|

市场调查报告书

商品编码

1844486

丙酮:市场占有率分析、产业趋势、统计数据、成长预测(2025-2030)Acetone - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

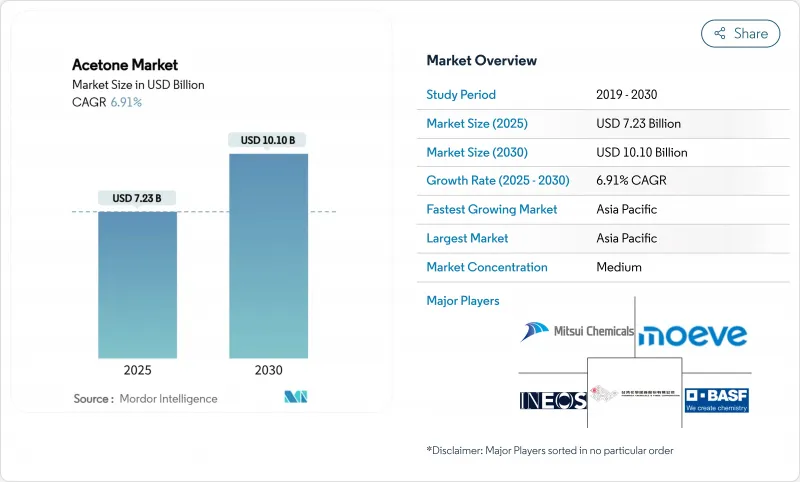

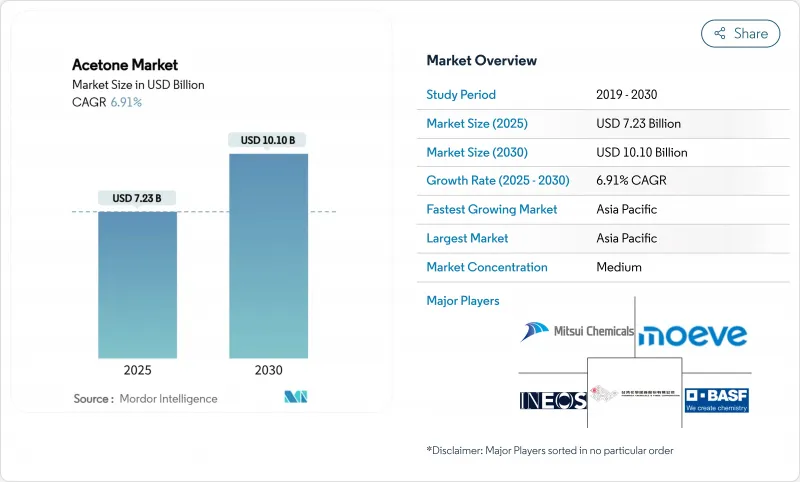

预计 2025 年丙酮市场规模为 72.3 亿美元,到 2030 年将达到 101 亿美元,预测期内(2025-2030 年)的复合年增长率为 6.91%。

这一市场规模成长轨迹得益于丙酮作为挥发性有机化合物(VOC)豁免溶剂、甲基丙烯酸甲酯 (MMA) 和双酚A (BPA) 联产原料以及製药行业高纯度介质日益重要的作用。轻量化电动车、新兴市场的个人护理需求以及后疫情时代的製药产能扩张正在推动销售量的成长。同时,由于对双酚A的监管压力和炼油厂合理化措施导致传统原料供应紧张,生物丙酮技术正在削弱基于异丙苯的供应链优势。随着新兴企业展现可能重塑产业成本曲线的碳负性丙酮路线,同时垂直整合的大型企业确保了原料和下游销售通路的稳定,竞争态势仍将保持稳定。

全球丙酮市场趋势和见解

电动车轻量化对MMA基丙烯酸板材的需求快速成长

电动车製造商正在用基于甲基丙烯酸甲酯 (MMA) 的丙烯酸板材取代玻璃和金属,以减轻汽车重量。由于生产一磅 MMA 需要消耗约 0.5 磅丙酮,因此丙酮的需求量正在翻倍。到 2023 年,北美平均每辆汽车将含有价值 4,371 美元的化学物质。日益严格的 CAFE 燃油经济性法规正在提升丙烯酸嵌装玻璃在较重基材上的吸引力。三菱化学集团拥有先进的微波辅助 PMMA 回收技术,创造了封闭式溢价,进一步推动了下游丙酮市场的发展。

东南亚个人护理溶剂需求不断成长

东南亚地区收入的成长和都市化正在重塑人们的美容习惯,丙酮成为洗去光水和化妆品配方的首选溶剂。丙酮挥发速度快,对皮肤刺激性小,因此非常适合高端化妆品。当地生产商利用丙酮的挥发性有机化合物(VOC)豁免特性,规避了替代溶剂所面临的严格排放费,使其在泰国、越南和印尼市场具有成本竞争力。

欧盟和欧洲化学品管理局加强 BPA 法规

欧盟于2025年1月对食品接触用品实施了广泛的双酚A(BPA)限制,减少了苯酚和丙酮的联产,并消除了欧洲丙酮的一个主要出口管道。生产商必须转向甲基丙烯酸甲酯(MMA)、溶剂和生物基路线,以弥补需求缺口。北美和亚洲部分地区正在就监管限制进行同步讨论,这可能会进一步增加异丙苯基企业的压力。

細項分析

受丙酮快速挥发和VOC法规豁免(尤其是在涂料和黏合剂领域)的推动,预计溶剂类产品将在2024年占据市场收入的43.22%。受电动车和建筑领域丙烯酸玻璃取代玻璃的推动,MMA预计将以7.45%的复合年增长率增长最快。双酚A产业面临监管限制,但一些双酚A(BPA)仍透过聚碳酸酯在家用电器中的使用。甲基异丁基酮和特种中间体将利用丙酮的多样化反应性来实现细分市场成长。

供应方面的变化同样引人注目。汽车轻量化推动了对MMA的需求,而三菱化学集团的微波PMMA回收技术则创造了一个循环的需求环,扩大了丙酮市场的发展机会。溶剂混合商重视丙酮的交叉极性相溶性,这使得低VOC涂料能够满足更严格的排放法规,而无需昂贵的再製造成本。总体而言,即使BPA法规不断发展,应用组合的多样化也使丙酮市场免受任何单一细分市场的影响。

由于油漆、被覆剂和黏合剂在各行各业的广泛应用,到2024年,它们将消耗37.88%的丙酮。而到2030年,化妆品和个人护理品的复合年增长率将达到最高,达到7.23%。东南亚日益壮大的中产阶级将推动指甲油和护肤的使用,而丙酮的温和特性在这些领域备受推崇。电子产品透过聚碳酸酯树脂供应丙酮,确保了稳定的需求。汽车应用将透过基于甲基丙烯酸甲酯(MMA)的压克力面板实现成长,而製药业也将随着亚洲新建的原料药工厂而扩张。

稳定的需求多样性正在推动产品韧性。个人护理配方师正在利用丙酮的双重混溶性,将水和油性活性成分融合在一个产品中,从而提高配方灵活性。在北美和欧洲,专业沙龙连锁店正在采用富含丙酮的卸妆液,以缩短使用时间,并增加重复购买週期。工业终端使用者正在使用需要快速干燥的建筑被覆剂来维持基准用量。

区域分析

受中国庞大的苯酚、丙酮和双酚A(BPA)产能以及东南亚不断扩张的利基化工产业丛集的推动,亚太地区将在2024年占据42.45%的销售量。预计该地区的需求成长将超过经合组织国家,到2030年,复合年增长率将达到7.66%。中国政府的化工产业蓝图强调自给自足和高附加价值产品,引导资本流向能够在利润率波动的情况下在燃料和石化产品之间切换的综合炼油厂。中国2023年的原油产量将达到1,480万桶/日,为下游丙酮生产装置提供了可行的原料。

