|

市场调查报告书

商品编码

1844585

辐射固化涂料:市场占有率分析、产业趋势、统计数据和成长预测(2025-2030)Radiation Curable Coatings - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

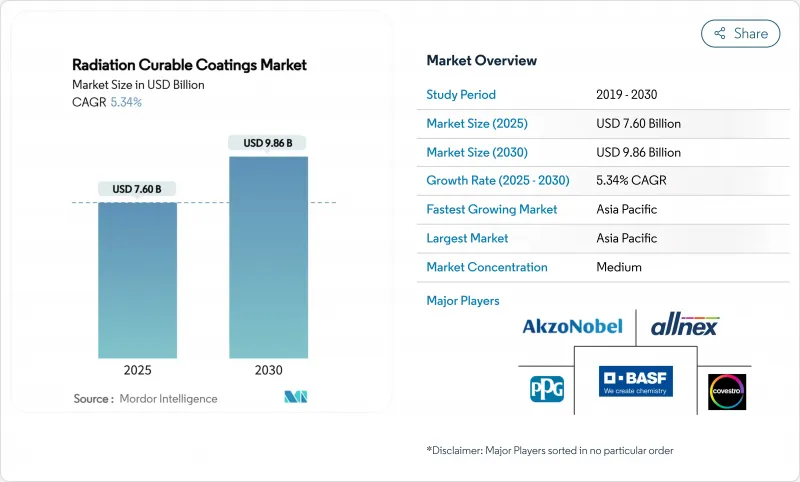

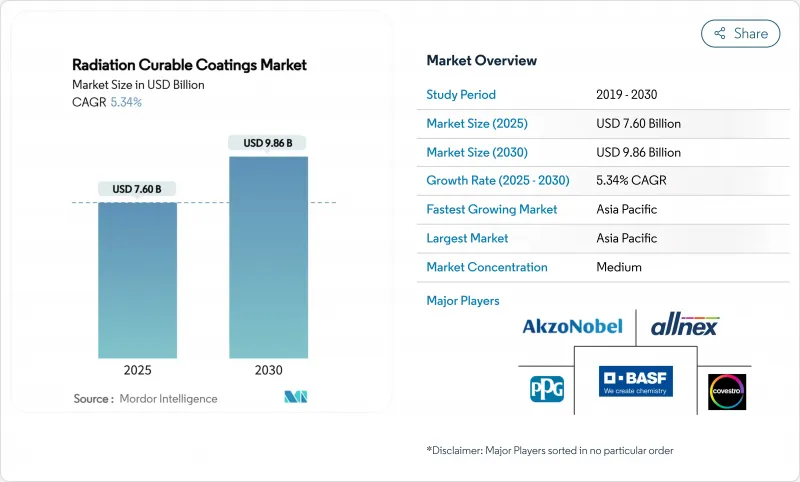

辐射固化涂料市场规模预计在 2025 年达到 76 亿美元,预计到 2030 年将达到 98.6 亿美元,预测期内(2025-2030 年)的复合年增长率为 5.34%。

市场参与企业将此增长归因于全球范围内VOC法规的加强、对节能生产方法的探索以及无溶剂化学技术的稳步应用。亚太地区凭藉着监管协调和新型工业化生产,巩固了其区域优势。美国环保署(EPA)针对气雾涂料的挥发性有机化合物排放标准于2025年1月17日生效,合规截止日期延长至2027年1月17日,为製造商提供了24个月的时间来改进其产品,监管势头加速了市场采用。

全球辐射固化涂料市场趋势与洞察

日益严格的VOC和碳中和法规加速了无溶剂UV/EB的采用

全球各地的监管机构持续降低挥发性有机化合物 (VOC) 的允许基准值,推动辐射固化被覆剂市场朝向无溶剂、100% 固体含量配方迈进。美国环保署于 2025 年 1 月 17 日更新了气溶胶涂料的 VOC排放标准,并给予製造商两年时间实施。加州空气资源委员会正在实施类似的限制措施,将水和豁免化合物排除在「VOC 限值」的计算之外。这些措施旨在奖励那些部署了无需溶剂炉即可即时固化的紫外光或电子束 (EB) 生产线的涂料企业,从而减少能源消耗并提高工厂产量。工业维护涂料的联邦基准值上限为 450 克/公升,但一些州已将此限值降低至 100-250 克/公升,这使得无溶剂技术更具吸引力。

