|

市场调查报告书

商品编码

1687306

气相二氧化硅:市场占有率分析、产业趋势与成长预测(2025-2030)Fumed Silica - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

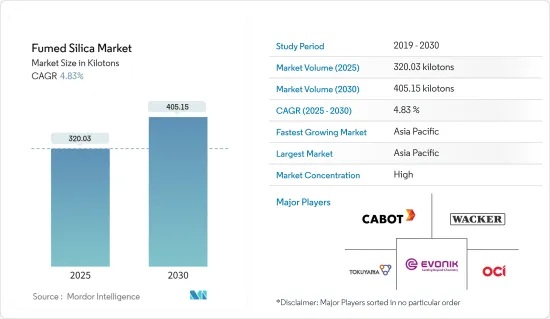

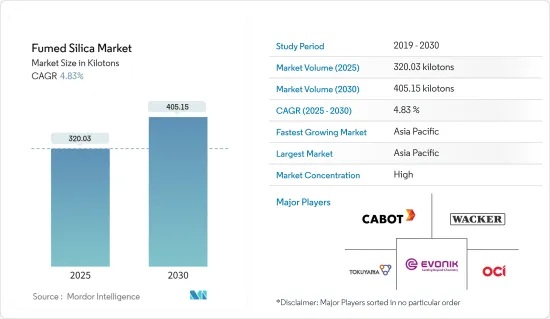

气相二氧化硅市场规模预计在 2025 年为 320.03 千吨,预计到 2030 年将达到 405.15 千吨,预测期(2025-2030 年)的复合年增长率为 4.83%。

2020 年,市场受到新冠疫情的负面影响。由于疫情,建筑业和汽车製造活动暂时停止。这减少了用于黏合剂、油漆、被覆剂、塑胶和复合材料等产品配方的添加剂的需求,对气相二氧化硅的市场需求产生了负面影响。不过,去年随着各行各业恢復生产,市场维持了成长轨迹。

关键亮点

- 短期内,牙膏、乳霜等个人护理产品对气相二氧化硅的需求激增预计将推动市场成长。

- 预计生物来源二氧化硅和沈淀二氧化硅等气相二氧化硅替代品的开发将阻碍市场发展。

- 气相二氧化硅在各行业的新兴应用预计将带来机会。

- 亚太地区占据全球市场主导地位,其中中国和印度等国家占最大消费量。

气相二氧化硅市场趋势

黏合剂和密封剂应用占据市场主导地位

- 气相二氧化硅在黏合剂和密封剂中的主要用途是作为防流挂添加剂、流变控制添加剂和防沉降添加剂。气相二氧化硅也可用作流变控制添加剂和密封剂增强剂。提高黏合剂和密封剂的储存稳定性和加工效率。

- 黏合剂和密封剂行业中的气相二氧化硅用于增加产品黏度、增强储存期间的防沉降性能、调整应用期间的挤出性能以及赋予固化期间的防流挂性能。

- 在建筑业,气相二氧化硅黏合剂和密封剂用于结构嵌装玻璃和耐候性,有助于提高建筑物的能源效率。它还有助于提高现场生产力,减少材料浪费,延长建筑物的使用寿命并降低生命週期成本。

- 根据英国土木工程师学会的数据,预计到 2025 年,中国、印度和美国将占全球建筑业成长的近 60%,推动气相二氧化硅市场的成长。

- 美国是世界领先的建筑市场之一。根据美国人口普查局的数据,2022 年建设业是美国第 12 大产业,约占 GDP 总量的 4.3%。根据美国人口普查局的数据,2022年美国建筑业的市场规模约为1.79兆美元。

- 根据美国人口普查局的数据,2023年前九个月的建筑支出为1.4635兆美元,较2022年同期的1.3989兆美元增加4.6%。

- 在欧洲,DIY 黏合剂市场的製造商正在转向透明包装,用气相二氧化硅取代不透明增强添加剂和用于流变控制的增强材料,气相二氧化硅的屈光与透明聚合物非常接近。

- 经过处理的气相二氧化硅显示出比涂层沉淀碳酸钙(PCC)更高的黏合强度,而涂层沉淀碳酸钙(PCC)通常用于 STP 和聚氨酯接着剂和密封剂中的流变控制。此外,气相二氧化硅的比重比碳酸钙低,因此对黏合剂重量的贡献要小得多,这在关注黏合剂重量的应用中(例如轻型汽车)是一个优势。

- 汽车产业是黏合剂和密封剂的主要消费者之一。应用包括热交换器管密封、变速箱和油底壳盖垫圈以及内部仪表板粘合。根据OICA预测,2022年全球汽车产量将达8,502万辆,较上年的8,020万辆成长6%。

- 因此,预计这些因素将在预测期内对气相二氧化硅市场产生重大影响。

亚太地区占市场主导地位

- 亚太地区占比最大,其中中国、印度等国的需求量较大。

- 硅胶黏合剂的生产始于从硅胶中分离二氧化硅。二氧化硅以纯净形式存在于多种矿物中。硅胶黏合剂因其优异的弹性体性能、宽的温度范围、耐燃料影响以及低收缩率和剪切应力而被广泛使用。

- 中国、印度和越南等亚太国家的建设活动正在强劲增长,预计这将在预测期内推动该地区气相二氧化硅的消费。

- 中国和印度占亚太地区黏合剂和密封剂市场总份额的50%以上。它也是亚太地区最大的油漆和被覆剂生产商。

- 2023 年 1 月,亚洲涂料公司核准投资 200 亿印度卢比(2.4053 亿美元),在印度中央邦建立一座年产 40 万千公升的水性涂料新生产厂。该工厂预计将在三年内开始生产。

- 2022年7月,BASF欧洲公司透过其子公司BASF涂料(广东)有限公司(BCG)扩大了位于中国南方广东省江门市的涂料工厂的汽车修补漆生产能力。扩建计划将使公司的生产能力提高至每年3万吨。

- 印度製药业是气相二氧化硅的主要消费者,气相二氧化硅用作高纯度赋形剂和多功能添加剂。中国是全球最大的学名药供应国,满足了美国40%的非专利需求和英国25%的所有药品需求。

- 气相二氧化硅用于许多严格要求的黏合剂应用,包括建筑、施工、汽车应用和包装。预计黏合剂和密封剂领域的高需求将推动气相二氧化硅市场的发展。

- 在建筑业中,气相二氧化硅用于黏合剂、密封剂、被覆剂和塑胶。中国建筑业正在经历强劲成长。根据中国国家统计局的数据,中国建筑业产出预计将在 2022 年达到峰值,约 4.64 兆美元。与 2021 年的 4.36 兆美元相比,这一数字将成长 6%。

- 黏合剂、密封剂、油漆和被覆剂也用于汽车工业。亚太地区的汽车製造业是世界上最大的。 OICA 预计,2022 年亚太汽车产量将达到 5,002 万辆,较 2021 年的 4,677 万辆成长 7%。

- 预计上述因素将在预测期内推动亚太地区对气相二氧化硅的需求。

气相二氧化硅产业概况

气相二氧化硅市场已整合到大约主要参与企业(无特定顺序)包括 Evonik Industries AG、Cabot Corporation、Wacker Chemie AG、Tokuyama Corporation 和 OCI COMPANY Ltd.

其他福利

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 驱动程式

- 亚太地区个人护理应用需求激增

- 油漆和涂料行业需求增加

- 其他驱动因素

- 限制因素

- 沉淀二氧化硅作为替代品

- 生物气相二氧化硅的开发

- 价值链分析

- 波特五力分析

- 供应商的议价能力

- 买家的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章市场区隔

- 类型

- 亲水性气相二氧化硅

- 疏水性气相二氧化硅

- 应用

- 硅胶橡胶

- 塑胶复合材料(不饱和聚酯树脂)

- 饮食

- 油漆(包括油墨)

- 黏合剂和密封剂

- 其他用途(药品、个人护理、肥料)

- 地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 其他欧洲国家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争格局

- 併购、合资、合作与协议

- 市场占有率(%)**/排名分析

- 主要企业策略

- 公司简介

- AMS Applied Material Solutions

- Cabot Corporation

- China-Henan Huamei Chemical Co. Ltd

- Dongyue Group Co. Ltd

- Evonik Industries AG

- Gelest Inc.

- Heraeus Holding

- Kemitura AS

- Kemipex

- OCI Company Ltd

- Tokuyama Corporation

- Wacker Chemie AG

第七章 市场机会与未来趋势

- 气相二氧化硅的新应用

- 永续生产气相二氧化硅的新技术

The Fumed Silica Market size is estimated at 320.03 kilotons in 2025, and is expected to reach 405.15 kilotons by 2030, at a CAGR of 4.83% during the forecast period (2025-2030).

The market was negatively impacted by the COVID-19 pandemic in 2020. Construction and automotive manufacturing activities were on a temporary halt due to the pandemic. This minimized the demand for additives used in the formulation of products such as adhesives, paints, coatings, plastics, and composites, negatively impacting the market demand for fumed silica. However, the market retained its growth trajectory last year due to all the industries resuming production processes.

Key Highlights

- Over the short term, the surging demand for fumed silica from products in the personal care segment, such as toothpaste, creams, and others, is expected to drive the market's growth.

- The development of biogenic fumed silica and precipitated silica as a substitute for fumed silica is anticipated to hinder the market's growth.

- The emerging applications of fumed silica in various industries are likely to act as an opportunity.

- The Asia-Pacific region dominated the global market, with the highest consumption coming from countries such as China and India.

Fumed Silica Market Trends

Adhesives and Sealants Application to Dominate the Market

- The primary uses of fumed silica in adhesives and sealants are as anti-sag additives, rheological control additives, and anti-settling additives. Fumed silica is also used as a rheological control additive and sealant reinforcing agent. It enhances the storage stability and processing efficiency of adhesives and sealants.

- Fumed silica in the adhesives and sealants industry is used to enhance the viscosity of the product, enhance anti-settling characteristics during storage, regulate the extrusion characteristics during application, and provide anti-sag characteristics during curing.

- In the construction industry, fumed silica adhesives and sealants are used in structural glazing and weatherproofing, contributing to the energy efficiency of buildings. They also help improve in-shop productivity, reduce material waste, extend building life, and reduce lifecycle costs.

- According to the Institution of Civil Engineers, China, India, and the United States are expected to account for almost 60% of all global growth in the construction sector by 2025, thus increasing the market growth of fumed silica in the industry.

- The United States was among the top construction markets globally. As per the United States Census Bureau, construction was the 12th largest industry in the country in 2022 and accounted for approximately 4.3% of its total GDP. As per the US Census Bureau, the market size of the US construction sector was around USD 1.79 trillion in 2022.

- According to the US Census Bureau, during the first nine months of 2023, construction spending amounted to USD 1,463.5 billion, 4.6% above the USD 1,398.9 billion for the same period in 2022.

- In Europe, manufacturers in the do-it-yourself (DIY) adhesives market have switched to clear packaging, where the opaque reinforcing aids additives used for rheology control and the reinforcements are replaced by fumed silica, which closely matches its refractive index with transparent polymers.

- Treated fumed silica provides significantly more adhesive strength than the coated precipitated calcium carbonates (PCC), usually used for rheology control of STP and polyurethane adhesives and sealants. Compounding the benefit of lower loading, fumed silica has a lower specific gravity than calcium carbonate and, thus, contributes far less to adhesive weight, which may be a benefit in applications where adhesive weight is a concern, e.g., automotive light-weighting.

- The automotive industry is one of the major consumers of adhesives and sealants. The applications include sealing heat exchanger tubes, gearbox and sump cover gasketing, bonding interior dashboards, and others. According to the OICA, global vehicle production reached 85.02 million units in 2022, with an increase of 6% from the previous year's production of 80.20 million units.

- Therefore, such factors are expected to impact the fumed silica market significantly over the forecast period.

Asia-Pacific Region to Dominate the Market

- The Asia-Pacific region dominated the market with the largest share and high demand from countries such as China and India.

- The manufacture of silicone adhesives begins by isolating silica from silicon. Silica can be found in its pure form in some minerals. Silicone adhesives are widely used due to their excellent elastomeric properties, extended temperature range, resistance to the effects of fuels, and low shrinkage and shear stress.

- Countries in the Asia-Pacific region, such as China, India, and Vietnam, have been registering strong growth in construction activities, which is expected to drive the consumption of fumed silica in the region over the forecast period.

- China and India contribute to more than 50% of the total share of the Asia-Pacific region in the adhesives and sealants market. They are also the largest producer of paints and coatings in the Asia-Pacific region.

- In January 2023, Asian Paints approved an investment of INR 2,000 crore (USD 240.53 million) for a new waterborne paint manufacturing plant with 400,000 kiloliters per annum capacity in Madhya Pradesh, India. The facility's manufacturing is expected to be commissioned in three years.

- In July 2022, BASF SE, through its subsidiary BASF Coatings (Guangdong) Co. Ltd (BCG), expanded its manufacturing capabilities for automotive refinish coatings at its coatings site in Jiangmen, Guangdong Province, South China. The company increased its production capacity to 30,000 ton annually through this expansion project.

- The pharmaceutical industry in India is a major consumer of fumed silica, used as a high-purity excipient and multi-functional additive. The country is the largest provider of generic drugs globally, fulfilling 40% of the generic demand in the United States and 25% of all medicine demand in the United Kingdom.

- Fumed silica is used in many demanding adhesive applications, from building, construction, and automotive applications to packaging. High demand from the adhesives and sealants sector is expected to drive the fumed silica market.

- In the construction industry, fumed silica is used in adhesives, sealants, coatings, and plastics. China is experiencing massive growth in its construction sector. According to the National Bureau of Statistics of China, the construction output value in China achieved its peak at around USD 4.64 trillion in 2022. It rose by 6% compared to USD 4.36 trillion in 2021.

- Adhesives, sealants, paints, and coatings are also finding application in the automotive industry. The Asia-Pacific automotive manufacturing industry is the largest in the world. According to the OICA, automotive production in Asia-Pacific stood at 50.02 million units in 2022, up 7% from 46.77 million units in 2021.

- The factors above are expected to increase the demand for fumed silica in the Asia-Pacific region over the forecast period.

Fumed Silica Industry Overview

The fumed silica market is mostly consolidated. The major players (not in any particular order) include Evonik Industries AG, Cabot Corporation, Wacker Chemie AG, Tokuyama Corporation, and OCI COMPANY Ltd, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Surging Demand from Personal Care Applications in the Asia-Pacific Region

- 4.1.2 Increasing Demand from the Paints and Coatings Industry

- 4.1.3 Other Drivers

- 4.2 Restraints

- 4.2.1 Precipitated Silica as a Substitute

- 4.2.2 Development of Biogenic Fumed Silica

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Volume)

- 5.1 Type

- 5.1.1 Hydrophilic Fumed Silica

- 5.1.2 Hydrophobic Fumed Silica

- 5.2 Application

- 5.2.1 Silicone Rubber

- 5.2.2 Plastics and Composites (Unsaturated Polyester Resin)

- 5.2.3 Food and Beverages

- 5.2.4 Paints and Coatings (Including Inks)

- 5.2.5 Adhesives and Sealants

- 5.2.6 Other Applications (Pharmaceutical, Personal Care, and Chemicals and Fertilizers)

- 5.3 Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle East and Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share (%)**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 AMS Applied Material Solutions

- 6.4.2 Cabot Corporation

- 6.4.3 China-Henan Huamei Chemical Co. Ltd

- 6.4.4 Dongyue Group Co. Ltd

- 6.4.5 Evonik Industries AG

- 6.4.6 Gelest Inc.

- 6.4.7 Heraeus Holding

- 6.4.8 Kemitura AS

- 6.4.9 Kemipex

- 6.4.10 OCI Company Ltd

- 6.4.11 Tokuyama Corporation

- 6.4.12 Wacker Chemie AG

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Emerging Applications of Fumed Silica

- 7.2 New Technology for Sustainable Production of Fumed Silica