|

市场调查报告书

商品编码

1844702

硫化学品:市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)Thiochemicals - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

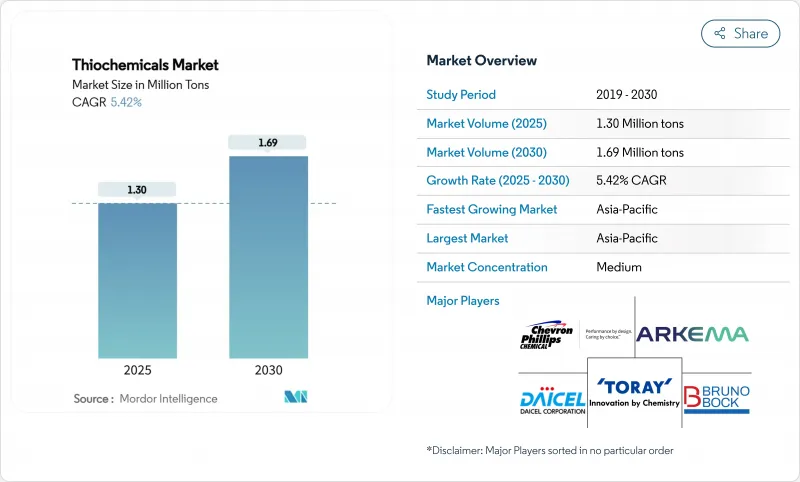

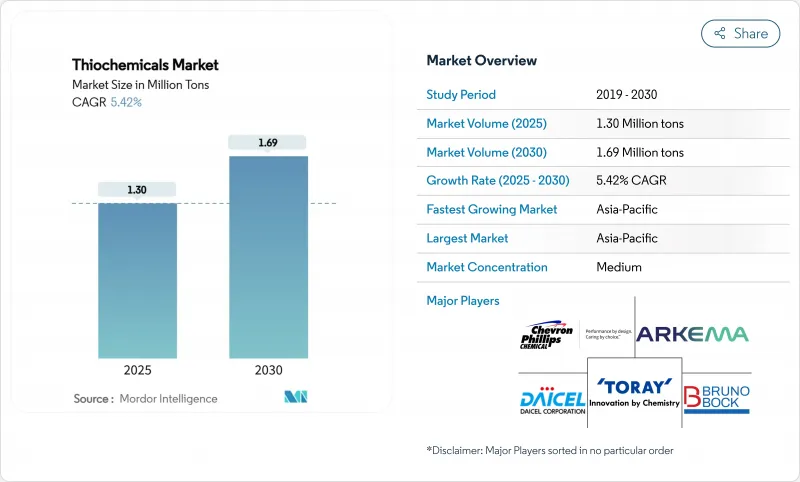

预计 2025 年硫化工市场规模为 130 万吨,到 2030 年将达到 169 万吨,预测期间(2025-2030 年)的复合年增长率为 5.42%。

强劲的蛋白质消费、稳定的炼油催化剂需求以及新兴的电池级溶剂应用是支撑硫化学品市场的关键成长动力。亚太地区畜牧业现代化进程的加强、炼油厂为满足超低硫柴油车需求而进行的升级改造,以及高纯度二甲基亚砜在电子产品製造业的日益普及,这些因素共同支撑了市场的积极发展轨迹。综合製造商正在引入专有技术并扩展区域产能,以确保硫原料的安全、优化成本,并深化客户在动物营养、炼油和电子产品领域的参与度。监管部门对更安全硫化剂的需求日益增长,加上生物基途径的创新,在带来新机会的同时,也提高了合规成本。因此,供应链的韧性,尤其是元素硫采购的韧性,是硫化学品市场长期成功的关键差异化因素。

全球硫化学品市场趋势与洞察

工业规模动物饲料生产商对甲硫胺酸的需求快速成长

全球家禽和水产养殖生产商正在扩大依赖硫代化学品衍生甲硫胺酸的优质饲料配方,从而刺激整个硫代化学品市场的额外资本投资。赢创工业集团在安特卫普、莫比尔和新加坡设有综合枢纽,年总产能超过70万公吨。亚太地区的消费量成长最为显着,商业性农场整合正在推动收入和蛋白质摄取量的增加。科学评估表明,DL-甲硫胺酸可改善肝臟代谢和氧化压力,而L-甲硫胺酸可促进肉鸡增重,这为支撑高价的差异化添加剂创造了利基市场。硫代化学品-甲硫胺酸复合物的整合降低了物流成本,降低了硫输入的波动性,并保护了利润率,促使生产商加强后向整合策略。因此,即使饲料产业规模扩大,持续的甲硫胺酸拉动也将使硫代化学品市场保持强劲的需求基准。

