|

市场调查报告书

商品编码

1846177

二氧化钛:市场占有率分析、产业趋势、统计、成长预测(2025-2030)Titanium Dioxide - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

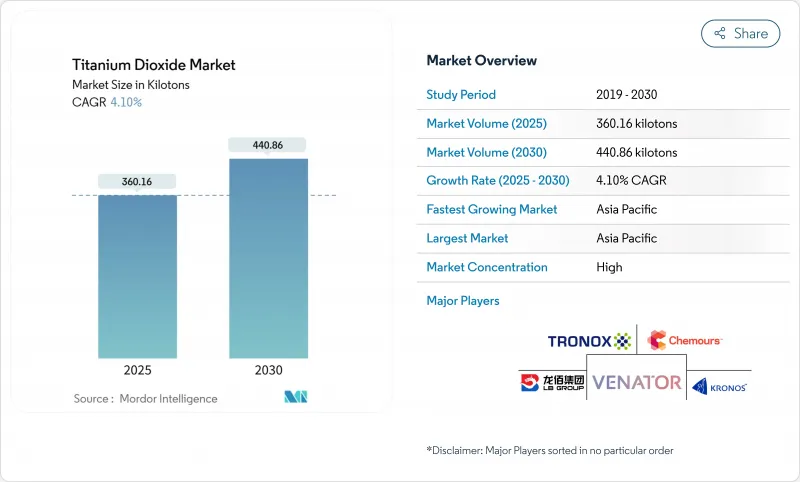

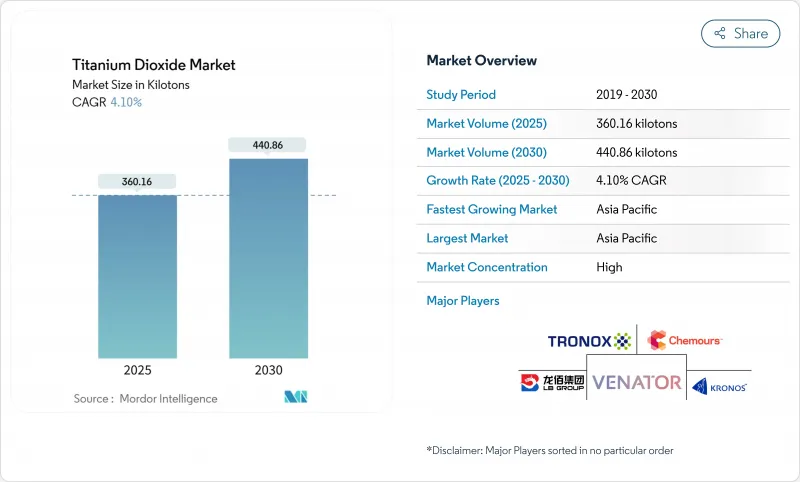

预计到 2025 年,二氧化钛市场规模将达到 360.16 千吨,到 2030 年将达到 440.86 千吨,预测期(2025-2030 年)复合年增长率为 4.10%。

对建筑、包装、汽车塑胶和冷屋顶涂料的需求不断增长,抵消了监管方面的不利因素,特别是欧洲的二级致癌性标籤规定以及对中国产原材料征收的反倾销税。亚太地区的复合年增长率为4.92%,这得益于中国的供应链和印度的在地化策略。製造商正努力平衡因钛铁矿和金红石原料价格波动而带来的成本压力,同时推进氯化物製程的技术升级。像Chemur这样的公司透过製程优化,在无需大量资本支出的情况下,将产能提高了15%;而像Tronox这样的公司则透过垂直整合,降低了原材料价格波动的影响。欧盟与其他地区监管政策的差异正在推动产品系列的差异化,并为区域套利创造了空间。

全球二氧化钛市场趋势与洞察

亚太地区对水性建筑涂料的需求激增

中国、印度和印尼对挥发性有机化合物的监管日益严格,加速了水性涂料从溶剂型涂料向溶剂型涂料的替代,推动了该地区金红石颜料贸易的成长。区域涂料生产线正在升级分散技术,以实现遮盖力平衡,从而支撑了二氧化钛市场的持续成长。印度和印尼的基础设施奖励策略将增加需求,而氯化物生产路线的区域化将确保供应的稳定性。配方师对低气味和更安全的工作环境的重视,提高了承包商的接受度。儘管原物料价格波动,但这种转变仍构成了一个结构性利多因素。

欧洲转向使用轻量、高光泽汽车塑料

欧盟严格的车辆平均二氧化碳排放法规已将轻量化置于设计策略的核心。透过将二氧化钛添加到聚丙烯和聚碳酸酯饰件中,製造商可以获得媲美涂层金属板的高光泽表面,同时显着降低重量,车辆重量每减轻10%,燃油经济性就能提高5-7%。高阶OEM厂商正在采用疏水性等级的二氧化钛,例如TIOXIDE TR48,这种材料在高温加工条件下仍能分散且不失去光泽。这些特种等级的产品价格较高,最大限度地降低了因法规限製而导致的替代风险,二氧化钛市场不仅销量成长,而且价值也大幅提升。

欧盟将二氧化钛列为疑似致癌性,提高了标籤成本。

欧盟法规2025/4要求,凡二氧化钛含量达到或超过1%的粉末配方均须标示致癌警告。涂料、塑性溶胶和印刷油墨供应商将面临返工、重新设计包装以及法律审查等问题,从而推高合规成本。英国和北美不同的法规使全球产品组合管理更加复杂,并迫使企业采用双重标籤策略。生产批量减少导致单位成本上升,并降低了DIY通路的非必需品需求。欧洲法院于2022年裁定该危险标籤无效,但经过科学重新评估后,该裁决于2025年被推翻,进一步加剧了二氧化钛市场的不确定性。

细分市场分析

金红石型二氧化钛具有高屈光(2.7)和优异的耐候性,预计2024年将占据二氧化钛市场78%的份额。这项优势在建筑外墙涂料、汽车面漆和聚合物母粒等领域尤其显着,因为这些应用对长期保持光泽度要求极高。而具有光催化性能的双功能金红石型二氧化钛则可望应用于新型自清洁表面,进一步巩固其市场领先地位。

锐钛矿满足了市场需求的平衡,其复合年增长率达到4.5%,主要得益于医药辅料和光催化建筑材料等细分市场的成长。表面改质的锐钛矿可延长食品接触纸的保质期,并赋予高檔办公用纸独特的蓝色色调。

硫酸法製程主要依靠低品位钛铁矿和较小的资本投入,预计2024年将占二氧化钛市场65%的份额。然而,随着监管机构加强对酸性硫酸盐废弃物的监管,氯化法产能正以4.7%的复合年增长率快速成长。氯化法工厂使用高二氧化钛矿渣或天然金红石,主要生产杂质含量较低的金红石颜料,在高端被覆剂和母粒领域拥有更高的价格。科慕公司报告称,其独特的350-450℃低温氯化製程可降低30%的能耗并提高产量比率。

印度新兴製造商正采用氯化技术,以达到与西方供应商相同的品质水平,并为不断变化的废水法规做好准备。北美和欧洲的扩建和瓶颈消除计划旨在从现有氯化设施中额外提取 5-15% 的产能,而无需待开发区投资,从而在区域产能关闭(例如 Tronox 的 Botlek 工厂)的情况下维持供应平衡。因此,製程主导的成本差异仍然是二氧化钛市场竞争力的关键。

二氧化钛市场报告按等级(金红石型和锐钛矿型)、工艺(氯化法和硫酸法)、应用领域(油漆和涂料、塑料、造纸和纸浆、化妆品及其他应用)、终端用户行业(建筑、汽车和运输、包装及其他)以及地区(亚太地区、北美地区、欧洲及其他地区)对行业进行细分。市场预测以吨为单位。

区域分析

亚太地区占全球二氧化钛市场的35%,预计2030年将以4.92%的复合年增长率快速成长。中国拥有全球大部分二氧化钛产能,在满足国内建筑和基础设施需求的同时,也兼顾了出口。政府为提高颜料品质和减少硫酸法製程废水排放而製定的政策,正推动生产商转向符合西方标准的氯化物技术。

北美二氧化钛市场主要由耐用消费品、航太涂料和包装薄膜等产业所驱动。成熟的环境法规有利于氯化钛的生产,而企业对环境、社会和治理(ESG)的承诺也推动了低碳颜料路线的研发。欧洲市场则受到两大限制:一是二类致癌性标示制度,二是对来自中国的进口产品征收明确的反倾销税。这些措施提高了本地生产成本,但也促使企业在高端产品领域进行创新,以支撑更高的价格分布。

中东和非洲正迎来由大型企划建筑项目推动的新机会。波湾合作理事会强制推行的「冷屋顶」政策以及旅游业的成长将促进高反射率涂料的应用。由于国内二氧化钛产量微乎其微,导致对进口的依赖以及对运费波动的担忧。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 亚太地区对水性建筑涂料的强劲需求正在推动金红石型二氧化钛颜料的消费。

- 欧洲转向使用轻量、高光泽汽车塑料

- 层压纸板包装在电子商务物流的成长

- 中东建设产业对抗紫外线冷屋顶涂料的欢迎

- 印度氯化钛生产能力的在地化

- 市场限制

- 由于欧盟将二氧化钛列为致癌性,标籤检视成本增加。

- 钛铁矿/金红石原料价格波动会影响利润率。

- 其他白色颜料的竞争压力

- 价值链分析

- 贸易分析

- 波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章 市场规模及成长预测(销售)

- 按年级

- 金红石

- 锐钛矿

- 透过流程

- 氯化物

- 硫酸盐

- 透过使用

- 油漆和涂料

- 塑胶

- 纸和纸浆

- 化妆品

- 其他用途(皮革、纺织品、橡胶)

- 按最终用户产业

- 建造

- 汽车和运输

- 包装

- 消费品

- 其他终端用户产业

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- ASEAN

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 北欧的

- 其他欧洲国家

- 南美洲

- 巴西

- 阿根廷

- 其他南美

- 中东和非洲

- 沙乌地阿拉伯

- 阿拉伯聯合大公国

- 南非

- 埃及

- 其他中东和非洲地区

- 亚太地区

第六章 竞争情势

- 市场集中度

- 策略倡议

- 市占率分析

- 公司简介

- Cinkarna Celje

- Evonik Industries AG

- Grupa Azoty SA

- Hangzhou Harmony Chemical Co.,Ltd

- INEOS

- ISHIHARA SANGYO KAISHA, LTD.

- Kemipex

- Kronos Worldwide, Inc.

- LB Group

- Precheza

- Shandong Jinhai Titanium Resources Technology Co., Ltd.

- TAYCA Co., Ltd.

- The Chemours Company

- Titanos

- Tronox Holdings Plc

- Venator Materials PLC

- Zhejiang TITAN Design& Engineering CO., Ltd

第七章 市场机会与未来展望

The Titanium Dioxide Market size is estimated at 360.16 kilotons in 2025, and is expected to reach 440.86 kilotons by 2030, at a CAGR of 4.10% during the forecast period (2025-2030).

Rising demand from construction, packaging, automotive plastics, and cool-roof coatings offsets regulatory headwinds, especially Europe's Category 2 carcinogen labeling and anti-dumping duties on Chinese material. Asia-Pacific, anchored by China's supply base and India's localization push, is advancing at a 4.92% CAGR. Manufacturers are balancing cost pressures from volatile ilmenite and rutile feedstock with technology upgrades in the chloride route. Process optimization by players such as Chemours is boosting capacity by 15% without major capital outlays, while vertical integration by Tronox and others mitigates raw-material volatility. Regulatory divergence between the EU and other regions is spurring differentiated product portfolios and creating scope for regional arbitrage.

Global Titanium Dioxide Market Trends and Insights

Surge in Demand for Waterborne Architectural Coatings in Asia-Pacific

Escalating volatile-organic-compound regulations across China, India and Indonesia are accelerating substitution of solvent systems by waterborne paints, driving incremental rutile pigment offtake in the region. Regional coating lines are upgrading dispersion technology to achieve hiding power parity, underpinning continuous volume growth for the titanium dioxide market. Infrastructure stimulus programs in India and Indonesia compound demand, while localized chloride-route capacity secures supply resilience. Formulators emphasize lower odor and safer worksite conditions, bolstering acceptance among contractors. The shift is adding a structural tailwind despite feedstock price swings.

Shift Toward Lightweight, High-Gloss Automotive Plastics in Europe

Stringent EU fleet-average carbon-dioxide limits have placed lightweighting at the center of design strategies. Incorporating titanium dioxide into polypropylene and polycarbonate trim delivers high-gloss surfaces that rival coated metal panels yet weigh markedly less, achieving a 5-7% fuel-efficiency gain per 10% vehicle weight reduction. Premium OEMs adopt hydrophobic grades such as TIOXIDE TR48, which disperse at high processing temperatures without loss of brightness. The titanium dioxide market gains not only in volume but in value because these specialty grades command premium pricing and carry minimal regulatory substitution risk.

EU Classification of TiO2 as Suspected Carcinogen Raising Labeling Costs

European Regulation 2025/4 mandates cancer warnings on powder formulations containing more than or equal to 1% titanium dioxide. Coating, plastisol, and printing-ink suppliers face reformulation, new packaging artwork, and legal reviews, inflating compliance costs. Divergent rules in the United Kingdom and North America complicate global portfolio management, requiring dual labeling strategies. Short-run manufacturing batches raise unit costs, dampening discretionary demand in DIY channels. Although the European Court annulled the hazard label in 2022, the ruling was reversed in 2025 after scientific reassessment, reinforcing uncertainty for the titanium dioxide market.

Other drivers and restraints analyzed in the detailed report include:

- Growth of Laminated Paperboard Packaging for E-Commerce Logistics

- Uptake of UV-Resistant Cool-Roof Coatings in Middle-East Construction

- Volatility in Ilmenite/Rutile Feedstock Prices Impacting Margins

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Rutile commanded 78% of the titanium dioxide market in 2024, reflecting its higher refractive index (2.7) and superior weatherability. This supremacy is entrenched in outdoor architectural coatings, automotive topcoats, and polymer masterbatches where long-term gloss retention is critical. Dual-function grades integrating photocatalytic traits are unlocking new self-cleaning surface opportunities, further entrenching the rutile's lead.

Anatase, accounting for the demand balance, is advancing at a faster 4.5% CAGR thanks to niche growth in pharmaceutical excipients and photocatalytic building materials. Surface-modified anatase grades extend shelf life in food-contact papers and offer distinct bluish undertones valued in premium office papers.

The sulfate route delivered 65% of the titanium dioxide market size in 2024 by leveraging lower-grade ilmenite and smaller capital footprints. Nevertheless, chloride-based capacity is expanding at 4.7% CAGR as regulators intensify scrutiny of acidic sulfate waste streams. Chloride plants use high-TiO2 slag or natural rutile and generate primarily rutile pigment with lower trace impurities, enabling higher pricing in premium coatings and masterbatch segments. Chemours reports that proprietary low-temperature chlorination at 350-450 °C can reduce energy use by 30% and improve yield.

Emerging producers in India are adopting chloride technology to achieve quality parity with Western suppliers and to hedge against evolving effluent norms. Incremental debottlenecking projects across North America and Europe aim to squeeze 5-15% extra output from existing chloride assets without greenfield spending, keeping supply balanced despite regional capacity closures such as Tronox's Botlek facility. Process-driven cost differentials, therefore, remain central to titanium dioxide market competitiveness.

The Titanium Dioxide Market Report Segments the Industry by Grade (Rutile and Anatase), Process (Chloride and Sulfate) Application (Paints and Coatings, Plastics, Paper and Pulp, Cosmetics and Other Applications), End-User Industry (Construction, Automotive and Transportation, Packaging, and More) and Geography (Asia-Pacific, North America, Europe, and More). The Market Forecasts are Provided in Terms of Volume (Tons)

Geography Analysis

Asia-Pacific controls 35% of the titanium dioxide market and delivers the fastest 4.92% CAGR through 2030. China alone houses a major portion of global TiO2 capacity, balancing exports with rising domestic architectural and infrastructure demand. Government directives to upgrade pigment quality and curb sulfate-process effluent are pushing producers toward chloride technology, replicating Western standards.

North America's titanium dioxide market remains driven by durable goods, aerospace coatings, and packaging films. Mature environmental regulations favor chloride output, and corporate ESG commitments spur research and development into lower-carbon pigment pathways. Europe's market is shaped by dual constraints: Category 2 carcinogen labeling and definitive anti-dumping duties on Chinese imports. These measures elevate local production costs but also encourage premium-grade innovation to justify higher price points.

The Middle-East and Africa present emergent potential propelled by construction megaprojects. Cool-roof mandates in the Gulf Cooperation Council and rising tourism facilities spur high-albedo coating uptake. Domestic TiO2 production remains negligible, driving import dependency and exposure to freight fluctuations.

- Cinkarna Celje

- Evonik Industries AG

- Grupa Azoty S.A.

- Hangzhou Harmony Chemical Co.,Ltd

- INEOS

- ISHIHARA SANGYO KAISHA, LTD.

- Kemipex

- Kronos Worldwide, Inc.

- LB Group

- Precheza

- Shandong Jinhai Titanium Resources Technology Co., Ltd.

- TAYCA Co., Ltd.

- The Chemours Company

- Titanos

- Tronox Holdings Plc

- Venator Materials PLC

- Zhejiang TITAN Design& Engineering CO., Ltd

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Surge in Demand for Waterborne Architectural Coatings in Asia-Pacific Boosting Rutile TiO2 Pigment Consumption

- 4.2.2 Shift Toward Lightweight, High-Gloss Automotive Plastics in Europe

- 4.2.3 Growth of Laminated Paperboard Packaging for E-Commerce Logistics

- 4.2.4 Uptake of UV-Resistant Cool-Roof Coatings in Middle-East Construction

- 4.2.5 Localization of Chloride-Route TiO2 Capacity in India

- 4.3 Market Restraints

- 4.3.1 EU Classification of TiO2 as Suspected Carcinogen Raising Labeling Costs

- 4.3.2 Volatility in Ilmenite/Rutile Feedstock Prices Impacting Margins

- 4.3.3 Competitive Pressure from Alternative White Pigments

- 4.4 Value Chain Analysis

- 4.5 Trade Analysis

- 4.6 Porter's Five Forces Analysis

- 4.6.1 Bargaining Power of Suppliers

- 4.6.2 Bargaining Power of Consumers

- 4.6.3 Threat of New Entrants

- 4.6.4 Threat of Substitute Products and Services

- 4.6.5 Degree of Competition

5 Market Size and Growth Forecasts (Volume)

- 5.1 By Grade

- 5.1.1 Rutile

- 5.1.2 Anatase

- 5.2 By Process

- 5.2.1 Chloride

- 5.2.2 Sulfate

- 5.3 By Application

- 5.3.1 Paints and Coatings

- 5.3.2 Plastics

- 5.3.3 Paper and Pulp

- 5.3.4 Cosmetics

- 5.3.5 Other Applications (Leather, Textiles, Rubber)

- 5.4 By End-user Industry

- 5.4.1 Construction

- 5.4.2 Automotive and Transportation

- 5.4.3 Packaging

- 5.4.4 Consumer Goods

- 5.4.5 Other End-user Industries

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 ASEAN

- 5.5.1.6 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Nordics

- 5.5.3.6 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle-East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 United Arab Emirates

- 5.5.5.3 South Africa

- 5.5.5.4 Egypt

- 5.5.5.5 Rest of Middle-East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Cinkarna Celje

- 6.4.2 Evonik Industries AG

- 6.4.3 Grupa Azoty S.A.

- 6.4.4 Hangzhou Harmony Chemical Co.,Ltd

- 6.4.5 INEOS

- 6.4.6 ISHIHARA SANGYO KAISHA, LTD.

- 6.4.7 Kemipex

- 6.4.8 Kronos Worldwide, Inc.

- 6.4.9 LB Group

- 6.4.10 Precheza

- 6.4.11 Shandong Jinhai Titanium Resources Technology Co., Ltd.

- 6.4.12 TAYCA Co., Ltd.

- 6.4.13 The Chemours Company

- 6.4.14 Titanos

- 6.4.15 Tronox Holdings Plc

- 6.4.16 Venator Materials PLC

- 6.4.17 Zhejiang TITAN Design& Engineering CO., Ltd

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment

- 7.2 Increased Use of Ultrafine Titanium Dioxide in Cosmetics and Cool-Roofing