对高吞吐量包装和数位印刷生产线的需求

生产感压标籤、软质包装和折迭纸盒的加工商依靠UV油墨来省去传统印刷机漫长的干燥过程。即时固化印刷品在排放线上完全黏合,可即时进行整理和运输,这对于即时订单和个人化设计至关重要。行业出版物预测,快速自动化、永续性以及数位和柔印混合工作流程将在2025年定义包装产业。像Inks International这样的设备供应商已经推出了兼容LED的能量固化油墨套装,这些油墨符合食品接触通讯协定,并支持用于收缩套标的大容量白色油墨。诸如此类的解决方案正在巩固辐射固化涂料在包装印刷应用中的市场地位。

特种寡聚物和光引发剂高成本

与商品树脂相比,专用寡聚物链和高纯度光引发剂的成本显着增加。 2025年美国关税导致的运费溢价、加拿大和墨西哥某些原物料价格上涨25%以及许多中国产品价格上涨10%,进一步加剧了涂料製造商的采购预算压力,迫使一些公司调整筹资策略。太阳化学及其同行已采取临时价格溢价措施,以抵消原材料成本上涨的影响,这凸显了整个辐射固化被覆剂市场的利润压力。

細項分析

到2024年,寡聚物将占据辐射固化涂料市场45.77%的份额,引领价值链。预计与寡聚物相关的辐射固化被覆剂市场规模将稳定扩大,以满足聚酯、胺甲酸乙酯、环氧树脂和丙烯酸等不同终端应用的需求。 Alnex的UCECOAT 7856就是一个典型案例,它为高光泽地板提供无溶剂分散体,消除了传统的挥发性有机化合物(VOC)。

同时,随着LED专用光引髮剂在低能量波长范围内的应用成长,以保护生产线操作员免受高温灯罩的伤害,预计光引发剂的复合年增长率将达到6.88%。单体持续调节黏度和交联密度,实验室使用生物基甲基丙烯酸酯稀释剂来减少对化石燃料的依赖。

受易于改装的经济效益和强大的全球分销网络的推动,到2024年,紫外线灯将占装置容量的69.67%。工厂正在用掺铁灯替换老化的汞灯,从而从现有生产线中提取更高的照度,并推迟了大规模检修。然而,与电子束设备相关的辐射固化涂料市场可能成长最快,到2030年复合年增长率将超过7.10%,因为加工商越来越重视光引发剂固化、深层薄膜渗透和氧不敏感聚合等优势。电子束生产线现在能够处理阻隔包装中常见的厚颜料体系,这引起了食品罐头厂和保护性被覆剂的兴趣。

LED-UV 光源曾经仅限于窄幅标籤印刷机,如今由于动作温度很少超过 40°C,它已应用于宽幅图形和工业拼花线的照明。混合双固化装置融合了紫外线和湿气固化化学成分,以确保在阴影凹槽中的黏合性,而新型雷射诱导光聚合装置则有望透过将曝光时间缩短至毫秒级,实现秒级的生产效率飞跃。

辐射固化被覆剂报告按原料(寡聚物、单体、光引发剂、添加剂)、固化技术(紫外线灯、电子束、其他)、树脂化学(环氧丙烯酸酯、胺甲酸乙酯丙烯酸酯、聚酯丙烯酸酯、其他)、最终用户行业(木材和家具、包装和印刷油墨、电子和半导体、其他地区(亚太地区)和欧洲地区(亚太地区)。

区域分析

亚太地区占据市场主导地位,占41.23%,预计到2024年复合年增长率为6.05%,使该地区呈现双头主导格局。中国、日本和印度在电子、包装和汽车领域占据主导地位,随着国内环境法规日益向欧洲标准看齐,这些国家推动了原材料需求的持续成长。家具、地板材料和塑胶消费品的添加剂产能正从越南中部向中国东部沿海地区扩张,而紫外光固化木器漆和塑胶面漆的营业额则保持在高位。

在北美,美国)的指令正在推动无溶剂涂料的普及,加州更是为挥发性有机化合物(VOC)法规设定了全国基准。密西根州和安大略省的汽车原始设备製造商正在将LED-UV光固化隧道应用于内饰,以减少能源足迹。然而,美国于2025年推出的关税制度正在鼓励固化树脂製造商加强国内后向整合,并降低市场波动性。

