|

市场调查报告书

商品编码

1687188

无尘室技术:市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Cleanroom Technology - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

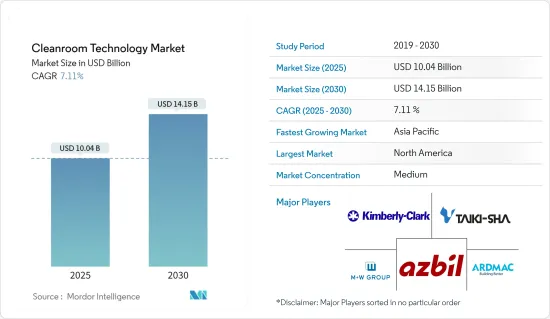

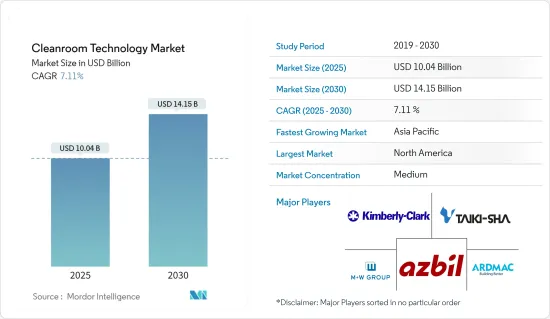

无尘室技术市场规模预计在 2025 年为 100.4 亿美元,预计到 2030 年将达到 141.5 亿美元,预测期内(2025-2030 年)的复合年增长率为 7.11%。

关键亮点

- 随着品质和安全标准不断发展且愈加严格,对无尘室技术的需求也日益增加。洁净室是指空气品质、粒状物水平、温度和湿度受到精确调节的受控环境。洁净室最大限度地降低了空气中的颗粒物、微生物和其他污染物对产品完整性产生不利影响的风险。製药、生物技术和电子等行业使用无尘室来满足监管机构规定的严格品质和安全要求。对品质和安全标准的日益关注推动了洁净室技术的采用,以维护和确保关键产品的品质和安全标准。

- 现代无尘室的发展始于第二次世界大战期间,旨在提高用于生产坦克、枪支和飞机的测量设备的品质和可靠性。在此期间,HEPA 过滤器也被开发用于容纳核分裂实验和化学和生物战争研究产生的危险放射性物质、微生物和化学污染物。洁净室的演变受到美国国家航空暨太空总署 (NASA) 在 1950 年代和 1960 年代的太空旅行计划的推动。在此期间,「层流」概念被引入,标誌着洁净室技术的一个转折点。

- 随着电子产品需求的成长,无尘室技术供应商的业务也不断成长。因此,已开发国家和开发中国家的政府都在做出巨大努力,确保拥有足够的无尘室来满足其国家所有稀缺情况。例如,美国政府去年正式通过了《CHIPS法案》。该法案要求美国公司在美国境内建造半导体製造无尘室,而不是外包给海外的无尘室。随着法案出台,海外半导体厂商也纷纷计画在美国新建无尘室,以获得美国政府的资助。

- 2024 年 4 月,拜登总统宣布根据《晶片与科学法案》与美光公司达成高达 61 亿美元的初步协议。这项投资将支持在纽约州克莱和爱达荷州建造两座晶圆厂,到 2030 年将释放 500 亿美元的私人投资,也是美光公司首次在两个州建造尖端记忆体製造生态系统的投资,未来 20 年总投资将达到 1,250 亿美元。资金筹措将用于支持计划中的四座晶圆厂「Megafun」工厂的前两座的建设,该工厂致力于生产尖端 DRAM 晶片。每个晶圆厂将拥有 60 万平方英尺的无尘室空间,四个工厂的总合。这是美国有史以来公布的最大的无尘室空间,相当于40个足球场的面积。

- 医疗设备需求的不断增长以及製药业研发支出的不断增加进一步推动了市场的成长。根据IQVIA统计,近年来全球医药市场经历了显着成长。到2023年,全球医药市场规模预计将达到约1.6兆美元。这比前一年增加了1000多亿美元。

- 随着品质和安全标准不断发展且愈加严格,对无尘室技术的需求也日益增加。洁净室是指空气品质、粒状物水平、温度和湿度受到精确调节的受控环境。洁净室最大限度地降低了空气中的颗粒物、微生物和其他污染物对产品完整性产生不利影响的风险。製药、生物技术和电子等行业使用无尘室来满足监管机构规定的严格品质和安全要求。对品质和安全标准的日益关注推动了洁净室技术的采用,以维护和确保关键产品的品质和安全标准。

- 例如,2023年8月,博世宣布计划在马来西亚建立一个最先进的晶片和感测器半导体测试中心。该设施占地超过 18,000平方公尺,包括无尘室、办公空间和专门的研究和开发实验室,可容纳多达 400 名员工。

- 由于需要受控环境来维持高品质的产品,洁净室在各种最终用户市场中越来越受欢迎。然而洁净室的成本不仅需要大量的建设投资,还取决于空气交换次数和过滤效率,这些都需要营运成本。

- 为了保持足够的空气质量,洁净室必须始终处于运作,这使得营运成本非常高。节能运作和持续遵守无尘室标准使无尘室成为製造技术和实验室最关键的基础设施之一。预计这将对市场成长构成挑战。

洁净室技术市场趋势

半导体製造终端用户正在推动市场成长

- 洁净室对于半导体製造至关重要,该产业严重依赖无尘室环境来生产精密的微电子产品。半导体晶片存在于每一种电脑化设备中,从行动电话等家用物品到汽车、国防技术和太空船等复杂机器。半导体晶片采用敏感材料製造,形成必须小心处理的精密层。因此,半导体晶片的製造、封装和测试等操作必须在受控的无尘室环境中进行。

- 半导体无尘室是要求最严格的无尘室之一。由于光刻线宽度低于 0.1 微米,这些无尘室通常属于 10 级或 100 级无尘室分类(ISO-4 或 ISO-5)。此外,半导体无尘室对温度和湿度有严格的要求。这些洁净室的面积从 500 平方英尺到 50 万平方英尺不等。半导体洁净室通常使用 ULPA 过滤器而不是 HEPA 过滤器来防止最小的亚微米颗粒进入无尘室。 HEPA 过滤器可以捕捉 0.3u 的 99.97% 的颗粒,而 ULPA 过滤器可以捕捉 0.12u 的 99.999% 的颗粒。

- 例如,2023年6月,全球领先的半导体公司美光科技公司宣布计划在印度古吉拉突邦建立自己的组装和测试工厂。美光公司的新工厂将实现 DRAM 和 NAND 产品的组装和测试製造,以满足国内和国际市场的需求。

- 全球半导体产业投资的增加是市场的主要成长动力。例如,Analog Devices Inc. 于 2023 年 7 月宣布,其打算增强无尘室能力以优化製造流程。作为最新投资的一部分,该公司将推出半导体维修培训计画。这项 10 亿美元的重大投资有望推动比佛顿半导体工厂的成长和效率。最值得注意的是,此次扩建将增加 25,000 平方英尺,使无尘室容量达到令人印象深刻的 118,000 平方英尺。

- 摩根州立大学最近获得了额外的 680 万美元州政府资助,用于推出两个尖端研究中心,以创造和推动半导体设计和製造领域的创新,并解决公共教育面临的挑战。

- 随着 5G 网路扩展、物联网 (IoT) 设备激增以及人工智慧 (AI) 和机器学习 (ML) 应用成长等趋势推动半导体需求成长,半导体製造商需要提高生产能力。这种产能的增加需要建造或扩建配备最新无尘室技术的无尘室设施,以满足半导体製造所需的严格清洁标准。根据WSTS预测,2024年全球半导体销售额预计将达5,883.6亿美元,较上年大幅成长。

- 总体而言,不断增长的半导体需求将推动对无尘室技术的投资,以支持半导体製造能力的扩大,并确保为各个行业和应用生产高品质的晶片。

预计北美将占据较大的市场占有率

- 预计北美在预测期内将出现显着增长,这主要归因于无尘室技术的进步、该地区医疗保健行业的增长以及产品认证的严格监管规范等推动该市场发展的因素。根据CMS的数据,美国全国医疗保健总支出预计将在2024年达到4.8兆美元,并在2031年达到7.1兆美元。

- 售后市场销售的成长以及从定长切割采伐技术的转变也促进了市场的成长。这种成长主要归功于生技产业的成长,该产业还很年轻,尤其是与汽车、化学和钢铁业相比。生技产业的发展是一个独特的故事,但它建立在美国其他产业通用的基础上。据美国国立卫生研究院(NIH)称,2023财政年度NIH对生物技术的资助约为89亿美元。预计到 2024 年将达到 91 亿美元。

- 多年来,政府和私人资助的研究继续提供世界上无与伦比的知识库。透过生物製造,美国的可持续生物质被转化为新产品,为基于石油的化学品、药品、燃料、材料等的生产提供替代品。

- 例如,《金融时报》美国製药和生物技术展将于2024年5月在纽约举办,并首次与Endpoints News合作。这项活动汇集了生物製药行业的领导者、监管机构、投资者和科学家,共用对未来一年的独特见解,并讨论影响该行业和国家的最重要趋势。这些努力可能会进一步刺激该地区的市场需求。

- 2024 年 4 月,安进在俄亥俄州新奥尔巴尼开设了一家新的人工智慧生物製造工厂。预计将僱用约400名员工。该投资 3.65 亿美元的工厂将采用自动化、人工智慧和资料驱动的製造流程,以优化即时效能。该设施按照环境永续性标准建造,并支持安进的碳中和目标。

- 该地区的国家主要希望提高晶片製造水平,并有望协助美国发展人工智慧、5G 和量子运算等未来战略技术,这些技术将决定未来几十年的全球经济和军事领导地位。美国半导体产业协会(SIA)最新报告指出,美国政府面临战略机会,可以扭转美国晶片製造业数十年来的衰退轨迹,加强国家安全,增强供应链的韧性,使美国成为全球最具吸引力的半导体製造业国家机会。随着各公司宣布未来几年重点发展北美地区业务的计划,预计这一增长将为北美无尘室技术市场带来巨大推动力。

洁净室技术市场概览

由于洁净室设备产业的分散性,无尘室技术市场的特点是竞争对手之间的竞争非常激烈,许多供应商都在争夺市场占有率。特别是在耗材领域,供应商之间的竞争非常激烈,都争相抢占大量市场份额。该领域的主要企业包括 M+W Group GmbH、Azbil Corporation、Taikisha Global Limited、Kimberly Clark Corporation 和 Ardmac Ltd.。

2024 年 4 月,AES Clean Technology 宣布于 2024 年 4 月 16 日在 INTERPHEX 2024 上推出 CleanLock 模组。无尘室气闸解决方案旨在透过整合 AES 独有的无尘室饰面、取得专利的照明、可预测的气流模式和先进的门控来最大限度地降低污染风险。这些功能可以立即融入任何设施。 CleanLock 模组可使人员和材料安全进入现有的无尘室。

2024年2月,ADI公司宣布与全球领先的专用半导体代工厂台积电达成特别协议,透过位于熊本县的台积电控股製造子公司日本先进半导体製造公司(JASM)提供长期晶圆生产能力。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概览

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买家的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

- 主要宏观经济趋势将如何影响市场

第五章市场动态

- 市场驱动因素

- 主要市场生物技术和医疗保健支出整体成长

- 严格的政府法规和对优质产品的需求

- 市场问题

- 安装维护成本高,缺乏技术纯熟劳工

第六章市场区隔

- 按组件

- 设备类型

- 无尘室空气浴尘室

- HVAC 系统

- 层流系统

- 高效过滤器

- 干燥柜

- 风机过滤机组

- 耗材类型

- 衣服

- 手套

- 擦拭巾

- 真空系统

- 消毒剂

- 其他耗材

- 设备类型

- 按最终用户

- 製药

- 生物技术

- 医疗设备

- 医院

- 半导体製造

- 其他的

- 按地区

- 北美洲

- 欧洲

- 亚洲

- 澳洲和纽西兰

- 拉丁美洲

- 中东和非洲

第七章竞争格局

- 公司简介

- M+W Group

- Azbil Corporation

- Taikisha Global Limited

- Kimberly Clark Corporation

- Ardmac Ltd

- Ansell Limited

- Clean Air Products

- Labconco Corporation

第八章投资分析

第九章:市场的未来

The Cleanroom Technology Market size is estimated at USD 10.04 billion in 2025, and is expected to reach USD 14.15 billion by 2030, at a CAGR of 7.11% during the forecast period (2025-2030).

Key Highlights

- The demand for cleanroom technology grows as quality and safety standards evolve and become more stringent. Cleanrooms offer controlled environments with precise regulation of air quality, particulate levels, temperature, and humidity. They minimize the risk of contamination from airborne particles, microorganisms, and other contaminants that can adversely affect product integrity. Industries such as pharmaceuticals, biotechnology, and electronics rely on cleanrooms to meet the strict quality and safety requirements imposed by regulatory bodies. The increasing focus on quality and safety standards drives the adoption of cleanroom technology to maintain and ensure significant product quality and safety standards.

- The modern, clean room development began during the Second World War to enhance the quality and reliability of instrumentation used in manufacturing tanks, guns, and aircraft. During this time, HEPA filters were also developed to contain the dangerous radioactive, microbial, or chemical contaminants that resulted from experiments into nuclear fission and research into chemical and biological warfare. The evolution of clean rooms gained momentum due to NASA's space travel program in the 1950s and 1960s. During this time, the 'laminar flow' concept was introduced, marking a turning point in clean room technology.

- With the growing demand for electronics, cleanroom technology providers are witnessing increased business. As a result of this, governments from developed and developing nations are significantly working toward securing ample cleanrooms to handle any scarce situation domestically. For instance, the US government officially passed the CHIPS Act in the previous year. Under this act, the US government wanted US companies to build cleanrooms in the United States for semiconductor manufacturing instead of outsourcing to cleanrooms in foreign countries. After introducing this act, foreign semiconductor manufacturers have also been planning new US-based cleanrooms to get US government funding.

- In April 2024, President Biden announced up to USD 6.1 billion preliminary agreement with Micron under the CHIPS and Science Act. This investment will support the construction of two fabs in Clay, New York, and one fab in Idaho, releasing USD 50 billion in private investment by 2030 as the first step toward Micron's investment of up to USD 125 billion across both states over the next two decades to create a leading-edge memory manufacturing ecosystem. Funding will support the construction of the first two fabs of a planned four-fab "megafan" focused on leading-edge DRAM chip production. Each fab will have 600,000 square feet of cleanrooms, totaling 2.4 million square feet of cleanroom space across the four facilities, the most extensive cleanroom space ever announced in the United States and the size of nearly 40 football fields.

- Growing demand for medical instruments and increasing R&D spending in the pharmaceutical industry further propel the market growth. According to IQVIA, the global pharmaceutical market has experienced significant growth in recent years. In 2023, the total global pharmaceutical market was around USD 1.6 trillion. This is an increase of over USD 100 billion compared to the previous year.

- The demand for cleanroom technology grows as quality and safety standards evolve and become more stringent. Cleanrooms offer controlled environments with precise regulation of air quality, particulate levels, temperature, and humidity. They minimize the risk of contamination from airborne particles, microorganisms, and other contaminants that can adversely affect product integrity. Industries such as pharmaceuticals, biotechnology, and electronics rely on cleanrooms to meet the strict quality and safety requirements imposed by regulatory bodies. The increasing focus on quality and safety standards drives the adoption of cleanroom technology to maintain and ensure significant product quality and safety standards.

- For instance, in August 2023, Bosch announced plans to establish a state-of-the-art semiconductor test center for chips and sensors in Malaysia. The facility boasts an expansive area of over 18,000 square meters, housing clean rooms, office spaces, and dedicated R&D laboratories to accommodate up to 400 associates.

- Cleanrooms are gaining popularity in various end-user markets as a controlled environment is necessary for maintaining high-quality products. However, the cost of a cleanroom is not only highly investment-intensive to build, but operational costs can also rely on the number of required air exchanges and filtration efficiency.

- The operation can be extremely costly, as holding the appropriate air quality means the room has to be in constant operation. Energy-efficient operation and continuous adherence to cleanroom standards make a cleanroom one of the most critical infrastructures for manufacturing technology and laboratories. This is anticipated to challenge the market's growth.

Cleanroom Technology Market Trends

Semiconductor Manufacturing End User Significantly Driving the Market Growth

- Cleanrooms are necessary for semiconductor manufacturing as this industry relies heavily on cleanroom environments to manufacture sensitive microelectronics. Semiconductor chips are utilized in every computerized device, from household objects like cell phones to complex machines such as vehicles, defense technology, or spacecraft. They are produced using susceptible materials to create delicate layers that must be worked on carefully. Thus, tasks like semiconductor chip manufacturing, packaging, and testing must be carried out in a controlled cleanroom environment.

- Semiconductor cleanrooms are among the most demanding cleanrooms. As photolithography linewidths go below 0.1 microns, these cleanrooms are usually class 10 or 100 cleanroom classification (ISO-4 or ISO-5). Additionally, semiconductor cleanrooms have tight temperature and humidity requirements. Such cleanrooms can vary in size from 500 SF to 500,000 SF; usually, semiconductor cleanrooms use ULPA filters instead of HEPA filters to prevent even the smallest submicron particles from entering the cleanroom. While HEPA filters can catch 99.97% of particles at 0.3u, ULPA filters can catch 99.999% at 0.12u.

- For instance, in June 2023, Micron Technology Inc., one of the world's significant semiconductor companies, announced plans to build a unique assembly and test facility in Gujarat, India. Micron's new facility will allow assembly and test manufacturing for DRAM and NAND products and address demand from domestic and international markets.

- The growing investments in the semiconductor industry worldwide are a key growth driver for the market. For instance, in July 2023, Analog Devices Inc. announced its intention to enhance its cleanroom capabilities to optimize manufacturing. The company will introduce a semiconductor maintenance training program as part of its latest investment. This substantial investment of USD 1 billion is poised to foster the growth and efficiency of the semiconductor facility in Beaverton. Notably, the expansion will result in an additional 25,000 square feet, boosting the cleanroom capacity to an impressive 118,000 square feet.

- Recently, Morgan State University secured an additional USD 6.8 million in state funding to support the launch of two latest research centers that will create and drive innovation in the design and fabrication of semiconductors and handle the challenges facing public school education.

- As the demand for semiconductors rises, driven by trends such as the expansion of 5G networks, the proliferation of Internet of Things (IoT) devices, and the growth of artificial intelligence (AI) and machine learning (ML) applications, semiconductor manufacturers need to ramp up production capacity. This increased production capacity requires constructing or expanding cleanroom facilities equipped with the latest cleanroom technology to meet the stringent cleanliness standards necessary for semiconductor fabrication. According to WSTS, 2024 semiconductor sales were expected to reach USD 588.36 billion worldwide, significantly more than the previous year.

- Overall, the growing demand for semiconductors drives investment in cleanroom technology to support the expansion of semiconductor manufacturing capacity and ensure the production of high-quality chips for various industries and applications.

North America is Expected to Hold Significant Market Share

- It is anticipated that North America will experience significant growth during the forecast period, primarily due to the technological advancements in cleanrooms, the growth of the healthcare sector in the region, and stringent regulatory standards for product approvals are the factors propelling the development of this market. According to CMS, the total US national health expenditure recorded was USD 4.8 trillion in FY 2024, and it is projected to reach USD 7.1 trillion by 2031.

- Rising aftermarket sales and the shift toward modified cut-to-length logging techniques also contribute to the market growth. This growth is primarily attributed to the growing biotechnology industry, which is still young, especially compared with the automotive, chemical, and steel industries. The development of the biotechnology industry is a unique story, and yet it rests on foundations common to other segments of American industry. According to NIH, biotechnology funding by the NIH was around USD 8.9 billion during the fiscal year 2023. Further, it is estimated to reach USD 9.1 billion by FY 2024.

- Years of research, both government-funded and privately funded, continue to provide a knowledge base unequaled in the world. Through biomanufacturing, sustainable biomass across the United States has been converted into new products and provides an alternative to petroleum-based production for chemicals, medicines, fuels, materials, and more.

- For instance, the Financial Times US Pharma and Biotech Summit returned to New York in May 2024, partnering with Endpoints News for the first time. The event gathered biopharma leaders, regulators, investors, and scientists to share unique insights about the year ahead and discuss the most critical trends affecting the industry and the country. Such initiatives may further propel the market demand in the region.

- In April 2024, Amgen opened a new AI-enabled biomanufacturing facility in New Albany, Ohio. It will employ roughly 400 people. The USD 365 million investment features automation, AI, and data-driven manufacturing processes, optimizing real-time performance. The facility was built with environmental sustainability standards, supporting Amgen's carbon neutrality goals.

- The regional countries are mainly looking forward to strengthening chip manufacturing, which is expected to help America with the strategic technologies of the future, including AI, 5G, and quantum computing, that will determine global economic and military leadership for decades to come. According to a new report by the Semiconductor Industry Association, the US government has a strategic opportunity to reverse the decades-long trajectory of declining chip manufacturing in America, strengthen national security, make supply chains more resilient, and make the country one of the most attractive places in the world to produce semiconductors. This growth is expected to provide a vast share of traction to the North American cleanroom technology market as the companies have announced their plans to majorize the region in the upcoming few years.

Cleanroom Technology Market Overview

In the cleanroom technology market, intense competitive rivalry prevails due to the fragmentation of the cleanroom equipment industry, with numerous vendors vying for market share. Fierce competition is evident among these vendors, especially in the consumable segments, as they seek to capture a larger portion of the market. Key players in this sector include M+W Group GmbH, Azbil Corporation, Taikisha Global Limited, Kimberly Clark Corporation, and Ardmac Ltd.

April 2024: AES Clean Technology announced the launch of its CleanLock Module at INTERPHEX 2024 on April 16, 2024. The airlock solution for cleanrooms is engineered to minimize the risk of contamination by integrating AES' proprietary cleanroom finishes, patented lighting, predictable airflow patterns, and advanced door controls. These features can be incorporated into any facility without delay. The CleanLock Module allows for a secure transition of people and materials entering existing cleanrooms.

February 2024: Analog Devices Inc. announced that the company made a special arrangement with TSMC, the world's significant dedicated semiconductor foundry, to supply long-term wafer capacity through Japan Advanced Semiconductor Manufacturing Inc. ("JASM"), TSMC's majority-owned manufacturing subsidiary in Kumamoto Prefecture, Japan.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Degree of Competition

- 4.3 Impact of Key Macroeconomic Trends on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Overall Growth in Biotechnology and Healthcare Spending in Major Markets

- 5.1.2 Stringent Government Regulations and Demand for Quality Products

- 5.2 Market Challenges

- 5.2.1 High Installation, Maintenance Costs, and Lack of Skilled Workforce

6 MARKET SEGMENTATION

- 6.1 By Component

- 6.1.1 Type of Equipment

- 6.1.1.1 Cleanroom Air Showers

- 6.1.1.2 HVAC Systems

- 6.1.1.3 Laminar Air Flow Systems

- 6.1.1.4 High Efficiency Filters

- 6.1.1.5 Desiccator Cabinets

- 6.1.1.6 Fan Filter Units

- 6.1.2 Type of Consumable

- 6.1.2.1 Apparels

- 6.1.2.2 Gloves

- 6.1.2.3 Wipes

- 6.1.2.4 Vacuum Systems

- 6.1.2.5 Disinfectants

- 6.1.2.6 Other Types of Consumables

- 6.1.1 Type of Equipment

- 6.2 By End User

- 6.2.1 Pharmaceutical

- 6.2.2 Biotechnology

- 6.2.3 Medical Devices

- 6.2.4 Hospitals

- 6.2.5 Semiconductor Manufacturing

- 6.2.6 Other End Users

- 6.3 By Geography

- 6.3.1 North America

- 6.3.2 Europe

- 6.3.3 Asia

- 6.3.4 Australia and New Zealand

- 6.3.5 Latin America

- 6.3.6 Middle East and Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 M+W Group

- 7.1.2 Azbil Corporation

- 7.1.3 Taikisha Global Limited

- 7.1.4 Kimberly Clark Corporation

- 7.1.5 Ardmac Ltd

- 7.1.6 Ansell Limited

- 7.1.7 Clean Air Products

- 7.1.8 Labconco Corporation