|

市场调查报告书

商品编码

1836724

喷涂胶:市场占有率分析、产业趋势、统计数据和成长预测(2025-2030 年)Spray Adhesive - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

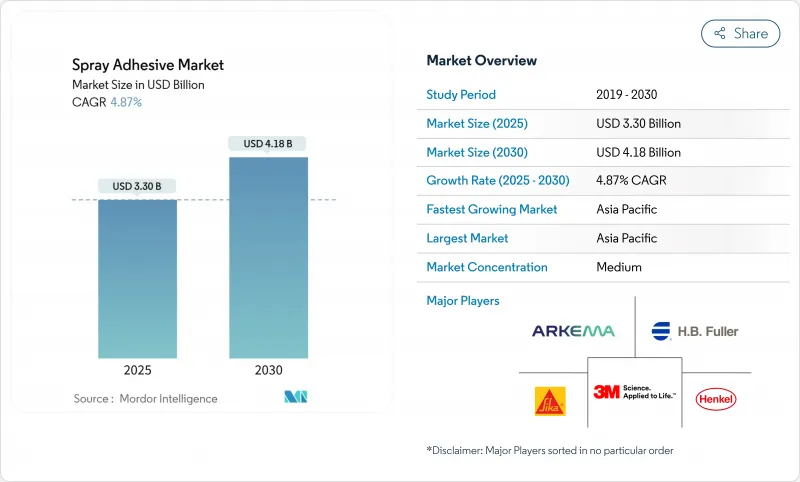

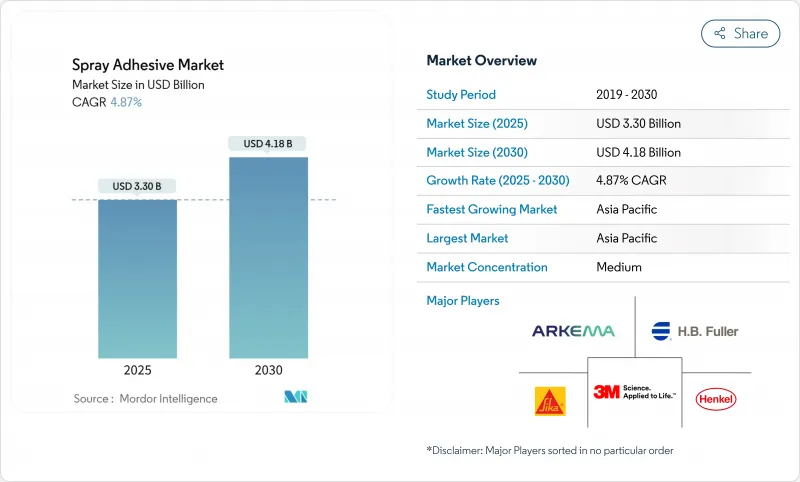

预计喷涂胶黏剂市场在 2025 年的价值将达到 33 亿美元,到 2030 年预计将成长至 41.8 亿美元,复合年增长率稳定在 4.87%。

儘管挥发性有机化合物 (VOC) 法规日益严格,但需求仍然强劲,因为生产商不断改进水性和热熔性化学品,使其黏合强度与传统溶剂型产品相当。成长主要集中在亚太地区,该地区的大型基础设施项目、不断扩张的家具出口基地以及不断深化的汽车供应链都需要快速、大批量的黏合剂解决方案。全球电商物流也蓬勃发展,履约中心指定使用气雾剂和热熔胶产品,以缩短包装时间。虽然竞争压力仍然适中,但价格敏感的买家可以从区域供应商那里获得新的选择,这些供应商可以以更低的成本复製优质化学品,同时透过永续的性能升级实现差异化。汽车轻量化、预製建筑和卫生食品包装等结构性驱动因素保护了喷涂胶合剂市场免受任何单一行业波动的影响,从而保持了终端用途的多样性。

全球喷涂胶黏剂市场趋势与洞察

新兴国家建筑业快速成长

中国、印度、印尼和海湾国家快速的公共和私人基础设施投资正在推动建筑化学品(包括喷涂胶)销售的持续成长。预製墙板、吸音板和隔热板都依靠高性能黏合剂来承受温度变化和地震荷载。一些地方政府的住房计画指定使用低VOC黏合剂以满足绿色建筑规范,这促使承包商转向水性喷涂系统。模组化建筑商青睐可携式罐式钻机,这可以减少过度喷涂和工时并提高大型计划的吞吐量。随着都市化的加速,当地公司正在采用即时固化热熔喷涂线,以便在高层建筑中快速组装厨柜和室内设备。这些共同的力量将喷涂胶市场与建筑活动紧密联繫在一起,特别是在亚太地区快速发展的特大城市。

转向水性、低VOC黏合剂

三大洲的监管机构均降低了排放上限,促使胶合剂製造商推出黏性和耐热性可与溶剂型系统相媲美的水性系统。德克萨斯州环境品质委员会修订了其规则,要求休士顿地区每天减少 3.12 吨 VOC,加州有毒物质控制部将喷涂胶列入其 2024-2026 年优先产品行动计画。陶氏的 PRIMAL CA 750 和 3M 的 Fastbond 1049 证明,水性聚合物无需昂贵的通风升级即可满足工业产量目标。大型买家,尤其是向欧盟出口家具的出口商,现在正在将低 VOC 要求纳入其采购合同,从而加速采用水性化学品。这些配方在固化炉中消耗更少的能量,为使用者直接节省水电费和范围 2排放。

VOC排放问题

空气品质机构正在收紧产品类型的限制,对仍依赖刺激性溶剂载体的品牌施加即时的合规负担。加州空气资源委员会降低了捲材喷雾剂和特殊用途配方的限量。新泽西州拟议的规则旨在将建筑胶粘剂中允许的挥发性有机化合物 (VOC) 含量减少一半以上。每项新法规都要求对易爆空气污染区的产品进行重新贴标、重新认证,有时甚至升级堆高机。全球生产者必须在多个司法管辖区内权衡阈值,导致生产分散,并削弱规模经济效益。无力资助快速再製造的公司可能会失去货架空间,从而暂时抑制喷雾胶合剂市场的成长。

报告中分析的其他驱动因素和限制因素

- 汽车业的使用日益增多

- 卫生食品包装需求不断增加

- 来自替代产品的竞争

細項分析

到了2024年,水性产品将占销售额的42.78%,这印证该产业对低排放化学品的承诺。该细分市场受益于监管支援和升级的聚合物设计,这些设计使水分散体能够耐受120°C以上的高温,从而拓宽了其应用范围。亚太地区的加工商已采用罐式喷雾系统,最大限度地减少清洁停机时间,从而有助于产品渗透到胶合板层压生产线。同时,热熔胶类别将录得最快的复合年增长率,达到5.16%,这得益于强调即时处理强度和零干燥炉的自动化家俱生产线。虽然溶剂型产品仍将占据航太工业复合材料修復等利基市场,但随着环保法规的日益严格,喷涂胶黏剂的市场规模预计将缩小。

推动水性胶合剂应用的第二个动力来自于可携式设备的开发,该设备可以延长适用期并减少过度喷涂。 Worthington Enterprises 与 3M 合作,提供轻型加压罐,即使在充满电的情况下也能保持均匀的喷涂模式,将工厂内输送效率提高高达 80%。这些改进使水性胶粘剂产品线在 2030 年前保持行业领先地位,并有助于在现有溶剂型胶粘剂用户面前捍卫喷涂胶粘剂的市场份额。

区域分析

到 2024 年,亚太地区将占销售额的 46.76%,复合年增长率最快,为 5.91%。中国的经济适用房奖励策略和印度的高速公路走廊计划将确保对板材层压喷涂剂和瓷砖胶黏剂的稳定需求。当地加工商正在提高产能,以满足对美国和欧盟的家具出口订单,并纳入符合目的地法规的低 VOC 指标。日本电子组装青睐高固态的水性喷涂剂,以降低印刷基板凝结的风险,促使当地复合材料製造商为其分包合作伙伴扩展配方。韩国电池产业正在整合聚氨酯喷涂线,以确保高密度电动车电池组的抗振性。

北美依赖房屋翻新、商业屋顶翻修以及国内汽车生产的復苏。犹他州环境品质部门估计,一旦消费品法规生效,每年可能减少4,000吨挥发性有机化合物(VOC)。这是一个合规时钟,目前已开始转向购买水性罐。墨西哥一家出口装潢工厂正在投资一个自动化热熔喷漆室,以增加运往美国的剧院座椅和饭店家具的产能。加拿大一家预製房屋工厂正在指定符合严格州法律的阻燃喷雾剂,以支持喷雾胶合剂市场的区域多元化。

欧洲日趋成熟,但创新主导。德国高檔汽车原始设备製造商 (OEM) 需要无味驾驶座黏合剂,促使供应商客製化无单体聚氨酯分散体。英国正在采用低排放喷涂泡沫板,并用建筑水性喷雾固定,以促进隔热材料。西卡 (Sika) 在 EMEA 地区建筑化学品的全球销售额为 118 亿瑞士法郎,成长了 7.3%,证明了黏合剂需求的弹性。义大利和波兰的家具製造商正在实现排放气体线自动化,以满足线上零售商对更短前置作业时间的期望。欧盟的绿色交易协议加速了溶剂替代,确保欧洲仍然是喷涂胶黏剂市场永续性的基准。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场状况

- 市场概况

- 市场驱动因素

- 新兴国家建筑业快速成长

- 转向水性、低VOC黏合剂

- 扩大在汽车产业的应用

- 卫生食品包装需求不断增加

- 履约中心对 FastTack 包装黏合剂的需求不断增长

- 市场限制

- VOC排放问题

- 由于配方先进,製造成本高

- 来自替代产品的竞争

- 价值链分析

- 波特五力分析

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章 市场规模及成长预测(金额)

- 按类型

- 溶剂型

- 水性

- 热熔胶

- 依树脂类型

- 环氧树脂

- 聚氨酯

- 合成橡胶

- 醋酸乙烯-乙烯

- 按用途

- 建筑/施工

- 包装

- 家具

- 运输

- 纤维

- 其他用途

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 东南亚国协

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 义大利

- 法国

- 其他欧洲国家

- 南美洲

- 巴西

- 阿根廷

- 其他南美

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争态势

- 市场集中度

- 策略趋势

- 市占率(%)/排名分析

- 公司简介

- 3M

- AFT Aerosols

- Arkema Group(Bostik)

- Avery Dennison Corporation

- BASF SE

- Blu-Sky UK Ltd

- Casa Adhesive Inc.

- Chemique Adhesives & Sealants Ltd

- Dow Inc.

- Gemini Adhesives Ltd

- HB Fuller Company

- Henkel AG & Co. KGaA

- Illinois Tool Works Inc.

- Kissel+Wolf GmbH

- Philips Manufacturing

- Powerbond

- Quin Global

- Sika AG

- Soudal NV

- Spray-Lock Inc.

- The Kroger Co.

- Westech Aerosol Corporation

- Worthen Industries

第七章 市场机会与未来展望

The spray adhesive market is valued at USD 3.30 billion in 2025 and is forecast to climb to USD 4.18 billion by 2030 on a steady 4.87% CAGR.

Demand holds firm despite tightening VOC rules because producers continue to refine water-based and hot-melt chemistries that match the bonding strength of legacy solvent products. Growth concentrates in Asia-Pacific, where large-scale infrastructure programs, expanding furniture export hubs, and a deep automotive supply chain all require fast-tack, high-volume bonding solutions. Momentum also comes from global e-commerce logistics, which pushes fulfillment centers to specify aerosol and hot-melt variants that shorten pack-out time. Competitive pressure stays moderate, yet price-sensitive buyers have new choices from regional suppliers that replicate premium chemistries at lower cost while multinational leaders differentiate through sustainable performance upgrades. Structural drivers such as vehicle lightweighting, prefab construction, and hygienic food packaging keep end-use diversity wide, shielding the spray adhesive market from volatility in any single sector.

Global Spray Adhesive Market Trends and Insights

Rapid Growth of Construction in Emerging Economies

Surging public and private infrastructure investment across China, India, Indonesia, and the Gulf states is driving relentless volume growth for construction chemicals, including spray adhesives. Prefabricated wall panels, acoustic boards, and insulation sheathing all rely on high-performance bonding to withstand temperature swings and seismic loading. Several municipal housing programs specify low-VOC adhesives to meet green-building codes, nudging contractors toward water-based spray systems. Modular builders favor portable canister rigs that reduce overspray and labor time, increasing throughput on large projects. As urbanization accelerates, local firms adopt hot-melt spray lines that cure instantly, allowing rapid assembly of kitchen cabinets and interior fixtures inside high-rise developments. These combined forces keep the spray adhesive market deeply tied to building activity, particularly in Asia-Pacific's fast-growing megacities.

Transition to Water-Based, Low-VOC Formulations Adhesives

Regulators on three continents have enacted lower emission ceilings, prompting adhesive formulators to launch waterborne systems with comparable tack and heat resistance to solvent grades. The Texas Commission on Environmental Quality amended rules that will eliminate 3.12 tons per day of VOCs around Houston, while California's Department of Toxic Substances Control placed spray adhesives on its 2024-2026 priority product work plan. Dow's PRIMAL CA 750 and 3M's Fastbond 1049 demonstrate that water-based polymers can meet industrial throughput targets without costly ventilation upgrades. Large buyers, especially furniture exporters shipping into the EU, now embed low-VOC requirements in purchase contracts, accelerating penetration of waterborne chemistries. As curing ovens consume less energy with these formulations, users realize direct savings on utility expenses and scope-2 emissions.

Concerns Due to VOC Emissions

Air-quality agencies have tightened product-category caps, placing immediate compliance burdens on brands that still rely on strong-solvent carriers. The California Air Resources Board lowered limits on web-spray and special-purpose formulations. New Jersey's draft rule aims to cut allowable VOCs in construction adhesives by more than half. Every new limit triggers relabeling, re-qualification, and sometimes forklift upgrades for explosive-atmosphere zones. Global producers must juggle multiple jurisdictional thresholds, fragmenting volume runs and trimming economies of scale. Firms unable to finance rapid reformulation risk losing shelf space, temporarily suppressing growth in the spray adhesive market.

Other drivers and restraints analyzed in the detailed report include:

- Increasing Utilization from the Automotive Industry

- Increasing Demand for Hygienic Food Packaging

- Competition from Alternative Products

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Water-based grades held the largest 42.78% portion of 2024 revenue, confirming industry commitment to low-emission chemistries. The segment benefits from regulatory support and from upgrades in polymer design that give water dispersions heat resistance above 120 °C, widening their application window. Asia-Pacific converters adopted canister spray systems that minimize cleaning downtime, advancing penetration across plywood lamination lines. In parallel, the hot-melt category is charting the quickest 5.16% CAGR, driven by automated furniture lines that value instant handling strength and zero drying ovens. Solvent products still occupy niche spaces such as aerospace composite repair, but their spray adhesive market size is set to shrink as environmental levies rise.

A second boost to water-based adoption comes from portable equipment developments that extend pot life and reduce overspray. Worthington Enterprises collaborated with 3M to deliver lightweight pressurized canisters that maintain uniform spray patterns for the full charge, lifting in-plant transfer efficiency to 80%. These improvements help the category defend its spray adhesive market share against entrenched solvent users, positioning water-based lines for sustained leadership through 2030.

The Spray Adhesive Market Report Segments the Industry by Type (Solvent-Based, Water-Based, and Hot Melt), Resin Type (Epoxy, Polyurethane, Synthetic Rubber, and More), Application (Building and Construction, Packaging, Furniture, Transportation, and More), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa). The Market Forecasts are Provided in Terms of Value (USD Million)

Geography Analysis

Asia-Pacific dominates with 46.76% revenue in 2024 and exhibits the fastest 5.91% CAGR outlook. China's stimulus for affordable housing and India's highway corridor projects ensure consistent demand for panel lamination sprays and tile adhesives. Local converters boost capacity to satisfy furniture export orders to the United States and the European Union, embedding low-VOC metrics that align with destination regulations. Japan's electronics assemblers champion high-solids water-based sprays that reduce condensation risk on printed-circuit boards, spurring local compounders to scale formulations for subcontract partners. South Korea's battery vertical integrates polyurethane spray lines to secure vibration isolation in high-density EV packs.

North America relies on strong residential remodeling, commercial reroofing, and resurgent domestic auto production. The Utah Department of Environmental Quality estimates a potential 4,000-ton annual VOC cuts once its consumer-product rule takes effect. This sets a compliance clock that already shifts purchase preference toward water-based canisters. Mexico's export-oriented upholstery factories invest in automated hot-melt spray booths that boost throughput for theater seating and hospitality furniture destined for the United States. Canadian prefab home plants specify flame-retardant sprays that meet stringent provincial codes, underpinning regional diversification within the spray adhesive market.

Europe shows a mature yet innovation-driven profile. Germany's premium auto OEMs require odor-free cockpit adhesives, steering suppliers to tailor monomer-free polyurethane dispersions. The United Kingdom's retrofit insulation drive deploys low-emission spray foam panels secured with construction-grade water-based sprays. Sika's CHF 11.8 billion global sales, with 7.3% growth in EMEA construction chemicals, evidence adhesive demand resilience. Italian and Polish furniture clusters automate spray lines to meet shorter lead-time expectations from online retailers. EU Green Deal policies accelerate solvent replacement, ensuring that Europe remains a reference market for sustainability in the spray adhesive market.

- 3M

- AFT Aerosols

- Arkema Group (Bostik)

- Avery Dennison Corporation

- BASF SE

- Blu-Sky UK Ltd

- Casa Adhesive Inc.

- Chemique Adhesives & Sealants Ltd

- Dow Inc.

- Gemini Adhesives Ltd

- H.B. Fuller Company

- Henkel AG & Co. KGaA

- Illinois Tool Works Inc.

- Kissel + Wolf GmbH

- Philips Manufacturing

- Powerbond

- Quin Global

- Sika AG

- Soudal NV

- Spray-Lock Inc.

- The Kroger Co.

- Westech Aerosol Corporation

- Worthen Industries

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rapidly Growth of Construction Sector in Emerging Economies

- 4.2.2 Transition to Water-based, Low-VOC Formulations Adhesives

- 4.2.3 Increasing Utilization from the Automotive Industry

- 4.2.4 Increasing Demand for Hygienic Food Packaging

- 4.2.5 Growth of E-Commerce Fulfilment Centers Requiring Fast-Tack Packaging Adhesives

- 4.3 Market Restraints

- 4.3.1 Concerns due to VOC Emissions

- 4.3.2 High Production Costs of Advanced Formulations

- 4.3.3 Competitions from Alternative Products

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces Analysis

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Type

- 5.1.1 Solvent-based

- 5.1.2 Water-based

- 5.1.3 Hot-Melt

- 5.2 By Resin Type

- 5.2.1 Epoxy

- 5.2.2 Polyurethane

- 5.2.3 Synthetic Rubber

- 5.2.4 Vinyl Acetate-Ethylene

- 5.3 By Application

- 5.3.1 Building and Construction

- 5.3.2 Packaging

- 5.3.3 Furniture

- 5.3.4 Transportation

- 5.3.5 Textile

- 5.3.6 Other Applications

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 ASEAN Countries

- 5.4.1.6 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 Italy

- 5.4.3.4 France

- 5.4.3.5 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle-East and Africa

- 5.4.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%)/Ranking Analysis

- 6.4 Company Profiles (includes Global-level Overview, Market-level Overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 3M

- 6.4.2 AFT Aerosols

- 6.4.3 Arkema Group (Bostik)

- 6.4.4 Avery Dennison Corporation

- 6.4.5 BASF SE

- 6.4.6 Blu-Sky UK Ltd

- 6.4.7 Casa Adhesive Inc.

- 6.4.8 Chemique Adhesives & Sealants Ltd

- 6.4.9 Dow Inc.

- 6.4.10 Gemini Adhesives Ltd

- 6.4.11 H.B. Fuller Company

- 6.4.12 Henkel AG & Co. KGaA

- 6.4.13 Illinois Tool Works Inc.

- 6.4.14 Kissel + Wolf GmbH

- 6.4.15 Philips Manufacturing

- 6.4.16 Powerbond

- 6.4.17 Quin Global

- 6.4.18 Sika AG

- 6.4.19 Soudal NV

- 6.4.20 Spray-Lock Inc.

- 6.4.21 The Kroger Co.

- 6.4.22 Westech Aerosol Corporation

- 6.4.23 Worthen Industries

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-need Assessment