欧洲的愿景集中在绿色交易和 REACH 的扩展上,后者已从 2025 年 9 月起禁止在指甲产品中使用 TPO光引发剂。计划于 2026 年对面板製造商实施甲醛限制,并限制包装和包装废弃物,这将加强有利于辐射固化化学品的市场环境。

随着跨国公司为规避运输和外汇风险而建立卫星涂层设施,南美、中东和非洲地区的需求正在兴起,但仍然强劲。巴西的柔性塑胶薄膜印刷和沙乌地阿拉伯的板式家具等计划表明,从北美引进的环境法规正在加速技术转移。虽然当地配方製造商仍依赖进口寡聚物,但逐步收紧的法规意味着,一旦基础设施和技能发展,这些地区很可能会成为下一个成长点。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场状况

- 市场概况

- 市场驱动因素

- 日益严格的VOC和碳中和法规加速了无溶剂UV/EB的普及

- 对高吞吐量包装和数位印刷生产线的需求

- 超薄电子产品和穿戴式装置三防胶的成长

- 亚太地区家具及地板製造产能快速扩张

- 原始设备製造商转向汽车内装零件的线上 LED-UV 固化

- 市场限制

- 特种寡聚物和光引发剂高成本

- 欧盟 REACH 分类变更后酰基氧化膦供应紧张

- 新兴生物构装基板的热敏感性

- 价值链分析

- 五力分析

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章市场规模及成长预测

- 按原料

- 寡聚物

- 单体

- 光引发剂

- 添加剂

- 透过固化技术

- 紫外线灯

- 电子束

- 混合/双重固化

- 微波/红外线

- 依树脂化学

- 环氧丙烯酸酯

- 胺甲酸乙酯丙烯酸酯

- 聚酯丙烯酸酯

- 丙烯酸酯

- 其他(有机硅、乙烯基醚)

- 按最终用户产业

- 木材/家具

- 包装印刷油墨

- 电子和半导体

- 汽车和运输设备

- 医疗设备

- 3D列印/积层製造

- 其他(光学、建筑)

- 按地区

- 亚太地区

- 中国

- 日本

- 印度

- 韩国

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 其他欧洲国家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争态势

- 市场集中度

- 策略倡议

- 市占率分析

- 公司简介

- 3M

- Akzo Nobel NV

- Allnex Netherlands BV

- Arkema

- Ashland

- Axalta Coating Systems LLC

- BASF

- Covestro AG

- Dymax Corporation

- Evonik Industries AG

- Henkel AG & Co. KGaA

- Lord Corporation

- Nippon Paint Holdings Co., Ltd.

- PPG Industries, Inc.

- Rahn AG

- The Sherwin-Williams Company

- Watson Coatings, Inc.

第七章 市场机会与未来展望

The Radiation Curable Coatings Market size is estimated at USD 7.60 billion in 2025, and is expected to reach USD 9.86 billion by 2030, at a CAGR of 5.34% during the forecast period (2025-2030).

Market participants attribute this upswing to stricter global VOC limits, the search for energy-efficient production methods, and steady uptake of solvent-free chemistries. Asia Pacific secured regional primacy on the back of regulatory harmonisation and new industrial output. Regulatory momentum accelerates market adoption as the EPA's National Volatile Organic Compound Emission Standards for aerosol coatings took effect January 17, 2025, with compliance deadlines extended to January 17, 2027, creating a 24-month window for manufacturers to reformulate products.

Global Radiation Curable Coatings Market Trends and Insights

Tightening VOC and Carbon-Neutrality Regulations Accelerate Solvent-Free UV/EB Adoption

Global regulators continue to narrow permissible VOC thresholds, a move that propels the radiation-curable coatings market toward 100% solids formulas that emit no solvents. The United States Environmental Protection Agency enforced updated National VOC Emission Standards for aerosol coatings on 17 January 2025, giving manufacturers a two-year window to reassess formulations. California's Air Resources Board operates parallel limits that exclude water and exempt compounds from "VOC regulatory" calculations. Together, these measures reward coaters that deploy UV or electron-beam (EB) lines capable of instant curing without solvent ovens, thereby trimming energy footprints and boosting plant throughput. Federal thresholds cap industrial maintenance coatings at 450 g/L, yet some states press down to 100-250 g/L, intensifying the appeal of solvent-free technologies.

