|

市场调查报告书

商品编码

1690929

印度工业自动化:市场占有率分析、行业趋势和成长预测(2025-2030 年)India Industrial Automation - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

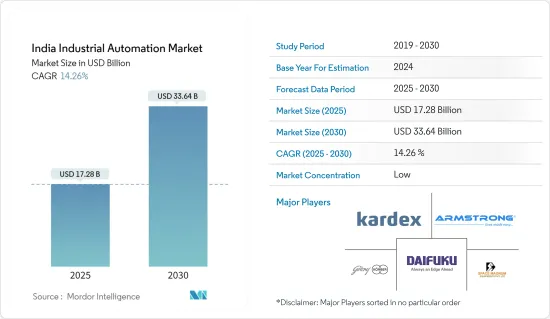

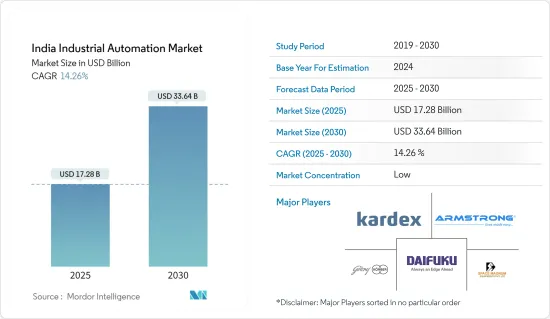

印度工业自动化市场规模预计在 2025 年为 172.8 亿美元,预计到 2030 年将达到 336.4 亿美元,预测期内(2025-2030 年)的复合年增长率为 14.26%。

工业自动化是指利用机器人、电脑、资讯科技和其他控制系统来取代人类处理产业中的多个流程和机器。从工业化范围来看,是机械化的第二阶段。

关键亮点

- 工业物联网和工业 4.0 是完整物流链演进、生产和管理的现代技术方法的核心,也称为智慧工厂自动化,是机器和设备透过网路连接的工业领域的主导趋势。

- 贴标设备是多个产业生产线的重要组成部分。除了基本结构外,它还具有自动标籤进纸器,可记录标籤长度并随着产品尺寸的变化而检索标籤。这些功能有利于减少停机时间、提高生产力并降低成本。

- 此外,随着印度製造业的成长,医疗保健产业对自动化设备的采用预计也会成长。私人医疗保健提供者的崛起、製药商的扩张以及全民医疗保健的引入等主要趋势预计将塑造未来的製药业。

- 智慧工厂自动化系统的实施和采购成本约占其总生命週期成本的一半。此外,网路和技术的频繁变化将大大增加初始投资以外的成本,进一步抑製印度工业自动化的采用。

- 新冠疫情和全球封锁规定严重影响了工业活动。封锁的影响包括劳动力短缺、供应链中断、製造过程中使用的原材料短缺、价格波动可能导致最终产品产量增加并导致预算超出、运输问题等。

印度工业自动化市场趋势

HMI推动成长

- 人机介面 (HMI) 是一种使用者介面或仪表板,其主要功能是将人与机器、系统或设备连接起来。 HMI 与可程式逻辑控制器 (PLC) 和输入/输出感测器通讯,以图形、图表和数位仪表板的形式检索和显示关键讯息,以及显示和管理警报,并连接到 SCADA、ERP 和 MES 系统,所有这些都来自单一主机。在工厂自动化范围内,促进与机器互动的关键组件是工业控制面板、工业用电脑和显示器、机器控制、触控萤幕、小键盘、开关和控制设备的软体。

- 在工业环境中,HMI 主要用于直观地显示资料、追踪生产时间、趋势、标籤、监控关键绩效指标 (KPI) 以及监控机器输入和输出。这些应用程式可提高生产力、降低硬体成本、简化管理任务并减少与工作相关的事故。

- HMI 对于与製造相关的行业非常有用,因为它们主要需要根据工厂的具体要求进行定製编程,并且可以监控、控制和保护机器和操作,无论是简单还是复杂的任务,都无需人工干预。

- HMI 技术正越来越多地被各行各业的组织所采用,包括能源、石油和天然气、运输、食品和饮料、电力、水和用水和污水、製造、回收和许多其他行业,其应用范围广泛,包括与设备互动和优化工业流程。

工厂自动化市场-汽车产业确认成长

- 汽车产业是世界自动化製造设施中占有重要地位的突出产业之一。据观察,各汽车製造商的生产设施都已自动化,以保持精度和效率。此外,电动车取代传统汽车的趋势日益增长,预计将进一步增加汽车产业的需求。

- 根据 IBEF 的汽车行业报告,随着印度中产阶级的不断壮大以及年轻人口的不断增加,两轮车在销售上占据了主导地位。此外,企业对开拓农村市场的兴趣日益浓厚,进一步推动了该领域的成长。物流和客运行业的成长正在推动商用车的需求。预计未来市场的成长将受到汽车电气化等新兴趋势的推动,尤其是小型车和三轮车。

- 此外,该公司正在使用自动化汽车组装来製造马达、变速箱、燃油系统和泵浦等零件。机器人技术和视觉技术非常适合建造符合人体工学且高效的产品线,可以快速完成组装,同时使人工远离危险环境。因此,安全也是印度汽车产业自动化背后的驱动力。

- 此外,印度是主要的汽车出口国,预计在预测期内出口将显着成长。此外,印度政府推出的多项倡议,如印度市场的报废措施、2026 年汽车使命计划以及与生产相关的奖励计划,可能会使印度成为两轮车和四轮车市场的强大参与企业。

印度工业自动化产业概况

印度工业自动化市场竞争激烈,有多家参与企业,包括 BHEL、ABB Limited、Grey Orange Pte Ltd、Kardex India Storage Solutions Pvt.Ltd、三菱电机等。为了增加市场占有率和可回收性,参与企业正在采用产品创新、合作、合併和收购来进一步推动市场发展。

- 2023 年 6 月 - Schaefer Systems International Pvt. Ltd 推出了 SSI 零件拣选应用程序,这是一个具有一系列创新功能的全自动零件拣选系统。这种高度通用的解决方案包括专用的智慧软体,并拥有先进的功能,例如使用人工智慧 (AI) 的物体识别、拾取和放置、取得专利的抓握点确定和极其温和的产品处理。

- 2023 年 6 月 - 三菱电机宣布,其全资子公司 ICONICS Corporation 已正式同意收购 ICONICS UK, Ltd. 的完全子公司,该公司销售 SCADA(监控和数据采集)*1 软体并开发相关的云端应用程式。三菱电机和 ICONICS 计划利用 ICONICS UK 的技术经营模式,以优化工厂设备和系统。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概览

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买家的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争

- 产业价值链分析

- COVID-19 工业影响评估

第五章市场动态

- 市场驱动因素

- 使用数位印刷技术生产的标籤的需求不断增加

- 医疗和化妆品领域的采用率很高

- 市场限制

- 缺乏能够承受恶劣天气条件的产品

第六章市场区隔

- 按解决方案类型

- 自动化物料输送解决方案

- 硬体

- 输送机/分类系统

- 自动储存和搜寻系统(AS/RS)

- 移动机器人(自动导引运输车和自主移动机器人)

- 自动识别资料撷取(AIDC)

- 软体 - 仓库管理系统 (WMS) / 仓库控制系统 (WCS)

- 工厂自动化解决方案

- 工业控制系统

- DCS

- SCADA

- PLC

- HMI

- 其他控制系统

- 现场设备

- 感应器和变送器

- 交流电交流变频器

- 伺服马达

- 电脑数值控制(CNC)机床

- 逆变器

- 工业机器人

- 其他工厂自动化解决方案

- 软体

- 製造执行系统(MES)

- 产品生命週期管理 (PLM)

- 其他的

- 自动化物料输送解决方案

- 按最终用户

- 自动化物料输送市场

- 製造业

- 非製造业

- 通用产品

- 医疗保健

- 快速消费品/非耐久财

- 其他的

- 工厂自动化市场

- 饮食

- 製药

- 车

- 纤维

- 力量

- 石油和天然气

- 石化产品和化肥

- 其他的

- 自动化物料输送市场

第七章 竞争基准化分析

- 竞争对手排名

- 市场排名分析:自动化物料输送

- 市场排名分析:工厂自动化解决方案

第八章竞争格局

- 物料输送公司简介

- Daifuku India Private Limited(Daifuku Co. Ltd)

- Space Magnum Equipment Pvt. Ltd

- Godrej Koerber Supply Chain Limited

- Kardex India Storage Solutions Private Limited(Kardex Holding AG)

- Armstrong Ltd

- Falcon Autotech Private Limited

- Grey Orange Pte Ltd

- Addverb Technologies Private Limited

- Hinditron Group

- The Hi-Tech Robotic Systemz Limited

- Bastian Solution Private Limited(Toyota Industries)

- ATS Conveyors India Pvt. Ltd(ATS Group)

- Kuka India Private Limited(Kuka AG)

- Schaefer Systems International Pvt. Ltd(SSI Schaefer AG)

- Rucha Yantra LLP

- 公司简介 - FA解决方案

- Bharat Heavy Electricals Limited(BHEL)

- ABB Ltd

- Yokogawa Electric Corporation

- Siemens AG

- Emerson Electric Co.

- Schneider Electric

- Honeywell International Inc.

- Rockwell Automation Inc.

- Mitsubishi Electric Corporation

- Danfoss A/S

- Fuji Electric Co. Ltd

- Larsen & Toubro Ltd

- Crompton Greaves Ltd

- Robert Bosch GmbH

- Bain & Company Inc

- Boston Consulting Group

第九章投资分析

第十章:投资分析市场的未来

The India Industrial Automation Market size is estimated at USD 17.28 billion in 2025, and is expected to reach USD 33.64 billion by 2030, at a CAGR of 14.26% during the forecast period (2025-2030).

Industrial automation refers to using control systems, like robots, computers, and information technologies, to handle several processes and machinery in an industry to replace human beings. It is the second step past mechanization in the scope of industrialization.

Key Highlights

- The Industrial Internet of Things and Industry 4.0 is at the center of the latest technological approaches for the evolution, production, and management of the complete logistics chain, also known as smart factory automation, and are dominating the trends in the industrial sector with machinery and devices being connected via the internet.

- Labeling equipment is a crucial component for production lines in several industries. In addition to the basic structure, the machines also feature an automatic label feeder to keep track of label length and retrieve it as the product changes size. These features are beneficial in reducing downtime, increasing productivity, and reducing costs.

- Moreover, The adoption of automated equipment in the healthcare industry is expected to grow, owing to the growing manufacturing sectors in India. Major trends, such as the growth of private healthcare providers, the expansion of drug manufacturing companies, and the rollout of universal healthcare, are expected to shape the pharmaceutical industry in the future.

- The installation and acquisition cost of an automation system for an intelligent factory represents approximately half of the total cost during its lifetime. Further, the frequent changes in networking and technology result in substantial cost increases, which is more than the initial investment, further restraining the adoption of industrial automation in India

- The COVID-19 outbreak and lockdown restrictions worldwide severely affected industrial activities. The effects of the lockdown include labor shortages, disruptions in the supply chain, lack of availability of raw materials utilized in the manufacturing process, fluctuating prices that could force the production of the final product to increase and go beyond budget, shipping problems, etc.

India Industrial Automation Market Trends

HMI to Witness the Growth

- A Human-Machine Interface (HMI) is a user interface or dashboard whose primary function includes connecting a person to a machine, system, or device. HMI functions by communicating with Programmable Logic Controllers (PLCs) and input/output sensors to fetch and display important information in the form of graphs, charts, or digital dashboards, along with other functions such as viewing and managing alarms, and connecting with SCADA, ERP, and MES systems, all through one console. In the factory automation scope, major components that facilitate interaction with that machine include industrial control panels, industrial PC and display, machinery controls, touchscreens, keypads, switches, and software for controlling equipment.

- In industrial settings, HMIs are primarily utilized for Visually displaying data, tracking production time, trends, and tags, overseeing key performance indicators (KPIs), and monitoring machine inputs and outputs. These applications boost production rates, minimize hardware costs, ease managerial tasks, and reduce work-related accidents.

- HMI is extremely useful for industries related to manufacturing as it primarily needs customized programming according to the plant's specific requirements, and it is ready to monitor, control, and safeguard machines and operations without the need for human intervention in either simple or complex jobs.

- The growing use of HMI technology in all industrial organizations, such as energy, oil and gas, transportation, food and beverage, power, water and wastewater, manufacturing, recycling, and many more, as well as a wide range of the application of other companies to interact with their devices and optimize their industrial processes.

Factory Automation Market - Automotive Sector to Witness the Growth

- The automotive industry is one of the prominent sectors that hold a significant in the worldwide automated manufacturing facilities. It is observed that the production facilities of various automakers are automated to maintain accuracy and efficiency. Moreover, the growing trend of replacing conventional vehicles with EVs is expected to augment the automotive industry's demand further.

- According to the IBEF automobile industry report, the two-wheelers segment dominates the market in terms of volume due to a growing middle-class population, and a considerable percentage of India's population is young. Moreover, the rising interest of companies in examining the rural markets is further aiding the sector's growth. The growing logistics and passenger transportation industries are driving the demand for commercial vehicles. Future market growth is expected to be fueled by new trends, including the electrification of vehicles, particularly small passenger automobiles and three-wheelers.

- Furthermore, companies are using automated automotive assembly lines for manufacturing components such as motors, gearboxes, fuel systems, and pumps. Robotics and vision are best suited for creating ergonomic and efficient product lines that protect the human workforce from hazardous conditions while completing assembly quickly. Hence, the safety factor is also driving automation in the automotive industry of India.

- India is also a major auto exporter and has substantial export growth expectations for forecast period. Additionally, several initiatives by the Government of India, like the scrappage policy, Automotive Mission Plan 2026, and production-linked incentive schemes in the Indian market, are likely to make India a prominent player in the two-wheeler and four-wheeler markets.

India Industrial Automation Industry Overview

India's industrial automation market is competitive due to multiple players, such as BHEL, ABB Limited, Grey Orange Pte Ltd, and Kardex India Storage Solutions Pvt. Ltd, Mitsubishi Electric, and more. Players adopt product innovations, partnerships, mergers, and acquisitions to increase their market shares and recyclability, further driving the market.

- June 2023 - The Schaefer Systems International Pvt. Ltd launched a fully automated piece-picking system with numerous innovative features the SSI Piece Picking application. This versatile solution includes dedicated smart software and boasts advanced functions such as object recognition using artificial intelligence (AI), pick-and-place, patented gripping point determination, and extremely gentle product handling.

- June 2023 -Mitsubishi Electric announced that its wholly owned subsidiary ICONICS, Inc., has formally agreed to completely acquire ICONICS UK, Ltd., which sells supervisory control and data acquisition (SCADA)1 software and develops related cloud applications. Mitsubishi Electric and ICONICS plan to leverage ICONICS UK's technology and to establish a Circular Digital-Engineering business model for factory-automation solutions that optimize factory equipment and systems

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Assessment of the Impact of COVID-19 on the Industry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing Demand for Labels Manufactured with Digital Print Technologies

- 5.1.2 High Adoption from the Healthcare and Cosmetic Segment

- 5.2 Market Restraints

- 5.2.1 Lack of Products with the Ability to Withstand Harsh Climatic Conditions

6 MARKET SEGMENTATION

- 6.1 By Type of Solution

- 6.1.1 Automated Material Handling Solutions

- 6.1.1.1 Hardware

- 6.1.1.1.1 Conveyor/Sortation Systems

- 6.1.1.1.2 Automated Storage and Retrieval System (AS/RS)

- 6.1.1.1.3 Mobile Robots (Automated Guided Vehicles and Autonomous Mobile Robots)

- 6.1.1.1.4 Automatic Identification and Data Capture (AIDC)

- 6.1.1.2 Software - Warehouse Management System (WMS)/ Warehouse Control System (WCS)

- 6.1.2 Factory Automation Solutions

- 6.1.2.1 Industrial Control Systems

- 6.1.2.1.1 DCS

- 6.1.2.1.2 SCADA

- 6.1.2.1.3 PLC

- 6.1.2.1.4 HMI

- 6.1.2.1.5 Other Control Systems

- 6.1.2.2 Field Devices

- 6.1.2.2.1 Sensors and Transmitters

- 6.1.2.2.2 Electric AC Drives

- 6.1.2.2.3 Servo Motors

- 6.1.2.2.4 Computer Numerical Control (CNC) Machines

- 6.1.2.2.5 Inverters

- 6.1.2.2.6 Industrial Robots

- 6.1.2.2.7 Other Factory Automation Solutions

- 6.1.2.3 Software

- 6.1.2.3.1 Manufacturing Execution System (MES)

- 6.1.2.3.2 Product Lifecycle Management (PLM)

- 6.1.2.3.3 Other Types

- 6.1.1 Automated Material Handling Solutions

- 6.2 By End-user

- 6.2.1 Automated Material Handling Market

- 6.2.1.1 Manufacturing

- 6.2.1.2 Non-manufacturing

- 6.2.1.2.1 General Merchandise

- 6.2.1.2.2 Healthcare

- 6.2.1.2.3 FMCG/Non-durable Goods

- 6.2.1.2.4 Other End-Users

- 6.2.2 Factory Automation Market

- 6.2.2.1 Food and Beverage

- 6.2.2.2 Pharmaceutical

- 6.2.2.3 Automotive

- 6.2.2.4 Textiles

- 6.2.2.5 Power

- 6.2.2.6 Oil and Gas

- 6.2.2.7 Petrochemicals and Fertilizers

- 6.2.2.8 Other End-Users

- 6.2.1 Automated Material Handling Market

7 COMPETITIVE BENCHMARKING

- 7.1 Competitors Ranking

- 7.1.1 Market Ranking Analysis - Automated Material Handling

- 7.1.2 Market Ranking Analysis - Factory Automation Solution

8 COMPETITIVE LANDSCAPE

- 8.1 Company Profiles - Automated Material Handling

- 8.1.1 Daifuku India Private Limited (Daifuku Co. Ltd)

- 8.1.2 Space Magnum Equipment Pvt. Ltd

- 8.1.3 Godrej Koerber Supply Chain Limited

- 8.1.4 Kardex India Storage Solutions Private Limited (Kardex Holding AG)

- 8.1.5 Armstrong Ltd

- 8.1.6 Falcon Autotech Private Limited

- 8.1.7 Grey Orange Pte Ltd

- 8.1.8 Addverb Technologies Private Limited

- 8.1.9 Hinditron Group

- 8.1.10 The Hi-Tech Robotic Systemz Limited

- 8.1.11 Bastian Solution Private Limited (Toyota Industries)

- 8.1.12 ATS Conveyors India Pvt. Ltd (ATS Group)

- 8.1.13 Kuka India Private Limited (Kuka AG)

- 8.1.14 Schaefer Systems International Pvt. Ltd (SSI Schaefer AG)

- 8.1.15 Rucha Yantra LLP

- 8.2 Company Profiles - Factory Automation Solution

- 8.2.1 Bharat Heavy Electricals Limited (BHEL)

- 8.2.2 ABB Ltd

- 8.2.3 Yokogawa Electric Corporation

- 8.2.4 Siemens AG

- 8.2.5 Emerson Electric Co.

- 8.2.6 Schneider Electric

- 8.2.7 Honeywell International Inc.

- 8.2.8 Rockwell Automation Inc.

- 8.2.9 Mitsubishi Electric Corporation

- 8.2.10 Danfoss A/S

- 8.2.11 Fuji Electric Co. Ltd

- 8.2.12 Larsen & Toubro Ltd

- 8.2.13 Crompton Greaves Ltd

- 8.2.14 Robert Bosch GmbH

- 8.2.15 Bain & Company Inc

- 8.2.16 Boston Consulting Group