由于炼油厂关闭,北美异丙苯丙烯供应量正在下降,但汽车和航太轻量化领域表现良好。欧洲正面临对双酚A(BPA)的监管审查日益严格,但对永续生产的投资正在抵消部分产量损失。英力士的马尔工厂就是一个结合原料管理和减碳策略,以确保未来丙酮供应的典范。

南美,尤其是巴西,由于国内产能有限,工业化进程加快,正在推动新的进口。国家鼓励围绕乙醇原料建设化工园区,预计在预测期内可能会刺激发酵计划的发展。在中东和非洲,低成本的石脑油和液化石油气正在支持待开发区石化综合体,包括苯酚-丙酮一体化项目,提供出口导向供应,但国内需求有限。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场状况

- 市场概况

- 市场驱动因素

- 随着电动车减重工作的持续推进,MMA 基丙烯酸板材的需求激增

- 家电中聚碳酸酯的消费量不断增加

- 东南亚个人护理溶剂需求不断成长

- 新冠疫情后,对药物原料药成分溶剂的需求增加

- 废甘油发酵生产生质丙酮的成本平准化

- 市场限制

- 欧盟和欧洲化学品管理局加强 BPA 法规

- 炼油厂关闭导致异丙苯原料供应受限

- 溶剂使用的新VOC法规

- 价值链分析

- 监管状况

- 五力分析

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

- 生产能力分析

- 贸易分析

第五章市场规模及成长预测

- 按用途

- 甲基丙烯酸甲酯(MMA)

- 双酚A(BPA)

- 溶剂

- 甲基异丁基酮(MIBK)

- 其他用途(化学中间体)

- 按最终用途行业

- 化妆品和个人护理

- 电子产品

- 车

- 製药

- 油漆、被覆剂、黏合剂

- 纺织品

- 其他终端用户产业(塑胶)

- 按製造工艺

- 异丙苯工艺

- 异丙醇氧化

- 丙烯直接氧化

- 生物基发酵

- 按年级

- 技术等级

- 医药级

- 试剂/分析级

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- ASEAN

- 亚太地区其他国家

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 俄罗斯

- 其他欧洲国家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 阿拉伯聯合大公国

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争态势

- 市场集中度

- 策略倡议

- 市占率分析

- 公司简介

- Altivia

- BASF SE

- Borealis GmbH

- Deepak

- Formosa Chemicals & Fibre Corp.

- Honeywell International Inc.

- INEOS

- Kumho P&B Chemicals

- LG Chem

- Mitsui Chemicals Inc.

- Moeve

- PTT Phenol Co. Ltd.

- SABIC

- Shell plc

- Ufaorgsintez(Bashneft)

第七章 市场机会与未来展望

The Acetone Market size is estimated at USD 7.23 billion in 2025, and is expected to reach USD 10.10 billion by 2030, at a CAGR of 6.91% during the forecast period (2025-2030).

This market size trajectory is supported by acetone's expanding role as a VOC-exempt solvent, a feedstock for methyl methacrylate (MMA) and bisphenol A (BPA) co-production, and a high-purity medium for pharmaceutical manufacturing. Electric vehicle lightweighting, personal care demand in emerging economies, and post-COVID pharmaceutical capacity additions are accelerating volume growth. At the same time, bio-acetone technologies are eroding the dominance of cumene-based supply chains, while regulatory pressures on BPA and refinery rationalizations tighten traditional feedstock availability. Competitive dynamics remain moderate as vertically integrated majors secure raw materials and downstream outlets, even as biotechnology start-ups demonstrate carbon-negative acetone routes that could re-set industry cost curves.

Global Acetone Market Trends and Insights

Surging Demand for MMA-Based Acrylic Sheets in EV Lightweighting

Electric vehicle makers are replacing glass and metal with MMA-based acrylic sheets to cut curb weight, which multiplies acetone demand because MMA consumes roughly 0.5 pounds of acetone per pound produced. The average North American auto contained USD 4,371 worth of chemistry in 2023, underscoring the material intensity of modern vehicles. Stricter CAFE fuel-economy rules heighten the appeal of acrylic glazing over heavier substrates. Mitsubishi Chemical Group has advanced microwave-assisted PMMA recycling, creating a closed-loop premium that further strengthens downstream pull on the acetone market.

