|

市场调查报告书

商品编码

1836653

汽车燃油滤清器:市场占有率分析、产业趋势、统计数据和成长预测(2025-2030 年)Automotive Fuel Filter - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

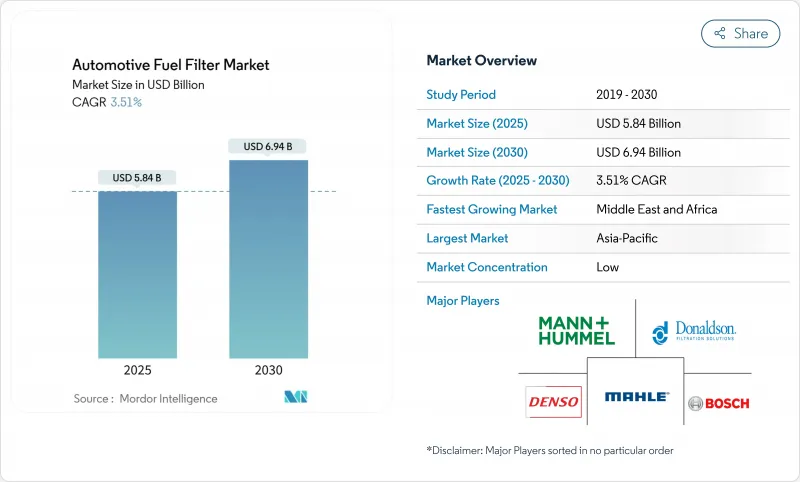

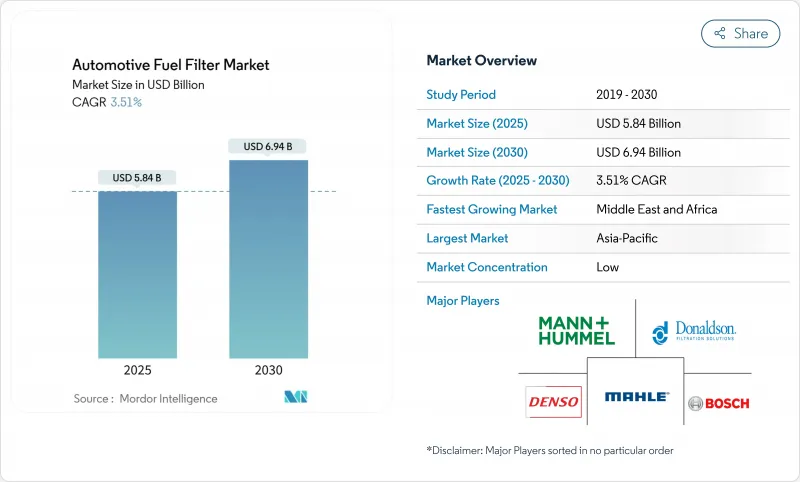

预计汽车燃油滤清器市场规模到 2025 年将达到 58.4 亿美元,到 2030 年将达到 69.4 亿美元,年复合成长率为 3.51%。

由于车辆老化、排放法规趋严以及新兴市场内燃机汽车产量持续成长,抵销了电气化带来的结构性阻力,全球需求仍保持韧性。由于超低硫燃料法规要求采用先进的水分离器设计,柴油应用仍然是重要的收益来源,而生质燃料混合物和压缩天然气则构成了特种滤清器的平行增长通道。亚太和非洲汽车产量的快速成长支撑了对原厂配件的需求,而北美和欧洲则强调更换週期。数位零售、仿冒品风险和密封的「终身」模组正在重塑汽车燃油滤清器市场各个环节的竞争策略。

全球汽车燃油滤清器市场趋势与洞察

全球汽车老化将增加对替换车辆的需求

随着家庭预算收紧和新车库存波动,全球汽车保有量正在成长。主要经合组织 (OECD) 市场的车龄已超过 13 年,导致车辆维护週期延长,滤清器更换频率也更高,以保护敏感的喷油器。配备复杂高压燃油输送系统的轻型卡车和 SUV 正在推动零件周转率。经销商、独立维修店和电器平台正在利用售后市场的这一利好,扩大其在汽车燃油滤清器市场的客户群。零件经销商越来越多地将燃油滤清器与其他维修套件捆绑销售,以在价格敏感的市场中获取整体价值并保住市场份额。

