|

市场调查报告书

商品编码

1686630

聚烯(PO):市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Polyolefin (PO) - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

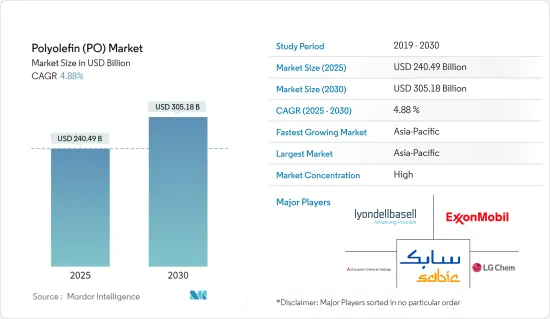

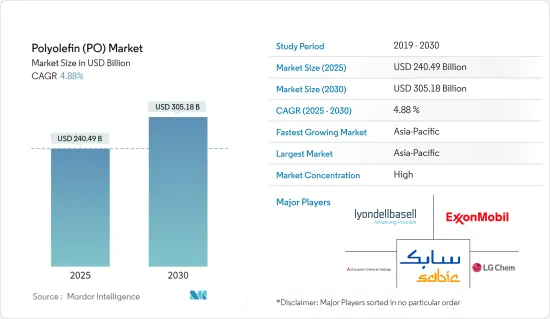

聚烯(PO) 市场规模预计在 2025 年为 2,404.9 亿美元,预计到 2030 年将达到 3051.8 亿美元,预测期内(2025-2030 年)的复合年增长率为 4.88%。

COVID-19 的蔓延严重影响了市场,迫使许多终端用户产业暂停营运。中国是聚烯的主要消费国之一,包装、玩具製造、建筑和汽车等产业蓬勃发展,因此疫情期间聚烯市场受到严重影响。然而,随着各行业恢復製造活动,市场很可能在 2021 年復苏。

主要亮点

- 由于其先进的性能,聚烯被用于电子、汽车和其他行业。预计这将在短期内推动市场成长。

- 然而,世界各国政府日益严格的塑胶环境法规可能会限制市场的发展。

- 人们对绿色聚烯的日益关注可能会在未来几年创造新的机会。

- 亚太地区占据全球市场主导地位,其中印度和中国是最大的消费国。

聚烯(PO)市场趋势

薄膜和片材行业需求的不断增长推动了市场的成长

- 薄膜和片材用于运输、包装、建筑和建筑行业。

- 农业部门正在推动市场扩张,对温室用聚烯薄膜和片材、覆盖物和青贮饲料拉伸膜的需求较大。青贮饲料片材、窗膜和医疗产业也有需求。

- 以聚烯为基础的农业薄膜还可以加速水果、蔬菜和花卉的成熟,保护它们免受霜冻、风、雨和害虫的侵害,同时允许农民在一年内种植几种不同的作物。聚烯薄膜还可以减少蒸发,有助于节约用水。

- 另一方面,聚烯片材也用于建筑业。聚乙烯板充当蒸气阻滞剂,安装在板下。此片材可以保留较长时间而不会劣化。因此,建设产业对聚烯的需求日益增长。

- 预计亚太地区建设产业将成为全球规模最大、成长最快的产业,全球 45% 的建筑支出来自该地区。在接下来的几年里,我们预计会看到更多的人选择薄膜或片材。

- 22财年,印度的聚烯总产能超过12,000千吨。大部分聚烯由信实工业有限公司生产,该公司占印度聚烯总产能的近47%。

- 因此,由于对薄膜和片材的需求不断增加,未来几年聚烯市场可能会成长。

亚太地区占市场主导地位

- 亚太地区在聚烯市场占据主导地位,因为中国是全球最大的聚烯消费国。这一增长是由电子商务的兴起推动的,宅配业务的蓬勃发展导致塑胶包装的需求激增。中国製造业对经济的贡献巨大。