Expansion of Personal-Care Solvent Demand in Southeast Asia

Rising incomes and urbanization in Southeast Asia are reshaping beauty routines, making acetone a preferred solvent for nail polish removers and cosmetic blends. The chemical's rapid evaporation and low dermal irritation suit premium formulations. Local producers capitalize on acetone's VOC-exempt status, avoiding the stricter emission fees faced by alternative solvents and enhancing cost competitiveness across Thailand, Vietnam, and Indonesia.

Tightening BPA Regulations by EU & ECHA

The EU enforced broad BPA restrictions in January 2025 for food-contact articles, reducing phenol-acetone co-production volumes and removing a notable outlet for acetone in Europe. Producers must pivot to MMA, solvents, or bio-routes to cushion the demand gap. Parallel debates in North America and parts of Asia may duplicate regulatory limits, compounding pressure on cumene-based operations.

Other drivers and restraints analyzed in the detailed report include:

- Growing Pharmaceutical API Solvent Requirements Post-COVID

- Bio-Acetone Cost Parity via Waste-Glycerol Fermentation

- Emerging VOC Limits on Solvent Use

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Solvents held 43.22% of 2024 revenues, supported by acetone's rapid evaporation and exemption from most VOC caps, especially in paints and adhesives. MMA is the fastest riser at 7.45% CAGR as acrylic glazing replaces glass in electric vehicles and construction. The bisphenol A segment faces regulatory drag, yet consumer electronics sustain some BPA volume through polycarbonate use. Methyl isobutyl ketone and specialty intermediates provide niche growth by leveraging acetone's versatile reactivity.

Supply-side changes are equally stark. Automotive lightweighting magnifies MMA pull, whereas microwave PMMA recycling from Mitsubishi Chemical Group creates circular demand loops that lengthen acetone market opportunity windows. Solvent blenders prize acetone for miscibility across polarities, permitting lower VOC coatings that meet tougher emission caps without costly reformulation. Overall, application mix diversification shields the acetone market from single-segment shocks even as BPA curbs unfold.

Paints, coatings, and adhesives consumed 37.88% of acetone in 2024 due to broad industrial adoption, yet cosmetics and personal care post the highest 7.23% CAGR to 2030. Southeast Asia's rising middle class fuels nail polish and skincare volumes, where acetone's low irritation profile is prized. Electronic devices channel acetone through polycarbonate resins, locking in stable demand. Automotive applications grow through MMA-based acrylic panels, while pharmaceuticals expand alongside new API plants in Asia.

Stable demand diversity bolsters resilience. Personal care formulators exploit acetone's dual miscibility to pair water and oil actives in a single product, raising formulation flexibility. In North America and Europe, professional salon chains adopt acetone-rich removers that cut service times, boosting repeat purchase cycles. Industrial end users maintain baseline volume through architectural coatings that need fast dry times.

The Acetone Market Report is Segmented by Application (Methyl Methacrylate, Bisphenol A, Solvents, and More), End-Use Industry (Cosmetics and Personal Care, Electronics, and More), Production Process (Cumene Process, Isopropanol Oxidation, and More), Grade (Technical Grade, Pharmaceutical Grade, and More), and Geography (Asia-Pacific, North America, Europe, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia Pacific captured 42.45% of 2024 volume owing to China's vast phenol-acetone and BPA base and Southeast Asia's expanding niche chemicals clusters. The region is projected to post a 7.66% CAGR to 2030 as local demand outstrips OECD growth. Government chemical industry roadmaps emphasize self-sufficiency and higher value products, steering capital into integrated refineries that can toggle between fuels and petrochemicals amid margin swings. China processed 14.8 million b/d of crude in 2023, underscoring feedstock availability for downstream acetone units.

North America enjoys a strong automotive and aerospace lightweighting pull, although refinery closures narrow the propylene supply for cumene. Europe faces the sharpest regulatory scrutiny on BPA but offsets some volume loss through sustainable production investments. INEOS's Marl facility exemplifies strategy that pairs feedstock control with carbon-cuts to future-proof acetone supply.

South America's industrialization, especially in Brazil, invites new imports as local capacity remains limited. State incentives to build chemical parks around ethanol feedstocks could spur fermentation projects over the forecast period. In the Middle East and Africa, low-cost naphtha and LPG underpin greenfield petrochemical complexes that include phenol-acetone integration, providing export-oriented supply but limited domestic pull.

- Altivia

- BASF SE

- Borealis GmbH

- Deepak

- Formosa Chemicals & Fibre Corp.

- Honeywell International Inc.

- INEOS

- Kumho P&B Chemicals

- LG Chem

- Mitsui Chemicals Inc.

- Moeve

- PTT Phenol Co. Ltd.

- SABIC

- Shell plc

- Ufaorgsintez (Bashneft)

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Surging demand for MMA-based acrylic sheets in EV light-weighting

- 4.2.2 Rising polycarbonate consumption in consumer electronics

- 4.2.3 Expansion of personal-care solvent demand in Southeast Asia

- 4.2.4 Growing pharmaceutical API solvent requirements post-COVID

- 4.2.5 Bio-acetone cost parity via waste-glycerol fermentation

- 4.3 Market Restraints

- 4.3.1 Tightening BPA regulations by EU and ECHA

- 4.3.2 Refinery closures curbing cumene feedstock supply

- 4.3.3 Emerging VOC limits on solvent use

- 4.4 Value Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Porter's Five Forces

- 4.6.1 Bargaining Power of Suppliers

- 4.6.2 Bargaining Power of Buyers

- 4.6.3 Threat of New Entrants

- 4.6.4 Threat of Substitutes

- 4.6.5 Degree of Rivalry

- 4.7 Production Capacity Analysis

- 4.8 Trade Analysis

5 Market Size and Growth Forecasts (Value)

- 5.1 By Application

- 5.1.1 Methyl Methacrylate (MMA)

- 5.1.2 Bisphenol A (BPA)

- 5.1.3 Solvents

- 5.1.4 Methyl Isobutyl Ketone (MIBK)

- 5.1.5 Other Applications (Chemical Intermediates)

- 5.2 By End-Use Industry

- 5.2.1 Cosmetics and Personal Care

- 5.2.2 Electronics

- 5.2.3 Automotive

- 5.2.4 Pharmaceutical

- 5.2.5 Paints, Coatings and Adhesives

- 5.2.6 Textile

- 5.2.7 Other End-user Industry (Plastics)

- 5.3 By Production Process

- 5.3.1 Cumene Process

- 5.3.2 Isopropanol Oxidation

- 5.3.3 Direct Propylene Oxidation

- 5.3.4 Bio-based Fermentation

- 5.4 By Grade

- 5.4.1 Technical Grade

- 5.4.2 Pharmaceutical Grade

- 5.4.3 Reagent/Analytical Grade

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 ASEAN

- 5.5.1.6 Rest of APAC

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Russia

- 5.5.3.6 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 United Arab Emirates

- 5.5.5.3 South Africa

- 5.5.5.4 Rest of Middle East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles {(includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)}

- 6.4.1 Altivia

- 6.4.2 BASF SE

- 6.4.3 Borealis GmbH

- 6.4.4 Deepak

- 6.4.5 Formosa Chemicals & Fibre Corp.

- 6.4.6 Honeywell International Inc.

- 6.4.7 INEOS

- 6.4.8 Kumho P&B Chemicals

- 6.4.9 LG Chem

- 6.4.10 Mitsui Chemicals Inc.

- 6.4.11 Moeve

- 6.4.12 PTT Phenol Co. Ltd.

- 6.4.13 SABIC

- 6.4.14 Shell plc

- 6.4.15 Ufaorgsintez (Bashneft)

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment