|

市场调查报告书

商品编码

1848340

生物安全柜:市场占有率分析、产业趋势、统计数据、成长预测(2025-2030)Biological Safety Cabinet - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

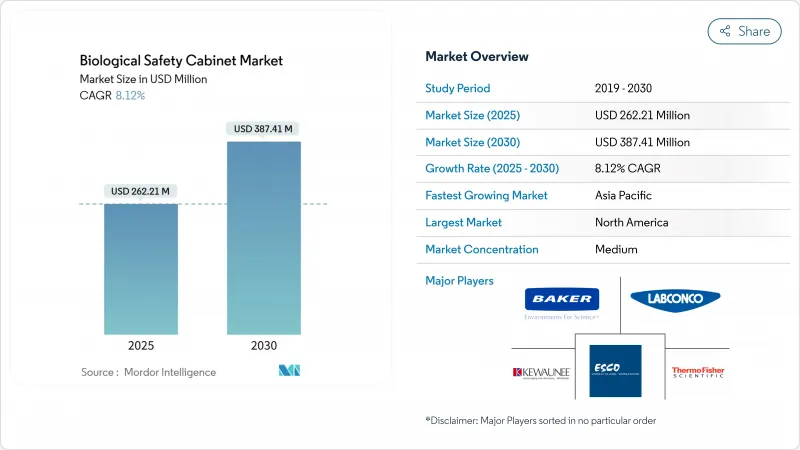

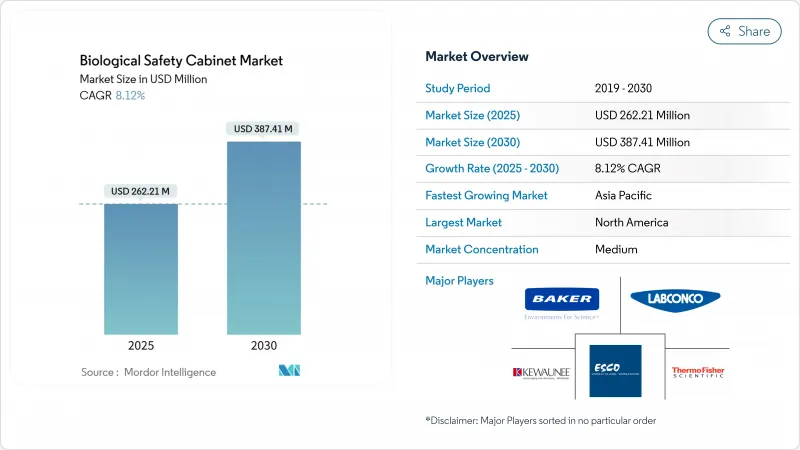

预计2025年生物安全柜市场价值将达到2.6221亿美元,到2030年将达到3.8741亿美元,复合年增长率为8.12%。

这一扩张是由细胞和基因治疗基础设施方面创纪录的资本投资、大规模无菌生产计划以及更先进的密封技术的稳步采用所推动的。诺和诺德公司 41 亿美元的灌装完成园区和赛默飞世尔科技 20 亿美元的美国产能升级等投资公告显示设备需求持续存在。外包的加速推动了合约开发和受託製造厂商(CDMO) 的橱柜采购份额不断增加,而节能无管设计在改造实验室中越来越受欢迎。围绕 ISO 14644-4 和欧盟机械法规的监管趋同正在缩小区域规范差距,并奖励具有全球合规专业知识的供应商。随着医药供应链从中国向印度和东南亚重新平衡,亚太地区预计将在新安装方面超过欧洲。

全球生物安全柜市场趋势与洞察

扩大製药和生物技术研究资金

强大的药物开发平臺正推动大型公司建造需要全新防护装置的研究中心。赛默飞世尔科技公司正在将其在美国四年投资计画中的15亿美元用于实验室基础设施建设,包括生物安全柜。人工智慧驱动的药物研发平台也正在重新配置工作空间,以适应自动化、高通量检测,而这些检测仍需要操作员的保护。因此,生物安全柜市场正从新设备的实验室中获得更多动力。大学正受益于扩大的津贴,用于生物安全升级,从而支撑公共部门的稳定需求。虽然这一趋势在北美最为明显,但西欧也正在进行类似的产能扩张。

加强全球对新兴感染疾病的防范

世界各国政府正优先考虑建造面向2024年及以后的弹性实验室网路。美国疾病管制与预防中心(CDC)的《微生物和生物医学实验室生物安全》(第六版)概述了更严格的气流和过滤器完整性性能标准,从而推动了安全柜的更换週期。美国职业安全与健康管理局(OSHA)即将出台的感染疾病法规将对临床实验室实施类似的要求,从而加速国内订购。研究生物气溶胶威胁的国防计画也依赖高效能空气微粒子过滤器(HEPA)工作站,这显示跨产业的需求。国家快速反应检测基础设施储备现在通常包括生物安全柜,以便在疫情爆发时立即部署。对准备就绪的关注正在维持近期的成长,尤其是在公共卫生实验室规模不断扩大的亚太地区。

资本和认证成本高

如果加上验证、结构修改和GMP文檔,设备总成本通常会比标价高出一倍。由于研究津贴很少涵盖基础设施,学术实验室难以获得升级融资。 ISO 14644-4相关未来认证规则的不确定性导致一些买家推迟了订单。规模较小的生物技术公司正在透过租赁共用实验室空间来降低成本,但这也减缓了设备的直接销售。处理高效化合物的客製化验证会推高成本,尤其对于首次开展CDMO业务的公司而言。

細項分析

II 级手套箱占生物安全柜市场占有率的 61.34%。然而,由于处理高效能原料药 (HPAPI) 和病毒载体的需求不断增长,III 级手套箱的复合年增长率预计将达到 10.45%。 Esco 的无洩漏 III 级系列支援化疗配製和疫苗製剂,确保操作员零暴露。随着 CRISPR 和溶瘤病毒产品线的扩展,III 级生物安全柜的市场规模预计将快速成长。所有级别的製造商都在整合触控萤幕气流分析和自动压力衰减测试,以简化年度重新认证。能源优化仍然是所有等级的设计重点,以满足 ISO主导的生命週期成本要求。

虽然技术差距正在缩小,但一级设备仍属于小众市场,主要服务于需要人员和环境保护的教学实验室,而这些实验室缺乏更高等级设备所提供的产品防护。软体整合现已将使用资料推送至建筑管理系统,使实验室管理人员能够即时验证通风合规性。全球统一的气流速度目标预计将推动生物维修,并维持各类生物安全柜市场的需求。

由于GMP(药品生产品质管理规范)设施的监管偏好,管道式配置将在2024年占到总收入的58.43%。无管道装置仍然至关重要,尤其是在大型生物製药设施中,这些设施必须直接去除有害空气。儘管如此,无管道装置仍以10.73%的复合年增长率增长,因为它们避免了在空间受限的建筑中进行昂贵的暖通空调系统(HVAC)返工。预计在新兴经济体中,无管道生物安全柜的市场规模将加速成长,因为这些地区的实验室维修超过了新建计划。 Better Basics Laborbedarf的SmartIntegrate模组代表了该领域的技术创新,可将工作站效率提高30%,并实现免工具过滤器更换。

随着能源标准推动净零建筑的发展,无管机组的优势在于能够最大限度地减少空调空气的损耗。目前,供应商提供混合模式,允许未来在管道式和循环式之间切换,从而在法规变化的情况下保护客户的资金。儘管有这些优势,高风险的HPAPI(高效原料药)设备仍指定使用硬管排气以确保负压,这意味着两种系统将在生物安全柜市场中共存。

区域分析

到2024年,北美将以42.45%的收入份额引领生物安全柜市场。诺和诺德140万平方英尺的无菌设施和赛默飞世尔科技的多年期资本计划等大型计划凸显了设备市场的持续成长。美国食品药物管理局(FDA)对ISO 14644-4标准的采用以及美国职业安全与健康管理局(OSHA)对感染疾病法规的实施将形成接连不断的合规週期,迫使生物安全柜进行升级。联邦政府对重组医药供应链的奖励也推动了对美国CDMO(合约研发生产组织)的投资,这些CDMO要求采用高度密封的设计。

亚太地区将成为成长最快的地区,到2030年复合年增长率将达到9.56%。美国《生物安全法案》正将外包业务转向印度,印度的CDMO市场规模将从2023年的156.3亿美元成长到2028年的267.3亿美元。颇尔公司在新加坡投资1.5亿美元的过滤工厂,体现了该地区不断发展的生态系统,整合了上游耗材和机柜製造。中国正在进行的製药厂建设和日本的疫苗自给自足计划将进一步推动需求。统一的标准将简化进口流程,并鼓励跨国供应商将最终组装设在更靠近客户的地方。

在严格的法规和绿建筑指令的支持下,欧洲正稳步扩张。机械和生态设计规则正在鼓励实验室采用配备数位护照的节能设备。 Lentiller Biopharma 对缓衝介质复合物和其他生技药品的投资,正在推动高性能安全柜更换的需求。该地区原料药市场的成长将支持现代化 GMP 设施,从而提振生物安全柜市场。到 2050 年实现净零排放的永续性目标,正在推动采购转向无管或低压设计,从而增强供应商之间的技术差异化。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场状况

- 市场概况

- 市场驱动因素

- 扩大製药和生物技术研究支出

- 加强全球对新兴感染疾病的防范

- 严格的职业健康与安全法规

- 加速细胞和基因治疗製造的扩张

- 智慧节能柜技术的应用日益广泛

- 市场限制

- 资本和认证成本高

- 替代封闭隔离系统的出现

- HEPA/ULPA过滤器组件供应链中的漏洞

- 遵守能源效率标准的压力越来越大

- 监管格局

- 波特五力分析

- 新进入者的威胁

- 买方的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争

第五章市场规模及成长预测

- 按类型

- I类

- II 类

- III 类

- 透过排气系统

- 风管类型(硬连接)

- 循环/无管

- 按用途

- 药物发现及临床前研发

- 临床/诊断实验室

- 生物製药製造和灌装

- 按最终用户

- 製药和生物技术公司

- 学术研究机构

- 合约研究/CDMO

- 其他最终用户

- 地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 其他欧洲地区

- 亚太地区

- 中国

- 日本

- 印度

- 澳洲

- 韩国

- 其他亚太地区

- 中东和非洲

- GCC

- 南非

- 其他中东和非洲地区

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 北美洲

第六章 竞争态势

- 市场集中度

- 市占率分析

- 公司简介

- Thermo Fisher Scientific, Inc.

- Esco Micro

- Labconco

- The Baker Company

- NuAire

- Kewaunee Scientific

- Germfree Laboratories

- Air Science

- BIOBASE

- Telstar(Azbil)

- Faster Srl

- Haier Biomedical

- PHCbi(Panasonic Healthcare)

- Erlab

- Bigneat

- Shanghai Boxun

- Heal Force

- Angelantoni Life Science

- AireLab Systems

- Astec Microflow

第七章 市场机会与未来展望

The biological safety cabinets market is valued at USD 262.21 million in 2025 and is forecast to reach USD 387.41 million by 2030, registering an 8.12% CAGR.

This expansion stems from record capital spending on cell and gene therapy infrastructure, large-scale aseptic manufacturing projects, and steady adoption of higher-containment technologies. Investment announcements such as Novo Nordisk's USD 4.1 billion fill-finish campus and Thermo Fisher Scientific's USD 2 billion U.S. capacity upgrade signal sustained equipment demand. Contract development and manufacturing organizations (CDMOs) now capture a growing share of cabinet purchases as outsourcing accelerates, while energy-efficient ductless designs win favor in retrofit laboratories. Regulatory convergence around ISO 14644-4 and the EU Machinery Regulation is eliminating regional specification gaps and rewarding suppliers with global compliance expertise. Asia-Pacific is set to overtake Europe in new installations as pharmaceutical supply chains rebalance away from China toward India and Southeast Asia.

Global Biological Safety Cabinet Market Trends and Insights

Expanding Pharmaceutical and Biotechnology Research Expenditure

Robust drug-development pipelines are prompting large companies to build redundant research hubs that need new containment suites. Thermo Fisher Scientific is allocating USD 1.5 billion of its four-year U.S. investment program to laboratory infrastructure that includes biological safety cabinets. Mergers that add late-stage assets further boost facility retrofits, and AI-enabled discovery platforms are re-configuring workspaces for automated, high-throughput assays that still require operator protection. As a result, the biological safety cabinets market gains additional pull-through from every newly equipped research laboratory. Universities benefit from expanded grant funding that covers biosafety upgrades, supporting steady public-sector demand. The trend is most visible in North America, but similar capacity builds are underway in Western Europe.

Escalating Global Preparedness for Emerging Infectious Diseases

Governments have prioritized resilient laboratory networks since 2024. The CDC's sixth edition of the Biosafety in Microbiological and Biomedical Laboratories outlines tighter performance criteria for airflow and filter integrity, prompting cabinet replacement cycles. OSHA's forthcoming infectious-disease rule will extend similar requirements to clinical laboratories, accelerating domestic orders. Defense programs that study bioaerosol threats also rely on HEPA-filtered workstations, underlining cross-sector demand. National stockpiles of rapid-response testing infrastructure now routinely include biosafety cabinets, ensuring immediate deployment during outbreaks. This focus on readiness sustains short-term growth, particularly in Asia-Pacific where public-health laboratories are scaling up.

High Capital and Certification Costs

Total installed cost often doubles list price once validation, construction modifications, and GMP documentation are added. Academic laboratories struggle to fund upgrades because research grants rarely cover infrastructure. Uncertainty over future certification rules tied to ISO 14644-4 has prompted some buyers to postpone orders. Smaller biotech firms mitigate expense by leasing shared lab space, which delays direct equipment sales. Custom validation for potent-compound handling pushes expenses higher, particularly for first-time CDMOs.

Other drivers and restraints analyzed in the detailed report include:

- Stringent Occupational Health and Safety Regulations

- Accelerating Cell and Gene Therapy Manufacturing Expansion

- Emergence of Alternative Closed Isolator Systems

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Class II units retained 61.34% of the biological safety cabinets market share in 2024 because they meet the majority of routine research and diagnostic needs. However, Class III glove-box designs are on a 10.45% CAGR trajectory thanks to rising HPAPI and viral-vector handling requirements. Esco's leak-tight Class III series supports chemotherapy compounding and vaccine formulation while ensuring zero operator exposure. The biological safety cabinets market size for Class III units is projected to grow rapidly as CRISPR and oncolytic-virus pipelines expand. Across all classes, manufacturers embed touch-screen airflow analytics and automatic pressure-decay tests that simplify annual recertification. Energy-optimization remains a cross-class design focus to satisfy ISO-driven lifecycle cost mandates.

Technological parity is narrowing, yet Class I equipment remains niche, serving teaching labs that require personnel and environmental protection without the product shielding offered by higher classes. Software integrations now push usage data to building-management systems, enabling laboratory managers to demonstrate ventilation compliance in real time. Global harmonization of airflow velocity targets is expected to drive retrofits, sustaining demand for all classes within the biological safety cabinets market.

Ducted configurations captured 58.43% of revenue in 2024 due to regulatory preference in GMP suites. They remain indispensable where direct hazardous-air removal is mandated, especially in large biopharmaceutical campuses. Even so, ductless units are advancing at a 10.73% CAGR because they avoid costly HVAC rework in space-constrained buildings. The biological safety cabinets market size for ductless models will accelerate in emerging economies where laboratory retrofits exceed new-build projects. Better Basics Laborbedarf's SmartIntegrate module boosts workstation efficiency by 30% and allows tool-free filter swaps, illustrating innovation in this segment.

Energy codes pushing toward net-zero buildings give ductless units an advantage by minimizing conditioned-air losses. Suppliers now offer hybrid models that allow future conversion between ducted and recirculating modes, protecting customer capital as regulations evolve. Despite these gains, high-risk HPAPI suites still specify hard-ducted exhaust to guarantee negative pressure, so both systems will coexist in the biological safety cabinets market.

The Biological Safety Cabinet Market Report is Segmented by Type (Class I, Class II, and Class III), Exhaust System (Ducted (Hard-Connected) and Recirculating / Ductless), Application (Drug Discovery & Pre-Clinical R&D, and More), End-User (Academic & Research Institutes, and More), Geography (North America, Europe, Asia-Pacific, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

North America led the biological safety cabinets market at 42.45% revenue share in 2024. Large-scale projects such as Novo Nordisk's 1.4-million-square-foot aseptic facility and Thermo Fisher Scientific's multiyear capital program underscore sustained equipment pull. FDA adoption of ISO 14644-4 plus OSHA's forthcoming infectious-disease rule create back-to-back compliance cycles that compel cabinet upgrades. Federal incentives for reshoring pharmaceutical supply chains also channel investment into U.S. CDMO campuses that specify high-containment designs.

Asia-Pacific is the fastest-growing region at a 9.56% CAGR through 2030. The US Biosecure Act is redirecting outsourcing toward India, where the CDMO market will climb from USD 15.63 billion in 2023 to USD 26.73 billion by 2028. Singapore's USD 150 million Pall Corporation filtration plant demonstrates the region's evolving ecosystem that integrates upstream consumables with cabinet manufacturing. China's ongoing pharmaceutical build-out and Japan's vaccine self-sufficiency plans further elevate demand. Harmonized standards simplify imports, encouraging multinational suppliers to locate final assembly closer to customers.

Europe shows steady expansion anchored by strict regulatory mandates and green-building directives. The Machinery Regulation and Ecodesign rules push laboratories to adopt energy-efficient units with digital passports. Rentschler Biopharma's buffer-media complex and other biologics investments bolster replacement demand for high-performance cabinets. The region's active-pharmaceutical-ingredient market growth supports modern GMP suites, lifting the biological safety cabinets market. Sustainability targets that require net-zero emissions by 2050 are tilting procurement toward ductless or low-pressure designs, reinforcing technology differentiation among suppliers.

- Thermo Fisher Scientific

- Esco Lifesciences

- Labconco

- The Baker Company

- NuAire

- Kewaunee Scientific

- Germfree Laboratories

- Air Science

- BIOBASE

- Telstar (Azbil)

- Faster Srl

- Haier Biomedical

- PHCbi (Panasonic Healthcare)

- Erlab

- Bigneat

- Shanghai Boxun

- Heal Force

- Angelantoni Life Science

- AireLab Systems

- Astec Microflow

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope Of The Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Expanding Pharmaceutical and Biotechnology Research Expenditure

- 4.2.2 Escalating Global Preparedness for Emerging Infectious Diseases

- 4.2.3 Stringent Occupational Health and Safety Regulations

- 4.2.4 Accelerating Cell and Gene Therapy Manufacturing Expansion

- 4.2.5 Rising Adoption of Smart Energy-Efficient Cabinet Technologies

- 4.3 Market Restraints

- 4.3.1 High Capital and Certification Costs

- 4.3.2 Emergence of Alternative Closed Isolator Systems

- 4.3.3 Supply Chain Vulnerabilities In HEPA / ULPA Filtration Components

- 4.3.4 Intensifying Energy Efficiency Compliance Pressure

- 4.4 Regulatory Landscape

- 4.5 Porter's Five Forces Analysis

- 4.5.1 Threat Of New Entrants

- 4.5.2 Bargaining Power Of Buyers

- 4.5.3 Bargaining Power Of Suppliers

- 4.5.4 Threat Of Substitutes

- 4.5.5 Intensity Of Competitive Rivalry

5 Market Size & Growth Forecasts (Value, USD)

- 5.1 By Type

- 5.1.1 Class I

- 5.1.2 Class II

- 5.1.3 Class III

- 5.2 By Exhaust System

- 5.2.1 Ducted (Hard-Connected)

- 5.2.2 Recirculating / Ductless

- 5.3 By Application

- 5.3.1 Drug Discovery & Pre-Clinical R&D

- 5.3.2 Clinical / Diagnostic Testing Labs

- 5.3.3 Biopharmaceutical Manufacturing & Fill-Finish

- 5.4 By End-User

- 5.4.1 Pharmaceutical & Biotechnology Companies

- 5.4.2 Academic & Research Institutes

- 5.4.3 Contract Research / CDMOs

- 5.4.4 Other End Users

- 5.5 Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 Europe

- 5.5.2.1 Germany

- 5.5.2.2 United Kingdom

- 5.5.2.3 France

- 5.5.2.4 Italy

- 5.5.2.5 Spain

- 5.5.2.6 Rest of Europe

- 5.5.3 Asia-Pacific

- 5.5.3.1 China

- 5.5.3.2 Japan

- 5.5.3.3 India

- 5.5.3.4 Australia

- 5.5.3.5 South Korea

- 5.5.3.6 Rest of Asia-Pacific

- 5.5.4 Middle East & Africa

- 5.5.4.1 GCC

- 5.5.4.2 South Africa

- 5.5.4.3 Rest of Middle East & Africa

- 5.5.5 South America

- 5.5.5.1 Brazil

- 5.5.5.2 Argentina

- 5.5.5.3 Rest of South America

- 5.5.1 North America

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Market Share Analysis

- 6.3 Company Profiles (includes Global level Overview, Market level overview, Core Business Segments, Financials, Headcount, Key Information, Market Rank, Market Share, Products and Services, and analysis of Recent Developments)

- 6.3.1 Thermo Fisher Scientific, Inc.

- 6.3.2 Esco Micro

- 6.3.3 Labconco

- 6.3.4 The Baker Company

- 6.3.5 NuAire

- 6.3.6 Kewaunee Scientific

- 6.3.7 Germfree Laboratories

- 6.3.8 Air Science

- 6.3.9 BIOBASE

- 6.3.10 Telstar (Azbil)

- 6.3.11 Faster Srl

- 6.3.12 Haier Biomedical

- 6.3.13 PHCbi (Panasonic Healthcare)

- 6.3.14 Erlab

- 6.3.15 Bigneat

- 6.3.16 Shanghai Boxun

- 6.3.17 Heal Force

- 6.3.18 Angelantoni Life Science

- 6.3.19 AireLab Systems

- 6.3.20 Astec Microflow

7 Market Opportunities & Future Outlook

- 7.1 White-Space & Unmet-Need Assessment