|

市场调查报告书

商品编码

1848172

光学三坐标测量机:市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)Optical Coordinate Measuring Machine - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

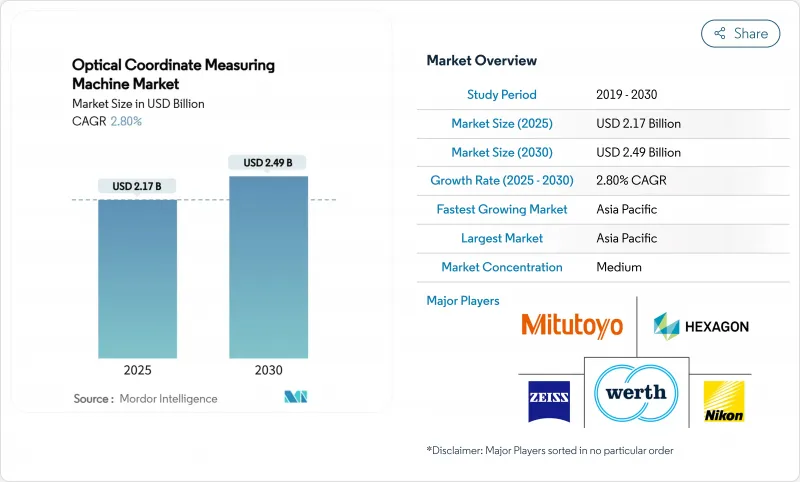

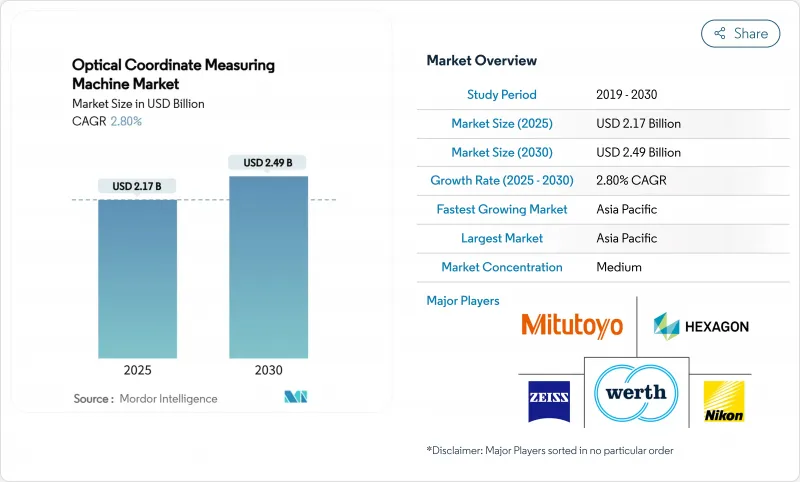

预计到 2025 年,光学座标测量机市场规模将达到 21.7 亿美元,到 2030 年将达到 24.9 亿美元,在此期间的复合年增长率为 2.80%。

随着工业4.0专案对即时尺寸资料的需求日益增长,其应用正从计量实验室转向生产线。儘管市场已趋于成熟,但汽车电气化、航太复合材料应用以及医疗设备个人化等因素仍在推动稳定的需求。采用结构光源和人工智慧技术的3D视觉系统正在提升速度和精确度,使製造商能够在不增加人手的情况下实现零缺陷目标。亚太地区39.6%的收入份额凸显了该地区作为全球精密製造中心的地位,而北美和欧洲则透过不断更新技术来确保符合监管要求。

全球光学三坐标测量机市场趋势与洞察

工业4.0产品设计的变化

为了实现产品个人化和轻量化,製造商不断增加产品的几何复杂性,从而推动了对能够快速捕捉复杂表面的非接触式测量解决方案的需求。光学三座标测量机 (CMM) 供应商目前正在整合网实整合介面 (CPI),使尺寸资料能够直接整合到製造执行系统 (MES) 中。结合结构光源和雷射扫描的多感测器平台可将设定时间缩短高达 40%,因此在汽车和精密机械工厂中广受欢迎。即时整合支援数位双胞胎倡议,因为高密度点云数据可以提高模拟精度。这些功能正在推动市场竞争朝着更快的更新周期发展,因为企业正在更换接触式设备以保持竞争力。

采用线上检测和自动化

汽车和电子产品製造商的目标是实现100%检测,以消除缺陷产品。配备光学感测器的协作机器人可在生产线旁进行无人值守测量,从而将检查週期週期缩短75%,并缓解劳动力短缺问题。机器学习软体能够预测尺寸偏差,使操作人员能够在产生废品之前纠正製程。早期采用者报告称,两年内节省的材料成本足以抵消较高的设备成本,这增强了光学三坐标测量机市场的资本投资决策。

高资本支出和总拥有成本

系统价格从 3 万美元到 25 万美元不等,这对小型製造商构成了准入门槛。再加上设备升级、校准和维护费用,总拥有成本将翻倍。虽然可量化的废料和返工节省提高了经济效益,但许多管理者仍然犹豫不决,导致光学三坐标测量机市场中对成本敏感的部分更换週期延长。

细分市场分析

到2024年,随着单次表面采集技术加速复杂形状的侦测,3D影像处理设备将占据43.1%的收入份额。结构光源平台虽然体积较小,但随着反射表面性能的提升,预计到2030年将以3.9%的复合年增长率成长。雷射扫描设备在白体测量领域仍然很受欢迎,因为在白体测量中,测量范围比微米级精度更为重要。

多感测器设计结合了触觉和光学模式,使单一工作站能够检测多种零件,从而提高运转率,并促进光学三坐标测量机市场的更广泛应用。软体主导的人工智慧演算法引导曝光和图案投射,以克服光照变化的影响,进一步增强了构造化照明的优势。儘管在不需要Z轴资料的情况下,二维影像处理系统在深度捕捉方面存在局限性,但它们仍然被用于高速电子装置检测。

桥式设计结合了热稳定性、亚微米级精度和自动托盘装载功能,预计到2024年将占据40.7%的市场。可携式桌上型侦测机将以4.0%的复合年增长率成长,可在生产线附近进行现场检测,从而缩短零件转移时间。龙门式检测机用于检测大型航太面板,而多关节臂则有助于进入内部空腔。

水平臂式三座标测量机广泛应用于汽车喷漆车间,用于侦测冲压件,其优势在于测量范围更广,且能与输送机无缝整合。桥式三坐标测量机也焕发新生,供应商纷纷认证其适用于±5 ℃的车间环境,从而降低了暖通空调成本,并扩大了光学三坐标测量机在註重成本的买家群体中的市场。人机协作技术为可携式设备增添了无人操作功能,为中阶供应商开闢了新的收入来源。

光学座标测量机市场按产品类型(多感测器、二维视觉、其他)、机器类型(桥式、龙门式、其他)、组件(硬体、软体、服务)、测量范围(小、中、大)、终端用户产业(航太与国防、汽车、其他)和地区进行细分。市场预测以美元计价。

区域分析

预计到2024年,亚太地区将占全球销售额的39.6%,并在2030年之前以3.6%的复合年增长率增长,这主要得益于中国半导体设备製造和日本精密机械出口的强劲增长。亚太地区的领先地位源自于其高度融合的电子、汽车和工具机供应链。诸如「中国製造2025」等政府计画鼓励智慧製造升级,使得非接触式测量成为工厂自动化补贴的重要组成部分。日本一级製造商不断利用人工智慧驱动的软体对桥式测量设备进行升级,以支援电动车零件的出口;而韩国电池製造商则正在部署线上结构光扫描仪来检验棱柱形电池外壳。

北美市场以航太、整形外科植入和高混合积层製造为主导。该地区优先考虑多元数据分析和监管可追溯性,从而推动了以软体为中心的采购决策。 FDA 和 FAA 的指导方针正在增强对检验的测量系统的需求,儘管销量有所下降,但光学三坐标测量机 (CMM) 市场仍然保持活力。

在欧洲,汽车和风力发电产业尤其重视永续性和零缺陷生产。一家德国工厂在其冲压生产线上引入了一台搭载协作机器人的3D视觉头,展示了车间在3°C温度波动下的稳定性。法国和义大利为那些无法负担花岗岩工作檯面基础设施的中型精密加工企业采用了可携式工作台,从而扩大了区域内光学计量技术的普及范围。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 工业4.0中的产品设计变革

- 引入线上检测和自动化

- 轻质复合材料零件需要光学计量技术

- 高精度积层製造的需求

- 加强对产品初始检验的监管

- 人工智慧驱动的纠错演算法

- 市场限制

- 高额资本投入与总拥有成本

- 熟练计量工程师短缺

- 现场环境考量

- 对网路安全和智慧财产权外洩的担忧

- 价值链分析

- 技术展望

- 监管环境

- 波特五力分析

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争

- 影响市场的宏观经济因素

第五章 市场规模与成长预测

- 依产品类型

- 多感测器

- 二维视觉测量机

- 3D视觉测量机

- 雷射扫描光学三座标测量机

- 结构光学座标测量机

- 按模型

- 桥

- 龙门架

- 铰接臂

- 水平的

- 可携式桌上型

- 按组件

- 硬体

- 软体

- 服务

- 按测量范围

- 小型(500毫米或以下)

- 中型(500-2000毫米)

- 大型(超过 2000 毫米)

- 按最终用户行业划分

- 航太与国防

- 车

- 医疗设备和整形外科

- 重型设备和金属加工

- 电子和半导体

- 能源与发电

- 其他终端用户产业

- 按地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 南美洲

- 巴西

- 阿根廷

- 智利

- 其他南美洲

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 其他欧洲地区

- 亚太地区

- 中国

- 日本

- 印度

- 韩国

- 澳洲

- 新加坡

- 马来西亚

- 亚太其他地区

- 中东和非洲

- 中东

- 沙乌地阿拉伯

- 阿拉伯聯合大公国

- 土耳其

- 其他中东地区

- 非洲

- 南非

- 奈及利亚

- 其他非洲地区

- 北美洲

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- Hexagon AB

- Carl Zeiss AG

- Mitutoyo Corp.

- Nikon Metrology NV

- Werth Messtechnik GmbH

- OGP(Quality Vision International, Inc.)

- Micro-Vu Corp.

- Keyence Corp.

- Renishaw plc

- FARO Technologies Inc.

- Creaform Inc.(AMETEK)

- Perceptron Inc.(Atlas Copco)

- LK Metrology Ltd.

- Coord3 Srl

- Automated Precision Inc.(API)

- Wenzel Group GmbH and Co. KG

- Vision Engineering Ltd.

- Metronor AS

- Helmel Engineering Products Inc.

- Aberlink Ltd.

- InspecVision Ltd.

- Innovative Optical Measuring Systems(IOMS)

第七章 市场机会与未来展望

The optical coordinate measuring machine market size is USD 2.17 billion in 2025 and is forecast to reach USD 2.49 billion in 2030, reflecting a 2.80% CAGR over the period.

Adoption is moving from metrology labs to production lines as Industry 4.0 programs demand dimensional data in real time. Automotive electrification, aerospace composite usage, and medical-device personalization keep demand steady despite the market's maturity. Structured-light and AI-enhanced 3D vision systems are improving speed and accuracy, which allows manufacturers to meet zero-defect goals without expanding headcount. Asia-Pacific's 39.6% revenue share underscores the region's role as the world's precision-manufacturing hub, while North America and Europe pursue technology refresh cycles to maintain regulatory compliance.

Global Optical Coordinate Measuring Machine Market Trends and Insights

Changing Product Designs in Industry 4.0

Manufacturers are increasing geometric complexity to personalize products and reduce weight, which drives demand for non-contact measurement solutions that can capture intricate surfaces quickly. Optical CMM suppliers now embed cyber-physical interfaces so dimensional data feeds directly into manufacturing-execution systems. Multi-sensor platforms that blend structured light and laser scanning shorten set-up time by up to 40%, a benefit valued by automotive and precision-machinery plants. Real-time integration supports digital-twin initiatives, since dense point-cloud data improves simulation accuracy. These capabilities push the optical coordinate measuring machine market toward faster refresh cycles as firms replace tactile equipment to stay competitive.

Adoption of In-line Inspection and Automation

Automotive and electronics producers target 100% inspection to eliminate escape defects. Collaborative robots equipped with optical sensors provide unattended measurements beside the production line, cutting inspection cycle times by 75% and mitigating technician shortages. Machine-learning software predicts dimensional drift, allowing operators to correct processes before scrap occurs. Early adopters report material savings that justify premium equipment costs within two years, reinforcing capital-expenditure decisions in the optical coordinate measuring machine market.

High Capital Expenditure and TCO

System prices ranging from USD 30,000 to USD 250,000 create adoption hurdles for small manufacturers. The total cost of ownership doubles when facility upgrades, calibration, and maintenance are added. Economic justification improves when scrap and rework savings are quantified, yet many managers still hesitate, slowing replacement cycles in cost-sensitive regions of the optical coordinate measuring machine market.

Other drivers and restraints analyzed in the detailed report include:

- Lightweight Composite Metrology

- High-precision Additive Manufacturing Demand

- Lack of Skilled Metrology Workforce

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

3D vision machines held 43.1% revenue share in 2024 because single-shot surface capture accelerates complex geometry inspection. Structured-light platforms, though smaller, are forecast to post a 3.9% CAGR through 2030 as reflective-surface performance improves. Laser-scanning units remain popular for body-in-white measurement, where range outweighs micron-level accuracy.

Multi-sensor designs combine tactile and optical modes, giving users one station for diverse parts, which elevates utilization rates and supports broader adoption within the optical coordinate measuring machine market. Software-driven AI algorithms now guide exposure and pattern projection to overcome variable lighting, further boosting structured-light appeal. 2D vision machines, although limited in depth capture, continue to serve high-speed electronic-component checks where z-axis data is unnecessary.

Bridge designs secured 40.7% market share in 2024 by blending thermal stability, sub-micron accuracy, and automated pallet loading. Portable benchtop machines, rising at a 4.0% CAGR, enable spot verification near production lines, reducing part-transfer times. Gantry models inspect very large aerospace panels, while articulated arms aid access to internal cavities.

Horizontal-arm variants serve stamped-body inspection in automotive paint shops, benefiting from extended reach and conveyor integration. Bridge systems gain new life as vendors certify them for +-5 °C shop-floor environments, cutting HVAC costs and broadening the optical coordinate measuring machine market size among cost-conscious buyers. Cobotic innovations add unattended operation capabilities to portable units, opening new revenue streams for mid-tier suppliers.

Optical Coordinate Measuring Machine Market is Segmented by Product Type (Multi-Sensor, 2D Vision Measurement Machine, and More), Machine Type (Bridge, Gantry, and More), Component (Hardware, Software, and Services), Measurement Volume Range (Small, Medium, and Large), End-User Industry (Aerospace and Defense, Automotive, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific accounted for 39.6% revenue in 2024 and is expected to post a 3.6% CAGR through 2030, led by China's semiconductor equipment build-out and Japan's precision machinery exports. Asia-Pacific's dominance stems from dense electronics, automotive, and machine-tool supply chains. Government programs such as Made in China 2025 incentivize smart-manufacturing upgrades, making non-contact metrology integral to factory-automation grants. Japanese tier-ones continue to refresh bridge-type machines with AI-driven software to support electric-vehicle component exports, while Korean battery makers install in-line structured-light scanners to verify prismatic cell cases.

North America's market revolves around aerospace, orthopedic implants, and high-mix additive manufacturing. The region values multivariate data analytics and regulatory traceability, driving software-centric procurement decisions. FDA and FAA guidelines reinforce demand for validated measurement systems, keeping the optical coordinate measuring machine market vibrant despite lower unit volumes.

Europe emphasizes sustainability and zero-defect production in the automotive and wind-energy sectors. German factories deploy cobot-mounted 3D vision heads on stamping lines, demonstrating shop-floor resilience under +-3 °C fluctuations. France and Italy adopt portable benchtops to serve midsized precision-machining firms that cannot justify granite-bed infrastructure, broadening regional access to optical metrology.

- Hexagon AB

- Carl Zeiss AG

- Mitutoyo Corp.

- Nikon Metrology NV

- Werth Messtechnik GmbH

- OGP (Quality Vision International, Inc.)

- Micro-Vu Corp.

- Keyence Corp.

- Renishaw plc

- FARO Technologies Inc.

- Creaform Inc. (AMETEK)

- Perceptron Inc. (Atlas Copco)

- LK Metrology Ltd.

- Coord3 S.r.l.

- Automated Precision Inc. (API)

- Wenzel Group GmbH and Co. KG

- Vision Engineering Ltd.

- Metronor AS

- Helmel Engineering Products Inc.

- Aberlink Ltd.

- InspecVision Ltd.

- Innovative Optical Measuring Systems (IOMS)

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Changing product designs in Industry 4.0

- 4.2.2 Adoption of in-line inspection and automation

- 4.2.3 Lightweight composite parts require optical metrology

- 4.2.4 High-precision additive manufacturing demand

- 4.2.5 Regulatory push for first-article inspection

- 4.2.6 AI-driven error-compensation algorithms

- 4.3 Market Restraints

- 4.3.1 High capital expenditure and TCO

- 4.3.2 Lack of skilled metrology workforce

- 4.3.3 Environmental sensitivity on shop-floor

- 4.3.4 Cyber-security and IP-leakage concerns

- 4.4 Value Chain Analysis

- 4.5 Technological Outlook

- 4.6 Regulatory Landscape

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Impact of Macroeconomic Factors on the Market

5 MARKET SIZE AND GROWTH FORECASTS (VALUES)

- 5.1 By Product Type

- 5.1.1 Multi-sensor

- 5.1.2 2D Vision Measurement Machine

- 5.1.3 3D Vision Measurement Machine

- 5.1.4 Laser Scanning Optical CMM

- 5.1.5 Structured-light Optical CMM

- 5.2 By Machine Type

- 5.2.1 Bridge

- 5.2.2 Gantry

- 5.2.3 Articulated Arm

- 5.2.4 Horizontal

- 5.2.5 Portable Benchtop

- 5.3 By Component

- 5.3.1 Hardware

- 5.3.2 Software

- 5.3.3 Services

- 5.4 By Measurement Volume Range

- 5.4.1 Small (<= 500 mm)

- 5.4.2 Medium (500-2 000 mm)

- 5.4.3 Large (> 2 000 mm)

- 5.5 By End-user Industry

- 5.5.1 Aerospace and Defense

- 5.5.2 Automotive

- 5.5.3 Medical Device and Orthopedics

- 5.5.4 Heavy Machinery and Metal Fabrication

- 5.5.5 Electronics and Semiconductor

- 5.5.6 Energy and Power Generation

- 5.5.7 Other End-user Industries

- 5.6 By Geography

- 5.6.1 North America

- 5.6.1.1 United States

- 5.6.1.2 Canada

- 5.6.1.3 Mexico

- 5.6.2 South America

- 5.6.2.1 Brazil

- 5.6.2.2 Argentina

- 5.6.2.3 Chile

- 5.6.2.4 Rest of South America

- 5.6.3 Europe

- 5.6.3.1 Germany

- 5.6.3.2 United Kingdom

- 5.6.3.3 France

- 5.6.3.4 Italy

- 5.6.3.5 Spain

- 5.6.3.6 Rest of Europe

- 5.6.4 Asia-Pacific

- 5.6.4.1 China

- 5.6.4.2 Japan

- 5.6.4.3 India

- 5.6.4.4 South Korea

- 5.6.4.5 Australia

- 5.6.4.6 Singapore

- 5.6.4.7 Malaysia

- 5.6.4.8 Rest of Asia-Pacific

- 5.6.5 Middle East and Africa

- 5.6.5.1 Middle East

- 5.6.5.1.1 Saudi Arabia

- 5.6.5.1.2 United Arab Emirates

- 5.6.5.1.3 Turkey

- 5.6.5.1.4 Rest of Middle East

- 5.6.5.2 Africa

- 5.6.5.2.1 South Africa

- 5.6.5.2.2 Nigeria

- 5.6.5.2.3 Rest of Africa

- 5.6.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 Hexagon AB

- 6.4.2 Carl Zeiss AG

- 6.4.3 Mitutoyo Corp.

- 6.4.4 Nikon Metrology NV

- 6.4.5 Werth Messtechnik GmbH

- 6.4.6 OGP (Quality Vision International, Inc.)

- 6.4.7 Micro-Vu Corp.

- 6.4.8 Keyence Corp.

- 6.4.9 Renishaw plc

- 6.4.10 FARO Technologies Inc.

- 6.4.11 Creaform Inc. (AMETEK)

- 6.4.12 Perceptron Inc. (Atlas Copco)

- 6.4.13 LK Metrology Ltd.

- 6.4.14 Coord3 S.r.l.

- 6.4.15 Automated Precision Inc. (API)

- 6.4.16 Wenzel Group GmbH and Co. KG

- 6.4.17 Vision Engineering Ltd.

- 6.4.18 Metronor AS

- 6.4.19 Helmel Engineering Products Inc.

- 6.4.20 Aberlink Ltd.

- 6.4.21 InspecVision Ltd.

- 6.4.22 Innovative Optical Measuring Systems (IOMS)

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment