|

市场调查报告书

商品编码

1687373

热塑性复合材料:市场占有率分析、产业趋势与统计、成长预测(2025-2030)Thermoplastic Composites - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

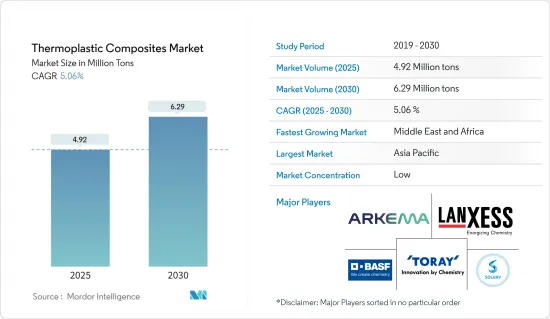

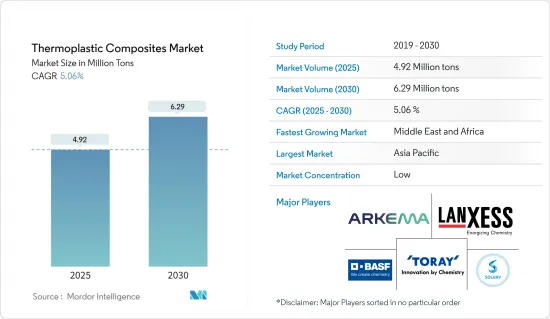

预计 2025 年热塑性复合材料市场规模为 492 万吨,到 2030 年将达到 629 万吨,预测期内(2025-2030 年)的复合年增长率为 5.06%。

新冠疫情迫使全球汽车製造商、风力发电机製造商和飞机製造商停工,并抑制了 2020 年对复合材料的需求。疫情影响了复合材料产业的几乎方面,从产品需求到劳动力发展,甚至加速或减缓了疫情爆发时已经出现的趋势。我们的客户和我们自己的公司暂时停产,降低了生产水平,需求的下降对所有生产过程产生了重大影响。

主要亮点

- 从中期来看,建设产业需求的增加以及航太和国防应用投资的增加是推动市场发展的关键因素。

- 另一方面,汽车产业的衰退和新冠疫情的负面影响可能会抑制市场成长。

- 亚太地区贡献了最高的市场占有率,预计在预测期内将占据市场主导地位。

热塑性复合材料市场趋势

汽车产业占市场主导地位

- 汽车是热塑性复合材料的主要终端用户产业。生产更轻、二氧化碳排放更低的汽车的需求不断增长,推动了汽车产业对热塑性复合材料的需求。

- 热塑性复合材料以其高韧性和轻质特性而闻名。汽车产业将玻璃纤维毡热塑性塑胶用于各种用途。

- 热塑性复合材料在汽车工业的应用包括座椅框架、电池托盘、保险桿梁、货物地板、前端、气门盖、户定板和引擎下盖。

- 根据国际汽车製造商组织(OICA)的预测,2022年全球汽车产量将超过85,016,728辆,与前一年同期比较增长6%,这表明由于基于热塑性复合材料的汽车零件生产,对热塑性复合材料的需求将增加。

- 此外,预计2022年美国汽车产量与前一年同期比较增加10%。加拿大、墨西哥和美国的汽车产量均成长10%,分别达到1,228,735辆、3,509,072辆和10,060,339辆。在南美洲,哥伦比亚的产量与去年同期相比增幅最大,成长了26%,达到51,455辆。阿根廷的产量也强劲成长了24%,达到536,893辆。

- 此外,美国汽车製造商宣布将在 2022 年向国内电动车製造投资 130 亿美元。丰田宣布将向其位于卡罗来纳州的製造工厂投资 25 亿美元。本田和 LG Energy Solution 宣布成立 44 亿美元的合资企业,投资电动车和电池製造。这些因素预计将增加汽车产量,从而使热塑性复合材料市场受益。

- 在欧洲,德国是主要的汽车製造国之一。根据德国工业协会(VDA)数据显示,2023年3月德国汽车产量为441,990辆,较去年同期成长67%。

- 因此,考虑到世界各地汽车的成长趋势和产量,汽车产业可能会主导市场,从而导致预测期内对热塑性复合材料的需求增加。

中国主导亚太地区

- 在亚太地区,中国是最大的热塑性复合材料生产国和消费国,其次是印度和日本。

- 由于印度在生产各种、品质精确的产品以满足产业需求方面具有优势,因此该国汽车产业对热塑性复合材料的需求很高。中国是全球产销最大的汽车市场。 2022年,儘管受到新冠疫情爆发、结构性晶片短缺、地区地缘政治衝突等诸多负面因素的影响,中国汽车市场仍实现了正增长。

- 根据中国工业协会预测,中国是全球最大的汽车生产基地,预计2022年汽车总产量将达到2,700万辆,较上年的2,600万辆成长3.4%。

- 官方资料显示,受生产和投资稳健成长的支撑,中国电子产业在2022年实现稳定成长。根据工业信部统计,2021年前三个月,製造业主要企业增加价值增加价值额增7.6%,成长率高增加价值额全部工业4个百分点。因此,电子产品需求的大幅成长正在支撑该产业对热塑性复合材料的需求。

- 根据国际贸易组织的统计,中国是全球最大的建筑市场,拥有全球最高的都市化。根据美国建筑师协会(AIA)上海分会的资料,到2025年,中国预计将建造一个相当于10个纽约市的城市。

- 中国政府正在采取措施紧缩经济。中国的「十四五」规划包括一项由政府主导的计划,将数位技术应用于建筑和施工过程。预计到2025年,建筑业将占全国GDP的6%,中国建筑业在振兴经济、稳定就业方面发挥越来越重要的作用。

- 根据航太公司空中巴士公司2023年4月发布的新闻稿,未来20年,中国航空运输量预计将以每年5.3%的速度成长,远高于全球3.6%的平均值。这意味着到 2041 年全球将需要 8,420 架客机和货机,占未来 20 年全球所需新飞机总数(约 39,500 架)的 20% 以上。

- 因此,由于上述原因,中国很可能在预测期内推动亚太地区的市场成长。

热塑性复合材料产业概况

全球热塑性复合材料市场本质上是部分分散的,有几家公司在全球和区域层面开展业务。市场的主要企业包括朗盛、索尔维、BASF、东丽工业公司和阿科玛公司。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 调查前提条件

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 驱动程式

- 汽车产业需求增加

- 建设产业支出增加

- 限制因素

- 热塑性复合材料成型的高成本且挑战大

- 其他的

- 产业价值链分析

- 波特五力分析

- 供应商的议价能力

- 买家的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章市场区隔

- 依树脂类型

- 聚丙烯(PP)

- 聚酰胺(PA)

- 聚醚醚酮(PEEK)

- 其他的

- 依纤维类型

- 玻璃纤维

- 碳纤维

- 其他的

- 依产品类型

- 短纤维热塑性塑胶(SFT)

- 长纤维热塑性塑胶(LFT)

- 连续纤维热塑性塑胶(CFT)

- 玻璃纤维毡热塑性塑胶 (GMT)

- 按最终用户产业

- 航太与国防

- 电气和电子

- 车

- 建筑学

- 医疗保健

- 其他的

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 东南亚国协

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 其他欧洲国家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争格局

- 併购、合资、合作与协议

- 市场占有率(%)**/排名分析

- 主要企业策略

- 公司简介

- Arkema SA

- AVANCO Group

- Avient Corporation

- BASF SE

- Celanese Corporation

- Daicel Corporation

- DSM

- Hexcel Corporation

- LANXESS

- LyondellBasell Industries Holdings BV

- Mitsubishi Chemical Group Corporation

- SABIC

- SGL Carbon

- Solvay

- TechnoCompound GmbH

- Toray Industries Inc.