Demand for High-Throughput Packaging and Digital Printing Lines

Converters running pressure-sensitive labels, flexible packaging, and folding cartons rely on UV inks to eliminate the long drying stages that slow conventional presses. Instant-cure prints exit the line fully bonded, permitting immediate finishing and shipment, vital for just-in-time orders and personalised designs. Trade journals foresee rapid automation, sustainability compliance, and hybrid digital-flexo workflows defining packaging in 2025. Equipment suppliers such as INX International have responded with LED-compatible energy-curable ink sets that satisfy food-contact protocols and support high-opacity whites for shrink sleeves. These solutions strengthen the position of the radiation-curable coatings market within print-for-pack applications.

High Cost of Specialised Oligomers and Photoinitiators

Tailored oligomer backbones and high-purity photoinitiators add notable expense compared with commodity resins. Freight surcharges arising from 2025 US tariffs, 25% on selected Canadian and Mexican inputs, and 10% on many Chinese goods have further strained coating producers' procurement budgets, prompting several companies to re-engineer sourcing strategies. Sun Chemical and peer formulators adopted temporary price surcharges to offset the spike in raw-material outlays, highlighting margin pressure across the Radiation curable coatings market.

Other drivers and restraints analyzed in the detailed report include:

- Growth in Ultra-Thin Electronic and Wearable Device Conformal Coatings

- Rapid Expansion of Asia Pacific Furniture and Flooring Manufacturing Capacity

- Supply Tightness After EU REACH Reclassification of Acyl-Phosphine Oxides

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Oligomers steered the value chain with 45.77% radiation curable coatings market share in 2024, underpinned by their decisive role in film hardness, flexibility, and chemical resistance. The radiation-curable coatings market size tied to oligomers is expected to widen steadily as producers exploit polyester-, urethane-, and epoxy-acrylated backbones to serve contrasting end-use demands. Allnex's UCECOAT 7856 exemplifies progress, delivering a solvent-free dispersion for high-gloss flooring that eliminates traditional VOCs.

In parallel, photoinitiators are projected to chart a 6.88% CAGR because LED-specific grades thrive under lower-energy wavelengths, safeguarding line operators from high-temperature lamp housings. Monomers continue to regulate viscosity and cross-link density, with laboratories channeling bio-based methacrylate diluents to cut fossil dependence.

UV lamps accounted for 69.67% of the 2024 installed capacity thanks to simple retrofit economics and a robust global distributor network. Plants replacing ageing mercury bulbs with iron-doped variants have squeezed higher irradiance out of existing lines, postponing large-scale overhauls. However, the radiation-curable coatings market size associated with electron-beam units could expand the fastest, potentially topping 7.10% CAGR to 2030 as converters weigh the merits of photoinitiator-free curing, deep-film penetration, and oxygen-insensitive polymerisation. EB lines now handle thick pigmented systems common in barrier packaging, spurring interest among food canners and protective-coatings applicators.

LED-UV sources, once confined to narrow-web label presses, now illuminate wide-format graphics and industrial parquet lines because operating temperatures rarely exceed 40 °C. Hybrid dual-cure set-ups merge UV and moisture-curable chemistries to ensure adhesion in shadowed recesses, whereas novel laser-induced photopolymerisation units promise second-level productivity leaps by cutting exposure times to milliseconds.

The Radiation Curable Coatings Report is Segmented by Raw Material (Oligomers, Monomers, Photoinitiators, and Additives), Curing Technology (UV Lamp, Electron Beam, and More), Resin Chemistry (Epoxy Acrylate, Urethane Acrylate, Polyester Acrylate, and More), End-User Industry (Wood and Furniture, Packaging and Printing Inks, Electronics and Semiconductor, and More), and Geography (Asia-Pacific, North America, Europe, and More).

Geography Analysis

Asia Pacific holds a commanding role with a 41.23% 2024 share and a 6.05% CAGR outlook that places the region on a dual leadership trajectory. China, Japan, and India dominate electronics, packaging, and automotive sectors, delivering constant feedstock demand as domestic environmental regulations increasingly mirror European norms. Additive capacity for furniture, flooring, and plastic consumer goods is expanding from central Vietnam to eastern coastal China, keeping UV-curable wood lacquers and plastic topcoats in high rotation.

North America remains technology-rich, with EPA edicts steering solvent-free adoption and California acting as a bellwether for national VOC limits. Automotive OEMs in Michigan and Ontario now integrate LED-UV tunnels for interior trims to achieve energy-footprint reductions. The US tariff regime introduced in 2025 has, however, prompted curing-resin producers to strengthen domestic backward integration to buffer volatility.

Europe's vision focuses on the Green Deal and REACH expansions, which have banned TPO photoinitiators in nail products since September 2025. The incoming 2026 formaldehyde rules for panel producers and the Packaging and Packaging Waste Regulation reinforce market conditions favourable to radiation-curable chemistries.

Across South America, the Middle East, and Africa, demand is emergent yet steady as multinationals deploy satellite coating facilities to sidestep freight and currency risk. Projects in Brazil for flexible plastic film printing and in Saudi Arabia for panel furniture underscore how environmental codes imported from Europe and North America accelerate technology transfer. While local formulators still rely on imported oligomers, gradual regulatory tightening suggests these regions will constitute the next growth flank once infrastructure and skills deepen.

- 3M

- Akzo Nobel N.V.

- Allnex Netherlands B.V.

- Arkema

- Ashland

- Axalta Coating Systems LLC

- BASF

- Covestro AG

- Dymax Corporation

- Evonik Industries AG

- Henkel AG & Co. KGaA

- Lord Corporation

- Nippon Paint Holdings Co., Ltd.

- PPG Industries, Inc.

- Rahn AG

- The Sherwin-Williams Company

- Watson Coatings, Inc.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Tightening VOC and Carbon?Neutrality Regulations Accelerate Solvent-Free UV/EB Adoption

- 4.2.2 Demand for High-Throughput Packaging and Digital Printing Lines

- 4.2.3 Growth in Ultra-Thin Electronic and Wearable Device Conformal Coatings

- 4.2.4 Rapid Expansion of Asia Pacific Furniture and Flooring Manufacturing Capacity

- 4.2.5 OEM Shift to In-Line LED-UV Curing for Automotive Interior Parts

- 4.3 Market Restraints

- 4.3.1 High Cost of Specialized Oligomers and Photoinitiators

- 4.3.2 Supply Tightness after EU REACH Reclassification of Acyl-Phosphine Oxides

- 4.3.3 Thermal Sensitivity of Emerging Bio-Based Packaging Substrates

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts

- 5.1 By Raw Material

- 5.1.1 Oligomers

- 5.1.2 Monomers

- 5.1.3 Photoinitiators

- 5.1.4 Additives

- 5.2 By Curing Technology

- 5.2.1 UV Lamp

- 5.2.2 Electron Beam

- 5.2.3 Hybrid / Dual-Cure

- 5.2.4 Microwave / Infra-red

- 5.3 By Resin Chemistry

- 5.3.1 Epoxy Acrylate

- 5.3.2 Urethane Acrylate

- 5.3.3 Polyester Acrylate

- 5.3.4 Acrylic Ester

- 5.3.5 Others (Silicone, Vinyl Ether)

- 5.4 By End-User Industry

- 5.4.1 Wood and Furniture

- 5.4.2 Packaging and Printing Inks

- 5.4.3 Electronics and Semiconductor

- 5.4.4 Automotive and Transportation

- 5.4.5 Medical Devices

- 5.4.6 3D Printing/Additive Manufacturing

- 5.4.7 Others (Optical, Construction)

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 Japan

- 5.5.1.3 India

- 5.5.1.4 South Korea

- 5.5.1.5 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle-East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 South Africa

- 5.5.5.3 Rest of Middle-East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 3M

- 6.4.2 Akzo Nobel N.V.

- 6.4.3 Allnex Netherlands B.V.

- 6.4.4 Arkema

- 6.4.5 Ashland

- 6.4.6 Axalta Coating Systems LLC

- 6.4.7 BASF

- 6.4.8 Covestro AG

- 6.4.9 Dymax Corporation

- 6.4.10 Evonik Industries AG

- 6.4.11 Henkel AG & Co. KGaA

- 6.4.12 Lord Corporation

- 6.4.13 Nippon Paint Holdings Co., Ltd.

- 6.4.14 PPG Industries, Inc.

- 6.4.15 Rahn AG

- 6.4.16 The Sherwin-Williams Company

- 6.4.17 Watson Coatings, Inc.

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment