|

市场调查报告书

商品编码

1848051

水性醇酸涂料:市场占有率分析、产业趋势、统计数据和成长预测(2025-2030 年)Water-based Alkyd Coatings - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

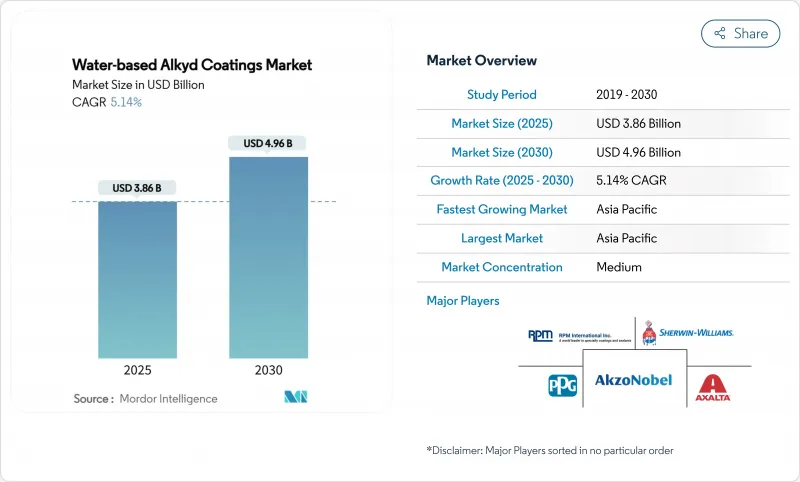

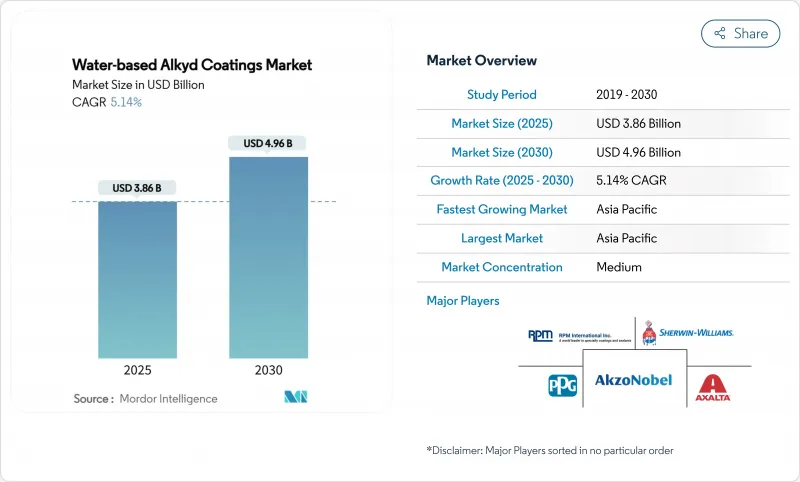

2025年水性醇酸涂料市场规模预估为38.6亿美元,预估至2030年将达49.6亿美元,预测期(2025-2030年)复合年增长率为5.14%。

日益严格的环境合规法规、建筑业的復苏以及持续的产品创新正在推动这一成长。製造商正专注于低挥发性有机化合物(VOC)配方和无钴干燥系统,以满足日益严格的全球法规要求。亚太地区占了大部分消费量,这主要得益于加速的工业化进程和政府对溶剂排放的严厉打击。北美和欧洲的建筑翻新週期维持了基准需求,而汽车翻新等快速成长的细分市场则受益于更短的製程时间和更低的能源成本。策略整合和垂直一体化赋予了知名品牌定价权,但生物基乳化也为差异化挑战者打开了市场之门。

全球水性醇酸涂料市场趋势及洞察

从溶剂型技术转向水性技术

全球法规推动了溶剂型醇酸涂料向水性醇酸涂料的转变。 2018年上海禁止使用溶剂型建筑涂料的政策,促使全国各地纷纷采用水性涂料,改变了原料的流动方向,并对当地供应链产生了影响。美国环保署(EPA)将于2025年更新气雾剂涂料的VOC排放标准,将进一步推动对低反应性原料的需求。像Perstorp这样的供应商正在推出新一代乳化剂,这些乳化剂能够在不牺牲硬度或光泽度的前提下,实现近乎零VOC排放。能够兼顾合规性和传统表现的公司,可以获得先发优势,并增强客户忠诚度。

建筑业復苏与重新粉刷週期

由于老旧住宅存量以及DIY成本的降低抵消了新建房屋数量的放缓,房屋重新粉刷的需求仍然强劲。宣伟公司报告称,其专业承包商管道已占据美国油漆销售量的63%,这进一步提升了其专业网络的价值。亚洲涂料公司为响应印度的「人人有房」计划,实施了一项48亿美元的计划,将其装饰产能提高了一倍以上。这些趋势表明,即使GDP成长温和,重新粉刷的需求也能确保销售稳定,并有助于抵御经济週期波动的影响。

与溶剂型系统相比,干燥和固化时间更长。

高湿度会减缓水分蒸发,延长计划并增加人事费用。 Polynt 的速干型 DTM 醇酸乳化可以缩短施工週期,但其依赖于优化的干燥剂配方。负责人正努力寻找钴的替代品,以降低毒性并保持其优异的性能。儘管近年来性能差距正在缩小,但赤道气候地区的承包商在进行外墙涂装时通常仍然选择溶剂型配方。

细分市场分析

到2024年,建筑涂料将占水性醇酸涂料市场规模的46.51%,这反映了持续的翻新週期以及法规主导的住宅室内装饰需求。配方师提供适用于生活空间的低气味涂料,其VOC含量低至50克/公升。以亚洲涂料及其区域同行主导的亚洲产能扩张,与都市区住宅规划相契合。更长的使用寿命,包括不易泛黄的涂层,增强了丙烯酸树脂的价值提案。

到2030年,汽车修补漆产业将以6.56%的复合年增长率成为成长最快的产业。阿克苏诺贝尔的Sikkens Autowave Optima可降低喷漆室能耗60%,减少1.5层喷涂,进而提高车间效率并降低碳排放强度。工业金属、木材和船舶产业正在采用水性醇酸树脂涂料,其乳液技术已达到ISO 12944防腐蚀标准。家具製造商正在积极采用符合企业永续性目标的生物基产品,而机械和海上涂料则代表需要先进阻隔添加剂的特殊机会。

水性醇酸涂料市场报告按应用领域(建筑、防护及工业金属、木器涂装、其他)、终端用户产业(建筑及基础设施、工业OEM、汽车及交通运输、船舶及近海、其他)及地区(亚太、北美、欧洲、南美、中东及非洲)进行细分。市场预测以美元计价。

区域分析

亚太地区预计到2024年将占全球销售额的41.32%,到2030年将以5.68%的复合年增长率成长。在中国,上海等城市实施的溶剂禁令正在推动符合规范的水性醇酸树脂的转型。全国90毫克/公斤的铅含量上限进一步强化了这一转变,为国内製造商提供了技术规范和出口优势。强劲的建筑业发展、不断增长的汽车保有量以及消费者意识的提高,都在支撑多个细分市场的需求。

北美凭藉着成熟的分销管道和严格的环境法规,保持着强劲的市场地位。加州50克/公升的污染物限值促进了研发,而专业的汽车修补服务则推动了销售量。美国生产商利用通路管理和自有品牌协议来优化净利率。随着汽车修理厂缩短维修週期,汽车修补漆的快速普及将进一步加速。

欧洲将继续引领创新,实现生物基乳化和无钴干燥剂的商业化。儘管消费成熟会导致销售成长放缓,但历史建筑的维修和节能维修将维持强劲的需求。欧盟的「绿色新政」激励措施鼓励公共采购低挥发性有机化合物(VOC)涂料,并为符合标准的供应商提供优惠的竞标资格。

在南美洲,随着城市基础设施的扩张,需求不断增长,尤其是在巴西为世界杯做准备而升级改造设施的情况下。儘管各国监管力道不尽相同,但日益增强的健康意识正促使买家转向水基系统。中东和非洲地区蕴藏早期发展机会,这些机会主要集中在高端商业和油气基础设施领域,需要既耐腐蚀又符合规范的解决方案。价格敏感度和极端气候条件减缓了转换率,凸显了开发湿度优化配方和本地化混合产品的必要性。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 从溶剂型技术转向水性技术

- 建筑业復苏与重新粉刷週期

- 全球加强对挥发性有机化合物(VOC)和有害空气污染物(HAP)的监管

- 偏好低气味的室内涂料。

- 生物基醇酸乳化实现商业化规模生产

- 市场限制

- 溶剂型体系的干燥/固化时间比溶剂型系统长。

- 新兴经济体的价格敏感性

- 湿度导致的耐候性受限

- 价值链分析

- 五力分析

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章 市场规模与成长预测

- 透过使用

- 建筑学

- 防护/工业金属

- 木饰面

- 汽车维修

- 其他(船舶、机械)

- 按最终用户行业划分

- 建筑和基础设施

- 工业OEM

- 汽车与运输

- 海洋/近海

- 家具和配件

- 其他的

- 按地区

- 亚太地区

- 中国

- 日本

- 印度

- 韩国

- ASEAN

- 亚太其他地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 俄罗斯

- 其他欧洲

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争情势

- 市场集中度

- 策略倡议

- 市占率(%)/排名分析

- 公司简介

- Akzo Nobel NV

- Axalta Coating Systems, LLC

- Benjamin Moore & Co.

- Brillux GmbH & Co. KG

- Caparol Paints

- Cloverdale Paint Inc.

- Hempel A/S

- Jotun

- Kansai Paint Co.,Ltd.

- NATIONAL PAINTS FACTORIES CO. LTD.

- NIPSEA Group

- PPG Industries Inc.

- RPM International Inc.

- The Sherwin-Williams Company

- Tikkurila

第七章 市场机会与未来展望

The Water-based Alkyd Coatings Market size is estimated at USD 3.86 billion in 2025, and is expected to reach USD 4.96 billion by 2030, at a CAGR of 5.14% during the forecast period (2025-2030).

Stronger environmental compliance rules, a recovering construction sector, and steady product innovation underpin this growth. Manufacturers focus on low-VOC formulations and cobalt-free drying systems to satisfy tightening global regulations. Asia-Pacific dominates consumption, helped by accelerated industrialization and government crackdowns on solvent emissions. Architectural repaint cycles in North America and Europe sustain baseline demand, while fast-growth niches such as automotive refinish benefit from shorter process times and lower energy costs. Strategic consolidation and vertical integration give leading brands pricing power, yet bio-based emulsions open doors for differentiated challengers.

Global Water-based Alkyd Coatings Market Trends and Insights

Shift from Solvent- to Water-based Technology

Global mandates catalyze the conversion from solvent systems to water-based alkyds. Shanghai's 2018 ban on solvent architectural paints triggered nationwide adoption across Chinese construction, altering raw-material flows and influencing regional supply chains. The U.S. EPA's 2025 update of aerosol-coating VOC rules further boosts demand for less reactive ingredients. Suppliers such as Perstorp showcase next-generation emulsifiers that allow near-zero VOC performance without sacrificing hardness or gloss. Firms able to balance compliance with legacy performance secure early mover premiums and strengthen customer loyalty.

Construction Sector Recovery and Repaint Cycles

Residential repainting remains resilient as aging housing stock and DIY affordability offset slower new builds. Sherwin-Williams reports that its pro-contractor channel already captures 63% of U.S. paint volumes, reinforcing the value of professional networks. Asian Paints more than doubled decorative capacity with a USD 4.8 billion program to serve India's Housing for All initiative. These patterns illustrate that even modest GDP growth can unlock steady volume through repaint demand, cushioning cyclicality.

Longer Drying/Curing Time vs. Solvent Systems

Water slows evaporation under high humidity, lengthening project schedules and raising labor costs. Fast-dry DTM alkyd emulsions from Polynt shorten cycles yet still depend on optimized drier blends. Formulators wrestle with cobalt-replacement to mitigate toxicity while preserving siccative action. Performance gaps narrow each year, but contractors in equatorial climates often default to solvent formulations for exterior work.

Other drivers and restraints analyzed in the detailed report include:

- Tightening Global VOC and HAP Regulations

- Preference for Low-odor Indoor Paints

- Humidity-Driven Weatherability Limitations

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Architectural coatings generated 46.51% of the water-based alkyd coatings market size in 2024, reflecting sustained repaint cycles and regulation-driven demand in residential interiors. Formulators deliver low-odor paints suited to occupied spaces and VOC limits as low as 50 g/L. Asian capacity expansion, led by Asian Paints and regional peers, keeps pace with urban housing programs. Longevity improvements such as non-yellowing finishes strengthen value propositions versus vinyl acrylics.

The automotive refinish segment will post the fastest 6.56% CAGR through 2030. AkzoNobel's Sikkens Autowave Optima cuts booth energy 60% and reduces layers to 1.5, enhancing shop throughput and lowering carbon intensity. Industrial metal, wood, and marine niches adopt water-borne alkyds as emulsification technologies hit ISO 12944 corrosion benchmarks. Furniture makers welcome bio-based variants that align with corporate sustainability goals, while machinery and offshore coatings represent specialized opportunities requiring advanced barrier additives.

The Water-Based Alkyd Coatings Report is Segmented by Application (Architectural, Protective/Industrial Metal, Wood Finishes, and More), End-User Industry (Construction and Infrastructure, Industrial OEM, Automotive and Transportation, Marine and Offshore, and More), and Geography (Asia-Pacific, North America, Europe, South America, and Middle-East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific commanded 41.32% of global revenue in 2024 and is set to advance at a 5.68% CAGR through 2030. China's solvent bans in cities such as Shanghai prompt wholesale migration to compliant water-based alkyds. National standards capping lead at 90 mg/kg further reinforce the shift, giving domestic producers technical mandates and export leverage. Robust construction, expanding automotive fleets, and rising consumer awareness anchor multi-segment demand.

North America maintains a strong position built on established distribution and stringent environmental codes. California's 50 g/L limit catalyzes research and development, while professional repaint services drive volume. U.S. producers leverage controlled channels and private-label contracts to optimize margins. Rapid adoption in automotive refinish accelerates as bodyshops realize cycle-time reduction.

Europe remains innovation-centric with early commercialization of bio-based emulsions and cobalt-free dryers. Mature consumption moderates volume growth, yet retrofitting of historical buildings and energy-efficient refurbishments sustain steady demand. EU Green Deal incentives encourage public-sector procurement of low-VOC coatings, giving compliant suppliers favored-bidder status.

South America witnesses incremental uptake as urban infrastructure expands, especially in Brazil's pre-World Cup facility renewals. Regulatory enforcement varies by country, but rising health awareness nudges buyers toward water-borne systems. Middle-East and Africa present early-stage opportunities centered on high-end commercial and oil-gas infrastructure needing corrosion-resistant yet compliant solutions. Price sensitivity and climate extremes temper speed of conversion, underlining the need for humidity-optimized formulations and local blending.

- Akzo Nobel N.V.

- Axalta Coating Systems, LLC

- Benjamin Moore & Co.

- Brillux GmbH & Co. KG

- Caparol Paints

- Cloverdale Paint Inc.

- Hempel A/S

- Jotun

- Kansai Paint Co.,Ltd.

- NATIONAL PAINTS FACTORIES CO. LTD.

- NIPSEA Group

- PPG Industries Inc.

- RPM International Inc.

- The Sherwin-Williams Company

- Tikkurila

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Shift from Solvent to Water-Based Technology

- 4.2.2 Construction Sector Recovery and Repaint Cycles

- 4.2.3 Tightening Global VOC and HAP Regulations

- 4.2.4 Preference for Low-Odor Indoor Paints

- 4.2.5 Bio-Based Alkyd Emulsions Reach Commercial Scale

- 4.3 Market Restraints

- 4.3.1 Longer Drying/Curing Time Vs. Solvent Systems

- 4.3.2 Price Sensitivity in Emerging Economies

- 4.3.3 Humidity-Driven Weatherability Limitations

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Rivalry

5 Market Size and Growth Forecasts (Value)

- 5.1 By Application

- 5.1.1 Architectural

- 5.1.2 Protective/Industrial Metal

- 5.1.3 Wood Finishes

- 5.1.4 Automotive Refinish

- 5.1.5 Others (Marine, Machinery)

- 5.2 By End-User Industry

- 5.2.1 Construction and Infrastructure

- 5.2.2 Industrial OEM

- 5.2.3 Automotive and Transportation

- 5.2.4 Marine and Offshore

- 5.2.5 Furniture and Joinery

- 5.2.6 Others

- 5.3 By Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 Japan

- 5.3.1.3 India

- 5.3.1.4 South Korea

- 5.3.1.5 ASEAN

- 5.3.1.6 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Russia

- 5.3.3.6 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share (%)**/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Akzo Nobel N.V.

- 6.4.2 Axalta Coating Systems, LLC

- 6.4.3 Benjamin Moore & Co.

- 6.4.4 Brillux GmbH & Co. KG

- 6.4.5 Caparol Paints

- 6.4.6 Cloverdale Paint Inc.

- 6.4.7 Hempel A/S

- 6.4.8 Jotun

- 6.4.9 Kansai Paint Co.,Ltd.

- 6.4.10 NATIONAL PAINTS FACTORIES CO. LTD.

- 6.4.11 NIPSEA Group

- 6.4.12 PPG Industries Inc.

- 6.4.13 RPM International Inc.

- 6.4.14 The Sherwin-Williams Company

- 6.4.15 Tikkurila