|

市场调查报告书

商品编码

1836709

氟聚合物涂料:市场份额分析、产业趋势、统计数据和成长预测(2025-2030 年)Fluoropolymer Coatings - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

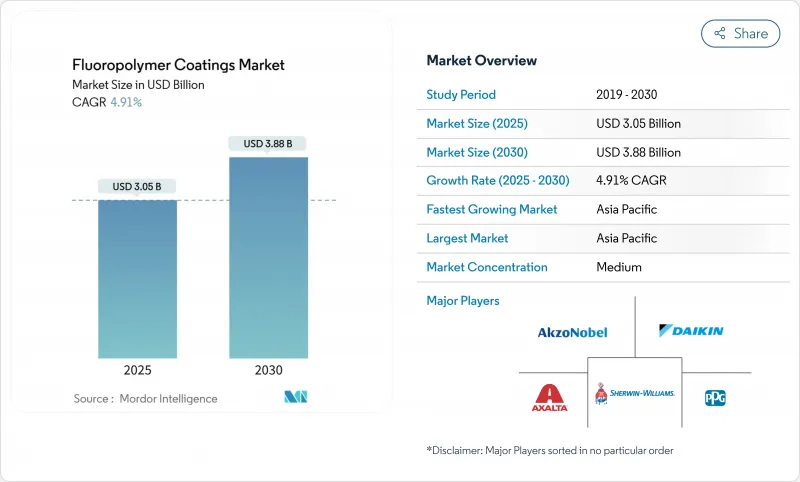

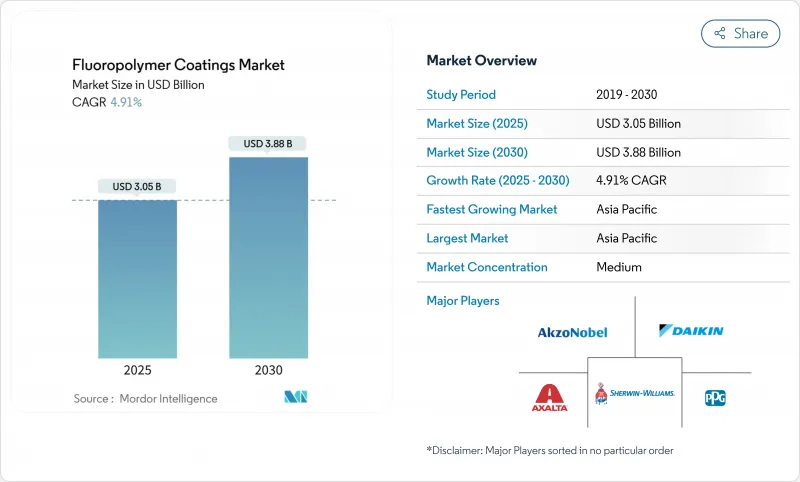

预计氟聚合物涂料市场规模在 2025 年将达到 30.5 亿美元,到 2030 年预计将达到 38.8 亿美元,预测期内(2025-2030 年)的复合年增长率为 4.91%。

儘管监管机构加强了对全氟和多氟烷基物质 (PFAS) 的审查,但在腐蚀性、高温和高电气要求环境下,对高性能表面保护的需求不断增长,这将继续支撑其成长。离岸风力发电、电动车动力传动系统和锂离子电池超级工厂的投资不断增长,支撑了中期成长势头,而氢气管道的建设则带来了长期的量产机会。

全球氟聚合物涂料市场趋势与洞察

离岸风力发电机塔架防腐涂料的需求不断增加

离岸风力发电的快速成长推动了对性能的要求,超越了传统环氧系统。如今,氟聚合物配方采用了有机-无机杂化材料,能够抵御海水、盐雾和积冰等可能导致涡轮机功率输出降低30%的因素。涂层寿命预计将延长至10-12年,使部署在深水中的下一代浮体式平台的维护窗口翻倍。原型溶胶-凝胶系统可提供强大的金属附着力,从而降低底漆腐蚀和停机成本,从而帮助营运商实现25年的使用寿命。

低摩擦涂层在电动车动力传动系统中的应用正在蓬勃发展。

电动车传动系统的运转转速、温度和电压都高于内燃机,这会导致摩擦应力增加。氟聚合物涂层可降低表面能,最大程度减少电弧放电,并保护 800V 电桥中的铜导体,从而将传动系统的整体效率提高 3-5%。领先的原始设备製造商 (OEM) 正在将 PTFE 改质涂层应用于轴承和花键齿轮,从而实现更小的润滑系统,延长零件寿命和续航里程。这些解决方案在中端电动车车型的标准化预计将在 2020 年下半年加速涂层产量的成长。

萤石衍生氢氟酸的供应和定价不稳定

中国控制着全球一半以上的萤石开采量,并收紧了出口配额以维持增值生产,挤压了外部氟化氢酸生产商。预计2024年现货价格将再次飙升,促使大型氟聚合物製造商签订多年合约并增加库存。规模较小的氟聚合物製造商面临利润率下降、订单量下降以及交付中断风险增加等问题,促使企业进行整合,以提高议价能力和供应链韧性。

报告中分析的其他驱动因素和限制因素

- 智慧烹调器具中高温不沾涂层的成长

- PVDF内衬锂离子电池超级工厂扩建

- 严格的环境政策和法规

細項分析

PTFE 在 2024 年保持了 44% 的氟聚合物涂料市场份额,因为其 260°C 的使用温度和化学惰性使其可用于半导体蚀刻工具、食品输送机和化学反应器等重型应用。

PVDF 的复合年增长率最高,达到 5.33%,主要用于锂离子正极黏合剂、隔膜和半导体洁净室硬件,这些材料的介电强度和溶剂相容性至关重要。扩大北美和欧洲的产能将确保区域供应稳定,而在地化生产将最大限度地降低碳排放和关税,从而进一步增强 PVDF 的成长潜力。

63% 的氟聚合物涂料市场是液体,水性涂料可在不损害薄膜完整性的情况下减少 VOC,有助于满足严格的加州和欧盟排放法规。

粉末涂料的 VOC 含量接近零,且过喷可回收,到 2030 年,其复合年增长率将达到 5.5%。 CARC 认证的粉末面漆等发展缩短了施工时间,同时为军事资产提供了耐化学性,将粉末涂料推向了以前由液体系统主导的航太、航海和重型机械领域。

区域分析

受中国庞大的氟化学产业基础和大规模可再生能源建设的推动,到2024年,亚太地区将占据氟聚合物涂料市场份额的44%。在印度,刺激电子和太阳能製造业的激励措施正在创造对防腐工厂设备涂料的持续需求。日本和韩国将保持主导,推动该地区的技术前沿发展,并稳定高端涂料的消费。

北美将受益于製造业回流,将推动PVDF和PTFE的国内生产,保护主要的电池和航太产业免受供应衝击。联邦政府的激励措施将鼓励需要ETFE内衬辅助设备的氢能计划,进一步刺激需求。

在欧洲,高环保标准与工业需求并进。德国和英国的离岸风力发电塔建造商正在指定使用寿命氟聚合物层,以最大限度地减少北海昂贵的维护宣传活动。然而,即将推出的PFAS法规迫使复合材料製造商考虑封闭式回收和低排放製造,以确保长期生存能力。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场状况

- 市场概况

- 市场驱动因素

- 离岸风力发电机塔架防腐涂料的需求不断增加

- 低摩擦涂层在电动车动力传动系统部件中快速应用

- 智慧烹调器具中高温不沾涂层的成长

- 北美和欧洲PVDF内衬锂离子电池超级工厂的扩建

- 氢气管道计划激增推动ETFE和FEP涂层需求

- 市场限制

- 受中国出口配额影响,萤石衍生氢氟酸的供应和价格不稳定

- 来自业界低成本防护涂层的竞争

- 严格的环境法规和政策

- 价值链分析

- 五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章 市场规模及成长预测(金额)

- 依树脂类型

- 聚四氟乙烯(PTFE)

- 聚二氟亚乙烯(PVDF)

- 氟化乙丙烯(FEP)

- 乙烯-四氟乙烯(ETFE)

- 全氟烷氧基烷烃(PFA)

- 聚氟乙烯(PVF)

- 其他树脂类型

- 按涂层技术

- 液体

- 粉末

- 按基材

- 金属

- 塑胶

- 复合材料

- 按用途

- 产业

- 建筑/施工

- 车

- 食品加工

- 航空航太

- 电

- 烹调器具

- 其他用途

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 义大利

- 法国

- 其他欧洲国家

- 南美洲

- 巴西

- 阿根廷

- 其他南美

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争态势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- AkzoNobel NV

- Arkema SA

- Axalta Coating Systems LLC

- Beckers Group

- Berger Paints India Ltd.

- Daikin Industries, Ltd.

- Dongyue Group Co., Ltd.

- Endura Coatings

- Hempel A/S

- Jiangsu Chenguang Fluoropolymer Co., Ltd.

- Jotun

- NIC Industries Inc.

- PPG Industries, Inc.

- Praxair Surface Technologies, Inc.

- Precision Coating Company, LLC(Integer Holdings Corporation)

- Solvay SA

- The Chemours Company

- The Sherwin-Williams Company

- Tnemec Company Inc.

- Walter Wurdack Inc.

- Whitford Corporation

第七章 市场机会与未来展望

The Fluoropolymer Coatings Market size is estimated at USD 3.05 billion in 2025, and is expected to reach USD 3.88 billion by 2030, at a CAGR of 4.91% during the forecast period (2025-2030).

Rising demand for high-performance surface protection in corrosive, high-temperature, and electrically demanding environments continues to underpin growth even as regulators tighten oversight of per- and polyfluoroalkyl substances (PFAS). Expanded investments in offshore wind farms, electric-vehicle powertrains, and lithium-ion battery gigafactories are anchoring mid-term momentum, while hydrogen pipeline build-outs promise long-term volume opportunities.

Global Fluoropolymer Coatings Market Trends and Insights

Increased Demand for Anti-corrosive Coatings in Offshore Wind Turbine Towers

Surging offshore wind installations are elevating performance requirements beyond conventional epoxy systems. Fluoropolymer formulations now integrate organic-inorganic hybrids that resist seawater, salt spray, and ice accumulation that can cut turbine output by 30%. Coating lifetimes are projected to stretch to 10 - 12 years, doubling the maintenance window for next-generation floating platforms deployed in deeper waters. Prototype sol-gel systems deliver strong metal adhesion, reducing under-film corrosion and cutting downtime expenses for operators who target 25-year service lives.

Fast-growing Adoption of Low-Friction Coatings in Electric-Vehicle Powertrains

Electrified drivetrains operate at higher rpm, temperature, and voltage than internal-combustion engines, amplifying tribological stress. Fluoropolymer layers reduce surface energy, minimize arcing, and protect copper conductors in 800 V e-axles, raising overall drivetrain efficiency by 3-5%. Leading OEMs specify PTFE-modified coatings on bearings and spline gears to enable downsized lubrication systems, extending part life and boosting range. Standardization of these solutions across mid-segment EV models will accelerate coating volumes by the latter half of the decade.

Volatile Supply and Pricing of Fluorspar-derived HF Acid

China controls well over half of mined fluorspar and tightens export quotas to retain value-added production, squeezing external producers of HF acid. Spot prices rose sharply again in 2024, prompting larger fluoropolymer makers to lock multi-year contracts and build stockpiles. Smaller coaters face margin erosion, shortened order books, and greater exposure to delivery disruptions, encouraging mergers aimed at negotiating power and supply-chain resilience.

Other drivers and restraints analyzed in the detailed report include:

- Growth of High-temperature Non-stick Coatings in Smart Cookware

- Expansion of PVDF-lined Lithium-ion Battery Gigafactories

- Strict Environmental Policies and Regulations

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

PTFE maintained 44% of fluoropolymer coatings market share in 2024 because its 260 °C service temperature and chemical inertness serve harsh duties in semiconductor etching tools, food-grade conveyors, and chemical reactors.

PVDF, posting the fastest 5.33% CAGR, is leveraged in lithium-ion cathode binders, separator films, and semiconductor clean-room hardware where its dielectric strength and solvent compatibility are critical. Capacity expansions in North America and Europe lock in regional security of supply, while localized production minimizes carbon footprints and tariffs, further entrenching PVDF's trajectory.

Liquid formulations held 63% of fluoropolymer coatings market size. Waterborne variants that slash VOCs without compromising film integrity are helping manufacturers comply with stringent emission rules in California and the EU.

Powder coatings deliver near-zero VOCs and over-spray recyclability, propelling a 5.5% CAGR through 2030. Developments such as CARC-qualified powder topcoats offer chemical-agent resistance for military assets while cutting application time, broadening powder use into aerospace, maritime, and heavy equipment segments formerly dominated by liquid systems.

The Fluoropolymer Coatings Market Report Segments the Industry by Resin Type (Polytetrafluoroethylene (PTFE), Polyvinylidene Fluoride (PVDF), and More), Coating Technology (Liquid and Powder), Substrate (Metal, Plastic, and Composite and Others), Application (Industrial, Building and Construction, Automotive, Food Processing, Cookware, and More), and Geography (Asia-Pacific, North America, Europe, and More).

Geography Analysis

Asia Pacific accounted for 44% of fluoropolymer coatings market share in 2024, driven by China's extensive fluorochemicals base and massive renewable-energy build-out. India follows with incentives that stimulate electronics and PV manufacturing, creating sustained coating demand for anti-corrosive plant equipment. Japan and South Korea maintain leadership in semiconductors, pushing the region's technology frontier and thereby steadying premium coating consumption.

North America benefits from reshoring that promotes domestic PVDF and PTFE production, insulating battery and aerospace primes from supply shocks. Federal incentives catalyze hydrogen projects that call for ETFE-lined balance-of-plant hardware, further bolstering demand.

Europe balances high environmental standards with industrial necessity. Offshore-wind tower builders in Germany and the United Kingdom specify long-life fluoropolymer layers to minimize expensive North Sea maintenance campaigns. Nevertheless, the looming PFAS restriction forces formulators to examine closed-loop recycling and lower-emission manufacturing to secure long-term viability.

- AkzoNobel N.V.

- Arkema SA

- Axalta Coating Systems LLC

- Beckers Group

- Berger Paints India Ltd.

- Daikin Industries, Ltd.

- Dongyue Group Co., Ltd.

- Endura Coatings

- Hempel A/S

- Jiangsu Chenguang Fluoropolymer Co., Ltd.

- Jotun

- NIC Industries Inc.

- PPG Industries, Inc.

- Praxair Surface Technologies, Inc.

- Precision Coating Company, LLC (Integer Holdings Corporation)

- Solvay SA

- The Chemours Company

- The Sherwin-Williams Company

- Tnemec Company Inc.

- Walter Wurdack Inc.

- Whitford Corporation

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Increased Demand for Anti-corrosive Coatings in Offshore Wind Turbine Towers

- 4.2.2 Fast-growing Adoption of Low-Friction Coatings in Electric Vehicle Powertrain Components

- 4.2.3 Growth of High-temperature Non-stick Coatings in Smart Cookware

- 4.2.4 Expansion of PVDF-lined Lithium-ion Battery Gigafactories in the North America and Europe

- 4.2.5 Surge in Hydrogen Pipeline Projects Driving ETFE and FEP Coatings

- 4.3 Market Restraints

- 4.3.1 Volatile Supply and Pricing of Fluorspar-derived HF Acid Due to Chinese Export Quotas

- 4.3.2 Competition from Low-priced Protective Coatings Available in the Industry

- 4.3.3 Strict Environmental Policies and Regulations

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Consumers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitute Products and Services

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Resin Type

- 5.1.1 Polytetrafluoroethylene (PTFE)

- 5.1.2 Polyvinylidene Fluoride (PVDF)

- 5.1.3 Fluorinated Ethylene Propylene (FEP)

- 5.1.4 Ethylene Tetrafluoroethylene (ETFE)

- 5.1.5 Perfluoroalkoxy Alkanes (PFA)

- 5.1.6 Polyvinyl Fluoride (PVF)

- 5.1.7 Other Resin Types

- 5.2 By Coating Technology

- 5.2.1 Liquid

- 5.2.2 Powder

- 5.3 By Substrate

- 5.3.1 Metal

- 5.3.2 Plastic

- 5.3.3 Composite and Others

- 5.4 By Application

- 5.4.1 Industrial

- 5.4.2 Building and Construction

- 5.4.3 Automotive

- 5.4.4 Food Processing

- 5.4.5 Aviation and Aerospace

- 5.4.6 Electrical

- 5.4.7 Cookware

- 5.4.8 Other Applications

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 Italy

- 5.5.3.4 France

- 5.5.3.5 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 South Africa

- 5.5.5.3 Rest of Middle East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves (Merger and Acquisition, JV, Capacity Expansions)

- 6.3 Market Share Analysis

- 6.4 Company Profiles {(includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)}

- 6.4.1 AkzoNobel N.V.

- 6.4.2 Arkema SA

- 6.4.3 Axalta Coating Systems LLC

- 6.4.4 Beckers Group

- 6.4.5 Berger Paints India Ltd.

- 6.4.6 Daikin Industries, Ltd.

- 6.4.7 Dongyue Group Co., Ltd.

- 6.4.8 Endura Coatings

- 6.4.9 Hempel A/S

- 6.4.10 Jiangsu Chenguang Fluoropolymer Co., Ltd.

- 6.4.11 Jotun

- 6.4.12 NIC Industries Inc.

- 6.4.13 PPG Industries, Inc.

- 6.4.14 Praxair Surface Technologies, Inc.

- 6.4.15 Precision Coating Company, LLC (Integer Holdings Corporation)

- 6.4.16 Solvay SA

- 6.4.17 The Chemours Company

- 6.4.18 The Sherwin-Williams Company

- 6.4.19 Tnemec Company Inc.

- 6.4.20 Walter Wurdack Inc.

- 6.4.21 Whitford Corporation

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-need Assessment

- 7.2 Sustainable and Eco-Friendly Coatings