第七章 市场机会与未来趋势

- 医疗保健领域的广泛应用

- 航太和国防工业的需求不断增长

The Thermoplastic Composites Market size is estimated at 4.92 million tons in 2025, and is expected to reach 6.29 million tons by 2030, at a CAGR of 5.06% during the forecast period (2025-2030).

The COVID-19 pandemic, on a global scale, has forced automakers, wind turbine manufacturers, and aircraft manufacturers to shut down their operations, lowering the demand for composites in 2020. The pandemic impacted almost every aspect of the composites industry, from product demand to workforce development to the acceleration or deceleration of trends that were already underway when it struck. Customers and their own temporary production stop reduced the production levels, and demand reductions have all had a significant impact on production processes.

Key Highlights

- In the medium term, the major factors driving the market studied are the increasing demand from the construction industry and increasing investments in aerospace and defense applications.

- On the flip side, the declining automotive industry and the negative impact of the COVID-19 pandemic are likely to restrain the market growth.

- Asia-Pacific accounted for the highest market share, and the region is likely to dominate the market during the forecast period.

Thermoplastic Composites Market Trends

Automotive Industry to Dominate the Market

- Automotive is the major end-user industry of thermoplastic composites. The growing demand for producing lightweight and low CO2 emission vehicles is driving the demand for thermoplastic composites in the automotive industry.

- Thermoplastic composites are known for their high toughness and lightweight characteristics. Automotive industries highly adopt glass mat thermoplastics for various uses.

- The application areas of these composites in the automotive industry include seat frames, battery trays, bumper beams, load floors, front ends, valve covers, rocker panels, and under-engine covers.

- According to the Organisation Internationale des Constructeurs d'Automobiles (OICA), more than 85,016,728 motor vehicles were manufactured worldwide in 2022, an increase of 6% from a year earlier, indicating an increased demand for thermoplastic composites from thermoplastic composite-based automotive part manufacturing.

- Additionally, America's automotive production grew by 10% Y-o-Y in 2022. Canada, Mexico, and the United States saw a production increase of 10%, with motor vehicle production reaching 12,28,735 units, 35,09,072 units, and 1,00,60,339 units, respectively. In the South American region, Colombia saw the greatest rise in Y-o-Y production, reaching 51,455 units, an increase of 26%. Argentina also saw a massive 24% increase, with production reaching 5,36,893 units.

- Moreover, in 2022, US auto manufacturing companies announced a USD 13 billion investment in domestic EV manufacturing, more than triple the investment in 2020. Toyota announced a USD 2.5 billion investment in the Carolina manufacturing facility. Honda and LG Energy Solution announced a USD 4.4 billion joint venture for investments in EV and battery manufacturing. These factors are expected to ascend vehicle production, thereby benefiting the thermoplastic composites market.

- In Europe, Germany is among the key manufacturer of vehicles. According to the German Association of the Automotive Industry (VDA), Germany produced 441,990 units of vehicles in March 2023, a growth of 67% compared to the number of vehicles produced in the month of March in the previous year.

- Thus, considering the growth trends and production of automobiles in different regions worldwide, the automotive industry is likely to dominate the market, which, in turn, is expected to enhance the demand for thermoplastic composites during the forecast period.

China to Dominate the Asia-Pacific Region

- China is the largest manufacturer and consumer of thermoplastic composites in the Asia-Pacific region, followed by India and Japan.

- The use of thermoplastic composites in the automotive sector in the country is in high demand, owing to the advantage of producing a wide range of products that fit the industry's needs with precise quality. China is the world's biggest automobile market in terms of both production and sales. China's automotive market experienced positive growth in 2022 despite the impact of several negative factors, including the occurrence of the COVID-19 pandemic, a structural chip shortage, and local geopolitical conflicts.

