|

市场调查报告书

商品编码

1836643

印尼纺织製造业:市场占有率分析、产业趋势、统计数据和成长预测(2025-2030 年)Indonesia Textile Manufacturing - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

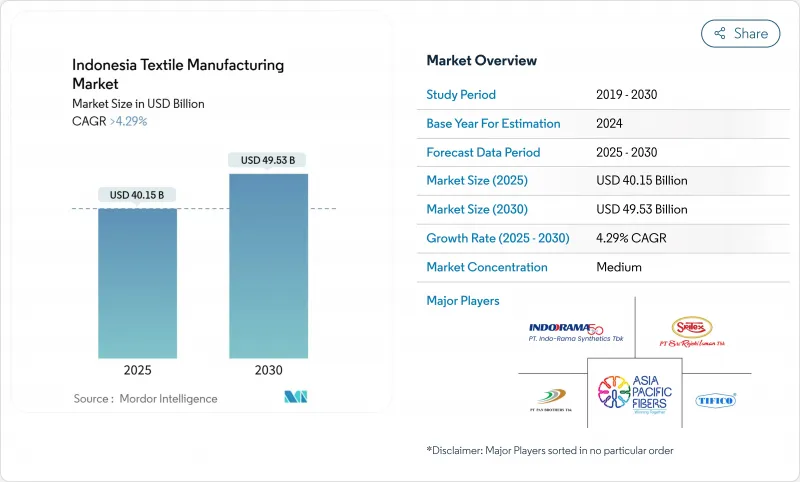

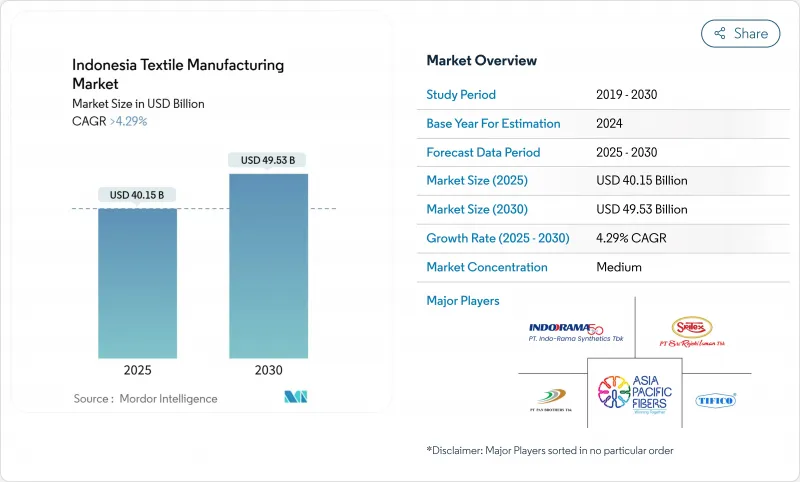

预计到 2025 年,印尼纺织製造市场价值将达到 401.5 亿美元,到 2030 年将达到 495.3 亿美元,复合年增长率为 4.29%。

「打造印尼4.0」蓝图带来的强大政策支持、丰富的技术纯熟劳工资源以及国际订单的復苏,使印尼成为寻求在亚洲实现供应链多元化的品牌的重要采购中心。爪哇岛成熟的工业生态系统,加上日益提升的工厂自动化和石化一体化水平,在工资压力不断上升的背景下仍保持着成本竞争力。适度穿着和技术纺织品的需求不断增长,持续提升生产质量,而向再生纤维的转变则表明其与全球永续性标准的接轨程度不断提高。儘管存在物流瓶颈和进口主导的价格竞争,但积极的税收优惠政策、绿色产业认证和区域发展计画仍为中期成长前景提供支持。

印尼纺织製造市场趋势与洞察

越来越多的美国和欧盟品牌将运动服订单转移到爪哇丛集

亚洲传统枢纽的人事费用不断上涨,以及对更快补货的需求,正促使西方品牌在爪哇岛扩张至更大的工厂。年产能达1.17亿件的Pan Brothers公司已获得更多高性能针织品合同,凸显了其向印尼的战略重心。爪哇工业内纱线、布料和服装工厂的紧密联繫缩短了前置作业时间,并降低了处理成本。即便如此,美国可能上调关税的不确定性仍是生产商观点。

穆斯林时尚出口繁荣推动增值服饰生产

印尼正利用其文化亲和性和设计人才,为不断扩张的全球时尚产业提供产品。据估计,到2023年,全球时尚产业的产值将达到3,610亿美元。在纽约时装週的展示提升了本土品牌的国际知名度,并使其能够获得更高的价格分布。高附加价值的产品线能够加强客户关係,并需要先进的装饰技术,这促使工厂投资于专用机械和熟练的工匠。

非法低成本进口侵蚀中小企业纺织利润

由于非法进口导致当地价格下跌,工厂倒闭和裁员,政府正在收紧进口许可证并加强检查。即使征收200%的保障性关税,执法不力也导致假冒仿冒品纺织品顺利通过港口,导致社区纺织丛集无法收回管理成本。新的Permenperin 5/2024法规旨在透过明确文件要求和同步海关资料库来弥补漏洞。

报告中分析的其他驱动因素和限制因素

- 政府的「印尼4.0」激励措施加速纺织自动化

- 电商主导国内服饰需求在天才消费者中激增

- 长期的港口和铁路瓶颈导致岛际物流成本膨胀

細項分析

至2024年,机织布料将在印尼纺织品製造市场中保持37.3%的份额,西爪哇省丛集已建成梭子织布机和剑桿织布机产能。生产将主要面向衬衫和丹宁布料,出口量将保持稳定。同时,受高性能服饰和休閒系列激增的推动,到2030年,针织品的复合年增长率将达到5.08%。生产商将采用圆针织机,这种机器可以实现小批量生产并采用功能性混纺纱线,以适应在线零售商青睐的短版生产模式。

针织品的成长也反映了运动服饰品牌寻求东南亚快速补货的订单增加。爪哇的製造商透过整合染色和印花设施,提供全套服饰,从而比仅提供布料的供应商获得更高的价值。从中期来看,无缝结构等先进的针织技术预计将提高生产力并减少后期生产浪费,从而增强印尼在舒适服装领域的竞争地位。

到2024年,服饰将占印尼纺织品製造市场份额的59.5%,这反映了该国深厚的缝纫专业知识和充足的劳动力。生产商正在从单一的裁剪、製衣和修剪服务转向全包装服务,为品牌客户提供设计意见、商品行销和合规文件。技术和工业纺织品将成为成长最快的细分市场,复合年增长率为5.04%,这反映了汽车原始设备製造商的基础设施投资和本地化进程。

服饰持续主导,也得益于印尼时装的利基市场。该市场将传统图案与现代轮廓融合,瞄准出口市场。控制上游布料和染色製程的综合性公司提高了利润率,并确保了与品牌审核的品质一致性。同时,仅生产布料的生产商正在将更多生产转向防护衣、过滤和汽车零件,从而减少对时尚週期的依赖。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场状况

- 市场概况

- 市场驱动因素

- 政府的「印尼製造4.0」奖励措施加速纺织自动化

- 越来越多的美国和欧盟品牌将运动服近岸外包至爪哇丛集

- 穆斯林时尚出口繁荣推动高附加价值服饰生产

- 电子商务主导Z世代消费者国内服饰需求激增

- 棉花依赖度高,人造纤维进口替代正在推进

- 中爪哇绿色染料厂升级专案投资者税收减免

- 市场限制

- 非法低成本进口损害中小企业纺织利润

- 长期的港口和铁路瓶颈增加了岛屿间的物流成本

- 不稳定的印尼国家电力收费系统对能源密集型纺织业带来压力

- 西爪哇的劳动力短缺和工资上涨

- 价值链/供应链分析

- 监管和政府主导的前景

- 技术展望-为工业4.0和数位转型做好准备

- 产业吸引力—五力分析

- 新进入者的威胁

- 买方的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争

- 近期全球动盪对印尼纺织製造业的影响

- 永续性和循环经济的趋势

第五章市场规模及成长预测

- 依流程类型

- 纺纱

- 织物

- 针织

- 精加工

- 其他工艺(不织布)

- 依纺织品类型

- 纤维

- 线

- 织物

- 衣服

- 其他纺织品

- 按材质

- 天然纤维(棉、丝等)

- 合成纤维(聚酯、尼龙等)

- 其他(再生及再循环纤维、特殊纤维)

- 按用途

- 服饰

- 家用纺织品

- 工业纺织品

- 其他用途

- 按地区(印尼)

- Java

- 苏门答腊

- 其他(加里曼丹、苏拉威西、峇里岛等)

第六章 竞争态势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介{ }(英文)

- PT Asia Pacific Fibres Tbk

- Indo-Rama Synthetics Tbk

- PT Sri Rejeki Isman Tbk(Sritex)

- PT Tifico Fiber Indonesia Tbk

- PT Pan Brothers Tbk

- PT Ever Shine Tex Tbk

- PT Trisula Textile Industries Tbk

- PT Century Textile Industry Tbk(Toray)

- PT Polychem Indonesia Tbk

- PT Argo Pantes Tbk

- Duniatex Group

- PT Kahatex

- PT Apac Inti Corpora

- PT Eratex Djaja Tbk

- PT Ateja Tritunggal

- PT Sinar Para Taruna

- PT Kewalram Indonesia

- PT Pura Group(Textile Div.)

- PT Multi Garmenjaya

- PT Delami Garment Industries

第七章 市场机会与未来展望

The Indonesia Textile Manufacturing Market is valued at USD 40.15 billion in 2025 and is projected to reach USD 49.53 billion by 2030, expanding at a 4.29% CAGR.

Robust policy backing through the Making Indonesia 4.0 roadmap, a large pool of skilled labor, and resurging foreign orders position the country as a vital sourcing hub for brands looking to diversify Asian supply chains. Java's mature industrial ecosystem, together with rising factory automation and petrochemical integration, sustains cost competitiveness even as wage pressures inch up. Expanding demand for modest wear and technical textiles continues to lift output quality, while the shift toward recycled fibers signals growing alignment with global sustainability standards. Despite logistics bottlenecks and import-led price competition, proactive tax incentives, green-industry certifications, and regional development programs underpin medium-term growth prospects.

Indonesia Textile Manufacturing Market Trends and Insights

Rising Near-Shoring of Activewear Orders from US & EU Brands to Java Clusters

Labor cost escalation in legacy Asian hubs and the need for faster replenishment bring Western labels to Java's large-scale plants. Pan Brothers, with annual capacity of 117 million pieces, has secured incremental contracts for performance knitwear, underscoring the pivot toward Indonesia. Close proximity among yarn, fabric, and garment units inside the island's industrial estates compresses lead times and lowers handling expenses. Nevertheless, uncertainty over potential US tariff hikes remains a watchpoint for producers.

Boom in Muslim Fashion Exports Driving Value-Added Garment Production

Indonesia leverages cultural affinity and design talent to supply the expanding global modest-fashion segment, estimated at USD 361 billion in 2023. Showcases at New York Fashion Week have raised international visibility, allowing local brands to command higher price points. Value-added lines create stickier customer relationships and require advanced embellishment techniques, prompting mills to invest in specialty machinery and skilled artisans.

Illegal Low-Priced Imports Eroding SME Weaving Margins

Unlawful inflows undercut local price points and have triggered factory closures and layoffs, pushing the government to tighten import permits and step up inspections. Even with 200% safeguard tariffs, weak enforcement lets counterfeit and sub-standard fabrics slip through ports, leaving community-based weaving clusters unable to recover overheads. The new Permenperin 5/2024 regulation aims to close loopholes by clarifying documentation requirements and synchronizing customs databases.

Other drivers and restraints analyzed in the detailed report include:

- Government "Making Indonesia 4.0" Incentives Accelerating Textile Automation

- Surge in E-Commerce-Led Domestic Apparel Demand Among Gen-Z Consumers

- Chronic Port & Rail Bottlenecks Inflating Inter-Island Logistics Cost

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Weaving retained a 37.3% share of the Indonesia textile manufacturing market in 2024, anchored by entrenched shuttle and rapier loom capacity across West Java clusters. Output caters mainly to shirtings and denim, segments that still support steady export volumes. Knitting, however, posts a 5.08% CAGR through 2030 as performance apparel and athleisure lines surge. Producers deploy circular knitting machines capable of smaller lot sizes and functional yarn blends, aligning with the short-run model favored by online retailers.

Knitting's growth also reflects rising orders from sportswear labels seeking quick replenishment out of Southeast Asia. Java-based makers leverage co-located dye-houses and print shops to deliver fully packaged garments, capturing greater value than fabric-only suppliers. In the medium term, advanced knitting techniques such as seamless construction are expected to lift productivity and reduce post-production waste, reinforcing Indonesia's competitiveness in comfort apparel.

Garments represented 59.5% of the Indonesia textile manufacturing market share in 2024, testifying to the country's deep sewing expertise and abundant workforce. Producers have moved beyond cut-make-trim to full-package services, offering design input, merchandising, and compliance documentation to brand customers. The fastest expansion occurs in technical and industrial textiles at 5.04% CAGR, reflecting infrastructure spending and automotive OEM localization.

Continued garment leadership also stems from Indonesia's modest-wear niche, where brands merge traditional motifs with modern silhouettes for export markets. Integrated players that control upstream fabric and dyeing steps capture improved margins and ensure quality alignment with brand audits. Meanwhile, fabric-only producers channel more output into protective wear, filtration, and automotive components, reducing reliance on fashion cycles.

The Indonesia Textile Manufacturing Market Report is Segmented by Process Type (Weaving, Knitting, Spinning, and More), by Textile Type (Fabric, Yarn, Fiber, and More), by Material Type (Natural Fibers (Cotton, Silk Etc. ), and More), by Application (Apparel, Home Textiles, and More), and by Region (Java, Sumatra and More). The Report Offers Market Size and Forecasts in Value (USD) for all the Above Segments.

List of Companies Covered in this Report:

- PT Asia Pacific Fibres Tbk

- Indo-Rama Synthetics Tbk

- PT Sri Rejeki Isman Tbk (Sritex)

- PT Tifico Fiber Indonesia Tbk

- PT Pan Brothers Tbk

- PT Ever Shine Tex Tbk

- PT Trisula Textile Industries Tbk

- PT Century Textile Industry Tbk (Toray)

- PT Polychem Indonesia Tbk

- PT Argo Pantes Tbk

- Duniatex Group

- PT Kahatex

- PT Apac Inti Corpora

- PT Eratex Djaja Tbk

- PT Ateja Tritunggal

- PT Sinar Para Taruna

- PT Kewalram Indonesia

- PT Pura Group (Textile Div.)

- PT Multi Garmenjaya

- PT Delami Garment Industries

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Government "Making Indonesia 4.0" incentives accelerating textile automation

- 4.2.2 Rising near-shoring of activewear orders from US & EU brands to Java clusters

- 4.2.3 Boom in Muslim fashion exports driving value-added garment production

- 4.2.4 Surge in e-commerce-led domestic apparel demand among Gen-Z consumers

- 4.2.5 Import-substitution push for man-made fibers amid high cotton dependency

- 4.2.6 Investor tax breaks for green dye-house upgrades in Central Java

- 4.3 Market Restraints

- 4.3.1 Illegal low-priced imports eroding SME weaving margins

- 4.3.2 Chronic port & rail bottlenecks inflating inter-island logistics cost

- 4.3.3 Volatile PLN electricity tariffs squeezing energy-intensive spinning

- 4.3.4 Tight labour pool in West Java driving wage inflation vs. Vietnam

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory & Government-Initiative Outlook

- 4.6 Technological Outlook - Industry 4.0 & Digital Transformation Readiness

- 4.7 Industry Attractiveness - Porter's Five Forces

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Impact of Recent Global Disruptions on the Indonesia Textile Manufacturing Industry

- 4.9 Sustainability & Circular Economy Trends

5 Market Size & Growth Forecasts (Value, In USD Billion)

- 5.1 By Process Type

- 5.1.1 Spinning

- 5.1.2 Weaving

- 5.1.3 Knitting

- 5.1.4 Finishing

- 5.1.5 Other Processes (non-woven)

- 5.2 By Textile Type

- 5.2.1 Fiber

- 5.2.2 Yarn

- 5.2.3 Fabric

- 5.2.4 Garments

- 5.2.5 Other Textiles

- 5.3 By Material Type

- 5.3.1 Natural Fibers (Cotton, Silk etc.)

- 5.3.2 Synthetic Fibers (Polyester, Nylon etc.)

- 5.3.3 Others (Regenerated & Recycled Fibers, Speciality Fibers)

- 5.4 By Application

- 5.4.1 Apparel

- 5.4.2 Home Textiles

- 5.4.3 Technical/Industrial Textiles

- 5.4.4 Other Applications

- 5.5 By Region (Indonesia)

- 5.5.1 Java

- 5.5.2 Sumatra

- 5.5.3 Others (Kalimantan, Sulawesi, Bali, etc.)

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles {(includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Products & Services, and Recent Developments)}

- 6.4.1 PT Asia Pacific Fibres Tbk

- 6.4.2 Indo-Rama Synthetics Tbk

- 6.4.3 PT Sri Rejeki Isman Tbk (Sritex)

- 6.4.4 PT Tifico Fiber Indonesia Tbk

- 6.4.5 PT Pan Brothers Tbk

- 6.4.6 PT Ever Shine Tex Tbk

- 6.4.7 PT Trisula Textile Industries Tbk

- 6.4.8 PT Century Textile Industry Tbk (Toray)

- 6.4.9 PT Polychem Indonesia Tbk

- 6.4.10 PT Argo Pantes Tbk

- 6.4.11 Duniatex Group

- 6.4.12 PT Kahatex

- 6.4.13 PT Apac Inti Corpora

- 6.4.14 PT Eratex Djaja Tbk

- 6.4.15 PT Ateja Tritunggal

- 6.4.16 PT Sinar Para Taruna

- 6.4.17 PT Kewalram Indonesia

- 6.4.18 PT Pura Group (Textile Div.)

- 6.4.19 PT Multi Garmenjaya

- 6.4.20 PT Delami Garment Industries

7 Market Opportunities & Future Outlook

- 7.1 White-Space & Unmet-Need Assessment