|

市场调查报告书

商品编码

1850301

三防胶:市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)Conformal Coatings - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

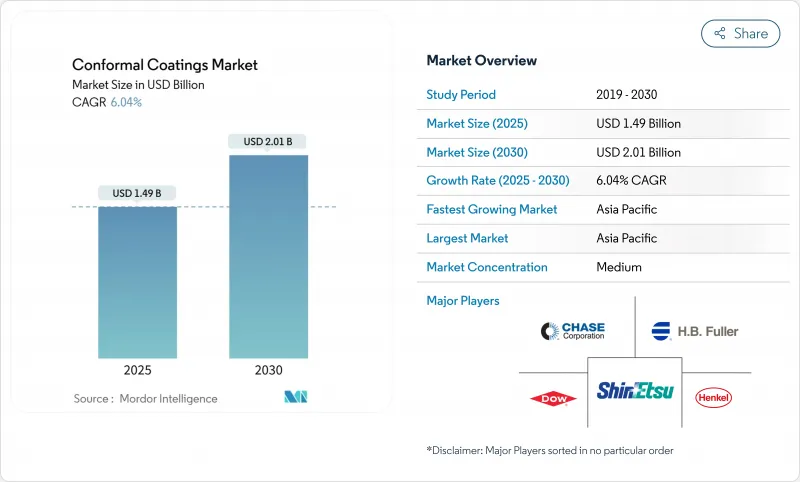

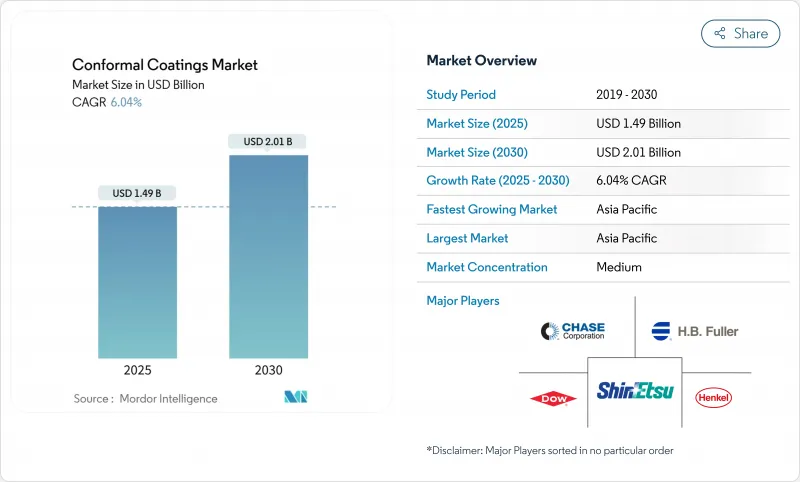

全球三防胶市场预计到 2025 年将达到 14.9 亿美元,到 2030 年将达到 20.1 亿美元,预测期内复合年增长率为 6.04%。

智慧型手机、5G基地台、电动车和卫星有效载荷对电路保护的需求强劲,且需求量不断增长。家用电子电器的微型化,元件间距缩小了30%至40%,推动了对能够阻隔水分、化学物质和离子污染的超薄膜的研究。对挥发性有机化合物(VOC)的更严格监管,促使配方师专注于水性配方和紫外光固化配方,这些配方既能减少排放,又能缩短製程时间。同时,选择性机器人点胶和化学沉淀透过仅涂覆最容易受损的线路和通孔,为设计释放了新的自由度。市场竞争适中,供应商正利用专有化学技术、线上等离子表面处理和本地技术中心来应对电子製造业不断扩大的地域覆盖范围。

全球三防胶市场趋势与洞察

亚洲5G智慧型手机和物联网穿戴装置推动小型电路保护的发展

用于下一代手持设备的高密度基板需要厚度为 5 至 25 微米的保形涂层,同时也要保持讯号完整性。亚洲领先的封装商正在使用等离子体表面活化技术来提高附着力,从而实现对微型 BGA 和堆迭晶粒的可靠涂层。机器人选择系统可将涂层用量减少 25%,并省去遮罩步骤,进而缓解生产瓶颈。这些进步使品牌能够在不增加重量的情况下保护更薄的设备,从而推动该地区三防胶市场的发展势头。

低地球轨道卫星和航空电子设备需要高性能涂层。

卫星群运营商越来越倾向于选择热稳定性涂层,这种涂层能够承受-65 度C至+200 度C的温度升高,并且耐原子氧侵蚀。 MAP Space Coatings 为主要整合商提供超低释气、真空相容的薄膜,以提高机载电子设备的可靠性。日益扩大的环境要求促使北美和欧洲的顶级航空供应商继续坚持使用优质化学材料,从而推动了专业航太三防胶市场的发展。

紫外光固化不透明薄膜返工与检验的复杂性

不透明配方会掩盖焊点,需要使用 X 光或红外线工具进行品管,从而增加资本投入。去除通常依赖于微磨损或化学剥离,但这可能会损坏垫片或导致晶片开裂,从而延长使用寿命。这些限制抑制了紫外线化学在混合晶片製造厂的应用,暂时限制了三防胶的市场渗透,直到透明或可示踪染料的版本得到更广泛的应用。

细分市场分析

到2024年,丙烯酸类三防胶市场总收入的44%,这主要得益于其均衡的防潮性能、易于返工以及具有竞争力的成本优势。预计该细分市场将以6.81%的复合年增长率成长,这主要得益于大批量智慧型手机生产线对快速、不黏手涂层的需求。 Electrolube的HFAC系列产品不含卤素且气味低,深受对空气品质要求严格的汽车和国防工厂的青睐。硅酮涂料在电动车电池组和胺甲酸乙酯等严苛的热负荷环境下越来越受欢迎,而环氧树脂和胺甲酸乙酯则在化学密集型应用和引擎室内应用领域保持着一定的市场份额。新型奈米氟聚合物混合物有望实现小于10微米的疏水性,凸显了轻量化涂料在微型化应用的持续发展趋势。

由于雷达、光达和高功率转换器的应用,三防胶市场规模正在扩大。相较之下,环氧树脂由于其不可逆性(这会增加基板返工的难度),增长速度较为缓慢。胺甲酸乙酯作为一种柔韧且耐化学腐蚀的防护材料,正重新受到青睐,用于驱动系统控制器和农业机械印刷电路基板。总体而言,材料多样化使原始设备製造商 (OEM) 能够根据设备的风险状况选择合适的防护等级,从而巩固了三防胶行业内多材料策略的有效性。

到2024年,溶剂型固化方法将占销售额的55%,但欧盟和加州排放严格的排放法规正在加速向更环保平台的转型。紫外光固化技术成长最快,复合年增长率达7.01%,其优势在于即时黏性和VOC含量≤50 g/L。汉高的无溶剂紫外光固化生产线展现了产业对线上固化的需求,可将占地面积减少一半。水性化学品可实现1-24小时固化,满足那些优先考虑设备简易性的生产线的需求。

由于加工速度快、能耗低、VOC排放量极低,紫外光固化涂料预计将成为成长最快的细分市场,2025年至2030年的复合年增长率将达到7.01%。德国和美国对该技术的采用最为积极,因为节能固化技术符合企业净零排放的承诺。

地理分析

亚太地区将在2024年以42%的市占率引领三防胶市场,并在2030年之前维持7.54%的复合年增长率。中国作为ODM中心以及5G小型基地台的日益普及将使该地区的市场份额保持在高位。印度和越南将透过激励措施吸引新的PCB产能,进而提振涂层需求。例如,Plasmatreat在德国国际电子製造展览会(productronica China)上展示的REDOX-Tool等本地演示,凸显了该地区与製程工程师和供应商的持续合作。

北美仍是严苛环境电子产品的高端市场。太空探勘、先进航空电子设备和植入式医疗设备都需要符合NASA和FDA通讯协定的合格涂层。这种对关键任务可靠性的重视推动了平均售价的上涨和合约量的稳定成长。在更北的地区,各国政府持续资助5G和雷达研究,深化了涂层巨头与国防相关企业的伙伴关係。这些因素共同推动了欧洲大陆三防胶市场的成长动能。

欧洲严格的环境管理体制正在加速向水性及紫外线平台的转型。德国的汽车供应链正在采用紫外线和水基混合化学製程来处理引擎室基板。随着汽车电气化进程的推进,每辆车的基板数量不断增加,预计该地区的三防胶市场规模将稳定成长。在其他地区,南美洲以及中东和非洲仍在发展中,但随着5G宏基地台和太阳能逆变器在需要耐腐蚀电子产品的气候条件下日益增多,这些市场也不断发展。供应商通常会将成套的涂层生产线运送给当地的代工製造商,以缩短Start-Ups时间并确保售后维护收入。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 亚洲5G智慧型手机和物联网穿戴装置推动小型电路保护的发展

- 北美和欧洲的低地球轨道卫星和航空电子设备需要高性能涂层。

- 向符合 RoHS 标准的低 VOC 水/紫外线系统过渡

- 通讯基础设施扩建和5G部署。

- 在航太和国防领域的应用日益广泛

- 市场限制

- 紫外光固化不透明薄膜返工与检验的复杂性

- 硅酮单体价格波动

- 欧盟关于溶剂型挥发性有机化合物的法规降低了对传统产品的需求。

- 用于医疗和航太航太领域的高纯度聚对二甲苯二聚体短缺

- 价值链分析

- 波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章 市场规模与成长预测

- 依材料类型

- 丙烯酸纤维

- 环氧树脂

- 胺甲酸乙酯/聚氨酯

- 硅酮

- 其他化学物质(氟聚合物、奈米涂层)

- 透过技术

- 溶剂型

- 水溶液

- 紫外线固化

- 混合/其他先进系统

- 透过操作方法

- 喷涂(雾化/薄膜)

- 浸涂

- 刷涂

- 其他(选择性/机器人点胶和化学沉淀(CVD))

- 按最终用户行业划分

- 消费性电子产品

- 汽车(内燃机汽车、电动车、先进驾驶辅助系统)

- 航太与国防

- 医疗与生命科学电子

- 其他(工业、电力、能源)

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 亚太其他地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 北欧国家

- 其他欧洲地区

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中东和非洲

- 沙乌地阿拉伯

- 阿拉伯聯合大公国

- 南非

- 奈及利亚

- 其他中东和非洲地区

- 亚太地区

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- 3M

- Actnano Inc.

- Altana AG

- Bostik(Arkema)

- Chase Corporation

- Chemtronics(KEMET)

- CHT UK Ltd

- Dow

- Dymax Corporation

- Electrolube

- Europlasma NV

- HB Fuller Company

- Henkel AG & Co. KGaA

- Illinois Tool Works Inc.

- MG Chemicals

- Nordson Corporation

- Panacol-Elosol GmbH

- PVA

- Shin-Etsu Chemical Co., Ltd.

第七章 市场机会与未来展望

The global conformal coatings market is valued at USD 1.49 billion in 2025 and is set to reach USD 2.01 billion in 2030, reflecting a 6.04% CAGR through the forecast window.

Robust demand for circuit protection across smartphones, 5G base stations, electric vehicles, and satellite payloads keeps volume requirements on an upward trajectory. Miniaturization in consumer electronics continues to shrink component spacing by 30-40%, steering research toward ultra-thin films that still block moisture, chemicals, and ionic contamination. Regulatory curbs on volatile organic compounds are redirecting formulator attention to water-borne and UV-cured options that lower emissions while cutting process time. At the same time, selective robotic dispensing and chemical vapor deposition are unlocking new design freedom by coating only the most vulnerable traces and vias, a capability that reduces material use and rework. Competitive intensity is moderate, and suppliers are leveraging proprietary chemistries, in-line plasma surface preparation, and local technical centers to match the expanding geographic footprint of electronics manufacturing.

Global Conformal Coatings Market Trends and Insights

5G Smartphones and IoT Wearables Driving Miniaturized Circuit Protection in Asia

High-density boards in next-generation handhelds require conformality at 5-25 μm while preserving signal integrity. Leading Asian assemblers rely on plasma surface activation to raise adhesion, enabling reliable coverage on micro-BGAs and stacked dies. Robotic selective systems further trim coating volume by 25% and cut masking steps, easing throughput bottlenecks. Together, these advances let brands protect thinner devices without adding weight, which sustains the conformal coatings market momentum in the region.

LEO Satellites and Avionics Electronics Demanding High-Performance Coatings

Constellation operators increasingly specify thermally stable coatings that withstand -65 °C to +200 °C excursions and resist atomic oxygen. MAP Space Coatings supplies vacuum-compatible films with ultralow outgassing to major integrators, reinforcing reliability of on-board electronics. Extended environmental envelopes keep North American and European tier-one aero suppliers loyal to premium chemistries, lifting the conformal coatings market in specialized aerospace segments.

Rework and Inspection Complexity for UV-Cured Opaque Films

Opaque formulations mask solder joints, mandating X-ray or infrared tools for quality control, which raises capital outlays. Removal often relies on micro-abrasion and chemical stripping that can lift pads or crack chips, extending service cycles. These constraints slow momentum for UV chemistries in high-mix factories, temporarily capping conformal coatings market penetration until transparent or dye-traceable versions proliferate.

Other drivers and restraints analyzed in the detailed report include:

- Regulatory Shift to RoHS-Compliant Low-VOC Water/UV Systems

- Expansion of Telecom Infrastructure and 5G Rollout

- Silicone Monomer Price Volatility

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

The acrylic subset of the conformal coatings market held 44% revenue in 2024, supported by balanced moisture protection, easy rework, and competitive cost profiles. The segment is expected to grow at a 6.81% CAGR, helped by high-volume smartphone lines that favor fast, tack-free times. Electrolube's HFAC series delivers halogen-free performance with low odor, appealing to automotive and defense plants that maintain strict air-quality guidelines. Silicone garners attention for harsh thermal loads in EV packs and avionics, while epoxy and urethane preserve niche roles in chemical-rich and under-hood niches. Emerging nano-fluoropolymer blends promise hydrophobicity at sub-10 μm, underscoring a constant push toward lighter coatings that align with miniaturization.

The conformal coatings market size is growing because of the installation of radar, lidar, and high-power converters that rely on -65 °C to +200 °C resilience. In contrast, epoxies grow at a muted clip because irreversibility complicates board rework. Urethane sees renewed interest as a flexible yet chemical-tough shield for drivetrain controllers and agricultural machinery printed circuit boards. Collectively, material diversification lets OEMs match protection levels to equipment risk profiles, cementing multi-material strategies within the broader conformal coatings industry.

Solvent-borne methods still anchor 55% of 2024 revenue, yet legislation in the EU and California tightens allowable emissions, accelerating migration to greener platforms. UV-cure technology logs the swiftest expansion at 7.01% CAGR, leveraging instant tack and <=50 g/L VOC. Henkel's solvent-free UV line attests to industrial appetite for in-line curing that halves floor space. Water-borne chemistries capture production lines that tolerate 1-24 hour cures and value equipment simplicity. Hybrid UV-moisture systems extend these gains to shadowed areas, preventing uncured pockets under tall components.

UV-cured coatings are emerging as the fastest-growing segment at 7.01% CAGR (2025-2030), driven by their rapid processing times, reduced energy consumption, and minimal VOC emissions. Adoption is most aggressive in Germany and the United States, where energy-efficient curing dovetails with corporate net-zero pledges. The conformal coatings market benefits as regulatory policy dovetails with production efficiency, aligning environmental stewardship and cost reduction.

The Conformal Coatings Market Report Segments the Industry by Material Type (Acrylic, Epoxy, Urethane/Polyurethane, and More), Technology (Solvent-Based, Water-Based, and More), Operation Method (Spray Coating, Dip Coating, Brush Coating, and Others), End-User Industry (Consumer Electronics, Automotive, and More), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa).

Geography Analysis

Asia Pacific led the conformal coatings market with 42% share in 2024 and posts a 7.54% CAGR to 2030. China's ODM hub and increasing penetration of 5G small cells keep regional line utilization high. India and Vietnam lure new PCB capacity through incentive schemes, driving coatings demand upward. Local demonstrations, such as Plasmatreat's REDOX-Tool at productronica China, underscore sustained supplier engagement with the region's process engineers.

North America remains a premium market for harsh-environment electronics. Space exploration, advanced avionics, and implantable medical devices require qualified coatings that meet NASA and FDA protocols. This focus on mission-critical reliability supports higher average selling prices and stable contractual volumes. Further north, governments continue to sponsor 5G and radar research that deepens partnerships between coating giants and defense primes. Together, these elements reinforce the conformal coatings market growth momentum on the continent.

Europe, occupying an environmentally stringent regulatory regime, hastens the shift to water-borne and UV platforms. German automotive supply chains deploy hybrid UV-moisture chemistries for under-hood control boards. The conformal coatings market size in the bloc is forecast to climb steadily as vehicle electrification raises board counts per car. Elsewhere, South America and the Middle East and Africa remain nascent but are evolving as 5G macro towers and photovoltaic inverters multiply in climates that demand corrosion-proof electronics. Suppliers often ship pre-packaged coating lines to local contract manufacturers to shorten start-up time and secure after-sales maintenance revenue.

- 3M

- Actnano Inc.

- Altana AG

- Bostik (Arkema)

- Chase Corporation

- Chemtronics (KEMET)

- CHT UK Ltd

- Dow

- Dymax Corporation

- Electrolube

- Europlasma NV

- H.B. Fuller Company

- Henkel AG & Co. KGaA

- Illinois Tool Works Inc.

- MG Chemicals

- Nordson Corporation

- Panacol-Elosol GmbH

- PVA

- Shin-Etsu Chemical Co., Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 5G Smartphones and IoT Wearables Driving Miniaturized Circuit Protection in Asia

- 4.2.2 LEO Satellites and Avionics Electronics Demanding High-Performance Coatings in North America and Europe

- 4.2.3 Regulatory Shift to RoHS-Compliant Low-VOC Water/UV Systems

- 4.2.4 Expansion of Telecom Infrastructure and 5G Rollout.

- 4.2.5 Increasing Use in Aerospace and Defense Sectors

- 4.3 Market Restraints

- 4.3.1 Rework and Inspection Complexity for UV-Cured Opaque Films

- 4.3.2 Silicone Monomer Price Volatility

- 4.3.3 EU Solvent-Based VOC Caps Shrinking Legacy Product Demand

- 4.3.4 Scarcity of High-Purity Parylene Dimer for Medical/Aerospace

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces Analysis

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Consumers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Material Type

- 5.1.1 Acrylic

- 5.1.2 Epoxy

- 5.1.3 Urethane/Polyurethane

- 5.1.4 Silicone

- 5.1.5 Other Chemistries (Fluoropolymer, Nano-coatings)

- 5.2 By Technology

- 5.2.1 Solvent-Based

- 5.2.2 Water-Based

- 5.2.3 UV-Cured

- 5.2.4 Hybrid/Other Advanced Systems

- 5.3 By Operation Method

- 5.3.1 Spray Coating (Atomised / Film)

- 5.3.2 Dip Coating

- 5.3.3 Brush Coating

- 5.3.4 Others (Selective/Robotic Dispense and Chemical Vapour Deposition (CVD))

- 5.4 By End-user Industry

- 5.4.1 Consumer Electronics

- 5.4.2 Automotive (ICE, EV, ADAS)

- 5.4.3 Aerospace and Defense

- 5.4.4 Medical and Life-Sciences Electronics

- 5.4.5 Others (Industrial, Power and Energy)

- 5.5 By Geography

- 5.5.1 Asia Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 Rest of Asia Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Nordics

- 5.5.3.6 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle-East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 United Arab Emirates

- 5.5.5.3 South Africa

- 5.5.5.4 Nigeria

- 5.5.5.5 Rest of Middle-East and Africa

- 5.5.1 Asia Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles {(includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)}

- 6.4.1 3M

- 6.4.2 Actnano Inc.

- 6.4.3 Altana AG

- 6.4.4 Bostik (Arkema)

- 6.4.5 Chase Corporation

- 6.4.6 Chemtronics (KEMET)

- 6.4.7 CHT UK Ltd

- 6.4.8 Dow

- 6.4.9 Dymax Corporation

- 6.4.10 Electrolube

- 6.4.11 Europlasma NV

- 6.4.12 H.B. Fuller Company

- 6.4.13 Henkel AG & Co. KGaA

- 6.4.14 Illinois Tool Works Inc.

- 6.4.15 MG Chemicals

- 6.4.16 Nordson Corporation

- 6.4.17 Panacol-Elosol GmbH

- 6.4.18 PVA

- 6.4.19 Shin-Etsu Chemical Co., Ltd.

7 Market Opportunities and Future Outlook

- 7.1 White-Space and Unmet-Need Assessment

- 7.2 Increasing Demand from Sensors and Displays