|

市场调查报告书

商品编码

1842660

造纸染料:市场占有率分析、产业趋势、统计数据和成长预测(2025-2030 年)Paper Dyes - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

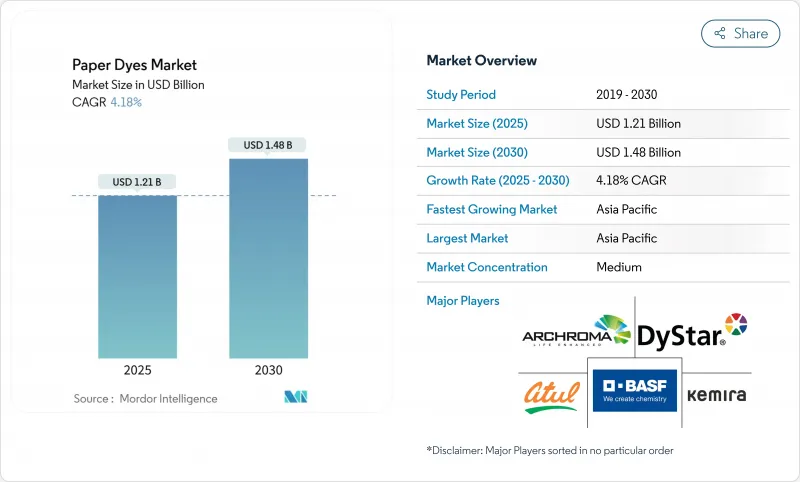

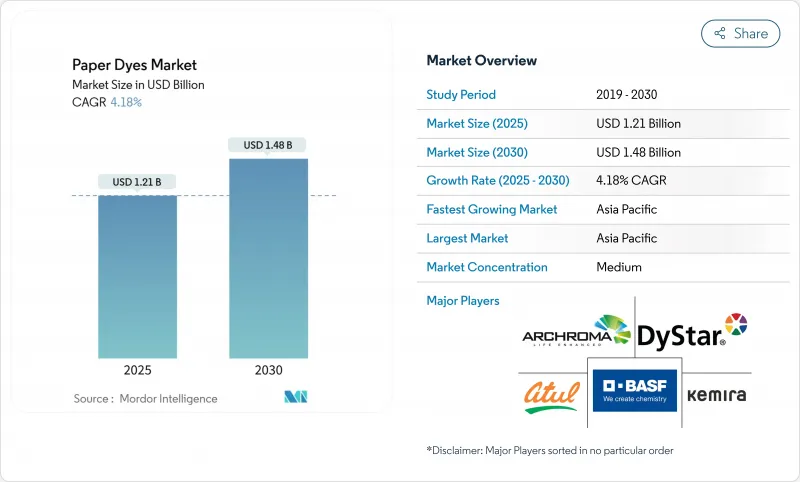

预计全球造纸染料市场规模到 2025 年将达到 12.1 亿美元,到 2030 年将达到 14.8 亿美元,复合年增长率为 4.18%。

这一稳定的成长轨迹反映了市场在数位文件替代方面的韧性,这得益于包装从塑料向纸质的结构性转变,以及电子商务货运对色彩鲜艳、品牌一致性图形日益增长的需求。与现代喷墨生产线无缝整合的墨水有助于加工商减少停机时间,而主要染料製造商的产能扩张则平衡了原材料供应。限制一次性塑胶的法规以及品牌所有者对可再生基材的偏好,即使在图形纸产量萎缩的情况下,也支撑着成长前景。对木质素相容和奈米封装化学品的投资,正在帮助供应商实现差异化,并赢得食品接触和高速数位应用领域的优质订单。

全球造纸染料市场趋势与洞察

从塑胶包装到纸质包装的转变

为了回应一次性塑胶禁令并满足消费者对纸张的偏好,零售品牌持续以可回收的纤维基材料取代石油基材。雀巢、联合利华和其他跨国公司目前正在从某些SKU中淘汰高达97%的塑料,从而加速了对高性能染料的订单,这些染料可透过多个回收循环保持一致的性能。欧盟《一次性塑胶指令》带来的监管确定性,支持了对需要食品级、抗迁移色素的加工商的资本投资。消费者愿意为永续包装支付溢价,这使得染料製造商能够确保新的、可靠的配方价格,这些配方能够承受回收纤维系统中的碱性脱墨和氧化漂白。

电子商务推动纸板和邮件需求激增

超过80%的线上订单采用纸箱运输,小包裹量持续成长,尤其是在亚太地区和北美地区。履约中心需要高速旋转喷墨生产线,并运作专为低维护印字头设计的液体染料,以实现当日大规模个人化服务。到2024年,包装厂租金将比20年平均值高出45%,这清楚地表明结构性产能扩张,并将在整个预测期内支撑纸染料市场。

无纸化办公室和数位文件的兴起

随着企业和教育用户加速数位化工作流程,图形纸的需求急剧萎缩。欧洲造纸工业联合会记录到,2023年纸张和纸板产量下降了13%,其中仅图形纸产量就下降了28%。远距办公通讯协定仍然有效,导致印刷量减少50%至70%,电子签章平台也减少了对纸本的需求。虽然包装染料弥补了部分损失,但图形纸产量的萎缩将限制整体产量的成长,尤其是在成熟地区。

細項分析

预计到2024年,流体将占销售额的51.92%,复合年增长率为6.40%,这将巩固其在支援电商包装升级的高速喷墨生产线中的关键作用。粉末级流体更易于散装运输,但必须满足粉尘暴露法规和缓慢的分散时间要求。奈米封装流体系统现在可实现超过1,000小时的列印头工作週期,从而最大限度地减少维护停机时间并提高加工商的OEE。稳定的温度黏度支援自动计量,并满足准时制生产目标。

乳化和微流体封装技术的不断进步正在延长保质期,使其在25°C下能够保持颜色强度超过12个月,而标准配方则只能保持6个月。因此,加工商能够减少因库存过期而造成的减损损失。粉末供应商正在透过压实和防尘技术来应对这项挑战,但数位化化工厂仍落后于液体粉末竞争对手。

直接染料因其经济高效的输送工艺而备受青睐,将在高产量箱板纸厂保持主导地位,到2024年将占其总收入的28.45%。然而,活性染料市场正以5.90%的复合年增长率增长,这得益于其卓越的耐洗牢度,而这一特性受到高端折迭纸盒用户的青睐,因为他们需要图案能够经受住回收利用。纤维测试表明,棉纤维含量高的特种纸品使用活性染料的上染率为41.45%,而其他化学染料的上染率为35.68%。

供应商正在将典型的反应槽温度从 90°C 降低至 60°C,同时不牺牲附着力,降低能耗,并扩大受脱碳目标限制的工厂的采用率。直接染料因其在中性 pH 下易于沉积而仍然是主要染料,但其市场份额正逐渐被符合循环经济要求的高价值化学品所取代。

区域分析

到2024年,亚太地区将以44.79%的收益保持领先地位,预计到2030年复合年增长率将达到5.70%,这反映了其作为全球製造业核心和快速扩张的消费市场的地位。中国化工产业的领导企业恆力、万华等企业正在利用政府对精细化工计划的奖励,提高该地区的自给自足能力。越南拥有7,500家纺织企业,僱用了430万名工人,这将增加纸板和特种纸的消费,从而导致该地区染料使用量增加。

北美以以金额为准计算位居第二,这得益于履约的成长以及食品饮料跨国公司积极减少塑胶使用的承诺。昂高位于南卡罗来纳州的工厂和索理思位于维吉尼亚的工厂正在实现供应本地化,而PFAS法规的明确性正推动加工商采用合规的水性系统。虽然图纸的收缩抑制了产量,但青睐环保染料的高端订单支撑了价格实现,使其涨幅超过通膨。

欧洲面临严格的《欧盟化学品註册、评估、许可和限制》(REACH) 修正案和波动的纸浆价格(北方漂白针叶木牛皮纸浆价格在 2024 年 4 月达到 1,380 欧元/吨),这给营业利润率带来了压力。然而,欧盟在循环经济法规方面的领导地位以及对木质素衍生着色剂研发的资金投入,使本地供应商在高价值、环保产品方面处于领先地位。水处理公司正在投资闭合迴路水处理以满足排放许可要求,这推动了对低盐、高排放染料的需求,符合零液体排放的目标。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场状况

- 市场概况

- 市场驱动因素

- 从塑胶包装到纸质包装的转变

- 电子商务推动瓦楞纸箱和邮件的需求

- 提高大型染料製造商的产能

- 生物基木质素相容染料的突破

- 奈米胶囊染料可在纸上进行数位喷墨列印

- 市场限制

- 无纸化办公室和数位文件的兴起

- 有毒胺和 REACH 合规成本上升

- 木浆供应和价格的波动

- 价值链分析

- 波特五力分析

- 新进入者的威胁

- 买方的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争程度

第五章市场规模及成长预测

- 按形状

- 粉末

- 液体

- 按类型

- 酸性

- 基本的

- 直接地

- 依产地分类

- 有机的

- 合成

- 按用途

- 列印/书写

- 包装

- 专业

- 其他(纸巾、卫生材料)

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 其他欧洲国家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争态势

- 市场集中度

- 策略倡议

- 市占率(%)/排名分析

- 公司简介

- Archroma

- Ashok Alco-chem

- Atul Ltd.

- BASF

- Celanese Corporation

- ChromaScape

- DyStar Singapore Pte Ltd

- Kemira Oyj

- Kiri Industries Limited

- Lonza

- Merck KGaA

- Milliken

- Nitin Dye Chem Pvt. Ltd

- Setas Kimya

- Standard Colors, Inc.

- Steiner-Axyntis

- Sudarshan Chemical Industries Limited.

- Synthesia, as

- Thermax Limited

- Vipul Organics Ltd.

- Zhejiang Longsheng

第七章 市场机会与未来展望

The global paper dyes market stood at USD 1.21 billion in 2025 and is forecast to reach USD 1.48 billion by 2030, advancing at a 4.18% CAGR.

This steady trajectory reflects the market's resilience in digital-document substitution, supported by the structural migration from plastic to paper-based packaging and rising demand for vivid, brand-consistent graphics in e-commerce shipments. Liquid formulations that integrate seamlessly with modern inkjet lines are helping converters reduce downtime, while capacity additions by major dye makers keep raw material supply balanced. Regulatory tailwinds that restrict single-use plastics and brand owners' preference for renewable substrates underpin an expansionary outlook even as graphic-paper volumes contract. Investments in lignin-compatible and nano-encapsulated chemistries further differentiate suppliers, positioning them to capture premium orders in food-contact and high-speed digital applications.

Global Paper Dyes Market Trends and Insights

Shift from Plastic to Paper-Based Packaging

Retail brands continue to replace petroleum-based substrates with recyclable, fiber-based formats to comply with single-use plastic bans and to meet consumer preference for paper. Nestle, Unilever, and other multinationals now eliminate up to 97% of plastic from certain SKUs, accelerating orders for high-performance dyes that remain stable through multiple recycling loops. Regulatory certainty created by the European Union's Single-Use Plastics Directive supports capital investment in converters that require food-contact-compliant, migration-safe colorants. Consumer willingness to pay premiums for sustainable packaging has held steady, allowing dye producers to defend pricing for novel, colorfast formulations that tolerate alkaline de-inking and oxidative bleaching in recovered-fiber systems.

E-commerce-Fueled Boom in Corrugated & Mailer Demand

Over 80% of online orders ship in corrugated formats, and parcel volumes continue to rise-particularly in Asia-Pacific and North America-creating concentrated demand for vivid graphics that elevate the unboxing experience. Fulfillment centers require rapid-turn inkjet lines that run on liquid dyes engineered for low-maintenance printheads, enabling same-day personalization at scale. Building leases for packaging plants rose 45% above the 20-year average in 2024, a clear signal of structural capacity expansion that will sustain the paper dyes market over the forecast horizon.

Paperless Office & Digital Documents Adoption

Graphic-paper demand contracted sharply after corporate and educational users accelerated digital workflows. The Confederation of European Paper Industries recorded a 13% fall in paper and board production in 2023, with graphic grades alone down 28%. Remote-work protocols that cut printing volumes by 50-70% remain in force, while e-signature platforms reduce the need for hard copies. Although packaging dyes offset some losses, graphic-paper contraction limits overall tonnage growth, particularly in mature regions.

Other drivers and restraints analyzed in the detailed report include:

- Capacity Expansions by Major Dye Manufacturers

- Breakthroughs in Bio-Based Lignin-Compatible Dyes

- Toxic Amines & Rising REACH Compliance Costs

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Liquid offerings held 51.92% of 2024 revenue and are projected to expand at a 6.40% CAGR, reinforcing their pivotal role in high-speed inkjet lines that power versioned e-commerce packaging. Powder grades, although easier to transport in bulk, must contend with dust-exposure rules and slower dispersion times. Nano-encapsulated liquid systems now enable print-head duty cycles exceeding 1,000 hours, minimizing maintenance shutdowns and improving OEE for converters. Stable viscosity across temperature swings supports automated dosing, aligning with just-in-time production targets.

Ongoing advances in mini-emulsion and microfluidic encapsulation increase shelf life, preserving hue intensity for over 12 months when stored at 25 °C, compared with six months for standard formulations. As a result, converters see reduced write-offs from expired stocks. Powder suppliers respond with compaction and dust-suppressant technologies but still trail liquid rivals in digitally enabled plants.

Direct dyes, favored for cost-efficient exhaust processes, commanded 28.45% of 2024 sales, maintaining dominance in high-volume linerboard mills. Yet the reactive segment is advancing at a 5.90% CAGR on the strength of superior wash-fastness, an attribute prized by premium folding-carton users who require graphics to survive recycling. According to fiber-specific trials, cotton-fiber-rich specialty grades register dye uptake of 41.45% with reactivatives versus 35.68% for other chemistries.

Suppliers reduce typical reactive-bath temperatures from 90 °C to 60 °C without sacrificing fixation, lowering energy loads, and broadening adoption in mills constrained by decarbonization targets. Direct dyes remain a staple because they attach readily under neutral pH, but their market share is gradually ceded to higher-value chemistries that align with circular-economy mandates.

The Paper Dyes Market Report Segments the Industry by Form (Powder and Liquid), Type (Acidic, Basic, and More), Origin (Organic and Synthetic), Application (Printing and Writing, Packaging, Specialty, and More), and Geography (Asia-Pacific, North America, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific retained leadership with 44.79% of 2024 revenue and is forecast to rise at a 5.70% CAGR to 2030, reflecting its status as a global manufacturing nucleus and fast-expanding consumer market. China's chemical champions-Hengli, Wanhua, and peers-channel government incentives into fine-chemical projects that lift regional self-sufficiency. Vietnam, hosting 7,500 textile enterprises employing 4.3 million workers, boosts regional consumption of corrugated and specialty papers, translating into higher local dye usage.

North America ranks second by value, propelled by e-commerce fulfillment growth and aggressive plastic-reduction pledges from food and beverage multinationals. Archroma's South Carolina site and Solenis's Virginia complex provide localized supply, while regulatory clarity on PFAS pushes converters to adopt compliant, water-based systems. Although graphic-paper contraction tempers total tonnage, premium-grade orders that favor environmentally optimized dyes support above-inflation price realization.

Europe grapples with stringent REACH amendments and pulp-price volatility-Northern Bleached Softwood Kraft touched EUR 1,380 / t in April 2024-pressuring operating margins. Yet the bloc's leadership in circular-economy regulation and R&D funding for lignin-derived colorants positions local suppliers at the forefront of high-value, eco-optimized offerings. Converters invest in closed-loop water treatment to meet discharge permits, raising demand for low-salt, high-exhaustion dyes that align with zero-liquid-discharge ambitions.

- Archroma

- Ashok Alco-chem

- Atul Ltd.

- BASF

- Celanese Corporation

- ChromaScape

- DyStar Singapore Pte Ltd

- Kemira Oyj

- Kiri Industries Limited

- Lonza

- Merck KGaA

- Milliken

- Nitin Dye Chem Pvt. Ltd

- Setas Kimya

- Standard Colors, Inc.

- Steiner-Axyntis

- Sudarshan Chemical Industries Limited.

- Synthesia, a.s.

- Thermax Limited

- Vipul Organics Ltd.

- Zhejiang Longsheng

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Shift from plastic to paper-based packaging

- 4.2.2 E-commerce-fuelled boom in corrugated & mailer demand

- 4.2.3 Capacity expansions by major dye manufacturers

- 4.2.4 Breakthroughs in bio-based lignin-compatible dyes

- 4.2.5 Nano-encapsulated dyes enabling digital inkjet printing on paper

- 4.3 Market Restraints

- 4.3.1 Paperless office & digital documents adoption

- 4.3.2 Toxic amines & rising REACH compliance costs

- 4.3.3 Volatility in wood-pulp availability & pricing

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces Analysis

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Bargaining Power of Suppliers

- 4.5.4 Threat of Substitute Products

- 4.5.5 Degree of Competition

5 Market Size & Growth Forecasts (Value)

- 5.1 By Form

- 5.1.1 Powder

- 5.1.2 Liquid

- 5.2 By Type

- 5.2.1 Acidic

- 5.2.2 Basic

- 5.2.3 Direct

- 5.3 By Origin

- 5.3.1 Organic

- 5.3.2 Synthetic

- 5.4 By Application

- 5.4.1 Printing and Writing

- 5.4.2 Packaging

- 5.4.3 Specialty

- 5.4.4 Others (Tissue and Hygiene)

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 South Africa

- 5.5.5.3 Rest of Middle East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products & Services, and Recent Developments)

- 6.4.1 Archroma

- 6.4.2 Ashok Alco-chem

- 6.4.3 Atul Ltd.

- 6.4.4 BASF

- 6.4.5 Celanese Corporation

- 6.4.6 ChromaScape

- 6.4.7 DyStar Singapore Pte Ltd

- 6.4.8 Kemira Oyj

- 6.4.9 Kiri Industries Limited

- 6.4.10 Lonza

- 6.4.11 Merck KGaA

- 6.4.12 Milliken

- 6.4.13 Nitin Dye Chem Pvt. Ltd

- 6.4.14 Setas Kimya

- 6.4.15 Standard Colors, Inc.

- 6.4.16 Steiner-Axyntis

- 6.4.17 Sudarshan Chemical Industries Limited.

- 6.4.18 Synthesia, a.s.

- 6.4.19 Thermax Limited

- 6.4.20 Vipul Organics Ltd.

- 6.4.21 Zhejiang Longsheng

7 Market Opportunities & Future Outlook

- 7.1 White-space & Unmet-need Assessment