- 中国政府宣布了未来十年的大规模建设计画,其中包括将2.5亿人口迁移到新兴特大城市的计划。这对于以不同形式使用建筑化学品来改善建筑物在施工过程中的表现是一个巨大的机会。

- 智慧型手机、 有机发光二极体电视和平板电脑等消费性电子产品正成为市场成长最快的产品。随着中产阶级的财富越来越丰富,对电子设备的需求也将增加,这可能会推动该国对聚烯的需求。

- 在中国,预计到 2023年终电子产业规模将达到 3,850 亿美元以上。

- 预计所有上述因素都将在预测期内增加对聚烯的需求。

聚烯(PO)产业概况

聚烯市场本质上正在整合。主要参与者(不分先后顺序)包括利安德巴塞尔工业控股公司、埃克森美孚公司、沙乌地阿拉伯基础工业公司、LG 化学和三菱化学控股公司。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 调查前提条件

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 驱动程式

- 从硬包装到软包装的偏好转变

- 对低成本室内家具的需求不断增加

- 限制因素

- 日益严格的环境法规

- 产业价值链分析

- 波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章 市场区隔

- 材料类型

- 聚乙烯 (PE)

- 高密度聚苯乙烯(HDPE)

- 低密度聚乙烯(LDPE)

- 线型低密度聚乙烯(LLDPE)

- 聚丙烯(PP)

- 聚乙烯 (PE)

- 应用

- 薄膜和片材

- 射出成型

- 吹塑成型

- 挤压涂布

- 纤维和拉菲草

- 地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 义大利

- 法国

- 其他欧洲国家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争格局

- 併购、合资、合作、协议

- 市场占有率/排名分析

- 主要企业策略

- 公司简介

- Arkema Group

- BASF SE

- Braskem

- Chevron Phillips Chemical Company

- China National Petroleum Corporation

- China Petrochemical Corporation

- Daelim

- Dow

- ExxonMobil Corporation

- Formosa Plastics Corporation

- Japan Polypropylene Corporation

- LG Chem Ltd.

- LyondellBasell Industries Holdings BV

- Mitsubishi Chemical Holdings Corporation

- Mitsui Chemicals Incorporated

- Nova Chemicals Corporation

- PetroChina Company Limited

- Reliance Industries Limited

- SABIC(Saudi Basic Industries Corporation)

- Sasol Ltd.

- Tosoh Corporation

第七章 市场机会与未来趋势

- 人们对绿色聚烯的兴趣日益浓厚

The Polyolefin Market size is estimated at USD 240.49 billion in 2025, and is expected to reach USD 305.18 billion by 2030, at a CAGR of 4.88% during the forecast period (2025-2030).

The spread of COVID-19 severely affected the market, causing many end-user industries to shut down. During the pandemic, China hampered the polyolefins market intensively, as it is one of the major consumers of polyolefins owing to its strong industries such as packaging, toy manufacturing, construction, and automotive. However, as the industries resumed their manufacturing activities in 2021, the market studied may also recover.

Key Highlights

- Polyolefin is used in electronics, cars, and other industries because of its advanced properties. This is expected to help the market grow in the short term.

- However, growing environmental regulations on plastic imposed by various governments may restrain the market.

- The growing focus on green polyolefin is likely to create new opportunities in the coming years.

- Asia-Pacific dominated the market worldwide, with the largest consumption coming from India and China.

Polyolefin (PO) Market Trends

Increasing Demand in the Films and Sheets Segment to Drive Market Growth

- Films and sheets can be used in the transportation, packaging, construction, and building industries.

- The agricultural sector is driving the market's expansion, with demand for polyolefin films and sheets for greenhouses, mulch, and silage stretch films. The demand is also seen in silage sheets and window films, as well as in the medical industry.

- Polyolefin-based agricultural films also protect vegetables from frost, wind, rain, and pests while speeding up the ripening of fruits, vegetables, and flowers, allowing farmers to grow several crops in a year. Polyolefin films also help reduce evaporation, thus saving water.

- On the other hand, polyolefin sheets are used in the building industry. Polyethylene sheeting, which works as a vapor retarder, is installed beneath the slab. These sheets can retard for a longer time without degrading. As a result, the demand for polyolefin from the construction industry is expanding.

- The Asia-Pacific construction industry is projected to become the world's largest and fastest-growing industry, with a 45% share of global construction spending coming from the region. In the coming years, this is likely to make more people opt for films and sheets.

- In fiscal year 2022, India had a total polyolefins production capacity of over 12 thousand kilotons. Most polyolefins were made by Reliance Industries Limited, which made up almost 47% of India's total polyolefins production capacity.

- Thus, due to these factors, the polyolefin market is likely to grow in the coming years as the demand for films and sheets rises.

Asia-Pacific to Dominate the Market

- Asia-Pacific is the dominant region in the polyolefins market, owing to China being the major consumer of polyolefins worldwide. The growth is driven by increasing e-commerce, as the strong courier business led to a spike in demand for plastic packaging. The country's manufacturing industry is one of the major contributors to its economy.

- The Chinese government announced big building plans for the next 10 years, including plans to move 250 million people to new megacities. This is a big chance for construction chemicals to be used in a variety of ways to improve building properties during construction.

- Electronic items, such as smartphones, OLED TVs, tablets, and other consumer electronics, are recording the fastest growth in the market. With more money in the pockets of the middle class, there will be more demand for electronics, which may drive the demand for polyolefins in the country.

- In China, the electronics segment was projected to reach over USD 385 billion by the end of 2023.

- All the above-mentioned factors are expected to increase the demand for polyolefins over the forecast period.

Polyolefin (PO) Industry Overview

The polyolefin market is consolidated in nature. Some of the major players (not in any particular order) include LyondellBasell Industries Holdings BV, ExxonMobil Corporation, SABIC, LG Chem, and Mitsubishi Chemical Holdings Corporation.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Shift in Preferences from Rigid Packaging to Flexible Packaging

- 4.1.2 Growing Demand for Low-Cost Interior Furnishings

- 4.2 Restraints

- 4.2.1 Growing Environmental Regulations

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Value)

- 5.1 Material Type

- 5.1.1 Polyethylene (PE)

- 5.1.1.1 High Density Polyethylene (HDPE)

- 5.1.1.2 Low Density Polyethylene (LDPE)

- 5.1.1.3 Linear Low-density Polyethylene (LLDPE)

- 5.1.2 Polypropylene (PP)

- 5.1.1 Polyethylene (PE)

- 5.2 Application

- 5.2.1 Films and Sheets

- 5.2.2 Injection Molding

- 5.2.3 Blow Molding

- 5.2.4 Extrusion Coating

- 5.2.5 Fibers and Raffia

- 5.3 Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 Italy

- 5.3.3.4 France

- 5.3.3.5 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Arkema Group

- 6.4.2 BASF SE

- 6.4.3 Braskem

- 6.4.4 Chevron Phillips Chemical Company

- 6.4.5 China National Petroleum Corporation

- 6.4.6 China Petrochemical Corporation

- 6.4.7 Daelim

- 6.4.8 Dow

- 6.4.9 ExxonMobil Corporation

- 6.4.10 Formosa Plastics Corporation

- 6.4.11 Japan Polypropylene Corporation

- 6.4.12 LG Chem Ltd.

- 6.4.13 LyondellBasell Industries Holdings BV

- 6.4.14 Mitsubishi Chemical Holdings Corporation

- 6.4.15 Mitsui Chemicals Incorporated

- 6.4.16 Nova Chemicals Corporation

- 6.4.17 PetroChina Company Limited

- 6.4.18 Reliance Industries Limited

- 6.4.19 SABIC (Saudi Basic Industries Corporation)

- 6.4.20 Sasol Ltd.

- 6.4.21 Tosoh Corporation

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Growing Focus on Green Polyolefin