|

市场调查报告书

商品编码

1848300

聚合物混凝土:市场占有率分析、产业趋势、统计数据和成长预测(2025-2030)Polymer Concrete - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

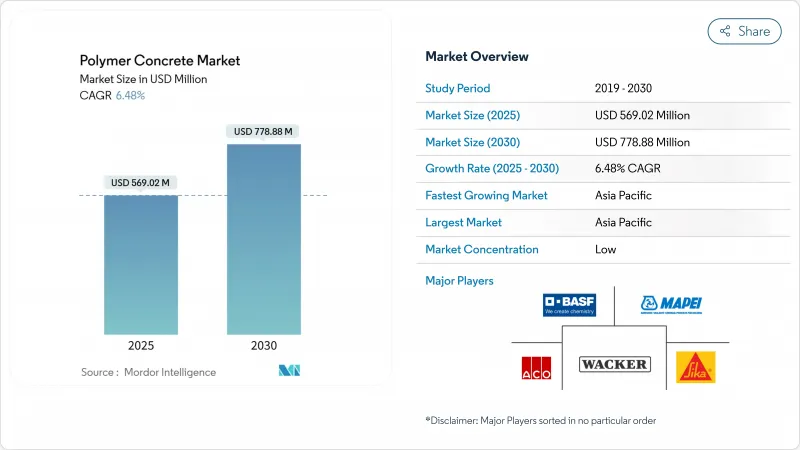

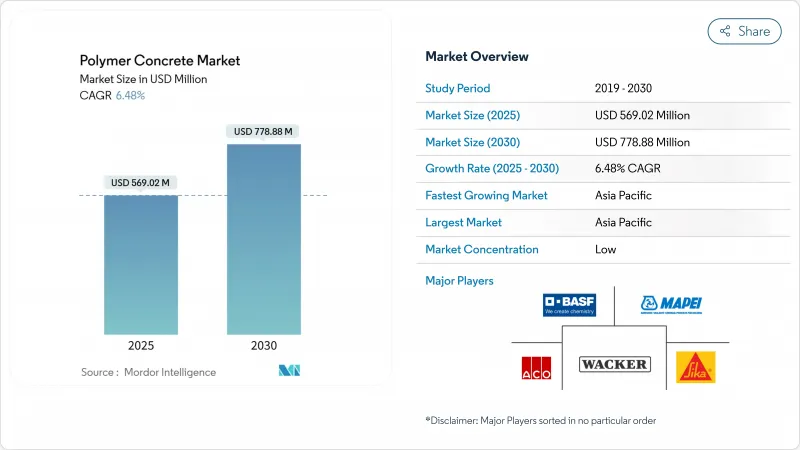

预计到 2025 年聚合物混凝土市场规模将达到 5.6902 亿美元,到 2030 年将达到 7.7888 亿美元,复合年增长率为 6.48%。

优先考虑耐腐蚀材料的基础设施升级项目、对资料中心排水网路的持续资本投资以及公用设备中非导电垫片的日益普及,共同推动了市场的成长。亚太地区的快速都市化、欧洲永续性法规的加强以及生物基黏合剂技术的进步,正在拓宽生物基黏合剂的整体应用范围。领先製造商的策略性收购,加上以性能主导的配方升级,为大多数地区提供了稳定的定价能力和利润率。

全球聚合物混凝土市场趋势与洞察

防腐蚀基础设施发展势头强劲

由于聚合物混凝土即使长时间暴露于酸和盐中也能保持高达90%的原始强度,因此区域公共正在用环氧粘结混凝土取代污水管道和海水淡化厂中的钢筋混凝土。海湾合作委员会各国政府指定在主管线和工厂容器中使用聚合物混凝土,以应对氯化物环境。 DAW Construction和卡达通用专案公司等当地建设公司正在推出能够承受极端温度变化的区域专用混凝土,这表明聚合物混凝土市场能够利用特定地区的化学特性来确保其使用寿命。

工业中心的耐化学腐蚀材料

主要亮点

- 中国沿海地区、韩国、美国墨西哥湾沿岸和德国的化学加工商正在使用富含树脂的配方来改造储槽基座、二次存储壳和装卸区。由于营运商意识到与传统混合料相比,更少的停机时间和更薄的壁厚所带来的生命週期节省,需求激增。电池化学品、肥料和特殊树脂产能的稳定扩张,为聚合物混凝土市场提供了持续的计划供应。

结构应用的认证障碍

主要亮点

- 聚合物混凝土地板和墙板的防火通讯协定尚未与主要建筑规范相协调。开发人员仍持谨慎态度,直至独立实验室发布全面的测试结果,证明其具有可靠的两小时耐火性能,这限制了其在中层建筑中的广泛应用,因为这些建筑的规范部门需要进行冗长的认证。

細項分析

环氧树脂占据聚合物混凝土市场的最大份额,2024年占总营收的52%,预计到2030年将以7.21%的复合年增长率成长。优异的黏结强度和耐酸性支撑了其双重领先地位。最近的动态负荷研究证实,环氧混合物即使在反覆衝击下也能保持较高的峰值应力,这是铁路枕木和桥樑路面的理想特性。甲基丙烯酸甲酯系列产品适用于机场跑道的快速固化修復,而这类跑道的交通中断成本正在迅速增加。丙烯酸酯和乳胶系统在柔性覆盖层和老化基材的黏合方面占据较小的市场份额。

环氧树脂的主导地位也塑造了添加剂的需求模式,促使玻璃纤维和硅粉供应商优化富含树脂基质的颗粒级配。聚酯在成本敏感型应用中仍然很重要,但由于抗压强度有限而面临阻力。随着价值链参与者不断扩展配方选择,聚合物混凝土产业正受益于能够解决价格/性能权衡问题的客製化化学配方。

合成树脂将在2024年占据80%的市场份额,这反映了数十年的现场检验。一项针对天然黏合剂的初步研究显示,明胶改质复合材料的抗压强度为59.6 MPa,证明了其技术可行性。政府对循环材料的激励措施正在鼓励实验室评估几丁聚醣、木质素和海藻酸盐作为部分替代品的可能性。这项研究支持天然树脂在2030年的复合年增长率达到7.56%。

生产商正在规划转型策略,实施化石燃料含量低至60%的混合系统。斯堪的斯堪地那维亚和日本的早期采用者正在购买试点批次,用于绿色认证的土木工程,这将形成一个需求市场,并在未来几年内波及聚合物混凝土市场。技术文献持续关注树脂-骨材相容性、流变控制和长期耐候性能。

区域分析

受中国「一带一路」走廊升级和印度智慧城市污水处理系统维修的推动,亚太地区将在2024年占据41.5%的市场份额。区域研究机构正在与国内製造商合作,针对热带潮湿和高硫酸盐土壤定製配方,从而加强区域供应链。受污水处理能力扩张和资料中心快速建设的推动,预计到2030年,亚太地区聚合物混凝土市场规模将以7.45%的复合年增长率成长。

由于《基础设施投资与就业法案》为桥面覆盖层、海岸线保护和弹性能源资产提供资金,北美将保持稳定成长,而欧洲更严格的碳和微塑胶法规正在加速耐用、易于维护的材料。

中东和非洲对海水淡化厂、区域冷却水道和化学品码头的需求正在增加。在南美洲,巴西的港口扩建、生质燃料设施和矿业资产是这项活动的核心,聚合物混凝土在酸性和磨蚀性操作条件下可实现生命週期节约。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场状况

- 市场概况

- 市场驱动因素

- 海湾合作委员会迅速采用聚合物混凝土建造耐腐蚀废水和海水淡化厂

- 耐化学腐蚀建材的需求不断增加

- 欧洲微塑胶法规加速向低渗透性环氧基道路路面的过渡

- 在美国公共营业单位硬化计画中指定非导电聚合物混凝土垫片

- 预製排水沟在资料中心建置中的普及

- 市场限制

- 防火性能认证差距限制了聚合物混凝土在中层建筑的使用

- 双酚A环氧树脂价格波动正在挤压承包商利润(NA)

- 依赖进口原料延长了新兴国家的前置作业时间

- 价值链分析

- 波特五力模型

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代产品和服务的威胁

- 竞争程度

第五章市场规模及成长预测(价值)

- 按聚合物类型

- 环氧树脂

- 聚酯纤维

- 甲基丙烯酸甲酯

- 乳胶

- 丙烯酸

- 其他(呋喃、苯酚甲醛、丙酮甲醛、尿素)

- 按粘合剂

- 天然树脂

- 合成树脂

- 按用途

- 沥青路面和覆盖层

- 建筑和维护

- 工业储槽

- 预製排水系统

- 其他(户外家具和建筑部件、固体表面檯面和覆盖层)

- 按最终用户产业

- 住宅

- 商业的

- 基础设施

- 产业

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 其他欧洲地区

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争态势

- 市场集中度

- 策略性倡议(併购、合资、合约)

- 市占率分析

- 公司简介

- ACO Ahlmann SE & Co. KG

- ACO FUNKI A/S

- Arizona Polymer Flooring Inc.(ICP Building Solutions Group)

- BASF SE

- Dudick Inc.

- Forte Composites Inc.

- Fosroc International Ltd.

- Hycrete Inc.

- Interplastic Corporation

- Mapei SpA

- Metro Cast Corporation

- QGPC

- Sika AG

- TPP Manufacturing Sdn. Bhd.

- Ulma Architectural Solutions

- Wacker Chemie AG

第七章 市场机会与未来展望

The polymer concrete market size stood at USD 569.02 million in 2025 and is on track to reach USD 778.88 million by 2030, advancing at a 6.48% CAGR.

Growth is anchored in infrastructure hardening programs that prioritize corrosion-proof materials, sustained capital spending on data-center drainage networks, and expanding use of non-conductive pads for utility equipment. Rapid urbanization in Asia Pacific, tighter European sustainability mandates, and progress in bio-based binder technology collectively widen application scope. Strategic acquisitions by leading producers, coupled with performance-driven formulation upgrades, are underpinning steady pricing power and stable margins in most regions.

Global Polymer Concrete Market Trends and Insights

Corrosion-proof Infrastructure Gains Momentum

Regional utilities are replacing steel-reinforced concrete with epoxy-bound alternatives in sewage mains and desalination plants because polymer concrete retains up to 90% of its initial strength after prolonged acid and salt exposure researchgate.net. GCC governments, contending with aggressive chloride environments, now specify polymer concrete for trunk lines and plant vessels. Local contractors such as DAW Construction and Qatar General Projects Company have launched region-specific mixes that resist extreme temperature swings, illustrating how the polymer concrete market leverages location-tailored chemistry for lifespan assurance

Chemical-resistant Materials in Industrial Hubs

Key Highlights

- Chemical processors in coastal China, South Korea, the U.S. Gulf Coast, and Germany are upgrading tank plinths, secondary containment, and loading bays with resin-rich formulations. Demand spiked after operators quantified lifecycle savings from fewer shutdowns and thinner wall sections compared with conventional mixes. Steady capacity expansions in battery chemicals, fertilizers, and specialty resins maintain a baseline flow of projects that feed the polymer concrete market.

Certification Hurdles in Structural Uses

Key Highlights

- Polymer concrete floor and wall panels still lack harmonized fire-rating protocols across major building codes. Developers stay cautious until independent labs publish full-scale test results that demonstrate reliable two-hour ratings, limiting uptake in mid-rise structures where code officials require redundant compliance proofs.

Other drivers and restraints analyzed in the detailed report include:

- European Micro-plastic Regulations Drive Road Overlay Upgrades

- U.S. Grid-hardening Favors Non-conductive Pads

- Extended Lead-times

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Epoxy accounted for 52% of 2024 revenue, the largest share within the polymer concrete market, and is projected to rise at a 7.21% CAGR through 2030. Superior bond strength and resistance to acids underpin this dual leadership. Recent dynamic-loading research confirmed that epoxy mixes sustain higher peak stress under cyclic impact, a feature favored in rail sleepers and bridge paving. Methyl methacrylate grades address rapid-set repairs on airport runways where traffic disruption costs escalate quickly. Acrylate and latex systems occupy small niches for flexible overlays and bonding to aged substrates.

Epoxy's dominance also shapes additive demand patterns, encouraging suppliers of chopped glass fibers and silica flour to optimize particle gradation for resin-rich matrices. Polyester retains relevance in cost-sensitive applications but faces headwinds from compressive-strength limits. As value-chain participants broaden formulation options, the polymer concrete industry benefits from tailored chemistries that serve price-performance trade-offs.

Synthetic resin held an 80% share in 2024, reflecting decades of validated field performance. Pilot studies on natural binders recorded 59.6 MPa compressive strength for gelatin-modified composites, signaling technical feasibility. Government incentives for circular materials are pushing laboratories to evaluate chitosan, lignin and alginate as partial replacements. This research pipeline supports a 7.56% CAGR for natural resin through 2030, the fastest rate in the binding-agent hierarchy.

Producers are mapping their transition strategy by introducing hybrid systems that cap fossil-derived content at 60%. Early adopters in Scandinavia and Japan are purchasing pilot batches for green-certified civic works, creating demand pockets that will ripple through the polymer concrete market in the coming years. Technical documentation continues to focus on resin-aggregate compatibility, rheology control, and long-term weathering performance.

The Polymer Concrete Market Report Segments the Industry by Polymer Type (Epoxy, Polyester, and More), Binding Agent (Natural Resin, Synthetic Resin), Application (Asphalt Pavement, Building and Maintenance, and More), End-User Industry (Residential, Commercial, and More), and Geography (Asia-Pacific, North America, Europe, and More). The Market Forecasts are Provided in Terms of Value (USD Million)

Geography Analysis

Asia Pacific dominated sales with a 41.5% share in 2024, supported by China's Belt and Road corridor upgrades and India's smart-city sewer rehabilitation. Regional research institutes collaborate with domestic producers to tune formulations for tropical humidity and sulfate-rich soils, reinforcing local supply chains. The polymer concrete market size in Asia Pacific is projected to expand at a 7.45% CAGR through 2030, stimulated by expanding wastewater treatment capacity and rapid data-center construction.

North America maintains steady growth as the Infrastructure Investment and Jobs Act funds bridge deck overlays, shoreline protection, and resilient energy assets. Europe's stringent carbon and micro-plastic regulations accelerate the adoption of durable, low-maintenance materials.

The Middle East and Africa record rising demand in desalination plants, district cooling channels, and chemical terminals. South America's activity centers on Brazil's port expansions, biofuel facilities, and mining assets; polymer concrete offers lifecycle savings under acidic and abrasive operating conditions.

- ACO Ahlmann SE & Co. KG

- ACO FUNKI A/S

- Arizona Polymer Flooring Inc. (ICP Building Solutions Group)

- BASF SE

- Dudick Inc.

- Forte Composites Inc.

- Fosroc International Ltd.

- Hycrete Inc.

- Interplastic Corporation

- Mapei S.p.A.

- Metro Cast Corporation

- QGPC

- Sika AG

- TPP Manufacturing Sdn. Bhd.

- Ulma Architectural Solutions

- Wacker Chemie AG

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rapid Adoption of Polymer Concrete for Corrosion-Proof Sewage and Desalination Assets in GCC

- 4.2.2 Increasing Need for Chemical Resistant Construction Material

- 4.2.3 Europe Mandates on Micro-plastics Accelerating Shift to Low-Permeability Epoxy-Based Road Overlays

- 4.2.4 U.S. Utility Hardening Programs Specifying Non-Conductive Polymer Concrete Pads

- 4.2.5 Growth of Prefabricated Polymer Concrete Drainage Channels in Data-Center Construction

- 4.3 Market Restraints

- 4.3.1 Fire-Rating Certification Gaps Limiting Polymer Concrete Use in Mid-Rise Buildings

- 4.3.2 High Volatility in Bisphenol-A Epoxy Pricing Compressing Contractor Margins (NA)

- 4.3.3 Raw-Material Import Dependence Elevates Lead-Times for Emerging economies

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitute Products and Services

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts ( Value)

- 5.1 By Polymer Type

- 5.1.1 Epoxy

- 5.1.2 Polyester

- 5.1.3 Methyl Methacrylate

- 5.1.4 Latex

- 5.1.5 Acrylate

- 5.1.6 Others (Furan, Phenolic-Formaldehyde, Acetone-Formaldehyde, Carbamide)

- 5.2 By Binding Agent

- 5.2.1 Natural Resin

- 5.2.2 Synthetic Resin

- 5.3 By Application

- 5.3.1 Asphalt Pavement and Overlays

- 5.3.2 Building and Maintenance

- 5.3.3 Industrial Tanks

- 5.3.4 Prefabricated Drainage Systems

- 5.3.5 Others (Outdoor Furniture and Architectural Components, Solid-Surface Counters and Overlays)

- 5.4 By End-User Industry

- 5.4.1 Residential

- 5.4.2 Commercial

- 5.4.3 Infrastruture

- 5.4.4 Industrial

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 South Africa

- 5.5.5.3 Rest of Middle East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves (Mergers and Acquisitions, Joint Ventures, Agreements)

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global Level Overview, Market Level Overview, Core Segments, Financials, Strategic Info, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 ACO Ahlmann SE & Co. KG

- 6.4.2 ACO FUNKI A/S

- 6.4.3 Arizona Polymer Flooring Inc. (ICP Building Solutions Group)

- 6.4.4 BASF SE

- 6.4.5 Dudick Inc.

- 6.4.6 Forte Composites Inc.

- 6.4.7 Fosroc International Ltd.

- 6.4.8 Hycrete Inc.

- 6.4.9 Interplastic Corporation

- 6.4.10 Mapei S.p.A.

- 6.4.11 Metro Cast Corporation

- 6.4.12 QGPC

- 6.4.13 Sika AG

- 6.4.14 TPP Manufacturing Sdn. Bhd.

- 6.4.15 Ulma Architectural Solutions

- 6.4.16 Wacker Chemie AG

7 Market Opportunities and Future Outlook

- 7.1 White-Space and Unmet-Need Assessment