|

市场调查报告书

商品编码

1842436

印刷感测器:市场份额分析、行业趋势、统计数据和成长预测(2025-2030)Printed Sensor - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

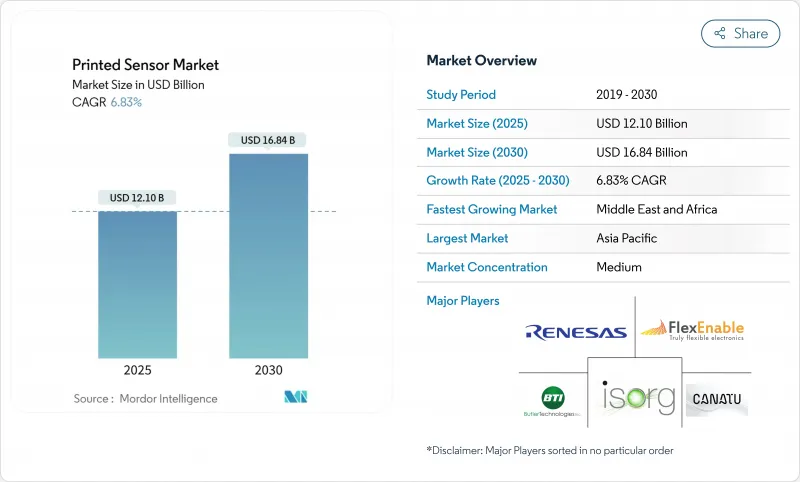

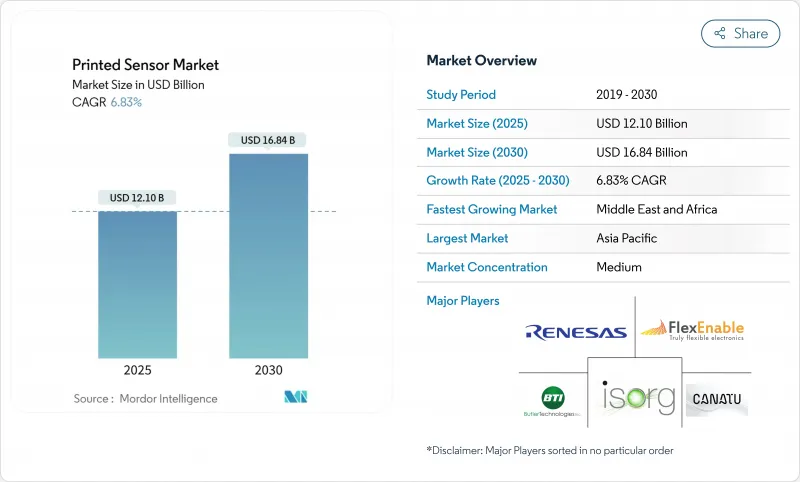

预计印刷感测器市场规模到 2025 年将达到 121 亿美元,到 2030 年将达到 168.4 亿美元,复合年增长率为 6.83%。

从刚性电子机械感测器转向柔性轻量化设计的是核心成长引擎,其驱动力来自卷对卷製造技术,该技术可减少高达 90% 的材料浪费并降低单位成本。量产的消费级物联网曲面汽车仪錶板和穿戴式健康设备都依赖这些成本节约。北美和欧洲的政府奖励策略正在降低新试点生产线的资本门槛,而亚太地区的供应商则利用长週期生产来维持平均售价的竞争力。导电油墨、网状电极和混合基板的进步正在扩大与传统 MEMS 的性能差距,使得印刷阵列成为纤薄、贴合感测器增值的预设选择。

全球印刷感测器市场趋势与洞察

柔性和穿戴式医疗设备的快速普及

亚太地区的医疗保健系统正在扩展远端监控项目,这推动了对可舒适佩戴在皮肤或织物上的生物感测器的需求。目前,基于汗液的平台无需刺穿身体即可分析发炎标记、水分和血糖水平。柔性混合电子装置整合了印刷阵列和硅逻辑,形成贴片,可透过蓝牙将即时生命体征数据传输到医院仪表板——预计到 2030 年,这项功能将推动全体检市场规模超过 670 亿美元。医院网路利用这些连续的资料流来缩短住院时间并及早发现併发症。不到 3 美元的单位成本使得即使是中等收入的医疗保健提供者也能在患者出院时为其配备设备,从而加速了该地区的普及。日本、韩国和中国的监管机构正在正式批准穿戴式诊断设备的快速审批,这将进一步推动单位销售额的成长。

汽车转向曲面 HMI 仪表板

全球汽车製造商正在用与车辆内饰轮廓相符的触控面板取代机械旋钮。库尔兹的PolyTC®金属网格电容层采用卷轴式工艺沉积在PET薄膜上,可透过2.5毫米厚的装饰塑料识别触摸,有助于满足原始设备製造商的造型目标。这些感测器可承受85°C和40°C的高温循环,确保车辆在整个使用寿命期间保持响应速度。一级製造商还在方向盘和扶手中嵌入印刷阵列,以检测驾驶员的参与度并相应地调整安全气囊和警告。软体定义驾驶座平台利用统一的感测器网格,支援无线升级,无需更换硬体即可更新控制布局。儘管欧洲和北美目前在部署方面处于领先地位,但中国电动车品牌仍处于落后地位,其全模压电容面板计划于2026年推出。

缺乏标准化测试通讯协定

伸缩性生物感测器需要弯曲、扭转和压缩以贴合人体,因此不受传统 IEC 60601 衝击和振动测试的约束。这需要内部开发伸长率、耐洗性和皮肤接触生物相容性测试,从而减慢设计週期。 UL 解决方案总结了目前错综复杂的 CE、FDA 和 IEC 要求,这些要求因产品类别和地区而异。产业组织正在开发通用的负载工况矩阵,但由于动态监视器、新生儿贴片和智慧运动衫的独特应变模式,尚未达成共识。认证延迟需要营运资金,这会阻碍小型参与企业的积极性,并限制其短期市场渗透。

报告中分析的其他驱动因素和限制因素

- 向固体气体检测器的过渡

- 卷轴式在物联网应用的成本优势

- 热循环下的稳定极限

細項分析

到2024年,触控/电容式感测器将以31.5%的市场份额引领印刷感测器市场。随着医院转向临床外的持续评估,目前体型较小的生物感测器正以11.8%的复合年增长率成长。奈米酶化学技术推动了这一浪潮,它能够实现乳酸、葡萄糖和感染标誌物的非侵入性检测。加拿大和德国远端患者监护报销的监管批准正在扩大可覆盖范围。气体/化学物质、温度、压力/力和压电/应变类别填补了安全、电池组和结构完整性等细分领域,而122 ppb氨气检测等突破性技术则为新的合规解决方案提供了可能。整合式多模态堆迭将触控、压力和生物辨识技术整合在一个层压板中,无需扩大占地面积,从而赢得了智慧戒指和耳塞等空间受限设计的青睐。

第二段:售价低于 10 美元的生物感测器贴片鼓励大规模筛检项目,并改善东南亚诊所的慢性病追踪。印在 TPU 薄膜上的压力阵列将力数据输入 AI 步态引擎,以预警老年护理机构的跌倒风险。嵌入锂离子模组的气体感测器可提供排气预警,帮助电池组製造商遵守 UN38.3 安全法规。工厂皮带中编织的压电纱线可解读应变,使预测性维护软体能够在重大故障发生前安排停机时间。这种功能多样性使供应商保持敏捷。定製油墨化学成分、基材选择和电极几何形状因计划而异,因此需要模组化生产套件包。

丝网印刷凭藉其成熟的产能、厚膜沉积能力以及数十年陶瓷和印刷电路板(PCB)的摊销设备,将在2024年占据42%的收益。典型的线宽约为100µm,可满足大多数电容式和电阻式的需求,但最近的网格升级已将解析度提升至接近50µm。喷墨印刷非常适合设计每週更新的短期生产。气溶胶喷射、电流体喷射和MEMS微喷嘴阵列可在3D轮廓上沉积小于10µm的轨迹,其复合年增长率最快,达到13.6%,非常适合用于外壳周围的蜿蜒天线和电池内部的精细温度网格。

当长度达到数百公尺且色彩套准公差至关重要时,二级柔印机表现出色。凹印擅长均匀涂覆奈米厚度,尤其适用于光学清晰度至关重要的应用,例如HUD挡风玻璃中的透明加热器。混合生产线融合了多种方法,例如喷墨列印种子层、雷射烧结熔化铜层以及丝网涂布保护性介电面漆。这种选择决定了成本、特征密度和可靠性,促使一级供应商越来越多地并行部署多台机器。新的AI视觉系统可即时调整刮刀角度和喷射停留时间,以维持公差,从而将产量比率提高到98%以上。

区域分析

受中国大规模生产能力、日本深厚的材料科学以及韩国显示器巨头的推动,到2024年,亚太地区将占据印刷感测器市场的39.2%。当地研发联盟正在迅速将实验室突破转化为中试生产线,缩短从概念到出口的週期。政府补贴抵销了用于印刷OLED触摸矩阵的新型凹版印刷机的折旧免税额成本,大学也正在衍生出瞄准医院穿戴式装置的新兴企业。该地区的研发产品线包括织物整合呼吸感测器和用于电子纸阅读器的可折迭触控膜,从而实现了手机以外的收益多元化。

北美正在利用《晶片与科学法案》拨款建造印刷电子测试平台,以帮助晶圆厂克服高昂的资本支出。与材料供应商和航太製造商的伙伴关係正在生产厚度仅为25微米的压力阵列,用于测量机翼偏转,且不会对动态造成不利影响。医疗保健生态系统正在诊所进行由医疗保险报销的家庭监测试点,以检验生物感测器贴片的商业可行性。波士顿和硅谷的研究中心正在迭代改进可在70°C下烧结的油墨配方,使其与热敏性热塑性塑胶相容。

随着海湾国家将石油收入转向智慧城市蓝图,到2030年,中东地区的复合年增长率将达到9.3%,位居全球最快。杜拜2020号地铁将在轨道上部署印刷应变计,以实现预测性维护;利雅德的计划将在整个施工现场嵌入空气品质阵列,以满足新的环保标准。一家外国合资企业正在杰贝阿里附近建立一条卷对卷生产线,并利用免税区为欧洲和非洲提供服务。欧洲市场保持着强劲的立足点,尤其是在德国,一级公司正在改进曲面人机的介面面板。欧盟的「欧洲晶片」倡议将为包括柔性混合晶片在内的半导体产能增加79亿欧元,从而支持长期竞争力。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场状况

- 市场驱动因素

- 柔性和穿戴式医疗设备在亚太地区迅速普及

- 汽车转向曲面 HMI 仪表板需要大面积电容式印刷感测器

- 智慧工厂中从机械检测到固体气体检测的转变(欧洲主导)

- 在大批量消费性物联网节点中,卷轴式比 MEMS 技术更具成本优势

- 市场限制

- 汽车热循环下导电油墨的长期稳定性有限

- 缺乏伸缩性生物感测器的标准化测试通讯协定,导致 OEM 认证延迟

- 将现有 PCB 生产线转换为卷对卷混合生产线的资本密集度

- PEDOT:PSS 配方的智慧财产权分散导致专利费成本上升

- 价值/供应链分析

- 监理展望

- 技术展望

- 波特五力分析

- 新进入者的威胁

- 买方的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争的激烈程度

- 技术简介

- 喷墨列印

- 网版印刷

- 柔版印刷

- 凹版印刷

- 气溶胶喷射和其他新方法

- 投资分析

- 资金筹措趋势

- 曼达拉局势

第五章市场规模及成长预测(金额)

- 依感测器类型

- 触控/电容式

- 压力/力

- 生物感测器

- 气体/化学品

- 压电/应变

- 温度感测器

- 透过印刷技术

- 萤幕

- 喷墨

- 柔版印刷

- 凹版印刷

- 气溶胶喷射等

- 按基材

- 塑胶薄膜(PET、PEN)

- 纸和纸板

- 玻璃

- 纺织品和弹性体

- 按最终用户

- 消费性电子产品

- 医疗保健和医疗设备

- 工业和製造业

- 汽车和运输设备

- 航太/国防

- 其他(智慧包装、农业)

- 按地区

- 北美洲

- 美国

- 加拿大

- 欧洲

- 德国

- 法国

- 英国

- 义大利

- 其他欧洲国家

- 亚太地区

- 中国

- 日本

- 韩国

- 印度

- 其他亚太地区

- 南美洲

- 巴西

- 其他南美

- 中东

- GCC

- 土耳其

- 其他中东地区

- 非洲

- 南非

- 其他非洲国家

- 北美洲

第六章 竞争态势

- 策略趋势

- Partnerships and Licensing

- Capacity Expansions

- 市占率分析

- 公司简介

- FlexEnable Ltd.

- ISORG SA

- Plastic Logic HK Ltd.

- Renesas Electronics Corp.

- Butler Technologies Inc.

- Canatu Oy

- SPEC Sensors LLC

- Peratech Holdco Ltd.

- Pressure Profile Systems Inc.

- Tekscan Inc.

- Thin Film Electronics ASA

- Molex LLC

- Interlink Electronics Inc.

- Fujifilm Dimatix Inc.

- Heraeus Noblelight GmbH

- Nissha Co. Ltd.

- T+Ink Inc.

- GSI Technologies LLC

- Brewer Science Inc.

- Henkel AG and Co. KGaA

第七章 市场机会与未来展望

The printed sensor market size stands at USD 12.1 billion in 2025 and is on track to reach USD 16.84 billion by 2030, advancing at a 6.83% CAGR.

The shift from rigid micro-electromechanical sensors toward flexible, lightweight designs is the core growth engine, helped by roll-to-roll manufacturing that cuts material waste by up to 90% and slashes unit costs. High-volume consumer IoT curved automotive dashboards, and wearable health devices all depend on these cost reductions. Government stimulus programs in North America and Europe are lowering the capital barrier for new pilot lines, while Asia-Pacific suppliers leverage long production runs to keep average selling prices competitive. Progress in conductive inks, mesh electrodes, and hybrid substrates is widening the performance gap versus conventional MEMS, positioning printed arrays as the default choice wherever low-profile, conformable sensors add value.

Global Printed Sensor Market Trends and Insights

Rapid Adoption of Flexible & Wearable Medical Devices

Asia-Pacific healthcare systems are scaling remote monitoring programs, elevating demand for biosensors that wrap comfortably around skin and textiles. Sweat-based platforms now profile inflammation markers, hydration, and glucose without puncturing the body. Flexible hybrid electronics integrate printed arrays with silicon logic, forming patches that relay real-time vitals over Bluetooth to hospital dashboards, a capability forecast to lift the FHE market past USD 67 billion by 2030. Hospital networks use these continuous data streams to shorten inpatient stays and flag complications early. With unit prices falling under USD 3, even mid-income providers can equip postoperative patients at discharge, accelerating regional adoption. Regulatory bodies in Japan, Korea, and China are formalizing fast-track approvals for wearable diagnostics, further supporting volume growth.

Automotive Shift to Curved HMI Dashboards

Global automakers are replacing mechanical knobs with sweeping touch surfaces that follow interior contours. PolyTC(R) metal-mesh capacitive layers from KURZ are deposited on PET using roll-to-roll lines and still register touch through 2.5 mm of decorative plastic, satisfying OEM styling goals. These sensors survive the 85 °C heat and 40 °C cold of qualification cycles, preserving responsiveness over vehicle life. Tier-1s are also embedding printed arrays into steering wheels and armrests to detect driver engagement and adjust airbags or alerts accordingly. Software-defined cockpit platforms capitalize on the uniform sensor grid, allowing over-the-air upgrades that refresh control layouts without hardware swaps. Europe and North America lead deployments today, but Chinese EV brands are close behind with fully moulded capacitive panels slated for 2026 launches.

Lack of Standardized Test Protocols

Stretchable biosensors bend, twist, and compress with the body, behaviours not covered by legacy IEC 60601 shock or vibration tests. Brands must invent in-house regimes for elongation, wash durability, and skin-contact biocompatibility, slowing design cycles. UL Solutions summarises the maze of CE, FDA, and IEC requirements that differ by product class and geography. Industry groups are drafting common load-case matrices, yet consensus remains elusive because gait monitors, neonatal patches, and smart jerseys all experience unique strain patterns. Qualification delays raise working capital needs and dissuade smaller entrants, capping near-term market penetration.

Other drivers and restraints analyzed in the detailed report include:

- Transition to Solid-State Gas Detection

- Roll-to-Roll Cost Advantage in IoT Applications

- Limited Stability Under Thermal Cycling

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Touch/Capacitive units led the printed sensor market with 31.5% share in 2024, a dominance tied to their ubiquity across phones, laptops, and infotainment displays. Biosensors, though smaller today, are growing at an 11.8% CAGR as hospitals shift to continuous assessment outside clinical walls. This wave is anchored by nanozyme chemistry that enables non-invasive detection of lactate, glucose, and infection markers. Regulatory green lights for remote patient monitoring refund schemes in Canada and Germany widen the addressable base. Gas/Chemical, Temperature, Pressure/Force, and Piezo/Strain categories fill niche roles in safety, battery packs, and structural health, with breakthroughs such as 122 ppb ammonia detection enabling new compliance solutions. Integrated multi-modal stacks combine touch, pressure, and biometrics in a single laminate without enlarging the footprint, winning space-constrained designs in smart rings and earbuds.

Second paragraph: Biosensor patches priced under USD 10 encourage mass screening programs across Southeast-Asian clinics, improving chronic disease tracking. Pressure arrays printed on TPU film feed force data to AI gait engines that flag fall risk in elder-care homes. Gas sensors embedded inside lithium-ion modules offer early venting alerts, helping pack makers comply with UN 38.3 safety rules. Piezo threads woven into factory belts decode strain, letting predictive maintenance software schedule downtimes before catastrophic tears. This functional diversity keeps suppliers agile; custom ink chemistries, substrate picks, and electrode geometries shift from project to project, forcing a modular production toolkit.

Screen printing captured 42% of revenue in 2024, thanks to proven throughput, thick-film build-up, and equipment amortized over decades in ceramics and PCBs. Typical line widths around 100 µm satisfy most capacitive and resistive formats, while recent mesh upgrades push resolution nearer 50 µm. Inkjet retains relevance for short runs where designs evolve weekly; brands can pivot without fabricating new screens. Aerosol-Jet, electrohydrodynamic jets, and MEMS micro-nozzle arrays post the fastest 13.6% CAGR by depositing sub-10 µm tracks on 3D contours, perfect for antennas snaking around housings or fine-pitch temperature grids inside batteries.

Second paragraph: Flexographic presses win when length hits hundreds of meters and colour registration is forgiving. Gravure excels at uniform nano-thick coatings where optical clarity matters, such as transparent heaters on HUD windshields. Hybrid lines mix methods: inkjet prints seed layers, laser sintering fuses copper, and screen coating applies protective dielectric topcoats. The choice shapes cost, feature density, and reliability, so tier-1s increasingly co-locate multiple machines. Emerging AI vision systems adjust squeegee angle and jet dwell time in real time to hold tolerance, lifting yield beyond 98%.

Printed Sensors Market Segmented by Sensor Type (Touch / Capacitive, Temperature, and More), Printing Technology (Screen, Inkjet and More), Substrate (Plastic Films (PET, PEN), Paper and Paperboard and More), End-User (Consumer Electronics, Healthcare and Medical Devices and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific commanded 39.2% of the printed sensor market in 2024, backed by China's large-scale production capacity, Japan's material science depth, and South Korea's display majors. Local R&D consortia turn lab breakthroughs into pilot lines fast, shortening the cycle from concept to export. Government grants offset depreciation on new gravure presses that print OLED touch matrices, while universities spin off start-ups targeting hospital wearables. The regional pipeline includes textile-integrated respiration sensors and foldable touch foils for e-paper readers, diversifying revenue beyond phones.

North America leverages the CHIPS & Science Act, which earmarked funds for printed electronics testbeds, helping fabs overcome high capex. Partnerships between material suppliers and aerospace primes produce pressure arrays as thin as 25 µm to measure wing flex without aerodynamic penalty. The healthcare ecosystem anchors adoption: clinics run at-home monitoring pilots reimbursed by Medicare, validating business cases for biosensor patches. Research centers in Boston and Silicon Valley iterate ink formulations that sinter at 70 °C, compatible with heat-sensitive thermoplastics.

The Middle East posts the swiftest 9.3% CAGR through 2030 as Gulf states channel oil revenue into smart city blueprints. Dubai's Route 2020 Metro deploys printed strain gauges on tracks for predictive maintenance, while Riyadh's giga projects embed air-quality arrays across construction sites to meet new environmental codes. Foreign joint ventures set up roll-to-roll lines near Jebel Ali, exploiting duty-free zones to serve Europe and Africa. Europe retains a strong foothold, notably Germany where Tier-1s refine curved HMI panels. The EU's Chips for Europe Initiative adds EUR 7.9 billion to semiconductor capacity including flexible hybrids, anchoring long-term competitiveness.

- FlexEnable Ltd.

- ISORG SA

- Plastic Logic HK Ltd.

- Renesas Electronics Corp.

- Butler Technologies Inc.

- Canatu Oy

- SPEC Sensors LLC

- Peratech Holdco Ltd.

- Pressure Profile Systems Inc.

- Tekscan Inc.

- Thin Film Electronics ASA

- Molex LLC

- Interlink Electronics Inc.

- Fujifilm Dimatix Inc.

- Heraeus Noblelight GmbH

- Nissha Co. Ltd.

- T+Ink Inc.

- GSI Technologies LLC

- Brewer Science Inc.

- Henkel AG and Co. KGaA

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Drivers

- 4.1.1 Rapid adoption of flexible and wearable medical devices across Asia-Pacific

- 4.1.2 Automotive shift to curved HMI dashboards requiring large-area capacitive printed sensors

- 4.1.3 Transition from mechanical to solid-state gas detection in smart factories (Europe-led)

- 4.1.4 Roll-to-roll cost advantage versus MEMS in high-volume consumer IoT nodes

- 4.2 Market Restraints

- 4.2.1 Limited long-term stability of conductive inks under automotive thermal cycling

- 4.2.2 Lack of standardized test protocols for stretchable biosensors slows OEM qualification

- 4.2.3 Capital intensity of converting existing PCB lines to roll-to-roll hybrid lines

- 4.2.4 Intellectual-property fragmentation around PEDOT:PSS formulations driving royalty costs

- 4.3 Value / Supply-Chain Analysis

- 4.4 Regulatory Outlook

- 4.5 Technological Outlook

- 4.6 Porter's Five Forces Analysis

- 4.6.1 Threat of New Entrants

- 4.6.2 Bargaining Power of Buyers

- 4.6.3 Bargaining Power of Suppliers

- 4.6.4 Threat of Substitutes

- 4.6.5 Intensity of Rivalry

- 4.7 Technology Snapshot

- 4.7.1 Inkjet Printing

- 4.7.2 Screen Printing

- 4.7.3 Flexographic Printing

- 4.7.4 Gravure Printing

- 4.7.5 Aerosol-Jet and Other Emerging Methods

- 4.8 Investment Analysis

- 4.8.1 VC Funding Trends

- 4.8.2 MandA Landscape

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Sensor Type

- 5.1.1 Touch/Capacitive

- 5.1.2 Pressure / Force

- 5.1.3 Biosensors

- 5.1.4 Gas/Chemical

- 5.1.5 Piezo/Strain

- 5.1.6 Temperature

- 5.2 By Printing Technology

- 5.2.1 Screen

- 5.2.2 Inkjet

- 5.2.3 Flexographic

- 5.2.4 Gravure

- 5.2.5 Aerosol-Jet and Others

- 5.3 By Substrate

- 5.3.1 Plastic Films (PET, PEN)

- 5.3.2 Paper and Paperboard

- 5.3.3 Glass

- 5.3.4 Textiles and Elastomers

- 5.4 By End-User

- 5.4.1 Consumer Electronics

- 5.4.2 Healthcare and Medical Devices

- 5.4.3 Industrial and Manufacturing

- 5.4.4 Automotive and Transportation

- 5.4.5 Aerospace and Defense

- 5.4.6 Others (Smart Packaging, Agriculture)

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.2 Europe

- 5.5.2.1 Germany

- 5.5.2.2 France

- 5.5.2.3 United Kingdom

- 5.5.2.4 Italy

- 5.5.2.5 Rest of Europe

- 5.5.3 Asia-Pacific

- 5.5.3.1 China

- 5.5.3.2 Japan

- 5.5.3.3 South Korea

- 5.5.3.4 India

- 5.5.3.5 Rest of Asia-Pacific

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Rest of South America

- 5.5.5 Middle East

- 5.5.5.1 GCC

- 5.5.5.2 Turkey

- 5.5.5.3 Rest of Middle East

- 5.5.6 Africa

- 5.5.6.1 South Africa

- 5.5.6.2 Rest of Africa

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Strategic Moves

- 6.1.1 Partnerships and Licensing

- 6.1.2 Capacity Expansions

- 6.2 Market Share Analysis

- 6.3 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.3.1 FlexEnable Ltd.

- 6.3.2 ISORG SA

- 6.3.3 Plastic Logic HK Ltd.

- 6.3.4 Renesas Electronics Corp.

- 6.3.5 Butler Technologies Inc.

- 6.3.6 Canatu Oy

- 6.3.7 SPEC Sensors LLC

- 6.3.8 Peratech Holdco Ltd.

- 6.3.9 Pressure Profile Systems Inc.

- 6.3.10 Tekscan Inc.

- 6.3.11 Thin Film Electronics ASA

- 6.3.12 Molex LLC

- 6.3.13 Interlink Electronics Inc.

- 6.3.14 Fujifilm Dimatix Inc.

- 6.3.15 Heraeus Noblelight GmbH

- 6.3.16 Nissha Co. Ltd.

- 6.3.17 T+Ink Inc.

- 6.3.18 GSI Technologies LLC

- 6.3.19 Brewer Science Inc.

- 6.3.20 Henkel AG and Co. KGaA

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet Need Analysis