|

市场调查报告书

商品编码

1850297

汽车绿色轮胎市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)Automotive Green Tires - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

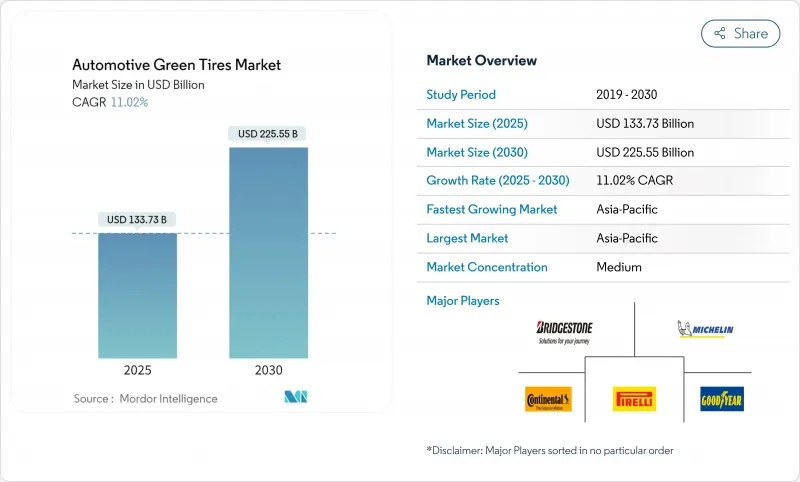

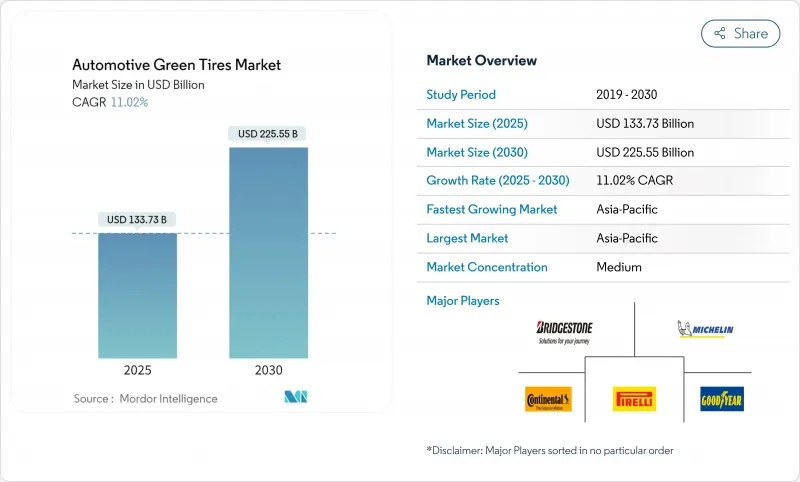

预计到 2025 年,汽车绿色轮胎市场规模将达到 1,337.3 亿美元,到 2030 年将达到 2,255.5 亿美元,年复合成长率为 11.02%。

全球车辆电气化、欧7轮胎颗粒物排放法规以及企业范围3脱碳目标,已使环境绩效成为核心设计指标。东协大规模生产稻壳灰二氧化硅、智慧感测器的快速普及以及政府对生物基聚合物的资助,正在降低生命週期成本并扩大潜在需求。随着主要製造商获得循环经济能力并确保生物橡胶原料供应,企业整合正在加速。供应链对东南亚乳胶的依赖以及轮胎颗粒物全球检测方法尚未统一,仍是关键的执行风险。

全球汽车绿色轮胎市场趋势与洞察

电动车产量激增

全球电动车组装需要能够支援瞬时扭力、低噪音和最小滚动阻力的轮胎。将于2025年12月生效的新版FMVSS 305a法规将轮胎安全与电池电力传动系统的要求一致。通用汽车计划在2025年在美国每年生产100万辆电动车,这将扩大对特种轮胎化合物的需求。美国环保署(EPA)2027-2032年的多项污染物排放标准旨在将轻型车辆的温室气体排放量减少50%,进一步强化了这项转变。这些法规将以电动车为中心的功能融入所有新型乘用车和商用车平台。随着汽车製造商竞相延长续航里程,针对电池效率优化的轮胎已成为采购的优先事项。

更严格的全球二氧化碳排放法规和轮胎标籤法规将大幅改变产品开发。

欧盟7标准将于2028年7月起在全球率先对轮胎磨损产生的颗粒物排放设定上限。永续产品的生态设计法规将在2025年4月前为轮胎添加数位产品护照,以追踪其全生命週期。中国2024年的碳足迹标准将要求轮胎製造商在生产过程中量化排放。美国轮胎工业协会已确定五种潜在的6PPD(六苯并噻唑啉酮)替代品,以满足加州的《更安全消费品法规》。合规性现在将带来切实的品牌优势,奖励那些将环境指标纳入核心设计而非附加标籤的公司。

高昂的初始成本溢价是市场渗透的一大挑战。

美国环保署(EPA)的有害空气污染物法规每年为美国轮胎工厂增加1,330万美元的遵循成本。中国的《2024-2025年节能行动计画》强化了工业排放,并提高了本地生产成本。美国能源部8,800万美元的车辆技术津贴承认,绿色出行仍需补贴以弥补成本差距。高昂的价格给那些优先考虑短期投资回报而非轮胎寿命的购车预算带来了压力。新兴经济体信贷准入的困难进一步减缓了绿色出行的普及。

細項分析

到2024年,乘用车将保持最大份额,达到63.31%,而商用车将以12.48%的复合年增长率新增一条增长通道。智慧感测器组件和低滚动阻力使营运商能够降低燃油成本,抵消价格溢价。美国环保署(EPA)公司平均燃油经济性(CAFE)的提升和车辆电气化指令将进一步扩大这一成长空间。相较之下,消费者的采用将取决于品牌讯息和经销商的影响力。随着商业测试检验了轮胎的耐用性,永续轮胎市场将持续多元化,推动销售扩张,所有类别都将从中受益。随着时间的推移,乘用车的采用将受益于货运业已建立的成本曲线。

商用平台也使轮胎暴露在电力传动系统的高扭力之下,加速了复合材料创新。车队管理人员利用远端资讯处理技术分析轮胎磨损情况,从而增强了对数据驱动型低碳车型的需求。加州和欧盟的政策将商用车排放与采购额度挂钩,进一步推动了永续技术的决策。乘用车市场成长仍然强劲,但面临收入弹性较大的购买行为,导致补贴地区以外的市场转型速度放缓。

售后市场项目正以 9.82% 的复合年增长率成长,逐渐蚕食原始设备製造商 68.45% 的市占率。汽车製造商将轮胎碳排放数据嵌入供应商记分卡,以实现范围 3 目标。通用汽车在 2040 年实现碳中和的承诺指明了方向。大批量合约为轮胎公司提供了可见性,并支持长期研发回报。同时,售后市场管道依赖消费者认知和安装人员推荐,这使得它们成为快速采用的可靠因素。

OEM厂商的成长改变了议价能力,迫使製造商调整策略以适应车辆开发週期和数位化通行证的要求。达到汽车製造商阈值的供应商可以在每次新车发布时获得重复销售和品牌曝光。售后市场需求仍然强劲,尤其是在老旧车辆更换方面,但随着OEM厂商在首次销售时就锁定永续的解决方案,售后市场的成长速度将会放缓。

汽车绿色轮胎市场按车辆类型(乘用车和商用车)、终端用户类型(原厂配套和售后市场)、材料类型(天然橡胶轮胎、合成橡胶轮胎、二氧化硅复合轮胎、生物基聚合物轮胎等)、分销渠道(线下和线上)以及地区进行细分。市场预测以价值(美元)和销售量(单位)为单位。

区域分析

预计到2024年,亚太地区将占据永续轮胎市场49.42%的份额,并在2030年前以9.64%的复合年增长率成长。中国的「十四五」规划旨在将资源生产力提高20%,并将轮胎和橡胶回收列为优先事项。印度正在实施湿地抓地力、滚动阻力和噪音方面的法规,以使国内生产与出口预期保持一致。日本正在资助一条纤维素奈米纤维试点生产线,该生产线可以减少轮胎化合物的全生命週期排放。这些合作政策正在建立区域供应链,降低进口风险,并确保亚太地区继续保持永续轮胎创新中心的地位。

欧洲正透过将环境标准直接写入法律来稳定经济成长,从而为製造商提供对低环境影响化合物的可预测需求。欧7颗粒物排放法规和生态设计数位护照很快就会要求提供轮胎磨损和碳足蹟的检验数据。投资回收炭黑和热解丛集可以帮助企业实现材料循环并获得合规积分。随着许多新兴市场采用欧盟标准,达到这些标准的企业将享有出口优势。

在北美,联邦研究津贴和各州回收激励措施的结合,正在推动永续轮胎市场向循环模式转型。美国能源部对生物丁二烯的资助以及加州的轮胎激励计划,体现了上游创新与下游需求刺激相结合的概念。车队营运商正在评估数据丰富的轮胎,以简化重型车辆遵守更严格的温室气体法规的流程,并鼓励其在远距运输中采用。虽然在南美、中东和非洲的扩张缓慢,但他们正在采用欧盟标籤来保护出口管道。针对跨国公司的原始设备製造商采购指南正在促进永续技术在这些价格敏感地区的传播,逐步将永续轮胎市场拓展到其传统据点之外。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概况

- 市场驱动因素

- 电动车产量快速成长

- 收紧全球二氧化碳排放和轮胎标籤法规

- 从2024年起,替换轮胎的需求将激增。

- 透过整合智慧轮胎感测器降低生命週期成本

- OEM Scope 3 会计推广更环保的材料

- 东协稻壳灰二氧化硅的商业化

- 市场限制

- 与传统轮胎相比,初始成本更高

- 大型商用车辆的承载极限

- 医用手套与生物橡胶原料之间的竞争

- 欧盟颗粒物排放限制延后了新化合物的引入

- 价值链/供应链分析

- 监管格局

- 技术展望

- 波特五力模型

- 新进入者的威胁

- 买方/消费者的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争

第五章 市场规模及成长预测(价值(美元)及销售量(单位))

- 按车辆类型

- 搭乘用车

- 商用车

- 按最终用户

- OEM

- 售后市场

- 依材料类型

- 富含天然橡胶的轮胎

- 富含合成橡胶的轮胎

- 二氧化硅基复合轮胎

- 生物基聚合物轮胎

- 再生材料轮胎

- 按分销管道

- 线下(经销商和零售连锁店)

- 线上(电子商务平台)

- 按地区

- 北美洲

- 美国

- 加拿大

- 北美其他地区

- 南美洲

- 巴西

- 阿根廷

- 其他南美

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 其他欧洲地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 其他亚太地区

- 中东和非洲

- 沙乌地阿拉伯

- 阿拉伯聯合大公国

- 南非

- 埃及

- 其他中东和非洲地区

- 北美洲

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- Michelin Group

- Bridgestone Corporation

- Continental AG

- Goodyear Tire & Rubber Company

- Pirelli & C. SpA

- Yokohama Rubber Co. Ltd.

- Apollo Tyres Ltd.

- Hankook Tire & Technology

- Sumitomo Rubber Industries Ltd.

- Nokian Tyres plc

- Toyo Tire Corporation

- Kumho Tire Co. Inc.

- Giti Tire

- Linglong Tire

- CEAT Ltd.

第七章 市场机会与未来展望

The Automotive Green Tires Market size is valued at USD 133.73 billion in 2025 and is forecast to climb to USD 225.55 billion by 2030, advancing at an 11.02% CAGR.

Electrification of global vehicle fleets, Euro 7 tire particulate limits, and corporate Scope-3 decarbonization targets have turned environmental performance into a core design metric. Scaling of rice-husk-ash silica in ASEAN, rapid smart-sensor deployment, and government funding for bio-based polymers are lowering lifecycle costs and widening addressable demand. Consolidation is accelerating as large manufacturers acquire circular-economy capabilities and secure bio-rubber feedstocks. Supply-chain exposure to Southeast-Asian latex and pending global test-method harmonization for tire particulates remains the principal execution risk.

Global Automotive Green Tires Market Trends and Insights

Surging Electric-Vehicle (EV) Production

Global EV assembly lines require tires that handle instant torque, low noise, and minimal rolling resistance. New FMVSS 305a rules, effective December 2025, align tire safety with battery-electric drivetrains . General Motors plans 1 million EV units of annual North American capacity by 2025, magnifying demand for specialized compounds. Environmental standards for 2027-2032, EPA multi-pollutant standards target a 50% GHG cut in light-duty vehicles, reinforcing the shift. These regulations embed EV-centric performance in every new passenger and commercial platform. As automakers race to extend driving range, tires optimized for battery efficiency become a procurement priority

Stricter global CO2 & Tire-Labelling Regulations Reshape Product Development

Euro 7 introduces the world's first mandatory tire-wear particulate caps beginning July 2028 . The Ecodesign for Sustainable Products Regulation will add digital product passports for tires by April 2025, capturing the end-to-end lifecycle. China's 2024 carbon footprint standard obliges tire producers to quantify emissions across manufacturing stages. The U.S. Tire Manufacturers Association has identified five potential 6PPD alternatives to meet California's Safer Consumer Products rule. Compliance now confers a tangible branding advantage, rewarding firms that embed environmental metrics into core design rather than bolt-on labeling.

High Upfront Cost Premium Challenges Market Penetration

EPA hazardous-air-pollutant rules add USD 13.3 million in annual compliance expense to U.S. tire plants . China's 2024-2025 Energy Conservation action plan tightens industrial emissions, raising local production costs. DOE's USD 88 million Vehicle Technologies grants acknowledge that greener mobility still needs subsidies to close cost gaps. Premium pricing strains fleet budgets that prioritize payback horizons shorter than tire life. Credit access in emerging economies further slows uptake.

Other drivers and restraints analyzed in the detailed report include:

- Booming Replacement-Tire Demand Creates Aftermarket Opportunities

- Smart-Tire Sensor integration Transforms Lifecycle Economics

- Load-Bearing Limits in Heavy Commercial Fleets Constrain Adoption

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Commercial vehicles added a 12.48% CAGR growth lane, even though passenger cars retained the largest share with 63.31% in 2024. Smart-sensor packages and lower rolling resistance allow operators to cut fuel bills, offsetting the price premium. EPA CAFE increments and fleet electrification mandates amplify this calculus. In contrast, consumer uptake depends on brand messaging and dealership influence. As commercial trials validate durability, the sustainable tire market continues diversifying, encouraging volume scaling that benefits all categories. Over time, passenger-vehicle adoption will gain from cost curves established in freight.

Commercial platforms also expose tires to higher torque from electric drivetrains, accelerating compound innovation. Fleet managers use telematics to analyze wear, reinforcing demand for data-ready, low-carbon models. California and the EU policies link commercial-fleet emissions to procurement credits, further tipping decisions toward sustainable technologies. Passenger market growth remains steady but faces income-elastic buying behavior, slowing conversion outside subsidized jurisdictions.

Aftermarket programs are growing at a 9.82% CAGR, slowly eroding the OEM's 68.45% hold. Automakers embed tire carbon data in supplier scorecards to hit Scope-3 targets. GM's carbon-neutral pledge by 2040 exemplifies the direction. Large volume contracts give tire firms forecast clarity, supporting long R&D paybacks. Meanwhile, aftermarket channels rely on consumer awareness and installer recommendations, factors less reliable for rapid penetration.

OEM growth shifts bargaining power, requiring manufacturers to align with vehicle development cycles and digital passport requirements. Suppliers that meet automaker thresholds gain repeat volume and brand exposure on every new model. Aftermarket demand remains sizeable, especially for replacement in aging vehicle parks, but growth moderates as OEM fitments lock in sustainable options at first sale.

The Automotive Green Tires Market is Segmented by Vehicle Type (Passenger Vehicles and Commercial Vehicles), End-User Type (OEM and Aftermarket), Material Type (Natural Rubber-Rich Tires, Synthetic Rubber-Rich Tires, Silica-Based Composite Tires, Bio-Based Polymer Tires, and More), and Distribution Channel (Offline and Online) Geography. The Market Forecasts are Provided in Terms of Value (USD) and Volume (Units).

Geography Analysis

Asia-Pacific held 49.42% of the sustainable tire market share in 2024 and is projected to grow at a 9.64% CAGR through 2030. China's 14th Five-Year Plan seeks a 20% rise in resource productivity and identifies tire-rubber recycling as a priority. India enforces wet-grip, rolling-resistance, and noise limits that align domestic production with export expectations. Japan funds cellulose-nanofiber pilot lines that can cut lifecycle emissions in tire compounds. These coordinated policies build localized supply chains, buffer import risks, and keep Asia-Pacific at the center of sustainable tire innovation.

Europe anchors growth by writing environmental criteria directly into law, giving manufacturers predictable demand for low-impact compounds. Euro 7 particulate caps and the Ecodesign digital passport will soon require verifiable data on tire wear and carbon footprints. Investments in recovered carbon black and pyrolysis clusters help companies close material loops and secure compliance credits. Firms that meet these benchmarks gain export leverage because many emerging markets adopt EU norms.

North America blends federal research grants with state recycling incentives, steering the sustainable tire market toward circular models. DOE funding for bio-butadiene and California's Tire Incentive Program illustrate the mix of upstream innovation and downstream demand pulls. Fleet operators value data-rich tires that simplify compliance with tighter heavy-duty greenhouse-gas standards, lifting uptake on long-haul routes. South America, the Middle East, and Africa expand more slowly yet adopt EU labeling to safeguard export access. Multinational OEM procurement guidelines diffuse sustainable technologies into these price-sensitive regions, gradually lifting the sustainable tire market size beyond its traditional strongholds.

- Michelin Group

- Bridgestone Corporation

- Continental AG

- Goodyear Tire & Rubber Company

- Pirelli & C. SpA

- Yokohama Rubber Co. Ltd.

- Apollo Tyres Ltd.

- Hankook Tire & Technology

- Sumitomo Rubber Industries Ltd.

- Nokian Tyres plc

- Toyo Tire Corporation

- Kumho Tire Co. Inc.

- Giti Tire

- Linglong Tire

- CEAT Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Surging electric-vehicle (EV) production

- 4.2.2 Stricter global CO2 and tire-labelling regulations

- 4.2.3 Booming replacement-tire demand post-2024

- 4.2.4 Smart-tire sensor integration lowers lifecycle cost

- 4.2.5 OEM Scope-3 accounting pushes greener materials

- 4.2.6 ASEAN rice-husk-ash silica commercialisation

- 4.3 Market Restraints

- 4.3.1 High upfront cost premium vs. conventional tires

- 4.3.2 Load-bearing limits in heavy commercial fleets

- 4.3.3 Bio-rubber feedstock competition with medical gloves

- 4.3.4 EU particulate-emission caps delaying new compounds

- 4.4 Value/Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers/Consumers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitute Products

- 4.7.5 Intensity of Competitive Rivalry

5 Market Size & Growth Forecasts (Value (USD) and Volume (Units))

- 5.1 By Vehicle Type

- 5.1.1 Passenger Vehicles

- 5.1.2 Commercial Vehicles

- 5.2 By End-User

- 5.2.1 OEM

- 5.2.2 Aftermarket

- 5.3 By Material Type

- 5.3.1 Natural-Rubber-Rich Tires

- 5.3.2 Synthetic-Rubber-Rich Tires

- 5.3.3 Silica-Based Composite Tires

- 5.3.4 Bio-Based Polymer Tires

- 5.3.5 Recycled-Material Tires

- 5.4 By Distribution Channel

- 5.4.1 Offline (Dealers & Retail Chains)

- 5.4.2 Online (E-commerce Platforms)

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Rest of North America

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Russia

- 5.5.3.7 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 India

- 5.5.4.3 Japan

- 5.5.4.4 South Korea

- 5.5.4.5 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 United Arab Emirates

- 5.5.5.3 South Africa

- 5.5.5.4 Egypt

- 5.5.5.5 Rest of Middle East and Africa

- 5.5.1 North America

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (Includes Global Level Overview, Market Level Overview, Core Segments, Financials as Available, Strategic Information, Market Rank/Share, Products & Services, Recent Developments)

- 6.4.1 Michelin Group

- 6.4.2 Bridgestone Corporation

- 6.4.3 Continental AG

- 6.4.4 Goodyear Tire & Rubber Company

- 6.4.5 Pirelli & C. SpA

- 6.4.6 Yokohama Rubber Co. Ltd.

- 6.4.7 Apollo Tyres Ltd.

- 6.4.8 Hankook Tire & Technology

- 6.4.9 Sumitomo Rubber Industries Ltd.

- 6.4.10 Nokian Tyres plc

- 6.4.11 Toyo Tire Corporation

- 6.4.12 Kumho Tire Co. Inc.

- 6.4.13 Giti Tire

- 6.4.14 Linglong Tire

- 6.4.15 CEAT Ltd.