|

市场调查报告书

商品编码

1844634

排放控制催化剂:市场占有率分析、产业趋势、统计数据和成长预测(2025-2030 年)Emission Control Catalysts - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

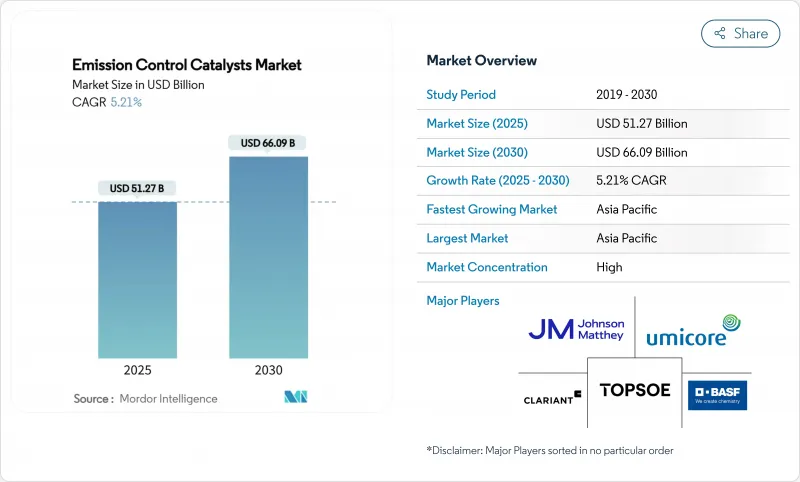

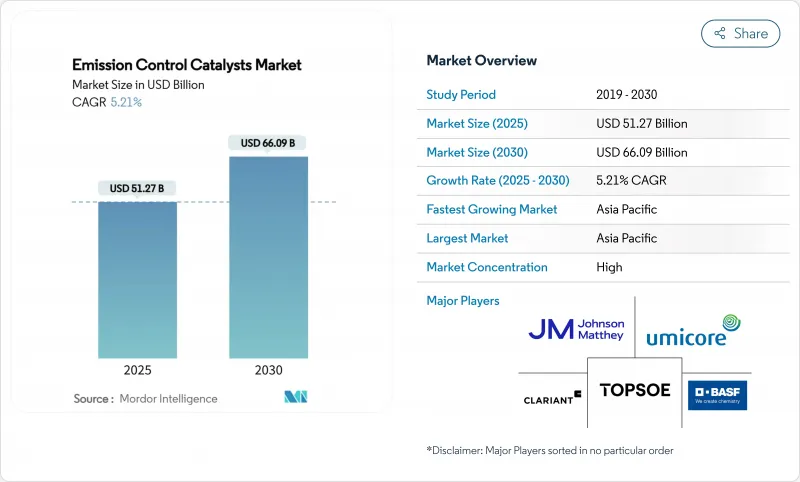

预计 2025 年排放控制催化剂市场规模将达到 512.7 亿美元,到 2030 年将达到 660.9 亿美元,复合年增长率为 5.21%。

全球排放法规的日益严格、新兴市场对内燃机的强劲需求以及触媒技术的持续创新,共同支撑着这一成长势头。欧盟、美国、中国和印度的监管机构都已收紧颗粒物和氮氧化物的排放限制,这大大加速了先进后后处理技术在新车中的应用。汽车製造商也不断改进催化剂配方,以降低贵金属用量,抵消价格波动,并在不影响性能的前提下加速铂金替代。随着空气品质法规的扩展至固定排放源,工业和发电客户也正在采用类似的技术。因此,排放控制催化剂市场正受益于两大成长引擎:稳定的汽车催化剂产量和日益增长的工业催化剂应用,从而支撑着强劲的前景。

全球排放控制催化剂市场趋势与洞察

更严格的道路和非道路排放气体标准

欧7法规降低了允许的颗粒物排放水平,并强制进行实际测试,强制要求普遍使用汽油颗粒过滤器和升级版三元催化器。类似的目标也影响了国六和印度国六法规,推动亚洲车辆广泛采用选择性催化还原(SCR)和GPF。北美Tier 4非道路排放法规对施工机械和农业机械也采取了类似的严格措施,从而扩大了催化剂需求。这些框架确保了排放气体控制催化剂市场维持成长势头,尤其是在新兴经济体纷纷效仿最佳实践立法的情况下。

小型和大型汽车产量大幅反弹

预计2024年全球轻型商用车产量将成长8%,其中基础建设重点经济体的商用车产量将强劲反弹,这将直接转化为催化剂出货量的增加。这一成长动能与新的监管阶段相吻合,迫使主机厂在产量增加的同时安装更先进的后处理装置。重型车辆的电气化进程仍然缓慢,因此到2030年,柴油SCR和DOC解决方案仍将至关重要。产量復苏与监管收紧之间的相互作用,为催化剂製造商提供了健康的订单管道。

价格波动和迫在眉睫的钯金过剩抑制了原始设备製造商的采购

世界铂金投资委员会预测,随着回收的增加和矿产供应的强劲增长,到2025年,钯金将从供不应求转为近90万盎司的过剩。汽车製造商正透过增加铂金替代品和奈米工程表面来应对,以减少铂族金属的用量并降低催化剂成本。短期波动继续使采购变得复杂,原始设备製造商转向长期合约和多元化筹资策略。

細項分析

2024年,钯金将占据排放控制催化剂市场的48.16%,巩固其在汽油三元催化剂领域的主导地位。由于替代率的上升,铂金将占据近35%的市场份额,而铑金凭藉其独特的氮氧化物选择性将保持12%的市场份额。 2024年,排放控制催化剂市场规模将达到约247亿美元。随着汽车製造商重新平衡其金属结构以降低钯金过剩的风险,铂金将拥有最快的成长速度,复合年增长率达到6.71%。液态镓钯合金和奈米结构丛集等新应用,能够以更低的负载实现相当的转化效率,从而提供更大的成本空间。

製造商越来越多地采用闭环回收技术来回收铂族金属,以平衡供应并降低现金排放。南非矿商已调整了资本支出,但长期催化剂研究表明,封闭式仍在稀薄燃烧和甲醇引擎中使用。因此,即使相对份额在未来十年内发生变化,排放控制催化剂市场仍将保持多金属格局。

到2024年,三元催化剂将占销售额的55.19%,反映出其在全球汽油动力汽车中的普及率。柴油氧化触媒、柴油/GPF过滤器和SCR系统总合将占销售额的约三分之一,成长主要集中在重型车辆和非公路车辆领域。新型奈米结构设计目前正以6.96%的复合年增长率成长,并在石化和低温应用中达到了显着的商业规模。为了响应欧盟7和国7法规,预计排放控制催化剂市场份额将逐渐转向整合汽油颗粒过滤器的混合优化三元催化剂(TWC)。

BASF的X3D列印技术能够实现复杂的流道几何形状,从而增加表面积并降低背压,在商业测试中将效率提高了1%。人工智慧驱动的铜沸石配方增强了低温SCR转换率,这是都市区配送卡车符合欧盟7排放标准的关键要求。这些进步能够保护排放控制催化剂市场免于商品化,因为性能差异化能够维持定价能力。

区域分析

预计亚太地区将引领排放控制催化剂市场,到2024年,其营收将超过187亿美元,占36.52%的市占率。该地区的复合年增长率为7.02%,这得益于强劲的汽车产量、快速的工业化以及中国国六B法规的实施,该法规要求普遍使用低温选择性催化还原(SCR)和汽油微粒过滤器(GPF)。印度的国六法规同样要求提高每辆车的催化剂负载量,同时提高燃油品质以减少硫中毒。日本和韩国正透过支持产学研联盟主导的开创性奈米催化剂计划,为引领研究做出贡献。东南亚国协在达到联合国排放标准后,也正在收紧标准,力争达到欧六排放标准,进而受惠于销售量的成长。

2024年,北美和欧洲总合全球汽车销售的53%,这些市场将由先进技术而非强度成长决定。美国环保署 (EPA) 的轻型车辆法规旨在实现2027年起车队平均温室气体减排50%,这将要求广泛推广混合动力汽车,并在冷启动场景下增加铂族金属 (PGM) 的使用。欧7道路测试范围扩大到煞车和轮胎磨损,刺激了二次过滤系统的研发,并拓宽了供应商组合。这两个地区在工业催化剂更换週期方面也处于领先地位,公用事业公司维修老化的煤炭资产以抑制氮氧化物峰值,石化公司正在试用积层製造的晶格催化剂。

到2024年,南美洲、中东和非洲合计将占据排放控制催化剂市场的10.48%,但其追赶潜力最大。巴西的乙醇柴油混合燃料已将颗粒物排放减少了44%,但需要氧化催化剂来控制醛类逃脱。波湾合作理事会国家正在努力使燃油标准与欧盟5接轨,这将推动对耐高硫配方的新需求。随着柴油发电机的普及和当地空气品质法规的完善,撒哈拉以南非洲地区的固定式催化剂用量将会成长。总体而言,随着监管趋同的推进,预计开发中地区将长期稳定采用催化剂。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场状况

- 市场概况

- 市场驱动因素

- 更严格的道路和非道路排放标准

- 小型和大型汽车产量快速復苏

- 人们对空气品质和公众健康的担忧日益加剧

- 工业和电力部门的采用率不断提高

- 汽车产业的扩张

- 市场限制

- 价格波动和钯金过剩危机抑制OEM采购

- 随着纯电动车的普及,汽车触媒的需求将停滞不前

- 开发中地区。

- 价值链分析

- 五力分析

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章市场规模及成长预测

- 按金属

- 铂

- 钯

- 铑

- 其他金属(钒、铜锌等)

- 依技术

- 三元催化器(TWC)

- 柴油氧化催化剂(DOC)

- 柴油颗粒过滤器(DPF/GPF)

- 选择性催化还原(SCR)

- 稀油氮氧化物捕集器和 NSC

- 新型奈米结构催化剂

- 按用途

- 移动废气法规

- 固定废气法规

- 按最终用户产业

- 车

- 工业的

- 其他终端用户产业(例如航太、发电)

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 东南亚国协

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 其他欧洲国家

- 南美洲

- 巴西

- 阿根廷

- 其他南美

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争态势

- 市场集中度

- 策略倡议

- 市占率(%)/排名分析

- 公司简介

- Aerinox Inc.

- ANAND Group

- BASF

- CATALER CORPORATION

- CDTi Advanced Materials Inc.

- Clariant

- CORMETECH

- Cummins Inc.,

- DCL International Inc.

- Evonik Industries AG

- Haldor Topsoe A/S

- Heraeus Precious Metals

- IBIDEN

- Johnson Matthey

- Kanadevia Corporation

- NEO

- NGK INSULATORS, LTD.

- Nikki-Universal Co., Ltd.

- SINOTECH Company Limited

- Umicore

第七章 市场机会与未来展望

The emission control catalysts market size is valued at USD 51.27 billion in 2025 and is set to reach USD 66.09 billion by 2030, advancing at a 5.21% CAGR.

Heightened global emission standards, resilient internal-combustion demand in emerging economies, and continuous catalyst innovation sustain this expansion. Regulatory bodies in the EU, the US, China, and India have tightened particulate and NOx limits, spurring near-universal adoption of advanced after-treatment technologies in new vehicles. Automakers are simultaneously refining catalyst formulations to lower precious-metal loadings, offset price volatility, and accelerate platinum substitution without compromising performance. Industrial and power-generation customers are also adopting similar technologies as air-quality rules broaden to cover stationary sources. The emission control catalysts market therefore benefits from a dual growth engine-persistent automotive volumes and widening industrial uptake-underpinning its robust outlook.

Global Emission Control Catalysts Market Trends and Insights

Stringent tightening of on-road & off-road emission norms

Euro 7 rules lower permissible particulate levels and require real-world driving tests, compelling universal use of gasoline particulate filters and upgraded Three-Way Catalysts. Similar ambitions shape China VI and India BS VI regulations, which drive widespread SCR and GPF deployment across Asia's vehicle fleets. Tier 4 off-road standards in North America extend comparable stringency to construction and agricultural machinery, broadening catalyst demand. Together, these frameworks ensure the emission control catalysts market maintains growth momentum, especially as developing economies replicate best-practice legislation.

Rapid rebound of light-duty & heavy-duty vehicle production

Global light-vehicle output climbed 8% in 2024, while commercial-vehicle production recovered strongly in infrastructure-focused economies, translating directly into higher catalyst unit shipments. The upturn coincides with new regulatory phases, forcing OEMs to install more sophisticated after-treatment even as production volumes rise. Electrification progress in heavy-duty fleets remains modest, meaning diesel SCR and DOC solutions will stay essential through 2030. This interplay between volume rebound and tightening standards supports a healthy order pipeline for catalyst suppliers.

Price volatility & looming surplus of palladium depressing OEM purchasing

World Platinum Investment Council forecasts a swing from deficit to a surplus of nearly 900 koz of palladium by 2025 as recycling expands and mining supply stays firm. Automakers respond by intensifying platinum substitution and lowering overall PGM loadings through nano-engineered surfaces, trimming catalyst costs. Short-term volatility still complicates procurement, nudging OEMs toward long-term contracts and diversified sourcing strategies.

Other drivers and restraints analyzed in the detailed report include:

- Growing concern for air quality and public health

- Increasing adoption by industrial and power sector

- Accelerated BEV penetration eroding autocatalyst demand growth

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Palladium held 48.16% of the emission control catalysts market in 2024, underpinning its primacy in gasoline Three-Way Catalysts. Platinum followed at nearly 35% on the back of rising substitution, while rhodium's unique NOx selectivity kept its 12% niche. The combined segment represented roughly USD 24.7 billion of emission control catalysts market size in 2024. Looking ahead, platinum's 6.71% CAGR makes it the fastest riser as OEMs rebalance metal mixes to mitigate palladium surplus risk. Emerging applications such as liquid-gallium palladium alloys and nano-structured clusters promise equivalent conversion at far lower loadings, widening cost headroom.

Manufacturers increasingly deploy closed-loop recycling to reclaim PGMs, smoothing supply and lowering cash exposure. South African miners reevaluate capex, yet long-term catalyst research indicates continued palladium relevance in lean-burn and methanol engines. The emission control catalysts market therefore retains a multi-metal foundation even as relative shares shift through the decade.

Three-Way Catalysts controlled 55.19% revenue in 2024, reflecting their near-universal fitment on global gasoline vehicles. Diesel Oxidation Catalysts, Diesel/GPF filters, and SCR systems collectively equaled about one-third of revenues, their growth tied to heavy-duty and off-road sectors. Emerging nano-structured designs now grow at 6.96% CAGR, reaching critical commercial scale in petrochemical and low-temperature applications. Within this mix, emission control catalysts market share is expected to tilt progressively toward hybrid-optimized TWCs integrating gasoline particulate filters in response to Euro 7 and China VII legislation.

Additive manufacturing is another inflection point: BASF's X3D printing enables complex channel geometries that raise surface area and cut back-pressure, improving efficiency by 1% in commercial trials. AI-driven copper-zeolite formulations enhance low-temperature SCR conversion, a crucial requirement for Euro 7 compliance in urban delivery trucks. Such advances safeguard the emission control catalysts market from commoditization, as performance differentiation continues to command pricing power.

The Emission Control Catalysts Market Report is Segmented by Metal (Platinum, Palladium, and More), Technology (Three-Way Catalysts, Diesel Oxidation Catalysts, and More), Application (Mobile Emission Control and Stationary Emission Control), End-User Industry (Automotive, Industrial, and More), and Geography (Asia-Pacific, North America, Europe, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific led the emission control catalysts market with 36.52% share in 2024, exceeding USD 18.7 billion in sales. The region's 7.02% CAGR is propelled by robust vehicle production, rapid industrialization, and the implementation of China VI-B norms that demand low-temperature SCR and universal GPF usage. India's BS VI regime similarly boosts catalyst loading per vehicle, while fuel-quality upgrades reduce sulfur-related poisoning. Japan and South Korea contribute research leadership, backing breakthrough nano-catalyst projects with academic-industry consortia. ASEAN nations, following UN-level equivalence, represent an incremental volume tailwind as their standards tighten toward Euro 6 parity.

North America and Europe together held 53% of 2024 revenues, their markets defined by advanced technology rather than raw unit growth. The US EPA's 2027-plus light-vehicle rules target a 50% fleet-average GHG cut, compelling widespread hybridization and elevated PGM use in cold-start scenarios. Euro 7's real-world testing extension to brake and tire wear triggers R&D for secondary filtration systems, broadening supplier portfolios. Both regions also lead industrial catalyst replacement cycles, with utilities retrofitting aged coal assets to curb NOx peaks and petrochemical outfits trialing additive-manufactured lattice catalysts.

South America and the Middle East & Africa combined accounted for 10.48% of the emission control catalysts market in 2024 but present the highest catch-up potential. Brazil's ethanol-diesel blends cut particulate output by 44%, yet still require oxidation catalysts to manage aldehyde slip. Gulf Cooperation Council states move to align fuel standards with Euro 5, prompting fresh demand for high-sulfur-resistant formulations. Diesel genset adoption across Sub-Saharan Africa adds incremental stationary catalyst volumes once local air-quality legislation matures. Overall, rising regulatory convergence guides steady long-term uptake across developing regions.

- Aerinox Inc.

- ANAND Group

- BASF

- CATALER CORPORATION

- CDTi Advanced Materials Inc.

- Clariant

- CORMETECH

- Cummins Inc.,

- DCL International Inc.

- Evonik Industries AG

- Haldor Topsoe A/S

- Heraeus Precious Metals

- IBIDEN

- Johnson Matthey

- Kanadevia Corporation

- NEO

- NGK INSULATORS, LTD.

- Nikki-Universal Co., Ltd.

- SINOTECH Company Limited

- Umicore

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Stringent tightening of on-road & off-road emission norms

- 4.2.2 Rapid rebound of light-duty & heavy-duty vehicle production

- 4.2.3 Growing concern for air quality and public health

- 4.2.4 Increasing adoption by industrial and power sector

- 4.2.5 Expansion of the automotive sector

- 4.3 Market Restraints

- 4.3.1 Price volatility & looming surplus of palladium depressing OEM purchasing

- 4.3.2 Accelerated BEV penetration eroding autocatalyst demand growth

- 4.3.3 Catalyst poisoning from higher-sulfur alternative fuels in developing regions

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size & Growth Forecasts (Value)

- 5.1 By Metal

- 5.1.1 Platinum

- 5.1.2 Palladium

- 5.1.3 Rhodium

- 5.1.4 Other Metals (Vanadium, Cu-Zn, etc.)

- 5.2 By Technology

- 5.2.1 Three-Way Catalysts (TWC)

- 5.2.2 Diesel Oxidation Catalysts (DOC)

- 5.2.3 Diesel/GPF Particulate Filters (DPF/GPF)

- 5.2.4 Selective Catalytic Reduction (SCR)

- 5.2.5 Lean NOx Traps & NSC

- 5.2.6 Emerging Nano-Structured Catalysts

- 5.3 By Application

- 5.3.1 Mobile Emission Control

- 5.3.2 Stationary Emission Control

- 5.4 By End-user Industry

- 5.4.1 Automotive

- 5.4.2 Industrial

- 5.4.3 Other End user Industries (Aerospace, Power Generation, etc.)

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 ASEAN Countries

- 5.5.1.6 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 South Africa

- 5.5.5.3 Rest of Middle East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products & Services, and Recent Developments)

- 6.4.1 Aerinox Inc.

- 6.4.2 ANAND Group

- 6.4.3 BASF

- 6.4.4 CATALER CORPORATION

- 6.4.5 CDTi Advanced Materials Inc.

- 6.4.6 Clariant

- 6.4.7 CORMETECH

- 6.4.8 Cummins Inc.,

- 6.4.9 DCL International Inc.

- 6.4.10 Evonik Industries AG

- 6.4.11 Haldor Topsoe A/S

- 6.4.12 Heraeus Precious Metals

- 6.4.13 IBIDEN

- 6.4.14 Johnson Matthey

- 6.4.15 Kanadevia Corporation

- 6.4.16 NEO

- 6.4.17 NGK INSULATORS, LTD.

- 6.4.18 Nikki-Universal Co., Ltd.

- 6.4.19 SINOTECH Company Limited

- 6.4.20 Umicore

7 Market Opportunities & Future Outlook

- 7.1 White-space & Unmet-Need Assessment