|

市场调查报告书

商品编码

1687786

高压压铸:市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)High-Pressure Die Casting - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

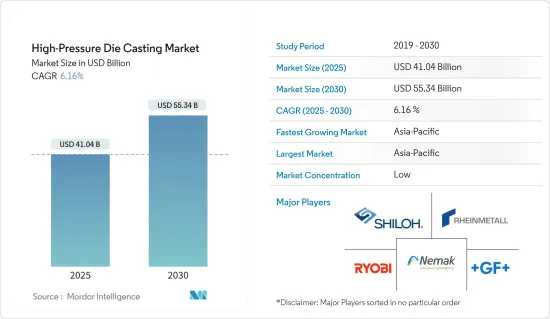

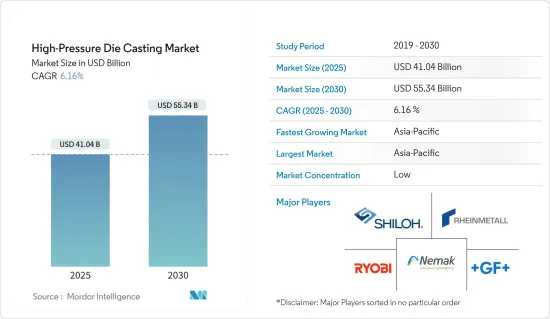

高压压铸市场规模预计在 2025 年为 410.4 亿美元,预计到 2030 年将达到 553.4 亿美元,预测期内(2025-2030 年)的复合年增长率为 6.16%。

全球向电动车的转变和严格的燃油效率标准正在增加对轻质耐用汽车零件的需求,从而推动高压压铸 (HPDC) 市场的发展。随着汽车製造商寻求延长车辆行驶里程并减少排放气体,HPDC 因其能够生产具有高尺寸精度和出色表面光洁度的复杂形状而受到青睐,使其成为生产轻质、结构合理的零件的理想选择。

汽车产业正在向电气化转型,这进一步加剧了这些需求,需要开发能够满足电动动力传动系统独特需求的零件,例如电池框架和马达外壳。因此,HPDC 市场正在经历显着成长,製造商正在投资新技术并扩大生产能力以满足不断变化的需求。

高压压铸产业正经历技术投资和产能扩张的显着趋势,这得益于对轻量化和结构高效零件的需求不断增长,尤其是电动车。随着汽车产业向电气化转变,HPDC 市场的公司正专注于提高零件性能和重量效率的创新。此举体现了整个产业对永续性和燃油效率的更广泛追求。例如

主要亮点

- 2024年4月,现代汽车宣布投资超级铸造技术。超级铸造技术可以一次生产整个车身,大大提高了製造效率并减少了材料浪费。

- 2024 年 4 月,本田宣布利用高压压铸机开发智慧动力单元 (IPU) 外壳,作为其俄亥俄电动车轮毂的一部分。这项发展展示了 HPDC 技术在生产更轻、结构更坚固的关键车辆零件方面的整合。

高压压铸市场趋势

预计在预测期内,汽车产业将继续成为关注的焦点

汽车产业是高压压铸 (HPDC) 市场的主要细分市场,主要受铝使用量激增和电动车产量激增的推动。向轻量化材料的转变是汽车产业的关键驱动力,主要是为了满足日益严格的燃油经济性和排放法规。

- 目前每辆汽车的平均铝含量约为 450 磅,预计到 2030 年将增加至 550 磅。这反映了近 22% 的成长,并标誌着该行业继续转向更轻、更省油的汽车。

这一趋势在电动车生产中尤其明显,电动车使用的铝比传统内燃机汽车更多。铝在汽车中的使用量不断增加,这与汽车行业对 HPDC 的需求相一致,HPDC 能够高效、永续生产复杂、精加工的零件。此外,电动车产量的激增进一步凸显了HPDC在汽车产业的重要性。

- 根据国际能源总署 (IEA) 的数据,电动车销量预计将从 2023 年的 1,400 万辆大幅增长至 2030 年的近 4,500 万辆,到 2035 年将达到 6,500 万辆。这一增长将反映在销售份额上,预计将从 2023 年的 15% 增长至 2030 年的约 40%,并于 2035 年超过 50%(既定政策情境)。

电动车产量的增加将需要更多的 HPDC 组件。特别是,需要轻质结构部件来适应电池增加的重量,同时又不影响车辆性能。

预计亚太地区将在预测期内实现最高成长

预计亚太地区将主导全球高压压铸市场并在预测期内呈现最快的成长率。在亚太地区,中国、印度和日本等国家可能会在市场上发挥关键作用。

- 例如,中国是压铸件的主要生产国之一,占据了区域压铸市场占有率的大部分份额。中国金属铸造业有3万多家企业,其中生产有色金属铸件的约8,000多家。中国铸件产量超过5500万吨。

省油车的日益普及和压铸技术的最新进步预计将进一步促进市场的发展。这些优势使得该地区的汽车製造商签订了长期合同,以持续供应原材料和扩大工厂。

为了生产符合消费者偏好和国际标准的产品,铸造厂越来越注重提高技术创新,为市场参与者提供新的机会。铸造公司注重技术品质和品牌导向,这是亚太地区压铸市场的关键市场驱动力。这些发展和案例可能有助于亚太国家市场的整体发展。

高压压铸产业概况

高压压铸市场高度分散,全球有许多地区和国际参与者。近年来,许多来自新兴国家的中小型企业进入市场并扩大业务,加剧了市场竞争。市场上一些公认的参与者包括 Nemak、Georg Fischer Automotive、Ryobi Die Casting、Rheinmetall AG、Form Technologies Inc. (Dynacast) 和 Shiloh Industries。其他主要企业包括科赫企业、利纳马集团和 Bocar 集团。

HPDC 市场的主要企业正在积极致力于技术进步、提高业务效率和策略扩张,以增强其产品供应并在不断发展的汽车市场(尤其是向电动车的转变)中占据一席之地。这些策略倡议旨在满足传统汽车和电动车对高品质精密零件日益增长的需求,从而占据更大的市场占有率。

- 例如, Ryobi Die Casting 于 2024 年 5 月宣布将斥资 5,000 万美元扩建其位于墨西哥的工厂,以提高产能,以满足未来对电动车的需求。此次扩张包括增加新的更大型的 HPDC 机器,并凸显了Ryobi根据市场趋势扩大业务的策略性倡议。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 调查前提条件

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 市场驱动因素

- 由于压铸设备中铝的使用增加,市场需求增加

- 家电成长

- 电动车销量上升导致汽车产业需求增加

- 市场限制

- 初期成本高

- 原物料价格波动

- 产业吸引力-波特五力分析

- 新进入者的威胁

- 购买者/消费者的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争强度

第五章 市场区隔

- 原料类型

- 铝

- 锌

- 镁

- 应用

- 车

- 电气和电子

- 工业应用

- 其他用途

- 生产流程

- 真空高压铸

- 挤压高压铸

- 地区

- 北美洲

- 美国

- 加拿大

- 北美其他地区

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 其他欧洲国家

- 亚太地区

- 印度

- 中国

- 日本

- 韩国

- 其他亚太地区

- 世界其他地区

- 南美洲

- 中东和非洲

- 北美洲

第六章 竞争格局

- 供应商市场占有率

- 公司简介

- Georg Fischer AG

- Shiloh Industries Ltd

- Ryobi Die Casting Inc.

- Nemak SAB De CV

- Rheinmetall AG(Rheinmetall Automotive, formerly KSPG AG)

- Sundaram-Clayton Ltd

- Koch Enterprises Inc.(Gibbs Die Casting Group)

- Engtek Group

- Officine Meccaniche Rezzatesi SpA

- Endurance Group

- Rockman Industries

- Dynacast(Form Technologies Inc.)

第七章 市场机会与未来趋势

The High-Pressure Die Casting Market size is estimated at USD 41.04 billion in 2025, and is expected to reach USD 55.34 billion by 2030, at a CAGR of 6.16% during the forecast period (2025-2030).

Increasing demand for lightweight yet durable automotive components, driven by a global shift toward electric vehicles and more stringent fuel efficiency standards, is driving the high-pressure die casting (HPDC) market. As automotive manufacturers aim to extend the range and reduce the emissions of their vehicles, HPDC is favored for its ability to produce complex shapes with high dimensional accuracy and excellent surface finish, making it ideal for creating components that are both lightweight and structurally robust.

This need is further amplified by the automotive industry's ongoing transition to electrification, which necessitates the development of components that can withstand the unique demands of electric powertrains, such as battery frames and motor housings. As a result, the HPDC market is experiencing substantial growth, with manufacturers investing in new technologies and expanding capacity to meet these evolving requirements.

The high-pressure die-casting industry is experiencing a key trend with increased investments in technology and capacity expansion, driven by the growing demand for lightweight and structurally efficient components, especially in electric vehicles. As the automotive industry shifts toward electrification, companies within the HPDC market are focusing on innovations that enhance the performance and weight efficiency of their components. This trend is reflective of a broader industry movement toward sustainability and increased fuel efficiency. For instance,

Key Highlights

- In April 2024, Hyundai Motor announced an investment in hypercasting technology, which allows for the production of entire car bodies in a single process, significantly enhancing manufacturing efficiency and reducing material wastage.

- In April 2024, Honda announced developments in the Intelligent Power Unit (IPU) case, utilizing high-pressure die-casting machines as part of its EV hub in Ohio. This development showcased the integration of HPDC technology in manufacturing critical vehicle components that are lighter and structurally sound.

High-Pressure Die Casting Market Trends

Automotive Segment Expected to Gain Prominence During the Forecast Period

The automotive industry is the predominant segment within the high-pressure die casting (HPDC) market, primarily driven by the surge in aluminum usage and the escalating production of EVs. The shift toward lightweight materials is a critical driver in the automotive industry, primarily due to the need to meet stricter fuel economy and emissions standards.

- The aluminum content in vehicles, which currently averages about 450 pounds per vehicle, is projected to increase to 550 pounds per vehicle by 2030. This reflects a nearly 22% rise, underscoring the industry's ongoing shift toward lighter and more fuel-efficient vehicles.

This trend is particularly pronounced in the production of electric vehicles, which are more aluminum-intensive than traditional combustion engine vehicles. The increased aluminum usage in vehicles aligns with the automotive industry's needs for HPDC as it allows for the efficient and sustainable production of complex, high-integrity parts. Furthermore, the surge in EV production further underscores the importance of HPDC in the automotive industry.

- According to the International Energy Agency (IEA), EV sales are projected to rise significantly from 14 million units in 2023 to nearly 45 million by 2030 and continue to rise to reach 65 million by 2035. This growth is mirrored in the sales share, which is expected to jump from 15% in 2023 to about 40% by 2030 and over 50% by 2035 in the Stated Policies Scenario.

This increase in EV production necessitates more HPDC parts, particularly because of the need for lightweight structural components that accommodate the additional weight of batteries without compromising vehicle performance.

Asia-Pacific Expected to Witness the Highest Growth During the Forecast Period

The Asia-Pacific region is expected to dominate the global high-pressure die-casting market, and it is also expected to witness the fastest growth rate during the forecast period. In the Asia-Pacific region, countries like China, India, and Japan are likely to play a key role in the market.

- For instance, China is one of the major producers of die-casting parts and accounts for the majority of the regional die-casting market's share. The metal casting industry in China has more than 30,000 facilities, of which around 8,000 facilities produce non-ferrous castings. China produces over 55.0 million metric tons of castings.

The increasing popularity of fuel-efficient vehicles and the latest advancements in die-casting techniques are expected to further contribute to the market's development. Thus, due to such benefits, automakers in the region are entering long-term deals for uninterrupted supply of raw materials, expansion of plants, etc.

The growing focus of foundries on improving innovation to produce products that meet consumer preferences and international standards offers new opportunities for players in the market. Foundries are focusing on technical quality and brand orientation, which are considered major growth drivers for the Asia-Pacific high-pressure die-casting market. Such developments and instances are likely to contribute to the overall development of the market across Asia-Pacific countries.

High-Pressure Die Casting Industry Overview

The high-pressure die-casting market is highly fragmented, with the presence of many regional and international players worldwide. Competition in the market has increased, as many small- and medium-scale players from developing countries have entered and expanded their business in the market over recent years. Some of the recognized players in the market are Nemak, Georg Fischer Automotive, Ryobi Die Casting, Rheinmetall AG, Form Technologies Inc. (Dynacast), and Shiloh Industries. Some other notable players include Koch Enterprise, Linamar Corporation, and Bocar Group.

Major players in the HPDC market are actively engaging in technological advancements, operational efficiency improvements, and strategic expansions to enhance their product offerings and better position themselves in the evolving automotive market, especially with the shift toward electric vehicles. These strategic moves are aimed at capturing a larger share of the market by meeting the increasing demands for high-quality, precision components in both conventional and electric vehicles.

- For instance, in May 2024, Ryobi Die Casting announced a USD 50 million expansion of its plant in Mexico to increase production capacity in anticipation of future EV demands. This expansion included the addition of new large HPDC machines, underscoring Ryobi's strategic initiative to scale operations in line with market trends.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Drivers

- 4.1.1 Growing Use of Aluminum in Die Casting Equipment to Increase Market Demand

- 4.1.2 Growth in Consumer Electronics

- 4.1.3 Automotive Industry Demand Rising Because of Increasing EV Sales

- 4.2 Market Restraints

- 4.2.1 High Initial Costs

- 4.2.2 Fluctuations in Raw Material Prices

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Threat of New Entrants

- 4.3.2 Bargaining Power of Buyers/Consumers

- 4.3.3 Bargaining Power of Suppliers

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

5 MARKET SEGMENTATION (Market Size in Value - USD Million)

- 5.1 Raw Material Type

- 5.1.1 Aluminum

- 5.1.2 Zinc

- 5.1.3 Magnesium

- 5.2 Application

- 5.2.1 Automotive

- 5.2.2 Electrical and Electronics

- 5.2.3 Industrial Applications

- 5.2.4 Other Applications

- 5.3 Production Process

- 5.3.1 Vacuum High-pressure Die Casting

- 5.3.2 Squeeze High-pressure Die Casting

- 5.4 Geography

- 5.4.1 North America

- 5.4.1.1 United States

- 5.4.1.2 Canada

- 5.4.1.3 Rest of North America

- 5.4.2 Europe

- 5.4.2.1 Germany

- 5.4.2.2 United Kingdom

- 5.4.2.3 France

- 5.4.2.4 Italy

- 5.4.2.5 Rest of Europe

- 5.4.3 Asia-Pacific

- 5.4.3.1 India

- 5.4.3.2 China

- 5.4.3.3 Japan

- 5.4.3.4 South Korea

- 5.4.3.5 Rest of Asia-Pacific

- 5.4.4 Rest of the World

- 5.4.4.1 South America

- 5.4.4.2 Middle East and Africa

- 5.4.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Vendor Market Share

- 6.2 Company Profiles

- 6.2.1 Georg Fischer AG

- 6.2.2 Shiloh Industries Ltd

- 6.2.3 Ryobi Die Casting Inc.

- 6.2.4 Nemak SAB De CV

- 6.2.5 Rheinmetall AG (Rheinmetall Automotive, formerly KSPG AG)

- 6.2.6 Sundaram - Clayton Ltd

- 6.2.7 Koch Enterprises Inc. (Gibbs Die Casting Group)

- 6.2.8 Engtek Group

- 6.2.9 Officine Meccaniche Rezzatesi SpA

- 6.2.10 Endurance Group

- 6.2.11 Rockman Industries

- 6.2.12 Dynacast (Form Technologies Inc.)