金属製造

- 橡胶加工

- 其他最终用户产业

- 地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 东南亚国协

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 义大利

- 法国

- 俄罗斯

- 其他欧洲国家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争格局

- 併购、合资、合作、协议

- 市场占有率(%)**/排名分析

- 主要企业策略

- 公司简介

- ADNOC Group

- China Petrochemical Corporation

- Gazprom International Limited

- Marathon Petroleum Company LLC

- Petrovietnam Chemical and Services Corporation(PVCHEM)

- Shell PLC

- Saudi Arabian Oil Co.

- Suncor Energy Inc.

- Tengizchevroil LLP

- Valero Energy Corporation

第七章 市场机会与未来趋势

- 硫在水泥聚合物混凝土。

- 硫电池的演变

The Sulfur Market is expected to register a CAGR of 4.73% during the forecast period.

Due to COVID-19, there has been a disruption in the supply of sulfur and a decline in the demand from multiple end-user industries, such as metal manufacturing and chemical processing. Moreover, the COVID-19 outbreak has completely disrupted the manufacturing and supply chains of fertilizers, which may hamper the market in the short term. However, the condition is expected to recover, which will restore the growth trajectory of the market studied during the latter half of the forecast period.

Key Highlights

- Over the short term, major factors driving the growth of the sulfur market are the rising demand from the fertilizer manufacturing sector and the increasing usage of sulfur for the vulcanization of rubber.

- On the flip side, stringent environmental regulations regarding emissions are expected to hinder the market's growth.

- Usage of sulfur in cement polymer concrete is expected to act as an opportunity in the future.

- Asia-Pacific dominated the global market, with the largest consumption in terms of volume and value. The market is expected to witness substantial growth during the forecast period.

Sulfur Market Trends

Rising Demand from the Fertilizer Manufacturing Sector

- Sulfur, being economical, is widely consumed in producing fertilizers such as calcium sulfate, which is well-known fertilizer for preventing nutrient runoff and soil erosion. It can kill insects, fungi, mites, and rodents. Therefore, sulfur has been registered for use in pesticides and fertilizers in the United States since the 1920s.

- Sulfur fertilizers are organic or synthetic ingredients put into the soil or plants, boosting growth and production by delivering critical plant nutrients. It is also used for increasing agricultural output, supplying extra nutrients to plants, and boosting plant development by improving soil fertility or replacing chemical components removed from the soil by previous crops.

- Moreover, sulfur fertilizer is considered a fourth macronutrient along with phosphorus, nitrogen, and potassium in the agriculture industry. Also, it has various functions in plants. Some of these significant roles are the synthesis of proteins and chlorophyll formation.

- According to the International Fertilizer Association, after declining by 2% in FY 2021 and 5% in FY 2022, a 3% recovery in global fertilizer consumption in FY 2023 to 194 Mt of nutrients (+5.9 Mt) is forecasted, returning consumption to just above the FY 2019 level.

- Also, the environmental policies related to fertilizer use, capacity expansions, extreme weather conditions, and geopolitical tensions have severely impacted fertilizer prices worldwide. However, fertilizer production in the Middle East is expected to hit 50 million tons by 2035.

- For instance, in September 2022, Nouryon, a Netherlands-based specialty chemicals company, acquired ADOB Fertilizers. This acquisition created an opportunity for ADOB to leverage a large global organization to advance to the next stage of global growth.

- Apart from that, various government initiatives for increasing fertilizer production in Asia-Pacific are driving the demand for sulfur.

- For instance, according to the Indonesian Fertilizer Producers Association (APPI), in February 2023, the government is in the process of fully launching the Pusri 3B fertilizer factory project that will replace the Pusri 3 and 4 fertilizer plants. This new project will be completed by 2030 and will have 16.87 million tons of fertilizer production capacity as compared to the current, which is 13.97 million tons.

- Therefore, considering the growth trends and production of fertilizers in different regions worldwide, the fertilizer industry is likely to dominate the market, which, in turn, is expected to enhance the demand for sulfur during the forecast period.

Asia-Pacific to Dominate the Market

- Asia-Pacific dominated the market due to the growing demand for sulfur in fertilizer and rubber processing from countries such as China and India.

- China is the leading global producer of sulfur in all forms. China is the world's leading producer of pyrites (source), which account for more than 50% of sulfur in all forms. The country is the leading sulfur importer, representing about 35% of the global imports, the bulk of which is used to manufacture sulfuric acid.

- Fertilizer production consumes about two-thirds of the sulfuric acid used in China. In the fertilizer industry, secondary fertilizers include calcium, magnesium, and sulfur. Yara China Limited and Nutrien Ltd are some of the companies that offer products related to secondary fertilizers.

- As per the National Bureau of Statistics of China, the production of sulfuric acid reached record highs in 2022 (consecutively rising for the third year) at 95.05 million metric tons, registering a growth of 1.3% from the output achieved in 2021.

- In terms of production,India produced 320.76 lakh metric tons of fertilizers during April-mid December of FY 2022-23, which contributed to a comfortable availability of fertilizers per the Ministry of Chemicals and Fertilizers. Fertilizer production has been gaining traction in the country due to favorable government policies. For instance, the subsidy outgo on P&K fertilizers in the country during 2022-23 rounded to INR 556.48 billion (USD 6.78 billion).

- India is one of the largest producers and consumers of rubber after China in the Asia-Pacific region. Despite being one of the largest rubber producers, the country imports a noticeable portion of the rubber from various countries to meet the local demand. India has about 6000 manufacturing units comprising 30 large-scale manufacturing units, 300 medium manufacturing scale, and around 5,600 small-scale and tiny sector manufacturing units. All these units manufacture more than 35,000 rubber products in the country, thus generating a substantial demand for sulfur

- About one-third of total global rubber consumption is natural rubber produced in plantations in Thailand, Indonesia, and Malaysia. Thailand is one of the largest producers and exporters of natural rubber globally.

- The aforementioned factors are contributing to the increasing demand for sulfur consumption in the Asia-Pacific region.

Sulfur Industry Overview

The sulfur market is fragmented in nature with several companies operating on both global and regional levels. Some of the major players in the market (Not in any particular order) include China Petrochemical Corporation (Sinopec), Gazprom International Limited, ADNOC Group, and Shell Plc, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Rising Demand From the Fertilizer Manufacturing Sector

- 4.1.2 Increasing Usage of Sulfur for Vulcanization of Rubber

- 4.1.3 Expansion of Petroleum Refining Plants

- 4.2 Restraints

- 4.2.1 Stringent Environmental Regulations Regarding Emissions

- 4.2.2 High Cost of Sulfur Mining Process

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Volume)

- 5.1 Form

- 5.1.1 Solid

- 5.1.2 Liquid

- 5.2 Technology (Finishing Process)

- 5.2.1 Granules

- 5.2.2 Pastilles

- 5.2.3 Prilling

- 5.3 End-User Industry

- 5.3.1 Fertilizer

- 5.3.2 Chemical Processing

- 5.3.3 Metal Manufacturing

- 5.3.4 Rubber Processing

- 5.3.5 Other End-user Industries

- 5.4 Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 ASEAN Countries

- 5.4.1.6 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 Italy

- 5.4.3.4 France

- 5.4.3.5 Russia

- 5.4.3.6 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle-East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle-East and Africa

- 5.4.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share(%)**/ Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 ADNOC Group

- 6.4.2 China Petrochemical Corporation

- 6.4.3 Gazprom International Limited

- 6.4.4 Marathon Petroleum Company LLC

- 6.4.5 Petrovietnam Chemical and Services Corporation (PVCHEM)

- 6.4.6 Shell PLC

- 6.4.7 Saudi Arabian Oil Co.

- 6.4.8 Suncor Energy Inc.

- 6.4.9 Tengizchevroil LLP

- 6.4.10 Valero Energy Corporation

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Usage of Sulfur in Cement Polymer Concrete

- 7.2 Evolution of Sulfur Battery