|

市场调查报告书

商品编码

1690081

熔模铸造:市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Investment Casting - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

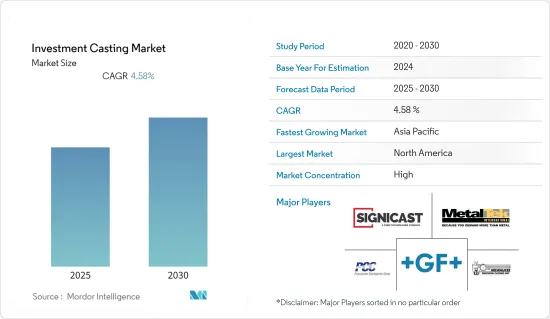

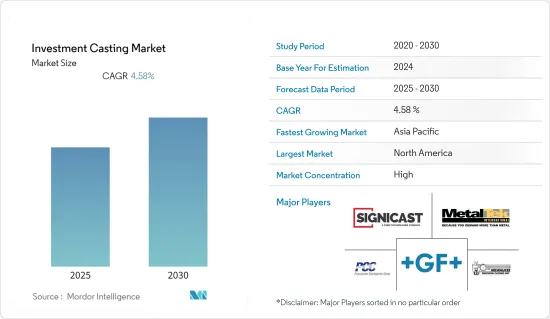

预测期内,熔模铸造市场预计将以 4.58% 的复合年增长率成长。

新冠肺炎疫情为全球多个产业带来了迅速且严重的影响。疫情导致全球需求下降,给该行业带来了巨大压力。随着需求下降,企业正在考虑疫情后的策略和产业计画。随着经济缓慢復苏,预计预测期内熔模铸造市场将出现正成长。

对熔模铸件的需求主要受到航太和国防工业的不断发展的推动。透过熔模铸造可以生产出飞机、直升机和喷射机等多种不同的应用和零件。透过熔模铸造生产的飞机、直升机和喷射机零件包括飞行关键、安全、着陆、煞车和液压油系统零件。

有几个因素阻碍了熔模铸造的需求,包括高生产成本和高能耗。然而,铸造厂正在寻求透过合作利用模拟技术创新先进的铸造技术来克服这些挑战,这可能会减少现场劳动时间并提高铸造产量比率。

北美目前引领熔模铸造市场。该地区的成长得益于製造业、医疗保健、航太和军事领域的扩张。预计亚太地区将成为预测期内成长最快的地区。中国很可能引领该地区,因为它是对熔模铸造行业成长做出重大贡献的关键国家之一。

熔模铸造市场趋势

硅酸钠製程成长率最高

硅溶胶铸造提高了熔模铸件的尺寸精度和表面光洁度,最大限度地减少了缺陷。因此此製程的成本较水玻璃铸造较高。硅溶胶锆锆砂价格昂贵,所需製备工艺较高,是其成本高的主要原因。

由于成本高,硅溶胶製程在铸造厂的应用相对较少。用于汽车和工业零件的硅溶胶熔模铸造的成本平均约为6.5美元/公斤。

目前,一些公司发现水玻璃铸造比陶瓷铸造更经济。然而,当最高的铸造品质和低修復率是最终用户关注的重点时,这种工艺是首选。与水玻璃製程相比,硅溶胶製程可生产重量达50-100公斤的大型零件。因此,此製程用于製造更大更重的零件,如水泵、叶轮、导流壳、泵体、球阀体和阀板。同时此製程也广泛应用于製造对尺寸精度要求高的超小型零件(2-1000g)。

硅酸钠製程在亚太地区逐渐流行起来,其中日本占据生产需求的前列。这是不断努力提高所生产零件的品质和尺寸精度的结果。

北美引领熔模铸造市场

北美引领熔模铸造市场,并可能保持其领先地位,其次是亚太地区和欧洲。成长要素主要得益于工业气体、航太和国防製造业的扩张,以及该地区重要国防飞机和零件製造商的存在,包括洛克希德马丁、雷神索尔和诺斯罗普格鲁曼。

航太工业是美国的主要产业之一,该地区是波音 737、波音 777、波音 787 和空中巴士 A220 等主要飞机项目的生产工厂所在地。在该国,F-35 等军用飞机项目的生产预计将产生对熔模铸造零件的需求。

美国是世界领先的汽车製造国,贡献了该国国内生产总值)的至少3%。中国也是豪华车市场最大的製造商之一,2021 年净收入达 50 亿美元。豪华车製造商宝马 2021 年销量累计历史新高,超过 336,600 辆。

然而,美国汽车业受到新冠疫情的严重打击,大多数製造工厂要么关闭,要么降低产能。 2022年4月美国新车销量为1,256,224辆,较2021年4月下降18%。此外,4月乘用车销量下降23.3%至278,827辆,SUV和卡车销量也下降16.3%至977,397辆。 2022年第一季对美国汽车业不利。汽车产业的扩张可能会引发汽车零件中熔模铸造应用的广泛利用,从而在长期内推动对熔模铸造的需求。

此外,根据加拿大航太工业协会的数据,空中巴士、波音、德哈维兰加拿大公司和庞巴迪是加拿大主要的航太製造商,其中 95% 的公司都以部分产能运作。德哈维兰加拿大公司计划分阶段开始生产该飞机。预计领先的航太公司将扩大其业务潜力,以推动该地区对熔模铸造的需求。例如,2022年11月,飞机引擎製造商普惠公司宣布将在美国开设一个新的涡轮翼型工厂。该工厂将容纳一座先进的铸造厂,总投资额为 6.5 亿美元。

此外,主要铸件製造商正在扩大其销售网络以满足不断增长的需求并扩大北美熔模铸造的范围。例如,2022 年 9 月,铸造技术公司 SigniCast Corporation 宣布开设一座最先进的熔模铸造工厂。

考虑到这些因素和不断发展的需求,熔模铸造由于其广泛的应用,预计在北美将具有较高的成长潜力。

熔模铸造产业概况

由于国际和地区熔模铸造製造商的存在,熔模铸造市场呈现分散状态。熔模铸造市场由美国铝业公司、蒂森克虏伯股份公司、Zollern GmbH and Co. KG、乔治费歇尔有限公司、Signicast、密尔瓦基精密铸造公司和 RLM Industries 组成。

市场分散,导致企业透过投资、合作、合资和收购来保持竞争力。例如,2021年10月,美国铝业公司宣布计画在2050年在其全球业务中实现温室气体(GHG)净零排放。 排放排放的目标与公司的永续战略重点相一致,并补充了其现有的目标,即到排放年将其铝冶炼和氧化铝精製业务的直接和间接温室气体排放减少30%,到2030年减少50%。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 调查前提条件

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 市场驱动因素

- 市场限制

- 波特五力分析

- 新进入者的威胁

- 购买者和消费者的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争强度

第五章 市场区隔

- 按类型

- 硅酸钠工艺

- 四乙硅酸酯/硅溶胶工艺

- 按最终用户

- 车

- 航太和军事

- 一般工业机械

- 医疗

- 其他最终用户

- 按地区

- 北美洲

- 美国

- 加拿大

- 北美其他地区

- 欧洲

- 德国

- 英国

- 法国

- 西班牙

- 其他欧洲国家

- 亚太地区

- 印度

- 中国

- 日本

- 韩国

- 其他亚太地区

- 世界其他地区

- 巴西

- 阿根廷

- 墨西哥

- 阿拉伯聯合大公国

- 其他国家

- 北美洲

第六章 竞争格局

- 供应商市场占有率

- 公司简介

- Signicast

- MetalTek International

- Milwaukee Precision Casting Inc.

- Impro Precision Industries Limited

- Alcoa Corporation

- Zollern GmbH and Co. KG

- Precision Castparts Corp(Berkshire Hathaway)

- Georg Fischer Ltd

- Dongying Giayoung Precision Metal

- Taizhou Xinyu Precision Manufacture Co. Ltd

第七章 市场机会与未来趋势

The Investment Casting Market is expected to register a CAGR of 4.58% during the forecast period.

The COVID-19 outbreak has had a swift and severe impact on many industries globally. The pandemic placed intense pressure on industries with a downward shift in global demand. With declining demand, the companies are examining their strategies and operational plans for the post-pandemic period. As economies are recovering slowly, the investment casting market is expected to grow positively during the forecast period.

The demand for investment casting is majorly driven by the growing aerospace and military industry, as there are many different applications and parts of aircraft, helicopters, and jets that are produced through investment casting. These include flight critical and safety components, landing and braking components, and hydraulic fluid system components, all of which are vital to the safety of the aircraft.

A few factors are hindering the demand for investment castings, such as manufacturing cost and high energy consumption. However, foundries are trying to overcome these challenges by collaborating to innovate advanced casting technologies using simulations, which is likely to reduce the shop-floor time and increase the casting yield.

North America is currently leading the investment casting market. The factors attributable to the region's growth are the expansion of the manufacturing, medical, and aerospace and military sectors. Asia-Pacific is projected to be the fastest-growing region over the forecast period. China is likely to lead the region as it is one of the significant countries that majorly contribute to the growth of the investment casting industry.

Investment Casting Market Trends

Sodium Silicate Process To Exhibit The Highest Growth Rate

Silica sol casting gives the investment castings better dimensional accuracy and surface finish with minimal defects. Hence, the cost of the process is higher than that of the water glass casting. Silica sol zircon sand is very expensive, and the preparation required is also higher, which is a prime reason for the higher costs.

Due to its higher costs, the silica sol process has comparatively less adoption in foundries. The silica sol investment casting used in automotive or industrial components costs around 6.5 USD/kg on average.

Several companies have now identifed the sodium silicate casting as the economical cause over the ceramic casting. However, this process is preferred if the highest casting quality and the low repair rate are the main focus of the end user. Compared to the water glass process, the silica sol process can produce extra-large parts weighing 50-100 kg. Hence, this process is used for producing larger and heavier parts, like water pumps, impellers, diversion shells, pump bodies, ball valve bodies, and valve plates. At the same time, this process is widely used to produce extra small parts (2-1000 g) that require high dimensional accuracy.

The sodium silicate process is slowly becoming more popular in regions like Asia-Pacific, where Japan has showcased itself to lead the production demand from forefront. As a result of the ongoing efforts to improve the quality and dimensional accuracy of the components produced.

North America Leads the Investment Casting Market

North America is leading the investment casting market and is likely to hold the top position, followed by Asia-Pacific and Europe. The factors attributable to North America's growth are the expanding manufacturing industry, primarily industrial gas and aerospace and defense applications, and the presence of significant defense aircraft and component manufacturers in the region, including Lockheed Martin, Raytheon, and Northrop Grumman.

Aerospace manufacturing is one of the major sectors in the United States, with production plants for major aircraft programs, like Boeing 737, Boeing 777, Boeing 787, and Airbus A220 located in the region. The manufacturing of military aircraft programs, like the F-35, in the country is expected to generate demand for investment casting parts.

The United States is one of the major automotive industries in the world, which contributes at least 3% to the overall gross domestic product (GDP) of the country. In addition, the country is one of the largest manufacturers of the luxury car market with net revenue of USD 5 billion in 2021. Luxury car maker BMW in 2021, reported record-breaking sales of over 336,600 units vehicles.

However, the automotive industry in the United States witnessed a hit due to the COVID-19 pandemic, as the majority of the production sites were either closed or operating at reduced capacity. In April 2022, United States new vehicles sales were reported 1,256, 224 units with a 18% decline compared to April 2021 figures. In addition, during April, passenger car sales dropped down to 23.3% with reporting 278,827 units, while SUV and truck sales also decreased 16.3% with 977,397 units. Q1 2022, has been less favorable for United States automotive sector. These expanding auto sector evoke high utilization of investment casting application for automotive parts and compnents will would likely to elevate the demand for investment casting during long term period.

Further, according to the Aerospace Industries Association of Canada, Airbus, Boeing, De Havilland Canada, and Bombardier Inc. are some of the major aerospace manufacturers in the countrywith 95% of companies running at partial capacity. De Havilland Canada plans to gradually begin the production of aircraft in phases. Key aersopace companies are seen expansing their business potential in order to elevate the demand for investment casting in the region. For instance, In November 2022, Aircraft engine manufacturer Pratt & Whitney announced the opening of their new turbine airfoil facility in United States. The fcility would be equipped with advance casting foundry with combined investment of USD 650 million.

Morover, key casting companies are also seeking oppotunities to expans their investment casting potnetial in North America to resonate elevated sales bars amid rising demand. For instance,In September 2022, Signicast Corporation which is form technology company announced the celebration of its new opening of latest investment casting facility.

Cosidering these factors and development demand for investment casting is anticipated to hold high potential for growth in North America owing to widely spread application.

Investment Casting Industry Overview

The investment casting market is fragmented due to the presence of international and regional investment casting manufacturers. The investment casting market is led by Alcoa Corporation, ThyssenKrupp AG, Zollern GmbH and Co. KG, Georg Fischer Ltd, Signicast, Milwaukee Precision Casting, and RLM Industries.

As the market is fragmented, companies are making investments, partnerships, joint ventures, acquisitions, etc., to stay ahead of the competition. For instance, In October 2021, Alcoa Corporation announced its plans to achieve net-zero greenhouse gas (GHG) emissions across its global operations by 2050. The aim to reach net-zero GHG emissions by 2050 for direct (scope 1) and indirect (scope 2) emissions aligns with the company's strategic priority to advance sustainably and complements its existing targets, which include reducing direct and indirect GHG emissions from aluminum smelting and alumina refining operations by 30% by 2025 and 50% by 2030.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Drivers

- 4.2 Market Restraints

- 4.3 Porter's Five Forces Analysis

- 4.3.1 Threat of New Entrants

- 4.3.2 Bargaining Power of Buyers/Consumers

- 4.3.3 Bargaining Power of Suppliers

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

5 MARKET SEGMENTATION (Market Size in Value USD Billion)

- 5.1 By Type

- 5.1.1 Sodium Silicate Process

- 5.1.2 Tetraethyl Orthosilicate/Silica Sol Process

- 5.2 By End-user Type

- 5.2.1 Automotive

- 5.2.2 Aerospace and Military

- 5.2.3 General Industrial Machinery

- 5.2.4 Medical

- 5.2.5 Other End-user Types

- 5.3 By Geography

- 5.3.1 North America

- 5.3.1.1 United States

- 5.3.1.2 Canada

- 5.3.1.3 Rest of North America

- 5.3.2 Europe

- 5.3.2.1 Germany

- 5.3.2.2 United Kingdom

- 5.3.2.3 France

- 5.3.2.4 Spain

- 5.3.2.5 Rest of Europe

- 5.3.3 Asia-Pacific

- 5.3.3.1 India

- 5.3.3.2 China

- 5.3.3.3 Japan

- 5.3.3.4 South Korea

- 5.3.3.5 Rest of Asia-Pacific

- 5.3.4 Rest of the World

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Mexico

- 5.3.4.4 United Arab Emirates

- 5.3.4.5 Other Countries

- 5.3.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Vendor Market Share

- 6.2 Company Profiles

- 6.2.1 Signicast

- 6.2.2 MetalTek International

- 6.2.3 Milwaukee Precision Casting Inc.

- 6.2.4 Impro Precision Industries Limited

- 6.2.5 Alcoa Corporation

- 6.2.6 Zollern GmbH and Co. KG

- 6.2.7 Precision Castparts Corp (Berkshire Hathaway)

- 6.2.8 Georg Fischer Ltd

- 6.2.9 Dongying Giayoung Precision Metal

- 6.2.10 Taizhou Xinyu Precision Manufacture Co. Ltd