扩大二甲基二硫作为炼油催化剂硫化剂的用途。

由于二硫化二甲基(DMDS) 比硫化氢安全隐患更少且硫供应量更高,炼油厂越来越多地使用其来活化加氢裂解催化剂。技术评估表明,基于 DMDS 的 Exact-S 级催化剂能够快速提高触媒活性,同时最大限度地减少危险操作,使炼油厂能够遵守更严格的燃料硫含量法规。全球向超低硫柴油的转变正在加速这一替代趋势,尤其是在北美、中东以及正在扩大产能的亚洲新兴炼油中心。发表在 ScienceDirect 上的一项研究表明,在深度脱硫条件下,DMDS 硫化催化剂的性能与 H2S 预硫化催化剂相当甚至更好。可再生柴油共处理进一步推动了 DMDS 的采用,因为混合原料需要一种能够稳定暴露于含氧化合物的催化剂的多功能硫化剂。这些操作优势共同支持了 DMDS 在整个硫化化学品市场的持续成长。

毒性和气味控製成本高

硫化化学品的强烈气味和毒性迫使生产商投资于围堵设施、洗涤器和专门的处理基础设施,从而增加了营运成本。美国环保署2024年风险管理计画修正案将使有机合成化工厂的年度遵循成本按3%的折扣率增加2.569亿美元,而多家硫化化学品工厂已经承担了这一成本。取得专利的气味吸附筒和膜生物反应器旨在100%去除DMSO,是可行的解决方案,但这些技术需要大量的资本支出和技术监督。台湾和韩国的半导体工厂正在应用针对含DMSO污水流定制的需氧膜反应器,这表明终端市场也在供应链下游通过更严格的排放标准。环境审查的加强可能会加速向低气味配方的转变,但这可能会限制现有工厂的短期产能扩张,并限制硫化化学品市场的短期成长。

細項分析

硫醇在二甲基二硫合成和甲硫胺酸生产中起着核心作用,在 2024 年占据了硫化学市场 71.19% 的份额。随着亚洲新的炼油厂和饲料厂寻求可靠的甲硫醇和乙硫醇供应,这一细分市场不断扩大。由于 DMDS 单位质量含硫量高,并且能够缩短触媒活性过程中的周转时间,它仍然是基准硫化剂。中东的大型炼油厂客户会提前几年下大订单,确保综合硫醇-DMDS 製造商的产量可预测。连续硫醇氧化反应器的进步也提高了产量并降低了变动成本,支持硫醇预计到 2030 年的复合年增长率达到 5.71%。生物硫醇计画可以带来进一步的上行空间,有望降低碳强度,同时也使供应商在碳边境调整机制正在兴起的司法管辖区获得行销优势。

二甲基亚砜在硫化化学品市场中占有相当大的份额(以产量计算)。家用电子电器组装现在要求高纯度产品,将金属离子限制在100 ppt以下,这促使生产商采用双蒸馏塔和不锈钢系统来减少污染。在欧洲,用于冷冻保存和肿瘤製剂的药用级二甲基亚砜(DMSO)的安全采购也在增加,扩大了其应用的多样性。巯基乙酸及其酯在护髮化妆品、PVC热稳定剂和微电子光阻剂剥离剂中保持着小众但稳定的地位。其他次要化学品,例如多硫化物和噻唑,支持油田中的橡胶硫化和硫化氢去除,为愿意进行客製化合成的创新者提供了辅助的高利润收益来源。

硫化学品市场报告按类型(硫醇、二甲基亚砜、巯基乙酸及酯、其他类型)、终端用途产业(动物营养、石油和天然气、聚合物和化学品、其他终端用途产业)和地区(亚太地区、北美、欧洲、南美、中东和非洲)进行细分。市场预测以产量(吨)为单位。

区域分析

2024年,亚太地区占据了全球硫化学品市场份额的38.42%,预计到2030年,该地区的复合年增长率将达到6.41%,这得益于生产规模和下游需求的多元化。中国炼油厂的建设和鸡肉产量的快速增长将确保硫醇产量的稳定增长,而当地电子组装则需要优质的二甲基亚砜 (DMSO) 用于液晶显示器和内存製造。受惠于全球「中国+1」采购模式,印度特种化学物品部门正在加速对甲硫胺酸和二甲基亚砜 (DMDS) 整合能力的投资。马来西亚和泰国正在透过吸引重视自由贸易准入和支持性政策框架的先进材料跨国公司,扩大硫化学品的区域需求节点。

北美严格的环保标准强制使用超低硫燃料和先进的气味控制技术,巩固了该地区的市场地位。美国工业理事会预测,到2033年,国内化学品需求将成长15%,但产能成长落后导致进口依赖度高,这为硫化工的进一步扩张创造了机会。墨西哥湾沿岸拥有一个垂直整合的硫化工园区,与该地区的甲硫胺酸和二甲基二硫(DMDS)生产相连,受益于丰富的页岩氢能和强大的物流。加拿大的硫磺产量使当地炼油厂成为硫醇製造商的战略供应来源,但铁路拥挤和港口限制有时会阻碍供应,促使人们采取库存囤积策略。

欧洲技术成熟,环境先进,在推动生物基硫化学研究的同时,对排放实施处罚。总部位于法国的阿科玛公司正在针对特种橡胶市场创新其Vultac硫供体,瞄准高端轮胎品牌。德国化工产业丛集正在资助专注于废弃物製硫和碳中和製程热的循环经济计划。虽然南美、中东和非洲目前占全球贸易的不到10%,但随着区域供应链的成熟和环境政策的加强,巴西炼油厂的升级和沙乌地阿拉伯石化产品的多元化发展,预示着硫化学市场未来将迎来机会。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场状况

- 市场概况

- 市场驱动因素

- 工业规模动物饲料製造商对甲硫胺酸的需求快速成长

- 扩大二硫化二甲基作为炼油催化剂硫化剂的用途。

- 先进电池中的硫化学品

- 扩大硫化学品在甲硫胺酸生产的应用

- 超低硫柴油脱硫宣传活动不断发展

- 市场限制

- 毒性和气味控製成本高

- 元素硫价格波动

- 导致供应衝击的生产者集中风险

- 价值链分析

- 五力分析

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章市场规模及成长预测(数量)

- 按类型

- 硫醇

- 二甲基亚砜(DMSO)

- 巯基乙酸及其酯

- 其他类型(例如硫化氢清除剂)

- 按最终用途行业

- 动物营养

- 石油和天然气

- 聚合物和化学品

- 其他终端用户产业(电子和半导体清洁、杀虫剂等)

- 按地区

- 亚太地区

- 中国

- 日本

- 印度

- 韩国

- 东南亚国协

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 北欧国家

- 其他欧洲国家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争态势

- 市场集中度

- 策略倡议

- 市占率(%)/排名分析

- 公司简介

- Arkema

- BRUNO BOCK

- Chevron Phillips Chemical Company LLC.

- Daicel Corporation

- Dr. Spiess Chemische Fabrik

- Hebei Yanuo Bioscience

- KIP Chemicals

- Merck KGaA

- Taizhou Sunny Chemical Co., Ltd.

- TCI Chemicals

- Toray Fine Chemicals

- WEIFANG YI HUA CHEMICAL CO., LTD.

第七章 市场机会与未来展望

The Thiochemicals Market size is estimated at 1.30 million tons in 2025, and is expected to reach 1.69 million tons by 2030, at a CAGR of 5.42% during the forecast period (2025-2030).

Strong protein consumption, steady refinery catalyst demand, and emerging battery-grade solvent applications are the principal growth vectors sustaining the thiochemicals market. Intensifying livestock modernization in Asia-Pacific, refinery upgrades aimed at ultra-low-sulfur diesel compliance, and rising adoption of high-purity dimethyl sulfoxide in electronic fabrication jointly anchor the market's positive trajectory. Integrated producers deploy proprietary technologies and expand regional capacities to secure sulfur feedstock, optimize costs, and deepen customer engagement across animal nutrition, refining, and electronics domains. Regulatory pressures for safer sulfiding agents, coupled with innovation in bio-based pathways, are opening new opportunities while simultaneously elevating compliance expenditures. Supply chain resilience, especially in elemental sulfur procurement, has therefore become a decisive differentiator for long-term success within the thiochemicals market.

Global Thiochemicals Market Trends and Insights

Surging Methionine Demand From Industrial-Scale Animal Feed Producers

Global poultry and aquaculture producers are scaling premium feed formulations that rely on methionine derived from thiochemicals, thereby stimulating additional capacity investments across the thiochemicals market. Evonik Industries operates integrated hubs in Antwerp, Mobile, and Singapore with aggregate output surpassing 700,000 t per year, underscoring the capital intensity tied to this demand surge. Consumption growth remains most pronounced in Asia-Pacific where incomes and protein uptake are climbing in tandem with commercial farm consolidation. Scientific assessments reveal DL-methionine improves liver metabolism and oxidative stress, while L-methionine accelerates weight gain in broilers, creating differentiated additive niches that support premium pricing. Integrated thiochemical-to-methionine complexes reduce logistics costs, lower sulfur input volatility, and protect margins, prompting leading producers to reinforce backward integration strategies. Consequently, sustained methionine pull-through ensures the thiochemicals market maintains a robust baseline of demand as feed industries upscale.

Expanding Use of Dimethyl Disulfide as a Refinery Catalyst Sulfiding Agent

Refineries increasingly prefer dimethyl disulfide (DMDS) to activate hydrotreating catalysts because it volumetrically delivers more sulfur with fewer safety concerns than hydrogen sulfide, aligning with worker protection norms and continuous operation imperatives. Technical evaluations show that DMDS-based Exact-S grades raise catalytic activity quickly while minimizing hazardous handling, enabling refineries to comply with stricter fuel sulfur limits. The global shift toward ultra-low-sulfur diesel accelerates this substitution trend, especially in North America, the Middle East, and emerging Asian refining hubs undergoing capacity expansions. Research published on ScienceDirect validates that DMDS-sulfided catalysts meet or exceed performance achieved with H2S presulfiding under deep desulfurization conditions. Renewable diesel co-processing is further bolstering DMDS uptake because mixed feedstocks require versatile sulfiding agents capable of stabilizing catalysts exposed to oxygenated compounds. Collectively, these operational advantages ensure persistent DMDS volume growth within the broader thiochemicals market.

High Toxicity and Odor Management Costs

Thiochemicals possess strong odors and toxicity profiles that oblige producers to invest in containment, scrubbers, and specialized handling infrastructure, thereby elevating operating costs. The 2024 U.S. EPA Risk Management Program amendments boost annual compliance spending for synthetic organic chemical plants by USD 256.9 million at a 3% discount rate, a burden borne by several thiochemical facilities. Patented odor-adsorbent cartridges and membrane bioreactors targeting 100% DMSO removal demonstrate available solutions, yet these technologies require meaningful capital outlays and technical oversight. Semiconductor fabs in Taiwan and South Korea apply aerobic membrane reactors tailored to DMSO-laden wastewater streams, showing that end-markets also pass stricter discharge criteria down the supply chain. Elevated environmental scrutiny may accelerate the shift toward low-odor formulations but will likely restrain short-term output expansion in legacy facilities, tempering near-term growth for the thiochemicals market.

Other drivers and restraints analyzed in the detailed report include:

- Adoption of Thiochemicals in Advanced Batteries

- Growing Usage of Thiochemicals in Methionine Production

- Volatility in Elemental Sulfur Prices

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Mercaptans captured 71.19% of thiochemicals market share in 2024 owing to their centrality in dimethyl disulfide synthesis and methionine manufacturing. The segment expanded alongside new Asian refineries and feed mills that demand reliable supplies of methyl mercaptan and ethanethiol. DMDS remains the benchmark sulfiding agent because it safely delivers high sulfur content per unit mass, reducing turnaround times during catalyst activation. Customers in Middle Eastern mega-refineries place bulk orders years in advance, ensuring predictable throughput for integrated mercaptan-DMDS producers. Advancements in continuous mercaptan oxidation reactors have also improved yields, lowering variable costs and supporting a 5.71% CAGR outlook for mercaptans through 2030. Further upside could arise from bio-mercaptan initiatives that promise to shrink carbon intensity while giving suppliers a marketing edge in jurisdictions with emerging carbon-border adjustment mechanisms.

Dimethyl sulfoxide holds a significant share in the thiochemicals market by volume. Consumer electronics assemblers now demand higher purity ranges that limit metal ions to below 100 ppt, spurring producers to install double-distillation columns and stainless-steel systems that inhibit contamination. Secure sourcing of pharmaceutical-grade DMSO for cryopreservation and oncology formulations is also rising in Europe, widening application diversity. Thioglycolic acid and esters maintain stable though niche roles in hair-care cosmetics, PVC heat stabilizers, and microelectronic photoresist stripping. Other minor chemistries such as polysulfides and thiazoles address rubber vulcanization and oilfield H2S scavenging, providing supplemental, high-margin revenue streams for innovators willing to engage in custom synthesis.

The Thiochemicals Market Report is Segmented by Type (Mercaptans, Dimethyl Sulfoxide, Thioglycolic Acid and Esters, Other Types), End-Use Industry (Animal Nutrition, Oil and Gas, Polymers and Chemicals, Other End-User Industries), and Geography (Asia-Pacific, North America, Europe, South America, Middle East and Africa). The Market Forecasts are Provided in Terms of Volume (tons).

