|

市场调查报告书

商品编码

1836463

甲基三级丁基醚(MTBE):市场占有率分析、产业趋势、统计数据、成长预测(2025-2030)Methyl Tertiary Butyl Ether (MTBE) - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

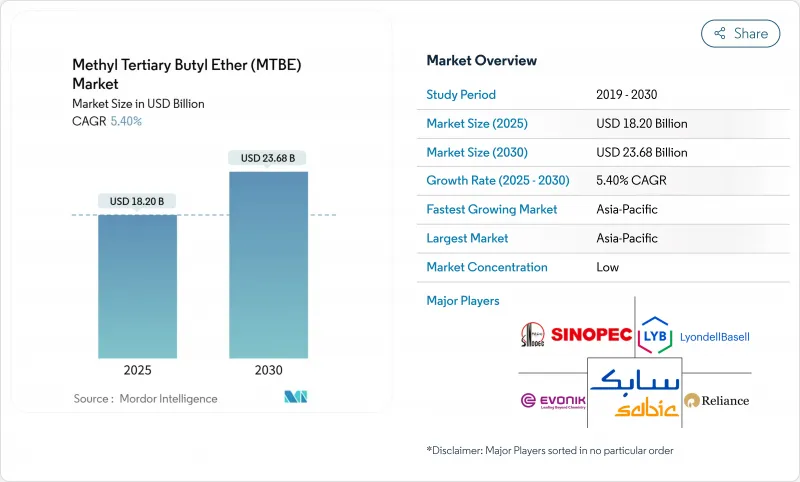

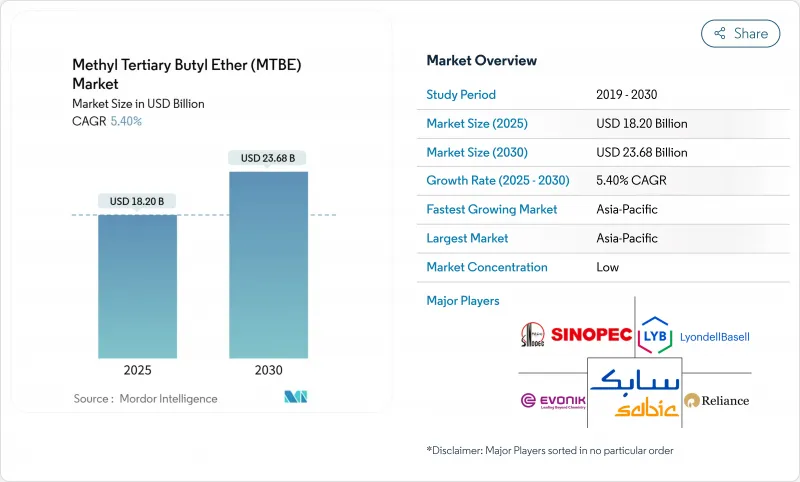

甲基三级丁基醚(MTBE) 市场规模预计在 2025 年为 182 亿美元,预计到 2030 年将达到 236.8 亿美元,预测期内(2025-2030 年)的复合年增长率为 5.40%。

需求成长的驱动因素包括:向更清洁燃烧、更高辛烷值汽油的转变、中东地区炼油厂的不断扩张以及药物提取过程的稳定应用。一体化炼油和石化联合体使生产商能够灵活地平衡汽油添加剂的生产和合成橡胶用高纯度异丁烯日益增长的需求。亚太地区的排放法规(例如国六排放标准)持续提高优质燃料中甲基叔丁基醚(MTBE)的平均混合比例,而中国各地的甲醇制汽油计划正在扩大甲基叔丁基醚(MTBE)作为中间体的可用资源。

全球甲基三级丁基醚(MTBE)市场趋势与洞察

亚太地区低芳烃、高辛烷值汽油法规激增

中国六国法规要求减少废气氨排放。对照研究表明,MTBE 混合物在低温冷启动循环中可显着降低排放。中国和印度的炼油厂正在将优质混合比例从 8% 提高到 15%。强劲的乘用车销售和强劲的都市区车队更新进一步支撑了需求。区域燃料经销商青睐 MTBE,因为在蒸气限制下,MTBE 比烷基化物或乙醇成本更低,测试辛烷值更高。这些法规支持持续投资于毗邻催化重整装置的专用 MTBE 生产线,为亚洲生产商提供规模经济,以抵消残油供应的波动性。

中东炼油厂扩建与专用MTBE装置整合

海湾石油生产商正在其混合进料裂解装置中整合甲基叔丁基醚(MTBE)迴路,以最大限度地提高Butene的利用率。沙乌地基础工业公司(SABIC)在Petrokemya的年产100万吨计划计画于2025年下半年完成机械竣工,这将巩固其作为该地区稳定供应商的地位。朱拜勒也制定了类似的计划,透过优化原料,针对性地分配异丁烯和甲醇原料,以确保利润率。这种整合将在汽油和丁基橡胶需求疲软期间提高运转率,增强甲基叔丁基醚市场的韧性。从物流角度来看,海湾地区靠近亚洲,在季节性混合料波动期间缩短了现货货物的前置作业时间。

替代产品的可用性

乙醇在美国汽油市场中的地位正在提升,监管机构根据联邦可再生燃料标准允许乙醇的掺混比例高达10%。加州空气资源委员会的模型假设,到2046年,乙醇市场将以10%的乙醇为主,而15%的乙醇市场将进一步扩大。美国炼油系统已于2007年从新配方汽油中淘汰了甲基叔丁基醚(MTBE),这降低了基准需求,并对全球经济成长产生了持久的负面影响。欧洲部分地区也出现了类似的政策趋势,可能会限制乙醇的长期应用。

报告中分析的其他驱动因素和限制因素

- 亚洲采用甲醇汽油路线导致 MTBE 需求增加

- MTBE 作为原料药特殊萃取中的助溶剂的应用日益增多

- 在北美被归类为污染物,随后禁止在汽油混合物中使用

細項分析

受汽油添加剂和大型化学中间体需求的推动,到2024年,工业级原油将占总产量的90%。原料纯度通常为98.50%,并透过沿海码头的专用油罐基础设施进行运输。医药级原油虽然只占总产量的10%,但随着连续製药厂采用甲基叔丁基醚(MTBE)进行结晶控制,预计其复合年增长率将达到5.98%。

到2024年,直接合约将涵盖70%的出货量,因为炼油厂和大型化学公司将透过长期协议购买驳船和铁路车辆。这种结构减少了物流交接,并确保了品管和混合原料规格的一致性。分销商为按托盘采购的中端油漆、橡胶和製药公司供货,占出货量的25%。随着买家利用数位竞标和合规文件工具,线上入口网站的复合年增长率达到6.40%。因此,叔甲基丁基醚市场正在逐步转向一种混合履约模式,将电子商务订单与区域油库交付相结合。

全球甲基三级丁基醚(MTBE) 市场报告按等级(工业级、医药级)、分销管道(直销、分销商、线上销售)、应用(汽油添加剂、异丁烯、其他)、最终用户行业(汽车、石油和天然气、其他)和地区(亚太地区、北美、欧洲、南美、中东和非洲)对行业进行细分。

区域分析

预计到2024年,亚太地区将占全球销售额的42%,到2030年复合年增长率将达到6.23%。在中国,欧VI等效燃油标准的日益严格,加上国内MTG计划的推进,正在结构性地推动辛烷值提升剂的需求。随着巴拉特第六阶段标准在全国推广,印度也正处于类似的发展阶段。

在北美,儘管美国墨西哥湾沿岸仍保持相当大的出口能力,但受州级禁令的影响,消费量有所放缓。欧洲的情况则是喜忧参半:儘管受到部分限制,但地中海沿岸的一些调合厂仍在优质无铅汽油中使用MTBE,从而维持着小众需求。

与此同时,中东生产商继续以具有竞争力的离岸价瞄准欧洲夏季需求缺口。南美洲和非洲继续成长,儘管规模较小,但巴西和奈及利亚扩大了无铅汽油合併规模,且MTBE在蒸气压合规性方面优于芳烃。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场状况

- 市场概况

- 市场驱动因素

- 亚太地区低芳烃、高辛烷值汽油强制标准的普及

- 中东炼油厂扩建及 MTBE 装置整合。

- 由于亚洲采用甲醇制汽油(MTG)路线,MTBE 需求增加

- 高性能轮胎对异辛烯(透过甲基叔丁基醚脱氢)的需求不断增加

- MTBE 作为原料药特殊萃取中的助溶剂的应用日益增多

- 市场限制

- 替代产品的可用性

- 在北美被归类为污染物,随后禁止在汽油混合物中使用

- 蒸汽裂解装置C4残液进料速率不稳定

- 价值链分析

- 波特五力分析

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章市场规模及成长预测(数量)

- 按年级

- 工业级

- 医药级

- 按分销管道

- 直销

- 经销商

- 网上销售

- 按用途

- 汽油添加剂

- 异丁烯

- 溶剂

- 其他用途

- 按最终用户产业

- 车

- 石油和天然气

- 化学

- 製药

- 其他最终用户产业

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 义大利

- 法国

- 其他欧洲国家

- 南美洲

- 巴西

- 阿根廷

- 其他南美

- 中东和非洲

- 沙乌地阿拉伯

- 阿拉伯聯合大公国

- 卡达

- 土耳其

- 南非

- 奈及利亚

- 其他中东和非洲地区

- 亚太地区

第六章 竞争态势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- BP plc

- Chevron Phillips Chemical Company LLC

- China Petrochemical Corporation

- CNPC

- Eni SpA

- ENOC Company

- Enterprise Products Partners LP

- ETRONAS Chemicals Group Berhad

- Evonik Industries AG

- Exxon Mobil Corporation

- Formosa Plastics Corporation, USA

- Gazprom

- Huntsman International LLC

- LUKOIL

- LyondellBasell Industries Holdings BV

- QAFAC

- Reliance Industries Limited

- SABIC

- Shell plc

- Vinati Organics Limited

- Wanhua

第七章 市场机会与未来展望

The Methyl Tertiary Butyl Ether Market size is estimated at USD 18.20 billion in 2025, and is expected to reach USD 23.68 billion by 2030, at a CAGR of 5.40% during the forecast period (2025-2030).

Demand is rooted in the shift toward cleaner-burning, high-octane gasoline, mounting petro-refinery expansion in the Middle East, and steady uptake in pharmaceutical extraction processes. Integrated refinery-petrochemical complexes give producers flexibility to balance gasoline additive volumes with rising requirements for high-purity isobutylene used in synthetic rubber. Asia Pacific emission standards, such as China-6, continue to lift average MTBE blend rates in premium fuel grades, while methanol-to-gasoline projects across China extend the addressable pool for MTBE as an intermediate.

Global Methyl Tertiary Butyl Ether (MTBE) Market Trends and Insights

Surging Low-Aromatic, High-Octane Gasoline Mandates in Asia Pacific

China-6 regulations require lower tail-pipe ammonia emissions; controlled studies show MTBE blends deliver measurable reductions during cold-start cycles at low ambient temperatures. Refiners in China and India are lifting blend ratios from 8% to 15% in premium grades. Robust passenger-car sales and steady urban fleet renewal further support demand. Regional fuel marketers prefer MTBE because it raises research octane at a lower cost than alkylate or ethanol under vapour-pressure limits. These mandates underpin sustained investment in dedicated MTBE trains adjacent to catalytic reformers, giving Asian producers scale economies that offset raffinate supply variance.

Petro-refinery Expansion in the Middle East Integrated with On-purpose MTBE Units

Producers in the Gulf are embedding MTBE loops within mixed-feed crackers to maximise butenes utilisation. SABIC's 1 million-tpa project at Petrokemya will reach mechanical completion in late 2025, reinforcing the region's role as a swing supplier. Similar schemes in Jubail allocate on-purpose isobutylene and methanol streams to safeguard margin through feedstock optimisation. Integration improves operating rates when gasoline or butyl rubber demand softens, thereby adding resilience to the methyl tertiary butyl ether market. Logistically, the Gulf's proximity to Asia shortens lead times for spot cargoes during seasonal blend swings.

Availability of Substitutes

Ethanol retains a firm foothold in US gasoline because regulators permit up to 10 vol% blends under the federal Renewable Fuel Standard. California Air Resources Board modelling assumes E10 remains dominant through 2046, with scenarios for E15 expansion. The US refining system eliminated MTBE from reformulated gasoline by 2007, lowering baseline demand and exerting a persistent negative pull on global growth. Similar policy currents in parts of Europe could temper long-run uptake, although energy density and vapour-pressure differences hinder full substitution in warmer climates

Other drivers and restraints analyzed in the detailed report include:

- Methanol-to-Gasoline Route Adoption in Asia Elevating MTBE Demand

- Growing Use of MTBE as Co-solvent in Specialty Extraction for Pharma APIs

- Classification as Pollutant and Consequent Ban of Use in Gasoline Blending in North America

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Industrial grade accounted for 90% of tonnage in 2024, driven by bulk gasoline additive demand and large-scale chemical intermediates. Material typically carries a purity of 98.50% and is routed through dedicated tank infrastructure at coastal terminals. Pharmaceutical grade, although just 10% by volume, is set to climb faster on a 5.98% CAGR as continuous drug manufacturing plants adopt MTBE for controlled crystallisations.

Direct contracts covered 70% of 2024 shipments as refineries and major chemical companies source barge or railcar lots via long-term agreements. This structure reduces logistical handoffs and aligns quality control with blend-stock specifications. Distributors supply mid-sized paint, rubber, and pharma firms that purchase pallet quantities, accounting for 25% of volumes. Online portals exhibit a 6.40% CAGR as buyers leverage digital tenders and compliance documentation tools. The methyl tertiary butyl ether market is thus moving gradually toward hybrid fulfillment models that integrate e-commerce ordering with regional tank farm delivery.

The Global Methyl Tertiary Butyl Ether (MTBE) Market Report Segments the Industry by Grade (Industrial Grade and Pharmaceutical Grade), Distribution Channel (Direct Sales, Distributors, and Online Sales), Application (Gasoline Additives, Isobutene, and More), End-User Industry (Automotive, Oil and Gas, and More), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa).

Geography Analysis

Asia Pacific held 42% of global revenue in 2024, and is forecast to grow at 6.23% CAGR to 2030. China's expanded Euro-VI equivalent fuel standard mandates, coupled with domestic MTG projects, raise structural demand for octane boosters. India follows a similar trajectory as Bharat Stage VI norms widen nationwide.

North America reflects subdued consumption after state-level bans, yet the US Gulf Coast retains substantial export capacity. Europe presents a mixed picture. While partial restrictions exist, certain Mediterranean blenders still use MTBE in premium unleaded formulations, maintaining niche demand.

Meanwhile, Middle Eastern producers continue to target European summer demand gaps with competitive FOB pricing. South America and Africa remain smaller but growing as Brazil and Nigeria widen unleaded gasoline pooling that benefits MTBE over aromatics in terms of vapour pressure compliance.

- BP plc

- Chevron Phillips Chemical Company LLC

- China Petrochemical Corporation

- CNPC

- Eni S.p.A

- ENOC Company

- Enterprise Products Partners L.P.

- ETRONAS Chemicals Group Berhad

- Evonik Industries AG

- Exxon Mobil Corporation

- Formosa Plastics Corporation, U.S.A.

- Gazprom

- Huntsman International LLC

- LUKOIL

- LyondellBasell Industries Holdings B.V.

- QAFAC

- Reliance Industries Limited

- SABIC

- Shell plc

- Vinati Organics Limited

- Wanhua

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Surging Low-Aromatic, High-Octane Gasoline Mandates in Asia Pacific

- 4.2.2 Petro-refinery Expansion in Middle-East Integrated with On-purpose MTBE Units

- 4.2.3 Methanol-to-Gasoline (MTG) Route Adoption in Asia Elevating MTBE Demand

- 4.2.4 Rising Demand for Iso-octene (via MTBE Dehydrogenation) in High-performance Tires

- 4.2.5 Growing Use of MTBE as Co-solvent in Specialty Extraction for Pharma APIs

- 4.3 Market Restraints

- 4.3.1 Availability of Substitutes

- 4.3.2 Classification as Pollutant and Consequent Ban of Use in Gasoline Blending in North America

- 4.3.3 Volatility in C4 Raffinate Availability from Steam Crackers

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces Analysis

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitute Products and Services

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Volume)

- 5.1 By Grade

- 5.1.1 Industrial Grade

- 5.1.2 Pharmaceutical Grade

- 5.2 By Distribution Channel

- 5.2.1 Direct Sales

- 5.2.2 Distributors

- 5.2.3 Online Sales

- 5.3 By Application

- 5.3.1 Gasoline Additives

- 5.3.2 Isobutene

- 5.3.3 Solvents

- 5.3.4 Other Applications

- 5.4 By End-user Industry

- 5.4.1 Automotive

- 5.4.2 Oil and Gas

- 5.4.3 Chemicals

- 5.4.4 Pharmaceuticals

- 5.4.5 Other End-user Industries

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 Italy

- 5.5.3.4 France

- 5.5.3.5 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 United Arab Emirates

- 5.5.5.3 Qatar

- 5.5.5.4 Turkey

- 5.5.5.5 South Africa

- 5.5.5.6 Nigeria

- 5.5.5.7 Rest of Middle East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global-level Overview, Market-level Overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 BP plc

- 6.4.2 Chevron Phillips Chemical Company LLC

- 6.4.3 China Petrochemical Corporation

- 6.4.4 CNPC

- 6.4.5 Eni S.p.A

- 6.4.6 ENOC Company

- 6.4.7 Enterprise Products Partners L.P.

- 6.4.8 ETRONAS Chemicals Group Berhad

- 6.4.9 Evonik Industries AG

- 6.4.10 Exxon Mobil Corporation

- 6.4.11 Formosa Plastics Corporation, U.S.A.

- 6.4.12 Gazprom

- 6.4.13 Huntsman International LLC

- 6.4.14 LUKOIL

- 6.4.15 LyondellBasell Industries Holdings B.V.

- 6.4.16 QAFAC

- 6.4.17 Reliance Industries Limited

- 6.4.18 SABIC

- 6.4.19 Shell plc

- 6.4.20 Vinati Organics Limited

- 6.4.21 Wanhua

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-need Assessment

- 7.2 Innovation in Bio-based MTBE for Gasoline