|

市场调查报告书

商品编码

1844492

聚合物奈米复合材料:市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)Polymer Nanocomposite - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

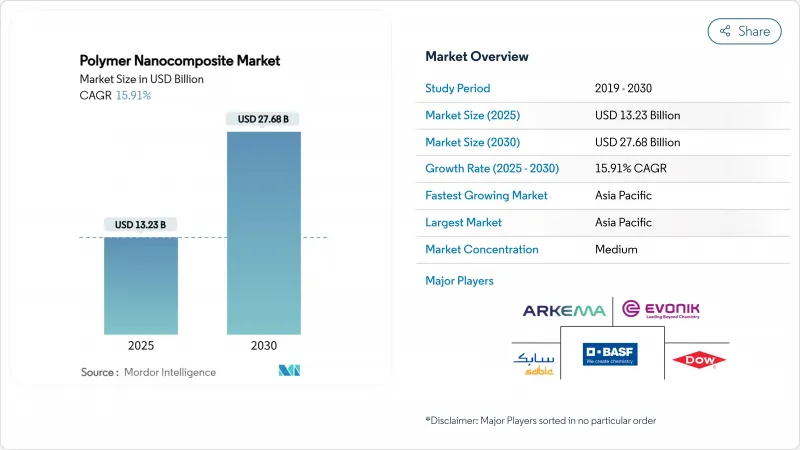

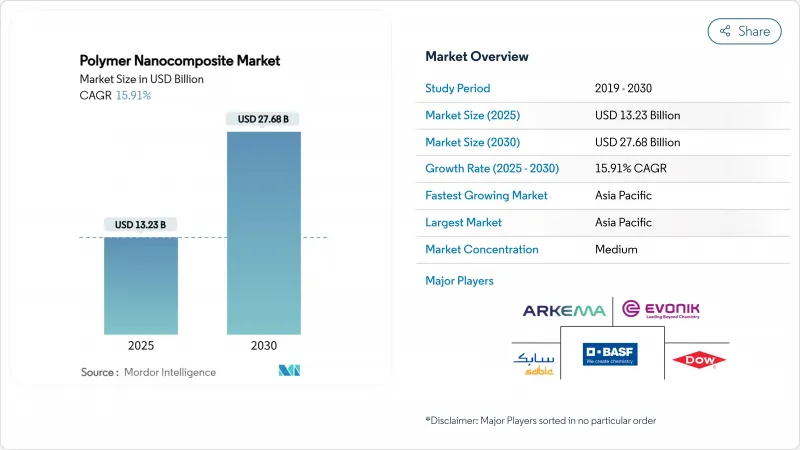

聚合物奈米复合材料市场规模预计在 2025 年为 132.3 亿美元,预计到 2030 年将达到 276.8 亿美元,预测期内(2025-2030 年)的复合年增长率为 15.91%。

随着奈米填充材能够同时提升强度、导热性和阻隔性能,使其成为轻量化电动车零件、高密度电子产品和下一代封装的核心材料,其需求将加速成长。虽然汽车专案正在推动近期产量成长,但蓬勃发展的5G基础设施和无卤化阻燃法规正在扩大客户群。石墨烯和奈米碳管生产成本的降低带来了经济效益的提升,而亚太地区供应链则持续缩短前置作业时间并保持成长势头。对可回收热塑性基质的投资进一步将聚合物奈米复合材料市场定位为实现循环经济目标的首选解决方案。

全球聚合物奈米复合材料市场趋势与洞察

食品和药品对高阻隔包装的需求不断增长

聚合物奈米复合材料可将氧气透过率降低至0.1 cc/m²/天以下,从而实现多层复合,同时将薄膜厚度减少高达40%。抗菌金属氧化物奈米颗粒可延长保质期,使食品加工商能够从化学防腐剂转向活性包装形式。对湿气敏感的药品也受益匪浅,可实现简化回收流程的单层泡壳设计。 FDA关于奈米材料风险评估的指导缩短了核准週期,生产线整合则省去了层压步骤,从而提高了产量并降低了废品率。

