|

市场调查报告书

商品编码

1686668

工业涂料:市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Industrial Coatings - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

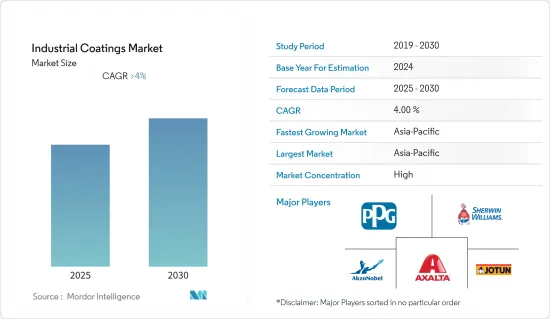

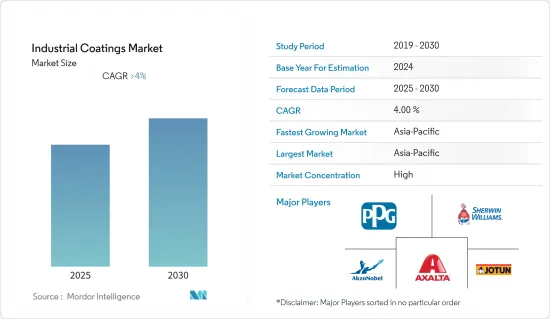

预计预测期内工业涂料市场的复合年增长率将超过 4%。

到了2020年,COVID-19对全球工业涂料产业的成长产生一定影响。然而,石油和天然气、化学品和采矿等各个工业领域对工业被覆剂的需求正在迅速增长。

主要亮点

- 由于对耐用产品的需求不断增长以及粉末涂料的使用不断增加等因素,工业涂料市场预计将以各种方式成长。

- 溶剂型涂料对环境的有害影响可能会阻碍市场成长。

- 未来,该市场可能会受益于对耐用产品日益增长的需求。

由于印度和中国等新兴市场的工业涂料使用量迅速扩大,亚太地区引领全球工业涂料市场。

工业涂料市场趋势

在石油和天然气行业的使用日益增多

- 石油和天然气产业包括用于石油和天然气探勘、生产和精製的海上和陆上平台、精製、管道、天然气管道、石化装置和储存终端。在石油和天然气工业中,保护涂层用于将石油和天然气输送到精製的上游和下游环节。该行业使用多种不同类型的保护涂层,包括防腐、耐热、耐磨和防火。

- 该行业一直在寻找降低资本成本的方法。这一点,加上需要遵守严格的环境法规,要求采用有效、持久的涂层系统来保护资产。

- 此外,海上石油和天然气生产是最苛刻的行业之一。因此,那里使用的涂层系统必须配备类似的装备。在海上,长时间暴露在穿透性的紫外线下以及不断接触波涛汹涌的海水增加了对保护涂层的需求。管道还将被涂上保护涂层。如果没有管道防腐保护,每年因生产时间损失和设备故障造成的石油和天然气腐蚀损失成本将是天文数字。

- 此外,美国、沙乌地阿拉伯、俄罗斯、中国和加拿大也是支持石油和天然气产业发展的主要大国。

- 受新冠疫情影响,美国能源使用量在2020年下降,但在2021年再次上升。截至2021年底,美国原油和凝析冷凝油探明蕴藏量从382亿桶增加到444亿桶,增加了62亿桶,增幅为16%。

- 2021年,石油和天然气需求较2020年增加5%,价格上涨,两种燃料的探明蕴藏量均增加,其中天然气创下了美国新纪录。石油钻机是美国数量最多的钻机。截至 2021 年底,全球共有约 480 个石油钻机投入运作中,而天然气钻井平台约为 106 个。

- 中国苏利亚格油田新开发天然气井1,204口,2022年新增日产量1,625万立方公尺。根据国家统计局数据,今年前10个月中国天然气产量为1,785亿立方米,年增6%。

- 预计预测期内全球工业被覆剂市场将受到上述所有因素的推动。

亚太地区主导工业涂料市场

- 在亚太地区,印度是占主导地位的国家之一。廉价劳动力、低原材料成本以及不断增长的城市人口是市场发展的驱动因素。

- 在政府对基础建设的投资支持下,印度的建筑业也正在快速成长。全国各地正在兴建地铁、桥樑、建筑等新计划。

- 印度的建设产业是该国第二大产业,对GDP的贡献庞大。疫情期间,印度建设产业成长大幅下降。然而,2021年该领域的公共和私人投资均出现激增。预计未来六到七年内,中国的住宅投资将达到约 1.3 兆美元,全国有可能建造 6,000 万套住宅。

- 政府的「印度製造」政策导致该国製造业的外国直接投资(FDI)增加。从而带动了许多产业的成长与提升,带动了国内工业涂料市场蓬勃发展。

- 作为电力产业改革计画的一部分,印度希望升级其能源基础设施并利用新技术使其电力供应更加可靠和有弹性。预测期内,这可能花费约 2.5 兆印度卢比(350 亿美元)。新产能的製造和发电行业的投资预计将促进该国对防护涂料市场的需求。

- 此外,更多的人可以使用电力,人均用电量增加,以及人口成长都会促进经济发展。截至2022年10月,印度发电装置容量为408.71吉瓦。截至2022年10月,印度发电装置容量为408.71吉瓦,是世界第三大电力生产国和消费国。

- 电力部已确定81座火力发电厂将在2026年前停止使用煤炭,并开始使用可再生能源。这将有助于印度实现500吉瓦可再生能源的目标,并解决每年煤炭供不应求的问题。此外,为协助印度实现2030年可再生能源达到450吉瓦的目标,英国政府于2021年9月宣布,将透过公共和私人投资向绿色计划和可再生能源投资12亿美元。

- 因此,上述因素正在推动对防护涂料的需求。这导致该国油漆和涂料市场的需求增加。

工业涂料产业概况

全球工业涂料市场是一个整合的市场,主要企业占据相当大的份额。主要企业包括(排名不分先后)Jotun、Akzo Nobel NV、PPG Industries、The Sherwin-Williams Company、Axalta Coating Systems 和 Nippon Paint(NIPSEA GROUP)。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 调查结果

- 调查前提

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 驱动程式

- 防护涂层需求不断成长

- 在石油和天然气行业的使用日益增多

- 限制因素

- 溶剂型涂料对环境的有害影响

- COVID-19疫情的影响

- 产业价值链分析

- 波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章市场区隔

- 树脂

- 环氧树脂

- 聚氨酯

- 丙烯酸纤维

- 聚酯纤维

- 其他树脂

- 涂层技术

- 水性涂料

- 溶剂型涂料

- 其他技术

- 最终用户产业

- 一般工业

- 防护外套

- 石油和天然气

- 矿业

- 力量

- 基础设施

- 其他防护涂层

- 地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 义大利

- 法国

- 俄罗斯

- 其他欧洲国家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争格局

- 併购、合资、合作与协议

- 市场占有率**/排名分析

- 主要企业策略

- 公司简介

- AkzoNobel NV

- Axalta Coating Systems

- BASF SE

- Beckers Group

- Chugoku Marine Paints, Ltd.

- Hempel A/S

- Jotun

- Kansai Paint Co.,Ltd.

- Nippon Paint(NIPSEA GROUP)

- PPG Industries

- RPM International, Inc.

- Sika AG

- The Sherwin-Williams Company

- Wacker Chemie AG

第七章 市场机会与未来趋势

- 耐用产品需求不断成长

The Industrial Coatings Market is expected to register a CAGR of greater than 4% during the forecast period.

COVID-19 had a moderate impact on the global industrial coatings industry's growth by 2020. However, there is an upsurge in demand for industrial coatings in various industrial sectors, including oil and gas, chemical, and mining industries,

Key Highlights

- The industrial coatings market is expected to grow in many ways, thanks to factors like the growing demand for products that last a long time and the increased use of powder coatings.

- The harmful environmental impact of solvent-borne coatings is likely to hinder the market's growth.

- In the future, the market is likely to have a chance to benefit from the rising demand for products that last a long time.

Asia-Pacific led the world market for industrial coatings because their use in developing countries like India and China is growing quickly.

Industrial Coatings Market Trends

Increasing Applications in Oil and Gas Industry

- The oil and gas segment includes offshore and onshore platforms for oil and gas exploration, production, and refining, as well as refineries, pipelines, gas pipelines, petrochemical units, and storage terminals.The oil and gas industry uses protective coatings in both the upstream and downstream segments for the movement of oil and gas toward the refineries. In this industry, different kinds of protective coatings are used, such as those that stop corrosion, resist heat, wear, and fire, among others.

- The industry has been trying to find ways to cut capital charges. This, along with the need to adhere to strict environmental regulations, has led to a demand for a coating system with a long life that will be effective in the protection of the assets.

- Furthermore, offshore oil and gas production has some of the most demanding conditions. As a result, the coating systems used there must be similarly outfitted. Offshore, there is prolonged exposure to penetrating UV rays and constant contact with rough seawater, which increases the need for protective coatings. Also, protective coatings are applied to pipelines. Without pipeline corrosion protection, the annual cost of oil and gas corrosion damages, due to lost production time and equipment failure, can be stellar.

- Also, the United States, Saudi Arabia, Russia, China, and Canada, among others, are some of the biggest countries that help the oil and gas industry grow.

- The COVID-19 pandemic caused energy use in the United States to drop in 2020, but it went back up in 2021.At year's end 2021, proved reserves of U.S. crude oil and lease condensate increased by 6.2 billion barrels (16%), from 38.2 billion barrels to 44.4 billion barrels.

- In 2021, demand for petroleum and natural gas increased by 5% from 2020, prices rose, and proved reserves increased for both fuels, setting a new U.S. record for natural gas. Oil rigs are the most common rigs in the United States. At the end of 2021, there were some 480 active oil rigs, compared with roughly 106 gas rigs.

- In China, 1,204 new natural gas wells were developed in the Sulige field, ramping up daily output by 16.25 million cubic meters in 2022. According to the National Bureau of Statistics, China produced 178.5 billion cubic meters of natural gas in the first 10 months of this year, up 6 percent year-on-year.

- During the forecast period, the global market for industrial coatings is likely to be driven by all of the above factors.

Asia Pacific Dominates the Industrial Coatings Market

- In the Asia-Pacific region, India is one of the dominant countries. The availability of inexpensive labor, low raw material costs, and the expanding urban population in the area are the main market drivers.

- The construction sector has also been increasing in India at a faster rate, supported by government investments for infrastructure development; new projects like metros, bridges, and buildings are being constructed across the country.

- The construction industry in India is the second largest in the country and makes a big contribution to its GDP.During the spread of the pandemic, the Indian construction industry saw a big drop in growth. However, in 2021, both public and private investments in the sector grew sharply.The country is likely to witness around USD 1.3 trillion of investment in housing over the next six to seven years and is likely to witness the construction of 60 million new homes in the country, which is a major boosting factor for the market studied.

- The "Make in India" policy of the government has led to more foreign direct investment (FDI) in the manufacturing sector of the country. This has helped many industries grow and improve.This in turn has boosted the market for industrial coatings in the country.

- India wants to update its energy infrastructure and use new technology to improve the reliability and resilience of its electricity supply as part of its plan to reform its power generation sector. This could cost almost INR 2.5 trillion (USD 35 billion) over the forecast period. The manufacturing and investment of new facilities in the power generation sector are expected to contribute to the demand for the protective coatings market in the country.

- Also, more people getting electricity, more people using electricity per person, and more people will all give the economy a boost.As of October 2022, India had 408.71 GW of installed power capacity. This made it the third-largest electricity producer and consumer in the world.

- The Ministry of Power has found 81 thermal units that will stop using coal and start using renewable energy instead by 2026. This will help India reach its goal of 500 GW of renewable energy and fix the problem of coal supply not meeting demand every year. Additionally, in order to help India reach its goal of 450 GW of renewable energy by 2030, the United Kingdom government announced in September 2021 that it would invest USD 1.2 billion through public and private investments in green projects and renewable energy.

- Hence, the aforementioned factors are driving the demand for protective coatings. This, in turn, is increasing the demand for the paint and coatings market in the country.

Industrial Coatings Industry Overview

The global market for industrial coatings segment is a consolidated market among the top players accounting for a major share of the market. Major Players include Jotun, Akzo Nobel NV, PPG Industries, The Sherwin-Williams Company, Axalta Coating Systems, and Nippon Paint ( NIPSEA GROUP) among others (not in any particular order).

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Deliverables

- 1.2 Study Assumptions

- 1.3 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Rising Demand for Protective Coatings

- 4.1.2 Increasing Applications in Oil and Gas Industry

- 4.2 Restraints

- 4.2.1 Harmful Environmental Impact Of Solvent-borne Coatings

- 4.2.2 Impact of COVID-19 Outbreak

- 4.3 Industry Value-Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Value)

- 5.1 Resin

- 5.1.1 Epoxy

- 5.1.2 Polyurethane

- 5.1.3 Acrylic

- 5.1.4 Polyester

- 5.1.5 Other Resins

- 5.2 Technology

- 5.2.1 Water-borne Coatings

- 5.2.2 Solvent-borne Coatings

- 5.2.3 Other Technologies

- 5.3 End-user Industry

- 5.3.1 General Industrial

- 5.3.2 Protective Coatings

- 5.3.2.1 Oil and Gas

- 5.3.2.2 Mining

- 5.3.2.3 Power

- 5.3.2.4 Infrastructure

- 5.3.2.5 Other Protective Coatings

- 5.4 Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 Italy

- 5.4.3.4 France

- 5.4.3.5 Russia

- 5.4.3.6 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle East & Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle East & Africa

- 5.4.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers & Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 AkzoNobel N.V.

- 6.4.2 Axalta Coating Systems

- 6.4.3 BASF SE

- 6.4.4 Beckers Group

- 6.4.5 Chugoku Marine Paints, Ltd.

- 6.4.6 Hempel A/S

- 6.4.7 Jotun

- 6.4.8 Kansai Paint Co.,Ltd.

- 6.4.9 Nippon Paint ( NIPSEA GROUP)

- 6.4.10 PPG Industries

- 6.4.11 RPM International, Inc.

- 6.4.12 Sika AG

- 6.4.13 The Sherwin-Williams Company

- 6.4.14 Wacker Chemie AG

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Increasing Demand For High Durable Products