- According to the China Association of Automobile Manufacturers (CAAM), China has the largest automotive production base in the world, with a total vehicle production of 27 million units in 2022, registering an increase of 3.4% compared to 26 million units produced in the previous year.

- According to official data, China's electronics sector recorded stable growth in 2022, supporting solid growth in terms of production and investment. According to the Ministry of Industry and Information Technology, the value added of major enterprises in the sector increased by 7.6% over the same period in 2021, exceeding the value added of all industries by 4%. Thus, a significant boost in demand for electronic goods supports the demand for thermoplastic composites from the industry.

- According to the International Trade Organization, China is the world's largest construction market and has the highest rate of urbanization globally. According to data from the American Institute of Architects (AIA) Shanghai, by 2025, China is anticipated to build a city equivalent to 10 New York City's worth of city space since the 1990s.

- The Chinese government is taking steps to tighten the economy. China's 14th Five-Year Plan includes a government-led effort to apply digital technology to the building and construction process. Furthermore, the construction industry is expected to account for 6% of the country's GDP by 2025. China's construction sector plays an increasingly important role in stimulating the economy and stabilizing employment.

- According to aerospace company Airbus' press release in April 2023, over the next 20 years, China's air traffic is projected to grow at an annual rate of 5.3%, well above the global average of 3.6%. This would require 8,420 passengers and freighters by 2041, or more than 20% of the world's need for new aircraft over the next 20 years, around 39,500.

- Hence, due to the reasons mentioned above, China is likely to drive the market's growth in the Asia-Pacific region during the forecast period.

Thermoplastic Composites Industry Overview

The global thermoplastic composites market is partially fragmented in nature, with several companies operating on both global and regional levels. Some of the major companies in the market include LANXESS, Solvay, BASF SE, Toray Industries Inc., and Arkema SA, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Increasing Demand from the Automotive Industry

- 4.1.2 Rising Consumption in the Construction Industry

- 4.2 Restraints

- 4.2.1 High Cost of Raw Materials and Challenges to Form Thermoplastic Composites

- 4.2.2 Other Restraints

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Volume)

- 5.1 Resin Type

- 5.1.1 Polypropylene (PP)

- 5.1.2 Polyamide (PA)

- 5.1.3 Polyetheretherketone (PEEK)

- 5.1.4 Other Resin Types

- 5.2 Fiber Type

- 5.2.1 Glass Fiber

- 5.2.2 Carbon Fiber

- 5.2.3 Other Fiber Types

- 5.3 Product Type

- 5.3.1 Short Fiber Thermoplastic (SFT)

- 5.3.2 Long Fiber Thermoplastic (LFT)

- 5.3.3 Continuous Fiber Thermoplastic (CFT)

- 5.3.4 Glass Mat Thermoplastic (GMT)

- 5.4 End-user Industry

- 5.4.1 Aerospace and Defense

- 5.4.2 Electrical and Electronics

- 5.4.3 Automotive

- 5.4.4 Construction

- 5.4.5 Medical

- 5.4.6 Other End-user Industries

- 5.5 Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 ASEAN Countries

- 5.5.1.6 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 South Africa

- 5.5.5.3 Rest of Middle East and Africa

- 5.5.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share (%) **/Rank Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Arkema SA

- 6.4.2 AVANCO Group

- 6.4.3 Avient Corporation

- 6.4.4 BASF SE

- 6.4.5 Celanese Corporation

- 6.4.6 Daicel Corporation

- 6.4.7 DSM

- 6.4.8 Hexcel Corporation

- 6.4.9 LANXESS

- 6.4.10 LyondellBasell Industries Holdings BV

- 6.4.11 Mitsubishi Chemical Group Corporation

- 6.4.12 SABIC

- 6.4.13 SGL Carbon

- 6.4.14 Solvay

- 6.4.15 TechnoCompound GmbH

- 6.4.16 Toray Industries Inc.

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Wide Application Scope in the Healthcare Sector

- 7.2 Rising Demand from the Aerospace and Defense Industry