Geography Analysis

Asia-Pacific held 38.42% of thiochemicals market share in 2024 and is projected to expand at a 6.41% CAGR through 2030, powered by manufacturing scale and downstream demand diversity. China's refinery build-out combined with surging poultry output secures steady mercaptan liftings, while local electronics assemblers consume premium DMSO grades for LCD and memory fabrication. India's speciality chemical segment benefits from global "China + 1" sourcing models, accelerating investment in integrated methionine and DMDS capabilities. Malaysia and Thailand attract advanced-material multinationals who value free-trade access and supportive policy frameworks, thereby expanding regional demand nodes for thiochemicals.

Strict environmental standards in North America, which mandate ultra-low-sulfur fuels and advanced odor controls, strengthen the region's market position. The American Chemistry Council anticipates 15% domestic chemical demand growth by 2033, but capacity additions lag, implying heavier import reliance and opportunity for incremental thiochemical expansions. The Gulf Coast hosts vertically integrated thiochemical parks that feed into regional methionine and DMDS production, benefiting from abundant shale-derived hydrogen and robust logistics. Canada's sulfur output renders local refineries strategic suppliers to mercaptan producers, yet rail congestion and port limitations occasionally disrupt flows, prompting inventory stockpiling strategies.

Europe remains technologically mature and environmentally progressive, promoting bio-based thiochemical research while penalizing emissions. Arkema, based in France, innovates Vultac sulfur donors catering to specialty rubber markets that service premium tire brands. German chemical clusters channel funding into circular-economy projects focusing on waste-to-sulfur and carbon-neutral process heat, initiatives that could reshape regional supply structures. South America and the Middle East & Africa collectively account for less than 10% of global trade today, yet refinery upgrades in Brazil and petrochemical diversification in Saudi Arabia hint at future thiochemicals market opportunities as localized supply chains mature and environmental policies tighten.

List of Companies Covered in this Report:

- Arkema

- BRUNO BOCK

- Chevron Phillips Chemical Company LLC.

- Daicel Corporation

- Dr. Spiess Chemische Fabrik

- Hebei Yanuo Bioscience

- KIP Chemicals

- Merck KGaA

- Taizhou Sunny Chemical Co., Ltd.

- TCI Chemicals

- Toray Fine Chemicals

- WEIFANG YI HUA CHEMICAL CO., LTD.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Surging methionine demand from industrial-scale animal feed producers

- 4.2.2 Expanding use of Dimethyl Disulfide as a refinery catalyst sulfiding agent

- 4.2.3 Adoption of thiochemicals in advanced batteries

- 4.2.4 Growing usage of thiochemcials in methionine production

- 4.2.5 Growth in ultra-low-sulfur diesel desulfurisation campaigns

- 4.3 Market Restraints

- 4.3.1 High toxicity and odour management costs

- 4.3.2 Volatility in elemental sulfur prices

- 4.3.3 Producer concentration risk causing supply shocks

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Volume)

- 5.1 By Type

- 5.1.1 Mercaptans

- 5.1.2 Dimethyl Sulfoxide (DMSO)

- 5.1.3 Thioglycolic Acid and Esters

- 5.1.4 Other Types (Hydrogen-Sulfide Scavengers, etc.)

- 5.2 By End-Use Industry

- 5.2.1 Animal Nutrition

- 5.2.2 Oil and Gas

- 5.2.3 Polymers and Chemicals

- 5.2.4 Other End-user Industries (Electronics and Semiconductor Cleaning, Agrochemicals, etc.)

- 5.3 By Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 Japan

- 5.3.1.3 India

- 5.3.1.4 South Korea

- 5.3.1.5 ASEAN Countries

- 5.3.1.6 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Spain

- 5.3.3.6 Russia

- 5.3.3.7 NORDIC Countries

- 5.3.3.8 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle East and Africa

- 5.3.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share (%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Arkema

- 6.4.2 BRUNO BOCK

- 6.4.3 Chevron Phillips Chemical Company LLC.

- 6.4.4 Daicel Corporation

- 6.4.5 Dr. Spiess Chemische Fabrik

- 6.4.6 Hebei Yanuo Bioscience

- 6.4.7 KIP Chemicals

- 6.4.8 Merck KGaA

- 6.4.9 Taizhou Sunny Chemical Co., Ltd.

- 6.4.10 TCI Chemicals

- 6.4.11 Toray Fine Chemicals

- 6.4.12 WEIFANG YI HUA CHEMICAL CO., LTD.

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment