|

市场调查报告书

商品编码

1689904

锌化合物:市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Zinc Chemicals - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

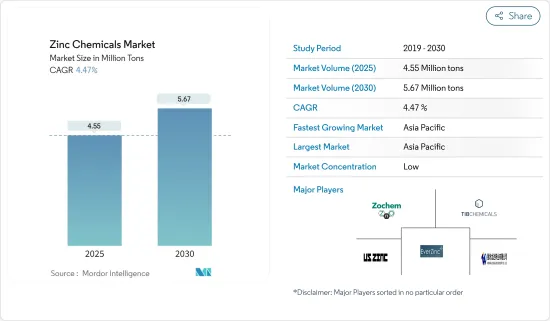

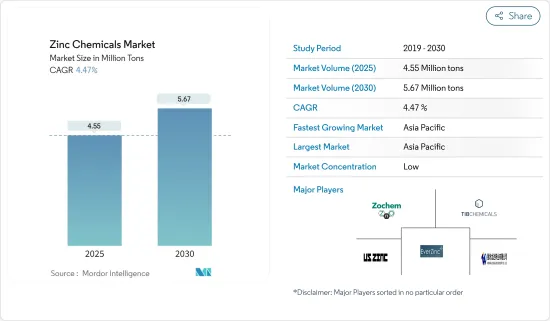

预计 2025 年锌化合物市场规模为 455 万吨,到 2030 年将达到 567 万吨,预测期间(2025-2030 年)的复合年增长率为 4.47%。

COVID-19 疫情对建筑、石化和其他行业产生了短期和长期影响,衝击了全球锌化合物市场。但现在市场已恢復到疫情前的水准。

主要亮点

- 短期内,汽车行业利用率的提高和橡胶轮胎行业需求的增加预计将推动锌化合物市场的成长。

- 然而,与锌基化学品相关的健康危害等因素预计会阻碍市场成长。

- 预计未来几年用于癌症诊断、成像和治疗的锌奈米粒子领域的新兴研究和技术进步将为锌市场提供重大机会。

- 亚太地区占据市场主导地位,预计在预测期内将继续占据主导地位。

锌化合物市场趋势

橡胶加工领域占据市场主导地位

- 由于镀锌和轮胎製造中锌化合物的消耗量很大,橡胶加工领域占据了市场主导地位。

- 锌化学品广泛用于汽车常用的轮胎和内胎的製造。预计不断发展的汽车产业将很快增加对锌化合物的整体需求。

- 根据国际橡胶研究小组(IRSG)的数据,2023年上半年全球天然橡胶产量将达到约650万吨,较2000年的约680万吨大幅增加。

- 根据天然橡胶生产国协会(ANRPC)统计,2023年3月全球天然橡胶需求量达130.6万吨,较去年同期成长7.9%。

- 电动车的普及预计将推动汽车轮胎的需求,并促进汽车行业的轮胎消费,这反过来有望推动锌化合物市场的发展。

- 此外,可透过增加氧化锌的用量来改善热空气和热老化性能,而氧化锌浓度过低可能会造成焦烧问题。此外,它还能减少轮胎的热量累积和磨损,使其成为橡胶轮胎产业的重要组成部分。因此,随着轮胎工业的成长,氧化锌的消费量也同步增加。

- 中国、印度、日本、韩国、泰国等亚太国家为汽车主要生产国。因此,预计该市场在预测期内将实现成长。

亚太地区占市场主导地位

- 由于锌化学衍生物广泛应用于橡胶加工、化学加工和农业等各种领域,预计亚太地区将占据市场主导地位。

- 中国是化学加工中心,占全球化学品产量的大部分。由于政府的鼓励措施和庞大的消费群,中国化学製造业预计在预测期内将保持稳定的成长。预计化学产品产量的增加将在不久的将来为该国的市场创造成长机会。

- 印度有 40 家轮胎製造商和约 6,000 家非轮胎製造商,生产用于汽车、铁路、国防、航太和其他应用的密封件、传送带和挤压橡胶型材。

- 此外,印度拥有超过2500家装饰製造商和超过800家工业涂料製造商。涂料需求的增加促使企业增加产量和产能。受此影响,预计国内液体合成橡胶市场的需求将会成长,这可能会进一步推动未来几年对锌化合物的需求。

- 在中国和印度,由于农业化学品产业和经济的成长,对锌化合物的需求预计会增加。化肥价格低廉且易于取得是推动市场成长的主要因素。硫酸锌在化肥中用作肥料添加剂,刺激了锌化合物市场的发展。

- 根据国际橡胶研究组织(IRSG)的研究,亚洲和大洋洲占全球橡胶消费量的70%以上,其次是中国(40%)和日本(6%)。

- 日本是主要的轮胎生产中心,拥有世界上最大的橡胶工业之一。

- 此外,该国是继中国和美国之后的世界第三大橡胶消费量。日本最大的轮胎製造商如东曹株式会社、ZEON株式会社和东洋轮胎工业株式会社正在提高生产能力,预计在预测期内将为橡胶加工行业的锌化学品带来良好的市场环境。

- 因此,预计预测期内所有这些市场趋势都将推动该地区对锌化合物市场的需求。

锌化合物产业概况

锌化合物市场较为分散,没有任何单一企业能够占据较大的市场份额。该市场的主要企业(不分先后顺序)包括美国 Zinc、Zochem Inc.、EverZinc、TIB Chemicals AG 和潍坊龙达锌业。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 调查前提条件

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 驱动程式

- 在汽车产业的应用日益广泛

- 橡胶轮胎产业需求增加

- 限制因素

- 锌化学品带来的健康危害

- 价值链分析

- 波特五力分析

- 供应商的议价能力

- 买家的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章 市场区隔

- 类型

- 氧化锌

- 硫酸锌

- 碳酸锌

- 氯化锌

- 其他类型

- 最终用户产业

- 农业

- 化工和石化

- 陶瓷製品

- 药品

- 油漆和涂料

- 橡胶加工

- 其他最终用户产业

- 地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 马来西亚

- 泰国

- 印尼

- 越南

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 土耳其

- 俄罗斯

- 北欧国家

- 其他欧洲国家

- 南美洲

- 巴西

- 阿根廷

- 哥伦比亚

- 南美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 奈及利亚

- 卡达

- 埃及

- 阿拉伯聯合大公国

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争格局

- 併购、合资、合作、协议

- 市场占有率(%)**/排名分析

- 主要企业策略

- 公司简介

- American Chemet Corporation

- Changsha Lantian Chemical Co. Ltd

- EverZinc

- Flaurea Chemicals

- Global Chemical Co. Ltd

- Hakusui Tech

- Intermediate Chemicals Company

- L. Brugge-mann GmbH & Co. KG

- Nexa

- Old Bridge Chemicals Inc.

- Pan-Continental Chemical Co. Ltd

- Rech Chemical Co. Ltd

- Rubamin

- Seyang Zinc Technology(Huai An)Co. Ltd

- Silox India Pvt. Ltd

- TIB Chemicals AG

- US Zinc

- Weifang Longda Zinc Industry Co. Ltd

- Zochem LLC

第七章 市场机会与未来趋势

- 锌奈米粒子在医疗产业的应用研究与开发

- 扩大在电子和半导体产业的应用

The Zinc Chemicals Market size is estimated at 4.55 million tons in 2025, and is expected to reach 5.67 million tons by 2030, at a CAGR of 4.47% during the forecast period (2025-2030).

The outbreak of COVID-19 brought several short-term and long-term consequences in the construction, petrochemical, and other industries, which affected the zinc chemicals market across the world. However, presently, the market has returned to the pre-pandemic level.

Key Highlights

- Over the short term, the rising utilization in the automotive industry and increasing demand from the rubber tire industry are likely to drive the growth of the zinc chemicals market.

- On the flip side, factors such as health hazards related to zinc-based chemicals are expected to hinder the growth of the market.

- The emerging research and technological advancements in the field of zinc nanoparticles employed for diagnosis, imaging, and treatment of cancer are expected to offer great opportunities for the zinc market over the upcoming years.

- Asia-Pacific has dominated the market and is expected to continue dominating it during the forecast period.

Zinc Chemicals Market Trends

The Rubber Processing Segment to Dominate the Market

- The rubber processing segment is the dominating segment due to the large-scale consumption of zinc chemicals in galvanizing and manufacturing tires.

- Zinc chemicals are widely used in manufacturing tires and tubes commonly used in automobiles. The growing automobile industry is expected to augment the overall demand for zinc chemicals shortly.

- According to the International Rubber Study Group (IRSG), the global output of natural rubber reached nearly 6.5 million metric tons during the first six months of 2023, a significant rise compared to 2000, when it stood at approximately 6.8 million metric tons.

- As per the Association of Natural Rubber Producing Countries (ANRPC), in March 2023, worldwide demand for natural rubber increased by 7.9% to 1.306 million tons over the same timeframe.

- The growing popularity of electric vehicles is expected to drive the demand for automotive tires, thereby propelling the consumption of tires in the automotive industry, which, in turn, drives the zinc chemical market.

- Also, higher loadings of zinc oxide can improve hot air/heat aging properties, and too low a concentration of zinc oxide can lead to scorching problems. Furthermore, it reduces heat buildup and wear in tires, thus making it an important segment in the rubber tire industry. Thus, with the growth in the tire industry, the consumption of zinc oxide is also increasing concurrently.

- Asia-Pacific countries like China, India, Japan, South Korea, and Thailand are the primary producers of automobiles. Hence, the market studied is expected to register growth during the forecast period.

Asia-Pacific to Dominate the Market

- Asia-Pacific stands to be the dominant region in the market studied owing to the extensive application of zinc chemical derivatives in various applications, including rubber processing, chemical processing, and agriculture.

- China is a hub for chemical processing, accounting for most chemicals produced worldwide. Owing to the encouraging government initiatives and a vast consumer base, the chemical manufacturing sector in China is expected to increase at a consistent rate during the forecast period. The increasing production of chemicals is expected to create an opportunity for the growth of the market in the country in the near future.

- In India, 40 tire manufacturers and around 6,000 non-tire manufacturers produce seals, conveyor belts, and extruded and molded rubber profiles for automotive, railway, defense, aerospace, and other applications.

- Furthermore, India is home to over 2,500 decorative and 800 industrial coating manufacturers. This increasing demand for coatings has prompted the companies to increase their production and production capacities. This is expected to drive the demand for the liquid synthetic rubber market in the country, which may further boost the demand for zinc chemicals in the coming years.

- In China and India, the demand for zinc chemicals is expected to increase due to the growing agrochemical industry and economy. The low cost and easy availability of chemical fertilizers act as key factors in the growth of the market. Zinc sulfate is used as a fertilizer additive in chemical fertilizers, stimulating the zinc chemicals market.

- According to the IRSG (International Rubber Study Group) research, Asia and Oceania account for more than 70% of the world's rubber consumption, with China and Japan accounting for 40% and 6%, respectively.

- Japan possesses one of the world's largest rubber industries, as it is a major hub for tire production.

- Furthermore, the country is ranked third globally, only behind China and the United States, in terms of the total amount of rubber consumed. The largest producers of tires in Japan, like Tosoh Corporation, Zeon Corp., and Toyo Tire & Rubber Co. Ltd, are undergoing capacity additions, which is expected to present an exciting market arena for zinc chemicals from the rubber processing industry over the forecast period.

- Hence, all such market trends are expected to drive the demand for the zinc chemicals market in the region during the forecast period.

Zinc Chemicals Industry Overview

The zinc chemicals market is fragmented, with no player capturing a significant share. Some of the key companies in the market (not in any particular order) include US Zinc, Zochem Inc., EverZinc, TIB Chemicals AG, and Weifang Longda Zinc Industry Co. Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Rising Utilization in Automotive Industry

- 4.1.2 Increasing Demand from the Rubber Tires Industry

- 4.2 Restraints

- 4.2.1 Health Hazard Related to Zinc Chemical

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size by Volume)

- 5.1 Type

- 5.1.1 Zinc Oxide

- 5.1.2 Zinc Sulfate

- 5.1.3 Zinc Carbonate

- 5.1.4 Zinc Chloride

- 5.1.5 Other Types

- 5.2 End-user Industry

- 5.2.1 Agriculture

- 5.2.2 Chemicals and Petrochemicals

- 5.2.3 Ceramic

- 5.2.4 Pharmaceutical

- 5.2.5 Paints and Coatings

- 5.2.6 Rubber Processing

- 5.2.7 Other End-user Industries

- 5.3 Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Malaysia

- 5.3.1.6 Thailand

- 5.3.1.7 Indonesia

- 5.3.1.8 Vietnam

- 5.3.1.9 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Spain

- 5.3.3.6 Turkey

- 5.3.3.7 Russia

- 5.3.3.8 NORDIC Countries

- 5.3.3.9 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Colombia

- 5.3.4.4 Rest of South America

- 5.3.5 Middle East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 Nigeria

- 5.3.5.3 Qatar

- 5.3.5.4 Egypt

- 5.3.5.5 United Arab Emirates

- 5.3.5.6 South Africa

- 5.3.5.7 Rest of Middle East and Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share (%)**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 American Chemet Corporation

- 6.4.2 Changsha Lantian Chemical Co. Ltd

- 6.4.3 EverZinc

- 6.4.4 Flaurea Chemicals

- 6.4.5 Global Chemical Co. Ltd

- 6.4.6 Hakusui Tech

- 6.4.7 Intermediate Chemicals Company

- 6.4.8 L. Brugge-mann GmbH & Co. KG

- 6.4.9 Nexa

- 6.4.10 Old Bridge Chemicals Inc.

- 6.4.11 Pan-Continental Chemical Co. Ltd

- 6.4.12 Rech Chemical Co. Ltd

- 6.4.13 Rubamin

- 6.4.14 Seyang Zinc Technology (Huai An) Co. Ltd

- 6.4.15 Silox India Pvt. Ltd

- 6.4.16 TIB Chemicals AG

- 6.4.17 US Zinc

- 6.4.18 Weifang Longda Zinc Industry Co. Ltd

- 6.4.19 Zochem LLC

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 R&D in Application of Zinc Nanoparticle in Medical Industry

- 7.2 Growing Use in Electronics and Semiconductor Industry