更严格的废气排放法规推动先进过滤的发展

欧6e法规将于2023年9月对新型内燃机车型生效,而欧7法规草案则提案了更低的颗粒物阈值,要求滤材在不牺牲纳污能力的前提下达到亚5微米的过滤效率。与之类似的国六和巴拉特六指令则要求多级过滤和强大的水分离功能。供应商正在与引擎原始设备製造商密切合作,以使滤清器规格与后处理系统保持一致,同时测试通讯协定也在不断收紧,以检验在各种含硫量下的耐久性。低端製造商面临着不断上升的认证成本,这可能会加速汽车燃油滤清器市场的整合。

电动车的加速普及将减少内燃机滤清器的数量

纯电动车将取代燃油滤清器,预计到2030年,其在全球汽车销售中的比例将达到50%。随着製造商改造组装以及政府实施零排放法规,成熟地区的燃油滤清器可维修市场将会萎缩。曾经依赖高利润替换零件的维修店现在正将重点转向电池诊断和软体更新。因此,在电气化进程较慢且辅助燃油模组仍整合到混合动力传动系统中的地区,汽车燃油滤清器市场将迎来显着成长。

报告中分析的其他驱动因素和限制因素

- 亚太和非洲新车产量增加

- 生质燃料混合物的激增需要相容性升级

- 钢铁和聚合物投入价格波动对净利率带来压力

細項分析

到 2024 年,柴油应用将成为最大的收益,占汽车燃油滤清器市场份额的 48.37%,因为卡车、非公路用车和许多 SUV 都需要强大的水分离技术。超低硫法规使油箱内部暴露于冷凝和微生物污染之中,这也支持了柴油滤清器的成长。车队营运商正在寻找能够捕获小至 2 微米颗粒并同时回收游离水的过滤器。工程师正在开发能够抵抗酯膨胀和甲烷特定污染物的弹性体和密封剂。替代燃料是成长最快的部分,到 2030 年的复合年增长率为 9.38%。印度的 CNG 公车和巴西的市政车队正在支撑早期的销售量,但这一部分的技术要求与柴油有很大不同,因此需要专门的 SKU 来控制溢价。

儘管汽油动力汽车市场面临电动车普及的压力,但在北美和欧洲部分地区,由于平均行驶里程数居高不下且停车场老化,汽油动力汽车市场仍保持着重要的地位。高压缸内喷油系统需要亚5微米的过滤和对乙醇的耐化学性。供应商收到独立维修店的稳定补货订单,这些维修店将滤清器更换与定期换油同步进行,增强了售后市场的韧性。柴油机製造商也在选择性催化还原方面进行创新,并加入了可在压差超出规定范围时向操作员发出警报的传感器。这些诊断趋势确保了替换零件的稳定供应,从而为整个汽车燃油滤清器市场带来了稳定的收益。

纤维素仍将是使用最广泛的介质,由于其生产成本低廉且原材料丰富,到 2024 年将占销售额的 44.19%。然而,其固有的亲水性和有限的耐温性使其难以用于生质燃料混合物。因此,生产商在纤维素纤维上涂覆疏水剂,同时增加褶皱数以增强纳污能力。合成复合材料、聚酯、聚丙烯和多层奈米纤维是成长最快的类别,复合年增长率为 5.72%。这些介质提供更长的维护间隔、更低的压力差,并且与腐蚀性燃料化学品相容。水分离器滤芯越来越多地采用双区设计,将褶皱合成纤维层与聚结绒相结合,可在排出之前将微滴压成更大的珠子。

处理公司正在投资等离子处理和表面接枝技术,以调整纤维的极性。广泛采用的方法是将氟化硅烷连接到聚酯上,使水接触角超过150°,并能抵抗富含界面活性剂的柴油。在高端市场,熔喷奈米纤维层可增强基体介质,阻挡亚微米颗粒,这对于超高压共轨柴油泵至关重要。拥有内部熔喷资产的製造商可以获得规模优势,从而从垂直整合的薄膜生产中获得更多价值。

区域分析

亚太地区以中国、印度、泰国和印尼的汽车生产为主,到2024年,该地区将维持41.85%的汽车燃油滤清器市场份额。印度与生产连结奖励计画的倡议计画已调动了数兆卢比的资本投资承诺,政策制定者预计零件出口也将呈现类似的成长轨迹。本地供应商正在与汽车製造商丛集相邻,以降低物流成本并利用熟练劳动力。儘管中国加大了对新能源汽车的推广力度,但传统的汽油和柴油平台仍然在郊区和农村地区占据主导地位,形成了稳定的更换週期。本土零件品牌正在加强对中东、东欧和南美的出口,其性价比在这些地区颇具吸引力。

中东和非洲是成长最快的地区,预计到2030年复合年增长率将达到5.11% 。波湾合作理事会国家正在利用碳氢化合物来实现道路建设、货运走廊和公共交通的现代化,并扩大其公车和商用卡车车队。环境湿度低往往会加剧燃料箱凝结,因此可靠的水分离能力尤其重要。进口商从欧洲和亚洲采购滤清器,但越来越多地考虑在岸组装,以促进就业并缩短前置作业时间。在撒哈拉以南非洲地区,由于机动车保有量低,加上排放气体法规宽鬆,导致传统柴油继续盛行,从而保护了汽车燃油滤清器市场免受电器产品的侵占。

由于电气化奖励和密封模组销售萎缩,北美和欧洲市场呈现温和成长。然而,更严格的颗粒物法规和缸内喷油的普及,迫使高端汽车升级,从而维持了平均售价。研讨会正在推广配套服务套餐,以抵消车辆需求的下降。再生滤清器方案在註重环保的驾驶中越来越受欢迎,他们希望在不影响保固的情况下减少对环境的影响。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场状况

- 市场概况

- 市场驱动因素

- 全球汽车保有量老化导致更换需求增加

- 更严格的废气排放法规推动先进过滤的发展

- 亚太和非洲新车产量增加

- 生质燃料混合物的激增需要相容性升级

- 超低硫柴油推动水分离过滤器需求

- 需要亚 5µm过滤的高压 GDI 和 CRDI 系统的成长

- 市场限制

- 由于电动车普及率加快,内燃机滤清器数量减少

- 钢铁和聚合物投入价格波动导致利润压力

- OEM转向密封「终身」燃油模组抑製售后市场

- 假冒廉价过滤器在开发中国家猖獗

- 价值/供应链分析

- 监管状况

- 技术展望

- 波特五力分析

- 新进入者的威胁

- 买家/消费者的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争强度

第五章市场规模与成长预测:价值(美元)、数量(单位)

- 按燃料类型

- 汽油

- 柴油引擎

- 替代燃料

- 按滤材

- 纤维素

- 合成材料(玻璃和聚酯)

- 多层复合材料

- 水分离器/聚结器元件

- 按车辆类型

- 搭乘用车

- 掀背车

- 轿车

- 运动型多用途车

- 多用途车辆

- 轻型商用车

- 中大型商用车

- 摩托车

- 非公路用车

- 农业机械

- 建筑和采矿设备

- 搭乘用车

- 按销售管道

- OEM

- 售后市场

- 有组织的零售商

- 独立车库

- 线上平台

- 按地区

- 北美洲

- 美国

- 加拿大

- 北美其他地区

- 南美洲

- 巴西

- 阿根廷

- 其他南美

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 其他欧洲国家

- 亚太地区

- 中国

- 日本

- 印度

- 韩国

- 澳洲和纽西兰

- 其他亚太地区

- 中东和非洲

- 沙乌地阿拉伯

- 阿拉伯聯合大公国

- 土耳其

- 南非

- 埃及

- 其他中东和非洲地区

- 北美洲

第六章 竞争态势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- MANN+HUMMEL

- Donaldson Company, Inc.

- MAHLE GmbH

- Robert Bosch GmbH

- DENSO CORPORATION

- Cummins Inc.(Fleetguard)

- Parker Hannifin Corp(Racor)

- Sogefi Group

- Hengst SE

- UFI Filters

- Baldwin Filters

- Fram Group

- K&N Engineering Inc.

- ACDelco(General Motors)

- Champion Laboratories

第七章 市场机会与未来展望

The automotive fuel filter market was worth USD 5.84 billion in 2025 and is forecast to reach USD 6.94 billion by 2030, reflecting a moderate 3.51% CAGR.

Global demand remains resilient as ageing vehicle fleets, stricter emission rules, and sustained production of internal-combustion vehicles in emerging economies offset the structural headwinds of electrification. Diesel applications preserve a sizeable revenue base because ultra-low-sulphur fuel legislation compels advanced water-separator designs, while bio-fuel blends and compressed natural gas create a parallel growth corridor for specialised filters. Rapid vehicle output in Asia-Pacific and Africa underpins original-equipment demand, whereas North America and Europe shift focus toward the replacement cycle. Digital retail, counterfeit risks, and sealed "lifetime" modules are reshaping competitive strategies across all tiers of the automotive fuel filter market.

Global Automotive Fuel Filter Market Trends and Insights

Ageing Global Vehicle Parc Expanding Replacement Demand

Global fleets are staying on the road for longer as household budgets tighten and new-car inventories fluctuate. Average passenger-car age in major OECD markets now exceeds 13 years, and extended maintenance schedules drive more frequent filter replacement to protect sensitive injectors. Light trucks and SUVs, which contain complex high-pressure fuel delivery systems, add to parts turnover. Dealers, independent garages, and e-commerce platforms leverage this aftermarket tailwind, enlarging the customer pool for the automotive fuel filter market. Parts distributors increasingly bundle fuel filters with other service kits to capture basket value and defend share in a price-sensitive environment.

Tighter Tail-Pipe Emission Norms Driving Advanced Filtration

Euro 6e rules took effect for new internal-combustion models in September 2023, and draft Euro 7 standards propose even lower particulate thresholds, forcing filter media to achieve sub-5-micron efficiency without sacrificing dirt-holding capacity. Comparable China VI and Bharat VI mandates require multi-stage filtration and robust water separation. Suppliers collaborate closely with engine OEMs to align filter specifications with after-treatment systems, while testing protocols have become stricter to validate durability across varying sulfur levels. Down-tier manufacturers face rising certification costs that may accelerate consolidation inside the automotive fuel filter market.

Accelerating EV Penetration Cannibalizing ICE Filter Volumes

Battery-electric vehicles eliminate the need for fuel filtration, and their share of world car sales is projected to reach 50% by 2030. As manufacturers convert assembly lines and governments introduce zero-emission mandates, the serviceable market for fuel filters in mature regions declines. Workshops that once relied on high-margin replacement parts now pivot toward battery diagnostics and software updates. The automotive fuel filter market, therefore, grows largely where electrification rollouts are slower or where hybrid powertrains still incorporate auxiliary fuel modules.

Other drivers and restraints analyzed in the detailed report include:

- Rising New-Vehicle Output in Asia-Pacific and Africa

- Surge in Bio-Fuel Blends Requiring Compatibility Upgrades

- Volatile Steel and Polymer Input Prices Squeezing Margins

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Diesel applications generated the highest revenue in 2024, holding 48.37% of the automotive fuel filter market share because trucks, off-highway machinery, and many SUVs require robust water-separator technology. Growth is sustained by ultra-low-sulfur mandates that expose tanks to condensation and microbial contamination. Fleet operators prize filters that trap particles down to 2 microns while collecting free water. Engineers are adapting elastomers and sealants to resist ester-induced swelling and methane-specific contaminants. Alternative fuels represent the fastest-growing segment at 9.38% CAGR through 2030. CNG buses in India and municipal fleets in Brazil underpin early volume, yet the segment's technical requirements differ sharply from diesel, leading to specialised SKUs that command premium pricing.

The gasoline category, although pressured by electric-vehicle uptake, retains importance in ageing car parks across North America and parts of Europe where average mileage remains high. High-pressure gasoline direct injection systems demand sub-5-micron filtration and chemical resistance to ethanol. Suppliers see steady replenishment orders from independent workshops that align filter swaps with scheduled oil changes, reinforcing aftermarket stickiness. Diesel manufacturers also innovate around selective catalytic reduction, embedding sensors to alert operators when differential pressure rises beyond specification. This diagnostic trend ensures consistent pull-through for replacement parts and supports overall revenue stability in the automotive fuel filter market.

Cellulose remained the most widely used medium, contributing 44.19% of 2024 revenue thanks to low production cost and abundant feedstock. Yet its innate hydrophilicity and limited temperature resistance challenge its suitability for bio-fuel blends. Producers therefore coat cellulose fibres with hydrophobic agents while boosting pleat counts to raise dirt-holding capacity. Synthetic composites, polyester, polypropylene, and multi-layer nanofibers form the fastest-growing cohort at a 5.72% CAGR. These media achieve longer service intervals, lower differential pressure, and compatibility with aggressive fuel chemistries. Water-separator cartridges increasingly incorporate dual-zone designs, pairing a pleated synthetic layer with a coalescing fleece that forces micro-droplets to form larger beads before drainage.

Suppliers invest in plasma treatment and surface grafting to tailor fibre polarity. One widely adopted method bonds fluorinated silanes onto polyester, achieving water contact angles above 150° and resisting surfactant-rich diesel. In premium segments, melt-blown nanofibre layers augment base media to block particles below 1 micron, essential for ultra-high-pressure common-rail diesel pumps. Fabricators with in-house melt-blown assets gain scale advantages because they capture more value from vertically integrated membrane production.

The Automotive Fuel Filters Market Report is Segmented by Fuel Type (Gasoline, Diesel, and Alternative Fuels), Filter Media (Cellulose, Synthetic (Glass and Polyester), and More), Vehicle Type (Passenger Cars, Light Commercial Vehicles, Medium and Heavy Commercial Vehicles, and More), Sales Channel (OEM and Aftermarket), and Geography. The Market Forecasts are Provided in Terms of Value (USD) and Volume (Units).

Geography Analysis

Asia-Pacific retained a commanding 41.85% share of the automotive fuel filter market in 2024, driven by prolific vehicle production across China, India, Thailand, and Indonesia. India's Production Linked Incentive initiative has mobilized trillions of rupees in capex commitments, and policy planners expect component exports to follow similar trajectories. Local suppliers co-locate near OEM clusters to lower logistics costs and tap skilled labour pools. Even as China intensifies its new-energy-vehicle push, legacy gasoline and diesel platforms still dominate suburban and rural fleets, creating a steady replacement cycle. Domestic component brands strengthen export footprints into the Middle East, Eastern Europe, and South America, where their cost-to-performance ratio resonates.

The Middle East and Africa region is the fastest-growing territory, forecast at 5.11% CAGR through 2030. Gulf Cooperation Council states allocate hydrocarbons windfalls to road construction, freight corridors, and public-transport modernisation, which enlarges the rolling stock of buses and commercial trucks. Low ambient humidity often accelerates fuel tank condensation, elevating the importance of reliable water-separation features. Importers source filters from Europe and Asia but increasingly explore onshore assembly to stimulate jobs and shorten lead times. Sub-Saharan Africa's young vehicle parc, coupled with lenient emission schedules, allows conventional diesel to remain prevalent, cushioning the automotive fuel filter market against electric encroachment.

North America and Europe exhibit modest growth as electrification incentives and sealed modules shrink volumes. Nevertheless, stringent particulate regulations and widespread adoption of gasoline direct injection force premium media upgrades, preserving average selling prices. Workshops promote bundled service packages to offset declining unit demand. Remanufactured filter programs gain popularity among eco-conscious drivers who seek lower environmental footprints without compromising warranty.

- MANN+HUMMEL

- Donaldson Company, Inc.

- MAHLE GmbH

- Robert Bosch GmbH

- DENSO CORPORATION

- Cummins Inc. (Fleetguard)

- Parker Hannifin Corp (Racor)

- Sogefi Group

- Hengst SE

- UFI Filters

- Baldwin Filters

- Fram Group

- K&N Engineering Inc.

- ACDelco (General Motors)

- Champion Laboratories

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Ageing global vehicle parc expanding replacement demand

- 4.2.2 Tighter Tail-Pipe Emission Norms Driving Advanced Filtration

- 4.2.3 Rising new-vehicle output in Asia-Pacific and Africa

- 4.2.4 Surge in bio-fuel blends requiring compatibility upgrades

- 4.2.5 Ultra-low-sulfur diesel boosting water-separator filter demand

- 4.2.6 Growth of high-pressure GDI and CRDI systems demanding Below 5 µm filtration

- 4.3 Market Restraints

- 4.3.1 Accelerating EV penetration cannibalizing ICE filter volumes

- 4.3.2 Volatile steel and polymer input prices squeezing margins

- 4.3.3 OEM shift toward sealed "lifetime" fuel modules curbing aftermarket

- 4.3.4 Proliferation of counterfeit low-cost filters in developing nations

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers/Consumers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitute Products

- 4.7.5 Intensity of Competitive Rivalry

5 Market Size and Growth Forecasts (Value (USD) and Volume (Units))

- 5.1 By Fuel Type

- 5.1.1 Gasoline

- 5.1.2 Diesel

- 5.1.3 Alternative Fuels

- 5.2 By Filter Media

- 5.2.1 Cellulose

- 5.2.2 Synthetic (Glass and Polyester)

- 5.2.3 Multi-layer Composites

- 5.2.4 Water-Separator / Coalescer Elements

- 5.3 By Vehicle Type

- 5.3.1 Passenger Cars

- 5.3.1.1 Hatchback

- 5.3.1.2 Sedan

- 5.3.1.3 Sport Utility Vehicle

- 5.3.1.4 Multi-Purpose Vehicle

- 5.3.2 Light Commercial Vehicles

- 5.3.3 Medium and Heavy Commercial Vehicles

- 5.3.4 Two-Wheelers

- 5.3.5 Off-Highway

- 5.3.5.1 Agricultural Machinery

- 5.3.5.2 Construction and Mining Machinery

- 5.3.1 Passenger Cars

- 5.4 By Sales Channel

- 5.4.1 OEM

- 5.4.2 Aftermarket

- 5.4.2.1 Organized Retailers

- 5.4.2.2 Independent Garages

- 5.4.2.3 Online Platforms

- 5.5 Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Rest of North America

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Russia

- 5.5.3.7 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 Japan

- 5.5.4.3 India

- 5.5.4.4 South Korea

- 5.5.4.5 Australia and New Zealand

- 5.5.4.6 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 United Arab Emirates

- 5.5.5.3 Turkey

- 5.5.5.4 South Africa

- 5.5.5.5 Egypt

- 5.5.5.6 Rest of Middle East and Africa

- 5.5.1 North America

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (Includes Global Level Overview, Market Level Overview, Core Segments, Financials as Available, Strategic Information, Market Rank/Share for Key Companies, Products and Services, SWOT Analysis, and Recent Developments)

- 6.4.1 MANN+HUMMEL

- 6.4.2 Donaldson Company, Inc.

- 6.4.3 MAHLE GmbH

- 6.4.4 Robert Bosch GmbH

- 6.4.5 DENSO CORPORATION

- 6.4.6 Cummins Inc. (Fleetguard)

- 6.4.7 Parker Hannifin Corp (Racor)

- 6.4.8 Sogefi Group

- 6.4.9 Hengst SE

- 6.4.10 UFI Filters

- 6.4.11 Baldwin Filters

- 6.4.12 Fram Group

- 6.4.13 K&N Engineering Inc.

- 6.4.14 ACDelco (General Motors)

- 6.4.15 Champion Laboratories

7 Market Opportunities and Future Outlook

- 7.1 White-space & Unmet-need Assessment