|

市场调查报告书

商品编码

1851102

印度金属加工:市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)India Metal Fabrication - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

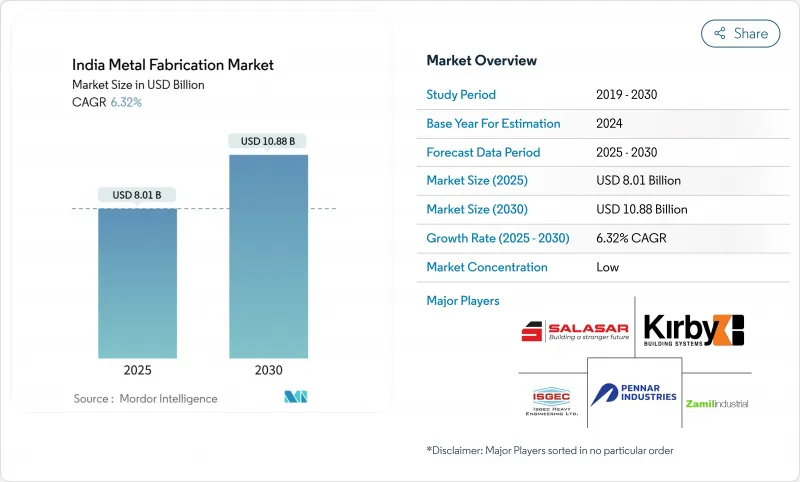

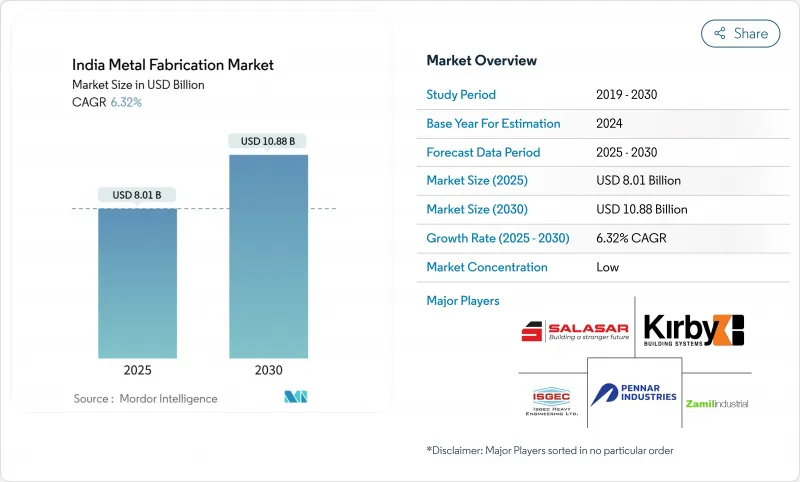

印度金属加工市场预计到 2025 年将达到 80.1 亿美元,到 2030 年将达到 108.8 亿美元,年复合成长率为 6.32%。

在总理加蒂·沙克蒂的领导下,印度金属加工产业将迎来重大发展,基础设施建设将得到大力推进,国防抵消贸易额的增加以及可再生能源设施规模的扩大也将推动产业扩张。机械加工仍然是行业主导服务,但焊接和铝材加工行业正在蓬勃发展,因为航太、数据中心和绿色氢能计划对更轻、更精确的组件提出了更高的要求。南部地区的製造丛集受惠于国防走廊和工业4.0的普及,而西部地区则持续吸引大部分大型钢铁和物流投资。印度的金属加工市场仍然青睐那些能够为资料中心和预製建筑提供模组化解决方案,同时又能规避焦煤价格波动风险并遵守日益严格的环境标准的一体化企业。

印度金属加工市场趋势与洞察

对可再生能源设备製造的需求快速成长

到2026年,国内太阳能组件产能将达到110吉瓦,从而确保安装框架、追踪器和逆变器外壳等精密加工零件的稳定供应。受可再生能源广泛应用的推动,2024年钢铁需求将成长7.7%。国家绿色氢能计画已累计146.6亿印度卢比(约1.7663亿美元)用于绿色氢能一体化,并已启动电解槽框架和压力容器的前置作业时间。风力发电机製造商目前已在地采购,并正在国内生产塔筒和机舱,出口到美国。这些项目将为印度金属加工市场提供未来数年的供应量,因为计划开发商优先考虑缩短交货週期和提高在地采购率。

政府的「Gati Shakti」基础设施管道将加速钢铁加工

此总体规划协调了200多个计划,满足了桥面、车站屋顶和公共电气化龙门架等建设需求。 12个新的工业节点,投资额达2860.2亿印度卢比(约34.5亿美元),预计为物流园区和公用设施走廊带来重型和轻型製造配套订单。预计到2047年,钢铁产能将成长三倍,达到5亿吨,这将增加对钢板切割、轧延和截面焊接的需求。德里-孟买工业走廊的开发已经吸引了塔塔电子等主要租户,并扩大了下游加工合约。

焦煤进口成本波动推高了投入价格。

2025财年上半年,印度炼焦煤进口量达到六年来的最高点2,960万吨,其中俄罗斯进口量年增200%,原因是钢厂寻求折扣。儘管澳洲的进口份额从2022财年的80%下降至54%,但对海底煤的依赖仍占总需求的85%以上。虽然政府正在探索联合采购和利用蒙古走廊来降低价格波动,但短期内钢板价格仍然脆弱。热轧捲板价格上涨可能会使加工商的毛利率下降80-120个基点,迫使他们将成本转嫁给EPC客户或推迟小额订单。因此,儘管印度金属加工市场面临暂时的压力,但从长远来看,发展国产焦炭将使其受益。

细分市场分析

2024年,机械加工将占印度金属加工市场份额的33.4%,这主要得益于航太、汽车和国防领域的多轴数控加工中心。采用人工智慧CAM软体(例如Hurco的ChatCNC)可缩短编程时间、提高主轴运转率,并加快出口召回的反应速度。自动化升级缓解了技术纯熟劳工短缺的问题,并实现了高价值组件的单件生产。

儘管焊接规模较小,但由于高层建筑、风力塔和液化天然气模组等项目对专业化、无损检测接头的需求,其复合年增长率(CAGR)仍高达7.01%,成为成长最快的产业。一体化企业采用机器人MIG焊接生产线和即时熔池分析技术,以满足品质法规要求和紧迫的计划工期。切割服务采用光纤雷射系统,能够以3米/分钟的速度切割25毫米厚的碳钢;成型单元则使用伺服弯折压床来弯曲先进的高强度钢。冲压、冲孔和精加工流程也正在升级,采用线上集尘机和水性喷漆室,以满足环保标准。 SAMARTH Udyog Bharat 4.0计划透过位于浦那和班加罗尔的体验中心为这些升级提供支持,并将新订单引导至印度金属加工市场中具备技术能力的研讨会。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 对可再生能源设备製造的需求快速成长

- 政府的「Gati Shakti」基础设施管道将加速钢铁加工

- 国防补偿和「印度製造」计画促进了精密加工的发展。

- 快速建造资料中心需要重型结构模组

- 二、三线城市采用预製建筑

- 市场限制

- 焦煤进口成本波动推高了投入价格。

- 中小微型企业製造商长期面临电力供应瓶颈问题

- 分散的供应链限制了出口级品质保证

- 环境(EPR 和碳)成本负担

- 价值/供应链分析

- 政府法规和重大倡议

- 技术展望

- 产业吸引力—五力分析

- 新进入者的威胁

- 买方的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争

- 近期全球动盪对印度金属加工市场的影响

第五章 市场规模与成长预测

- 按服务类型

- 切割

- 成型/弯曲

- 焊接

- 加工

- 冲压/冲压

- 表面处理/精加工

- 其他(组装等)

- 材料

- 碳钢

- 不銹钢和合金钢

- 铝

- 其他(铜、黄铜、特殊合金、金属薄板(冷轧钢板、镀锌钢板、热轧钢板))

- 按最终用户行业划分

- 建筑和基础设施

- 汽车及汽车零件

- 铁路和地铁

- 电力/公共产业

- 航太/国防

- 石油、天然气和炼油厂

- 海洋/造船

- 製造业(重型机械和耐用消费品)

- 其他(加工车间、农业设备、电器、耐用消费品等)

- 按地区

- 印度西部(马哈拉斯特拉邦、古吉拉突邦、果阿邦)

- 南印度(泰米尔纳德邦、卡纳塔克邦、特伦甘纳邦、安得拉邦、喀拉拉邦)

- 印度北部(德里 NCR、哈里亚纳邦、旁遮普邦、北方邦、北阿坎德邦、喜马偕尔邦、拉贾斯坦邦)

- 印度东部(西孟加拉邦、贾坎德邦、奥里萨邦、比哈尔邦)

- 印度中部(中央邦、恰蒂斯加尔邦)

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- Larsen & Toubro Ltd

- Kirby Building Systems India

- Zamil Industrial Investment Co.

- ISGEC Heavy Engineering Ltd

- Pennar Industries Ltd

- Salasar Techno Engineering Ltd

- JSW Severfield Structures Ltd

- Godrej Process Equipment

- Diamond Engineering(India)Pvt Ltd

- TEMA India Ltd

- Novatech Projects(India)Pvt Ltd

- Karamtara Engineering Pvt Ltd

- Bharat Heavy Electricals Ltd(Fabrication Div.)

- Tata Projects Ltd

- Welspun Corp Ltd

- Hindustan Dorr-Oliver Ltd

- Jindal Stainless-Fabrication Unit

- Bharat Forge Ltd(Fabrication Business)

- Essar Heavy Engineering Services

- Techno-Fab Engineering Ltd*

第七章 市场机会与未来展望

The India Metal Fabrication Market size stands at USD 8.01 billion in 2025 and is forecast to reach USD 10.88 billion by 2030 while advancing at a 6.32% CAGR.

Expansion is guided by large-scale infrastructure roll-outs under PM Gati Shakti, rising defense offsets, and the scale-up of renewable-energy equipment. Machining remains the dominant service, yet welding and aluminum processing are the fastest climbers as aerospace, data-center, and green-hydrogen projects demand lighter, high-precision assemblies. Southern fabrication clusters benefit from defense corridors and Industry 4.0 adoption, whereas Western hubs still attract the bulk of mega-steel and logistics investments. The India metal fabrication market continues to favor integrated players that can hedge volatile coking coal costs and comply with tightening environmental norms while supplying modular solutions for data centers and pre-engineered buildings.

India Metal Fabrication Market Trends and Insights

Surge in Renewable-Energy Equipment Manufacturing Demand

Domestic solar module capacity is set to hit 110 GW by 2026, ensuring a steady pipeline of mounting structures, trackers, and inverter housings that require precision fabrication. Steel demand increased 7.7% in 2024 on the back of renewable roll-outs. The National Green Hydrogen Mission earmarks INR 14.66 billion(USD 176.63 million) for green hydrogen integration, opening contracts for electrolyzer frames and pressure vessels. Wind turbine manufacturers, who already source 70-80% of components locally, keep tower and nacelle fabrication work onshore for export shipments to the United States. Collectively, these programs channel multi-year volumes to the India metal fabrication market as project developers prioritise short lead times and local content.

Government "Gati Shakti" Infrastructure Pipeline Accelerating Steel Fabrication

The master plan synchronises 200-plus projects, driving the need for bridge decks, station roofs, and overhead electrification gantries. Twelve new industrial nodes, cleared with INR 28,602 crore(USD 3.45 billion), promise ancillary orders for heavy and light fabrications across logistics parks and utility corridors. Steelmaking capacity is planned to triple to 500 million tonnes by 2047, ushering in incremental demand for plate cutting, rolling, and section welding. Progress on the Delhi-Mumbai Industrial Corridor has already secured anchor tenants such as Tata Electronics, broadening downstream fabrication contracts.

Volatile Coking-Coal Import Costs Inflating Input Prices

Coking-coal imports hit a six-year peak of 29.6 million tonnes in H1 FY25, and Russian cargoes surged 200% year-on-year as mills hunted discounts. Australian share slipped to 54% from 80% in FY 2022, yet reliance on seaborne coal still tops 85% of total demand. The government is exploring consortium-scale buying and Mongolian corridors to tame volatility, but near-term plate prices remain susceptible. Fabricators' gross margins drop by 80-120 basis points when hot-rolled coil prices spike, forcing them to pass costs to EPC clients or defer smaller orders. The India metal fabrication market thus faces temporary pressures yet benefits long-term from eventual domestic coke development.

Other drivers and restraints analyzed in the detailed report include:

- Defense Offsets & "Make in India" Stimulating Precision Fabrication

- Rapid Data-Center Build-outs Requiring Heavy Structural Modules

- Chronic Power-Supply Bottlenecks for MSME Fabricators

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Machining accounted for 33.4% of India metal fabrication market share in 2024, supplied by a network of multi-axis CNC shops that serve aerospace, automotive, and defense contracts. Adoption of AI-enabled CAM software, typified by Hurco's ChatCNC, cuts programming time and improves spindle utilization, letting shops respond quickly to export call-offs. Automation upgrades soften the skilled-labour deficit and allow lot-size-one production for high-value assemblies.

Welding, although smaller, registers the fastest 7.01% CAGR as high-rise infrastructure, wind towers, and LNG modules need specialized non-destructive-tested joints. Integrated players embed robotic MIG lines and real-time weld-pool analytics to meet both quality codes and compressed project schedules. Cutting services benefit from fiber-laser systems that slice 25 mm carbon steel at 3 m/min, while forming cells use servo-press brakes to bend advanced-high-strength steel. Punching, stamping, and finishing segments upgrade to inline dust-collection and water-borne paint booths to align with environmental norms. The SAMARTH Udyog Bharat 4.0 program backs these upgrades through experiential centres in Pune and Bengaluru, steering fresh orders to tech-ready workshops within the India metal fabrication market.

The India Metal Fabrication Market is Segmented by Service Type (Cutting, and Others), by Material (Carbon Steel, and Others), by End-User Industry (Construction & Infrastructure, and Others), and by Region (Western India, Southern India, Northern India, Eastern India, and Central India). The Market Forecasts are Provided in Terms of Value (USD).

List of Companies Covered in this Report:

- Larsen & Toubro Ltd

- Kirby Building Systems India

- Zamil Industrial Investment Co.

- ISGEC Heavy Engineering Ltd

- Pennar Industries Ltd

- Salasar Techno Engineering Ltd

- JSW Severfield Structures Ltd

- Godrej Process Equipment

- Diamond Engineering (India) Pvt Ltd

- TEMA India Ltd

- Novatech Projects (India) Pvt Ltd

- Karamtara Engineering Pvt Ltd

- Bharat Heavy Electricals Ltd (Fabrication Div.)

- Tata Projects Ltd

- Welspun Corp Ltd

- Hindustan Dorr-Oliver Ltd

- Jindal Stainless - Fabrication Unit

- Bharat Forge Ltd (Fabrication Business)

- Essar Heavy Engineering Services

- Techno-Fab Engineering Ltd*

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Surge in Renewable-Energy Equipment Manufacturing Demand

- 4.2.2 Government "Gati Shakti" Infrastructure Pipeline Accelerating Steel Fabrication

- 4.2.3 Defence Offsets & "Make in India" Stimulating Precision Fabrication

- 4.2.4 Rapid Data-Center Build-outs Requiring Heavy Structural Modules

- 4.2.5 Adoption of Pre-Engineered Buildings in Tier-2 & 3 Cities

- 4.3 Market Restraints

- 4.3.1 Volatile Coking-Coal Import Costs Inflating Input Prices

- 4.3.2 Chronic Power-Supply Bottlenecks for MSME Fabricators

- 4.3.3 Fragmented Supply Chain Limits Export-Grade Quality Assurance

- 4.3.4 Environmental-Compliance (EPR & Carbon) Cost Burden

- 4.4 Value / Supply-Chain Analysis

- 4.5 Government Regulations & Key Initiatives

- 4.6 Technological Outlook

- 4.7 Industry Attractiveness - Porter's Five Forces

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Impact of Recent Global Disruptions on the India Metal Fabrication Market

5 Market Size & Growth Forecasts (Value, In USD Billion)

- 5.1 By Service Type

- 5.1.1 Cutting

- 5.1.2 Forming / Bending

- 5.1.3 Welding

- 5.1.4 Machining

- 5.1.5 Punching / Stamping

- 5.1.6 Finishing / Surface Treatment

- 5.1.7 Others (Assembling, etc.)

- 5.2 By Material

- 5.2.1 Carbon Steel

- 5.2.2 Stainless & Alloy Steel

- 5.2.3 Aluminium

- 5.2.4 Others (Copper, Brass, Specialty Alloys, Sheet Metal (CRCA, GI, HR))

- 5.3 By End-User Industry

- 5.3.1 Construction & Infrastructure

- 5.3.2 Automotive & Auto Components

- 5.3.3 Railways & Metro

- 5.3.4 Power & Utilities

- 5.3.5 Aerospace & Defence

- 5.3.6 Oil, Gas & Refinery

- 5.3.7 Marine and Shipbuilding

- 5.3.8 Manufacturing (Heavy Machinery & Consumer Durables)

- 5.3.9 Others (Job shops, Agricultural Equipment, Electricals, Consumer Durables, etc.)

- 5.4 By Region

- 5.4.1 Western India (Maharashtra, Gujarat, and Goa)

- 5.4.2 Southern India (Tamil Nadu, Karnataka, Telangana, Andhra Pradesh, and Kerala)

- 5.4.3 Northern India (Delhi NCR, Haryana, Punjab, Uttar Pradesh, Uttarakhand, Himachal Pradesh, and Rajasthan)

- 5.4.4 Eastern India (West Bengal, Jharkhand, Odisha, and Bihar)

- 5.4.5 Central India (Madhya Pradesh and Chhattisgarh)

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global Level Overview, Market Level Overview, Core Segments, Financials as Available, Strategic Information, Products & Services, and Recent Developments)

- 6.4.1 Larsen & Toubro Ltd

- 6.4.2 Kirby Building Systems India

- 6.4.3 Zamil Industrial Investment Co.

- 6.4.4 ISGEC Heavy Engineering Ltd

- 6.4.5 Pennar Industries Ltd

- 6.4.6 Salasar Techno Engineering Ltd

- 6.4.7 JSW Severfield Structures Ltd

- 6.4.8 Godrej Process Equipment

- 6.4.9 Diamond Engineering (India) Pvt Ltd

- 6.4.10 TEMA India Ltd

- 6.4.11 Novatech Projects (India) Pvt Ltd

- 6.4.12 Karamtara Engineering Pvt Ltd

- 6.4.13 Bharat Heavy Electricals Ltd (Fabrication Div.)

- 6.4.14 Tata Projects Ltd

- 6.4.15 Welspun Corp Ltd

- 6.4.16 Hindustan Dorr-Oliver Ltd

- 6.4.17 Jindal Stainless - Fabrication Unit

- 6.4.18 Bharat Forge Ltd (Fabrication Business)

- 6.4.19 Essar Heavy Engineering Services

- 6.4.20 Techno-Fab Engineering Ltd*

7 Market Opportunities & Future Outlook

- 7.1 White-space & Unmet-Need Assessment