汽车和移动复合材料的轻量化目标

碳纤维增强热塑性奈米复合材料比钢材减轻了40%的重量,并支援自动化纤维铺放生产线,以支援大批量电动车专案。其可回收性提高了整体生命週期的经济性,并满足了循环经济的要求。除了减轻重量外,奈米级填料还能增强碰撞能量吸收、降低噪音振动 (NVH) 并实现薄壁设计。欧洲原始设备製造商计划在2030年实现20-25%的减重,这将推动对树脂和增强材料的投资。

配方和分散成本高

高长宽比填料的均匀分散需要高剪切双螺桿挤出机,与标准聚合物相比,加工成本会增加200-400%。为防止奈米管团聚而进行的功能化处理需要额外的步骤和许可费用。干粉和母粒降低了资本投资,但增加了供应链的复杂性。在实现规模经济之前,成本压力将限制其在价格敏感型包装和消费品领域的渗透。

細項分析

受低成本和成熟的薄膜挤出技术推动,奈米黏土将在2024年占据聚合物奈米复合材料市场份额的38.13%。更高的阻隔性使其能够在零嘴零食包装中实现5-7微米的凹槽,且不会影响保质期。奈米碳管占据高端市场,其10^3 S/m的电导率抵消了价格因素的影响,而金属氧化物填料则满足了防紫外线、抗菌和阻燃的需求。其他填料类别,包括可扩展的石墨烯和奈米钻石等级,将实现19.44%的复合年增长率,因为它们提供了电磁屏蔽和导热通道。综上所述,这些趋势表明配方的多样性正在不断增强,而不是单一填料的主导地位。

区域分析

到2024年,亚太地区聚合物奈米复合材料的市场份额将达到40.35%,这体现了其深厚的製造业生态系统和积极的国家项目。中国正在扩大石墨烯奈米管的生产规模并压缩成本曲线,而印度的积层製造蓝图瞄准了全球5%的市场份额,这将刺激下游需求。日本正在资助一个纤维素奈米纤维试点项目,该项目将永续性与高模量相结合,吸引了家电和汽车製造商。

北美将利用汽车轻量化法案和航太认证管道。 USMCA贸易框架将促进复合颗粒的跨境供应,支援在墨西哥组装并在美国销售的汽车平台。在欧洲,严格的环境、健康和安全法规与循环经济目标相结合,正在加速无卤奈米复合材料在建筑板材和铁路内饰的应用。中东和非洲将透过绿色建筑标准和石化产品多元化迎来需求成长,而南美将受益于巴西的包装加工商和新兴的电动车零件生产线。预测期内,区域差异化将推动聚合物奈米复合材料市场的均衡扩张。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场状况

- 市场概况

- 市场驱动因素

- 食品和药品对高阻隔包装的需求不断增长

- 汽车和移动出行复合材料的轻量化目标

- 5G和电力电子的温度控管需求

- 对阻燃和无卤材料的监管更加严格

- 电动汽车电池外壳材料

- 市场限制

- 混合和分散成本高

- 奈米毒性/EHS合规不确定性

- 石墨烯和碳奈米管供应规模化挑战

- 价值链分析

- 技术展望

- 五力分析

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

- 专利分析

第五章市场规模及成长预测

- 按填料类型

- 奈米碳管

- 金属氧化物

- 奈米黏土

- 奈米纤维

- 其他填充剂

- 按聚合物基质

- 热塑性塑料

- 热固性树脂

- 生物基聚合物

- 按最终用户产业

- 车

- 包装

- 航太/国防

- 电气和电子

- 能源与储存

- 其他最终用户产业

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- ASEAN

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 其他欧洲国家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 阿拉伯聯合大公国

- 南非

- 埃及

- 其他中东和非洲地区

- 亚太地区

第六章 竞争态势

- 市场集中度

- 策略倡议

- 市占率分析

- 公司简介

- 3D Systems Inc.

- Altana

- Arkema

- AxiPolymer Inc.

- BASF

- Birla Carbon

- Dow

- DuPont

- Evonik Industries AG

- Foster, LLC

- Hybrid Plastics Inc.

- Inframat Corporation

- Mitsubishi Chemical Group Corporation

- Nanocyl SA

- Powdermet Inc.

- RTP Company

- SABIC

- ShayoNano Singapore Private Ltd.

- Solesence

- Sumitomo Chemical Co. Ltd.

- TORAY INDUSTRIES, INC.

第七章 市场机会与未来展望

The Polymer Nanocomposite Market size is estimated at USD 13.23 billion in 2025, and is expected to reach USD 27.68 billion by 2030, at a CAGR of 15.91% during the forecast period (2025-2030).

Demand accelerates as nanoscale fillers unlock simultaneous gains in strength, thermal conductivity, and barrier performance, making the material central to lightweight electric-vehicle parts, high-density electronics, and next-generation packaging. Automotive programs anchor near-term volumes, while fast-moving 5G infrastructure and halogen-free flame-retardant regulations broaden the customer base. Cost-down progress in graphene and carbon-nanotube production improves economics, and regional supply chains in Asia-Pacific shorten lead times, sustaining momentum. Investments in recycling-friendly thermoplastic matrices further position the polymer nanocomposites market as a preferred solution for circular-economy goals.

Global Polymer Nanocomposite Market Trends and Insights

Growing Demand for High-Barrier Packaging in Food and Pharma

Polymer nanocomposites lower oxygen transmission below 0.1 cc/m2/day, matching multilayer laminates while cutting film thickness by up to 40%. Antimicrobial metal-oxide nanoparticles extend shelf life, so food processors shift from chemical preservatives to active-packaging formats. Moisture-sensitive pharmaceuticals also benefit, allowing single-layer blister designs that simplify recycling. FDA guidance on nanomaterial risk assessment shortens approval cycles, and line integration eliminates lamination steps, improving throughput and waste ratios.

Lightweighting Targets in Automotive and Mobility Composites

Carbon-fiber-reinforced thermoplastic nanocomposites yield 40% mass savings versus steel and support automated fiber-placement lines, aligning with high-volume e-mobility programs. Recyclability boosts total-life economics, meeting circular mandates. Beyond mass reduction, nanoscale fillers enhance crash energy absorption and damp NVH, enabling thin-wall designs. European OEMs plan 20-25% weight cuts by 2030, catalyzing resin and reinforcement investment.

High Compounding and Dispersion Costs

Uniform distribution of high-aspect-ratio fillers demands twin-screw extruders with intensified shear, adding 200-400% to processing cost versus standard polymers. Functionalization to curb nanotube agglomeration introduces extra steps and licensing fees. Dry-powder and masterbatch routes lower capex but widen supply-chain complexity. Cost pressure limits penetration into price-sensitive packaging and consumer goods until scale economies materialize.

Other drivers and restraints analyzed in the detailed report include:

- Thermal Management Needs in 5G and Power Electronics

- Regulatory Push for Flame-Retardant, Halogen-Free Materials

- Nanotoxicity/EHS Compliance Uncertainty

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Nanoclay held 38.13% polymer nanocomposites market share in 2024 on the strength of low cost and established film-extrusion know-how. Barrier gains allow 5-7 µm downgauging in snack packaging without compromising shelf life. Carbon nanotubes occupy premium niches where 10^3 S/m conductivity offsets price, while metal-oxide fillers address UV, antimicrobial, and flame-retardant needs. The other-filler category captures 19.44% CAGR as scalable graphene and nanodiamond grades unlock EMI shielding and thermal paths. Combined, these trends suggest widening formulation diversity rather than one-filler dominanc.

The Polymer Nanocomposites Market Report is Segmented by Filler Type (Carbon Nanotube, Metal Oxide, Nanoclay, and More), Polymer Matrix (Thermoplastics, Thermosets, and Bio-Based Polymers), End-User Industry (Automotive, Packaging, Aerospace and Defense, and More), and Geography (Asia-Pacific, North America, Europe, South America, and Middle-East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific's 40.35% polymer nanocomposites market share in 2024 mirrors deep manufacturing ecosystems and proactive state programs. China's scale in graphene nanotube production compresses cost curves, while India's additive-manufacturing roadmap targets a 5% global stake, stimulating downstream demand. Japan funds cellulose nanofiber pilots that blend sustainability with high modulus, drawing appliance and auto tier-ones.

North America leverages automotive lightweighting legislation and aerospace certification pipelines. The USMCA trade framework eases cross-border supply of compounded pellets, aiding vehicle platforms assembled in Mexico yet sold in the United States. Europe couples stringent EHS rules with circular-economy targets, accelerating halogen-free nanocomposite adoption in building panels and rail interiors. The Middle East and Africa open pockets of demand through green-building codes and petrochemical diversification, while South America's progress hinges on Brazilian packaging converters and nascent EV component lines. Collectively, regional differentiation ensures balanced expansion for the polymer nanocomposites market over the forecast horizon.

- 3D Systems Inc.

- Altana

- Arkema

- AxiPolymer Inc.

- BASF

- Birla Carbon

- Dow

- DuPont

- Evonik Industries AG

- Foster, LLC

- Hybrid Plastics Inc.

- Inframat Corporation

- Mitsubishi Chemical Group Corporation

- Nanocyl SA

- Powdermet Inc.

- RTP Company

- SABIC

- ShayoNano Singapore Private Ltd.

- Solesence

- Sumitomo Chemical Co. Ltd.

- TORAY INDUSTRIES, INC.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing Demand for High-Barrier Packaging in Food and Pharma

- 4.2.2 Lightweighting Targets in Automotive and Mobility Composites

- 4.2.3 Thermal Management Needs in 5G and Power Electronics

- 4.2.4 Regulatory Push for Flame-Retardant, Halogen-Free Materials

- 4.2.5 Battery-Housing Materials for Electric Vehicles

- 4.3 Market Restraints

- 4.3.1 High Compounding and Dispersion Costs

- 4.3.2 Nanotoxicity/EHS Compliance Uncertainty

- 4.3.3 Scale-Up Challenges for Graphene and CNT Supply

- 4.4 Value Chain Analysis

- 4.5 Technological Outlook

- 4.6 Porter's Five Forces

- 4.6.1 Bargaining Power of Suppliers

- 4.6.2 Bargaining Power of Buyers

- 4.6.3 Threat of New Entrants

- 4.6.4 Threat of Substitutes

- 4.6.5 Degree of Competition

- 4.7 Patent Analysis

5 Market Size and Growth Forecasts (Value)

- 5.1 By Filler Type

- 5.1.1 Carbon Nanotube

- 5.1.2 Metal Oxide

- 5.1.3 Nanoclay

- 5.1.4 Nanofiber

- 5.1.5 Other Filler Types

- 5.2 By Polymer Matrix

- 5.2.1 Thermoplastics

- 5.2.2 Thermosets

- 5.2.3 Bio-based Polymers

- 5.3 By End-user Industry

- 5.3.1 Automotive

- 5.3.2 Packaging

- 5.3.3 Aerospace and Defense

- 5.3.4 Electrical and Electronics

- 5.3.5 Energy and Storage

- 5.3.6 Other End-user Industries

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 ASEAN

- 5.4.1.6 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Spain

- 5.4.3.6 Russia

- 5.4.3.7 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle-East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 United Arab Emirates

- 5.4.5.3 South Africa

- 5.4.5.4 Egypt

- 5.4.5.5 Rest of Middle-East and Africa

- 5.4.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 3D Systems Inc.

- 6.4.2 Altana

- 6.4.3 Arkema

- 6.4.4 AxiPolymer Inc.

- 6.4.5 BASF

- 6.4.6 Birla Carbon

- 6.4.7 Dow

- 6.4.8 DuPont

- 6.4.9 Evonik Industries AG

- 6.4.10 Foster, LLC

- 6.4.11 Hybrid Plastics Inc.

- 6.4.12 Inframat Corporation

- 6.4.13 Mitsubishi Chemical Group Corporation

- 6.4.14 Nanocyl SA

- 6.4.15 Powdermet Inc.

- 6.4.16 RTP Company

- 6.4.17 SABIC

- 6.4.18 ShayoNano Singapore Private Ltd.

- 6.4.19 Solesence

- 6.4.20 Sumitomo Chemical Co. Ltd.

- 6.4.21 TORAY INDUSTRIES, INC.

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment