|

市场调查报告书

商品编码

1692121

製药喷雾干燥:市场占有率分析、行业趋势和统计、成长预测(2025-2030 年)Pharmaceutical Spray Drying - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

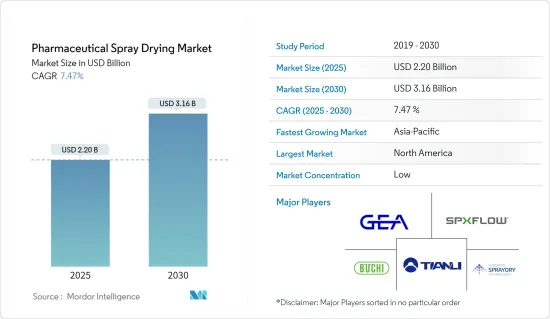

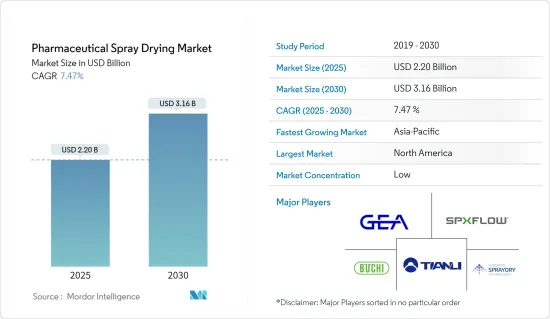

预计 2025 年医药喷雾干燥市场规模为 22 亿美元,预计到 2030 年将达到 31.6 亿美元,预测期内(2025-2030 年)的复合年增长率为 7.47%。

疫情初期,由于製造流程显着放缓以及药品供需受限,严重影响了医药喷雾干燥市场的成长。根据一些政府报告,由于新冠肺炎疫情导致活性药物成分短缺。同样,根据药品出口促进委员会 (PHARMEXCIL) 的数据,2021 年,由于对治疗爱滋病毒、癌症、癫痫和疟疾等各种疾病的药物的需求增加,新冠疫情导致药品价格大幅上涨。

然而,药品短缺的恢復以及 COVID-19 药物、製药应用和疫苗中药物喷雾干燥的使用增加,对市场产生了积极影响。例如,根据 2023 年 2 月发表的一项题为「喷雾冻干氯硝柳胺奈米晶体嵌入干粉用于高剂量肺部输送」的研究,氯硝柳胺 (NCL) 已显示出在 COVID-19 治疗中的潜在应用。然而,开发有效输送氯硝柳胺(NCL)的新配方仍然是一项挑战。在此背景下,采用新颖的喷雾冷冻干燥技术製备了含氯硝柳胺的吸入干粉(NeDPI),使药物输送更加容易。

这些案例表明,市场最初由于供应链中断而经历了成长放缓。然而,随着供不应求的恢復以及 COVID-19 药物和疫苗的药物喷雾干燥使用量的增加,市场在疫情期间受到了积极影响,预计在预测期内将继续呈现上升趋势。

慢性病盛行率的上升、技术进步、产品稳定性的提高以及研发支出的增加是推动市场发展的关键因素。

根据 PharmTech 2022 年 2 月的期刊出版物,生物製药的不断发展推动了对喷雾干燥的需求,作为生物製药製造和加工的替代方案,而不是传统的液体或冷冻干燥固体形式。新的药物喷雾干燥方法可以更好地控制所生产粉末的特性,为下游製程提供显着优势。透过适当的製程开发,喷雾干燥还可以直接压缩无定形固体分散体(ASD)製剂,避免了压片前製粒的需要。由于这些技术进步,大多数製药公司现在都采用喷雾干燥而不是传统方法。

此外,慢性病的增加也推动了市场的成长。例如,根据国际糖尿病联盟2021年发布的资料,全球约有5.37亿成年人患有糖尿病,预计2030年将有约6.43亿人患有糖尿病。另外,有报告指出,每四名成年人中就有三人患有糖尿病,每两名成年人中就有一人(2.4亿人)患有未确诊的糖尿病。同样,根据国际糖尿病联盟 2021 年的报告,超过 120 万名青少年和儿童患有第 1 型糖尿病。

此外,根据美国癌症协会2023年大肠癌统计数据,预计2023年美国将有超过153,020名成年人被诊断出罹患大肠癌。这些数字包括美国106,970例新发结肠癌病例和46,050例新发直肠癌病例。药物喷雾干燥是大多数製药公司生产高品质药物的首选技术。慢性病的发展预计将增加对治疗慢性病的高品质药物开发的需求,这也可能增加对喷雾干燥技术的需求。因此,预计预测期内慢性病的高盛行率将对市场成长产生正面影响。

然而,喷雾干燥的高成本以及对经验丰富的操作员的需求可能会在预测期内阻碍市场的成长。

医药喷雾干燥市场的趋势

预测期内辅料製造领域预计将大幅成长

- 药用辅料是除活性药物成分 (API) 之外,已经过适当的安全评估并有意包含在药物输送系统中的物质。干颗粒是透过喷雾干燥生产的,即将赋形剂溶解在水或有机溶剂中,然后在高于溶剂汽化点的温度下,使用压缩空气将所得溶液透过细雾化喷嘴喷出。释放出的细小液滴会迅速干燥,然后透过旋风机制收集颗粒。粒度由溶液中赋形剂的浓度和施加于气流的压力控制。

- 赋形剂的优势和日益增长的研究是市场的主要驱动力。辅料在药物配方中至关重要,因为它们能够实现药物输送,并且可占药物配方的 80-90%。对于品牌药物,使用新型辅料有可能优化药物性能和格式,开发以前无法开发的候选药物,为患者提供优化格式的创新药物。因此,考虑到这些分子的优势,製药公司正在大力投资这些辅料的生产。因此,喷雾干燥在特殊製造中的应用越来越多,从而促进了该领域的成长。

- 此外,日益增多的研究活动也有望推动该领域的成长。例如,2021年9月,美国食品药物管理局(USFDA)启动了一项新的试验计画,以审查用于满足新药配方中未满足的需求的新型辅料。透过该计划,FDA 旨在加速开发可能有用的辅料,以应对辅料製造商和药物开发商先前表示现有辅料难以使用的情况。预计这些政府措施将在预测期内促进该行业的成长。

- 此外,预计在预测期内,药品需求的增加、辅料生产设施的新投资以及政府推动药品和其他医药产品国内生产的倡议都将推动市场成长。例如,2023 年 6 月,Croda, Inc. 开始在宾州建造新工厂,以提高其药用辅料的生产能力。据该公司介绍,新工厂将用于生产用于 mRNA 疫苗和基因编辑疗法等新型疗法的药物传输系统的原料。因此,新的赋形剂製造设施的推出预计将推动对喷雾干燥机的需求,因为它们是赋形剂製造中必不可少的组件之一。

- 因此,鑑于喷雾干燥技术在赋形剂製造中的重要性,预计该技术带来的优势和赋形剂製造设施的增加将在预测期内推动该领域成长。

预计北美将在预测期内占据最大份额

- 由于大型製药企业的存在、药品需求量大、技术进步以及医药品研究开发费用高等因素,预计北美将占据主要份额。越来越多的公司注重市场扩张,并采取商业策略来保持其在市场中的地位,预计将推动市场成长。

- 例如,2022年1月,Eurofins(一家合约开发和製造组织)宣布在北美扩展其现有的喷雾干燥开发和製造服务。此次扩张进一步补充了 Eurofins 专注于增强临床开发和小规模商业项目的溶解度的广泛服务。

- 慢性病负担的增加和对药品研发活动的投资增加是预测期内推动该地区药品喷雾干燥市场发展的一些主要驱动因素。例如,根据美国癌症协会2022年的报告,2022年全国将报告约190万例癌症病例,乳癌将成为最常见的癌症形式。

- 此外,随着对干燥药品的需求不断增加,该公司正在采用先进的喷雾干燥技术来提高产量和工作流程。预计此类收购将在预测期内进一步推动美国市场的成长。

- 例如,2023 年 5 月,为生物製药行业服务的合约开发和受託製造厂商(CDMO) 和临床试验供应服务公司 Experic 宣布将增加喷雾干燥功能以支持生物製药配方和开发。

- 因此,由于慢性病发生率高和原料药製造设施的投资,预计预测期内北美的医药喷雾干燥市场将会成长。

製药喷雾干燥产业概况

由于有各种参与者,医药喷雾干燥市场较为分散。一些领先的公司正在积极寻求与其他公司的收购或合资,以加强其在全球的市场地位。一些占据市场主导地位的公司包括 GEA Group Aktiengesellschaft、山东天利干燥设备有限公司、Buchi Labortecknik AG、European SprayDry Technologies 和 Labplant。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 市场概况

- 市场驱动因素

- 慢性病盛行率不断上升

- 技术进步和产品稳定性提高

- 研发成本增加

- 市场限制

- 喷雾干燥高成本且需要熟练的操作员

- 波特五力分析

- 新进入者的威胁

- 购买者/消费者的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争强度

第五章 市场区隔

- 按应用

- 辅料製造

- 封装

- 提高生物有效性

- 其他用途

- 按地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 其他欧洲国家

- 亚太地区

- 中国

- 日本

- 印度

- 澳洲

- 韩国

- 其他亚太地区

- 中东和非洲

- GCC

- 南非

- 其他中东和非洲地区

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 北美洲

第六章 竞争格局

- 公司简介

- GEA Group Aktiengesellschaft

- SPX Flow

- PROCEPT

- Shandong Tianli Energy Co. Ltd

- BUCHI Labortechnik AG

- European SprayDry Technologies

- Labplant

- New AVM Systech Pvt. Ltd.

- Advanced Drying Systems

- Lemar Drying Engineering

第七章 市场机会与未来趋势

The Pharmaceutical Spray Drying Market size is estimated at USD 2.20 billion in 2025, and is expected to reach USD 3.16 billion by 2030, at a CAGR of 7.47% during the forecast period (2025-2030).

The initial phase of the pandemic has had a substantial impact on the growth of the pharmaceutical spray drying market owing to the significant decline in manufacturing processes and restricted demand and supply of drugs. The government of several countries has reported that active pharmaceutical ingredients are in short supply because of the COVID-19 pandemic. Likewise, according to the Pharmaceutical Export Promotion Council (PHARMEXCIL), in 2021, the COVID-19 pandemic resulted in a massive spike in medicine prices due to increased demand for drugs to treat a variety of diseases, including HIV, cancer, epilepsy, and malaria.

However, the recovery from the shortage and increasing use of pharmaceutical spray drying for COVID-19 drugs, drug applications, and vaccines have positively impacted the market. For instance, according to the study titled, 'Spray freeze-dried niclosamidenanocrystals embedded dry powder for high dose pulmonary delivery,' published in February 2023, niclosamide(NCL) has shown potential applications for treating COVID-19. However, the development of new formulations for effective niclosamide(NCL) delivery is still challenging. In such cases, niclosamide-embedded dry powder for inhalation (NeDPI) was fabricated by a novel spray freeze-drying technology, making it easier for drug delivery.

Therefore, such instances indicate that the market initially witnessed slow growth owing to supply chain disruption. However, with the recovery from shortage and increasing use of pharmaceutical spray drying for COVID-19 drugs and vaccines, the market witnessed a positive impact during the pandemic and is expected to continue the upward trend over the forecast period.

The increasing prevalence of chronic diseases, technological advancements, improvements in the stability of products, and increasing research and development spending are the major factors propelling market growth.

According to the journal published in February 2022 by PharmTech, the increased development of biologic-based drugs has fueled the demand for spray drying as an alternative for the manufacturing and processing of biologics instead of the more traditional liquid or lyophilized solid forms. The new pharmaceutical spray drying methods offer remarkable control over the properties of the manufactured powders, with significant downstream advantages. With adequate process development, spray drying can also enable amorphous solid dispersion (ASDs) formulations that are directly compressible, thus bypassing the need for granulation prior to tableting. Thus, owing to such technological advancements, the majority of pharmaceutical companies are adopting spray drying over traditional methods.

In addition, increasing cases of chronic diseases are also propelling market growth. For instance, according to the data published by the International Diabetes Federation in 2021, around 537.0 million adults are living with diabetes, and by 2030, around 643.0 million people are expected to live with diabetes. It also reported that 3 out of 4 adults live with diabetes, and around 1 out of 2 adults (240.0 million) are living with undiagnosed diabetes. Similarly, according to the report published by the International Diabetes Federation in 2021, more than 1.2 million adolescents and children are living with type 1 diabetes.

Furthermore, according to the American Cancer Society Colorectal Cancer Statistics in 2023, over 153,020 adults are estimated to be diagnosed with colorectal cancer in 2023 in the United States. These numbers include 106,970 new cases of colon cancer and 46,050 new cases of rectal cancer in the United States, as pharmaceutical spray drying is a technique preferred by most pharmaceutical companies to produce quality drugs. Increasing cases of chronic diseases are anticipated to boost the demand for quality drug development for treatment, which in turn may boost the demand for spray-drying techniques. Thus, the high prevalence of chronic diseases is expected to positively impact the market growth over the forecast period.

However, the high cost associated with spray drying and the requirement of experienced operators is likely to hinder the market growth over the forecast period.

Pharmaceutical Spray Drying Market Trends

Excipient Production Segment is Expected to Witness Considerable Growth Over the Forecast Period

- Pharmaceutical excipients are substances other than the active pharmaceutical ingredient (API) that have been appropriately evaluated for safety and are intentionally included in a drug delivery system. Manufacturing dry particles by the spray-drying method proceeds in such a way that excipients are dissolved in aqueous or organic solvents, after which the solution thus obtained is sprayed through a narrow atomization nozzle with high pressurized air at a temperature higher than the vaporization point of the solvent. The fine droplets thus emitted are quickly dried, followed by a collection of particles generated by a cyclone mechanism. The particle size is regulated by the concentration of excipients in the solution and the pressure given to the airflow.

- The advantages of excipients and increasing research work are the major drivers for the market. Excipients are essential to the formulation of drug products because they enable the effective delivery of drug substances and can account for as much as 80-90% of the drug product formulation. For branded drugs, novel excipients could be used to optimize drug product performance and presentation and possibly develop candidates that were deemed undevelopable, leading to transformative medicines with optimized patient presentations. Hence, considering the advantages of these molecules, pharmaceutical companies are investing huge amounts in manufacturing these excipients; therefore, there is increasing use of spray drying for the exception production, posting the segment growth.

- In addition, increasing research work is also anticipated to propel the segment growth. For instance, in September 2021, the UInted States Food and Drug Administration (USFDA launched a new pilot program to review novel excipients for use in meeting unmet needs in formulating new drug products. Through this program, the FDA intends to raise the development of excipients that may be useful in scenarios where excipient manufacturers and drug developers have cited prior difficulty in using existing excipients. Such initiatives by the government are expected to boost segment growth over the forecast period.

- Additionally, the rising demand for pharmaceuticals, new investments in the facilities for excipient production, and government initiatives to promote domestic manufacturing of drugs and other pharmaceutical products are expected to boost the market's growth over the forecast period. For instance, in June 2023, Croda, Inc. started constructing its new Pennsylvania facility to enhance its pharmaceutical excipients manufacturing capacity. As per the company, the new facility will be involved in manufacturing ingredients for drug delivery systems used in novel therapeutic drugs such as mRNA vaccines and gene editing therapies. Hence, the launch of new excipient manufacturing facilities is expected to boost the demand for spray dryers as they are one of the essential components for excipient production.

- Therefore, owing to the enormous significance of the spray drying technique in excipient production, the advantages offered by this technique and an increasing number of excipient manufacturing facilities are expected to boost segment growth over the forecast period.

North America is Expected to held Largest Share Over the Forecast Period

- North America is anticipated to have a significant share owing to factors such as the presence of major pharmaceutical players, high demand for pharmaceutical products, technological advancement, and high pharmaceutical research and development expenditure in the region. The increasing company focus on expansion and adopting business strategies to withhold their position in the market is likely to boost the growth of the market.

- For instance, in January 2022, Eurofins (Contract Development and Manufacturing Organization) announced the expansion of its existing spray dry development and production services in North America. With this expansion, Eurofins can further complement a broad range of services specializing in solubility enhancement for clinical development and small-scale commercial programs.

- The increasing burden of chronic diseases and increasing investment in pharmaceutical research and development activities are some of the major driving factors that are expected to drive the pharmaceutical spray drying market in the region over the forecast period. For instance, according to the 2022 report of the American Cancer Society, about 1.9 million cases of cancer were reported in the country in 2022, with breast cancer being the most prevalent form of cancer.

- Moreover, with the rising demand for dried pharmaceutical products, companies are acquiring advanced spray-drying technologies to enhance their production and workflow. Such acquisitions are further expected to boost the market's growth in the United States over the forecast period.

- For instance, in May 2023, Experic, a contract development and manufacturing organization (CDMO) and clinical trial supply services company serving the biopharmaceutical industry, announced the addition of spray drying capabilities to support the formulation and development of biopharmaceuticals.

- Therefore, owing to the high prevalence of chronic diseases and investment in active pharmaceutical ingredient manufacturing facilities, the pharmaceutical spray drying market is expected to grow in North America over the forecast period.

Pharmaceutical Spray Drying Industry Overview

The pharmaceutical spray drying market is fragmented due to the presence of various players in the market. Some prominent players are vigorously making acquisitions and joint ventures with other companies to consolidate their market positions across the globe. Some of the players who are dominating the market are GEA Group Aktiengesellschaft, Shandong Tianli Drying Equipment Corporation Ltd, Buchi Labortecknik AG, European SprayDry Technologies, and Labplant, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Increasing Prevalence of Chronic Diseases

- 4.2.2 Technological Advancements and Improvements in the Stability of Products

- 4.2.3 Increasing Research and Development Spending

- 4.3 Market Restraints

- 4.3.1 High Cost Associated with Spray Drying and Requirement of Experienced Operators

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Threat of New Entrants

- 4.4.2 Bargaining Power of Buyers/Consumers

- 4.4.3 Bargaining Power of Suppliers

- 4.4.4 Threat of Substitute Products

- 4.4.5 Intensity of Competitive Rivalry

5 MARKET SEGMENTATION (Market Size by Value - USD)

- 5.1 By Application

- 5.1.1 Excipient Production

- 5.1.2 Encapsulation

- 5.1.3 Enhancing Bioavailability

- 5.1.4 Other Applications

- 5.2 Geography

- 5.2.1 North America

- 5.2.1.1 United States

- 5.2.1.2 Canada

- 5.2.1.3 Mexico

- 5.2.2 Europe

- 5.2.2.1 Germany

- 5.2.2.2 United Kingdom

- 5.2.2.3 France

- 5.2.2.4 Italy

- 5.2.2.5 Spain

- 5.2.2.6 Rest of Europe

- 5.2.3 Asia-Pacific

- 5.2.3.1 China

- 5.2.3.2 Japan

- 5.2.3.3 India

- 5.2.3.4 Australia

- 5.2.3.5 South Korea

- 5.2.3.6 Rest of Asia-Pacific

- 5.2.4 Middle East and Africa

- 5.2.4.1 GCC

- 5.2.4.2 South Africa

- 5.2.4.3 Rest of Middle East and Africa

- 5.2.5 South America

- 5.2.5.1 Brazil

- 5.2.5.2 Argentina

- 5.2.5.3 Rest of South America

- 5.2.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 GEA Group Aktiengesellschaft

- 6.1.2 SPX Flow

- 6.1.3 PROCEPT

- 6.1.4 Shandong Tianli Energy Co. Ltd

- 6.1.5 BUCHI Labortechnik AG

- 6.1.6 European SprayDry Technologies

- 6.1.7 Labplant

- 6.1.8 New AVM Systech Pvt. Ltd.

- 6.1.9 Advanced Drying Systems

- 6.1.10 Lemar Drying Engineering