|

市场调查报告书

商品编码

1851146

无尘室照明:市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)Cleanroom Lighting - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

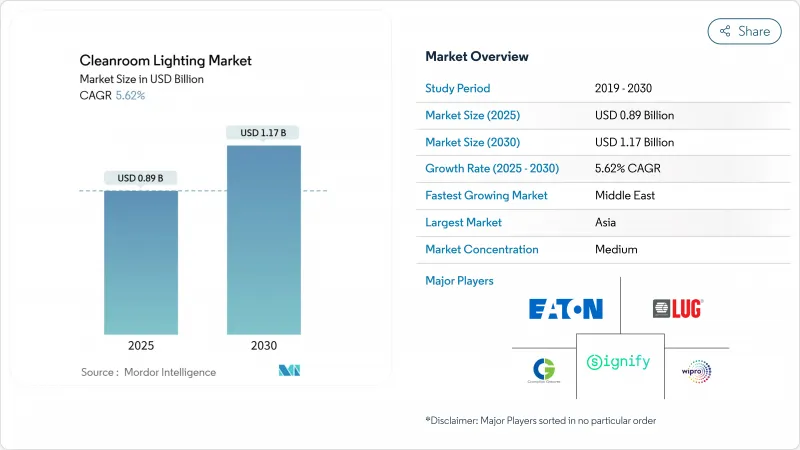

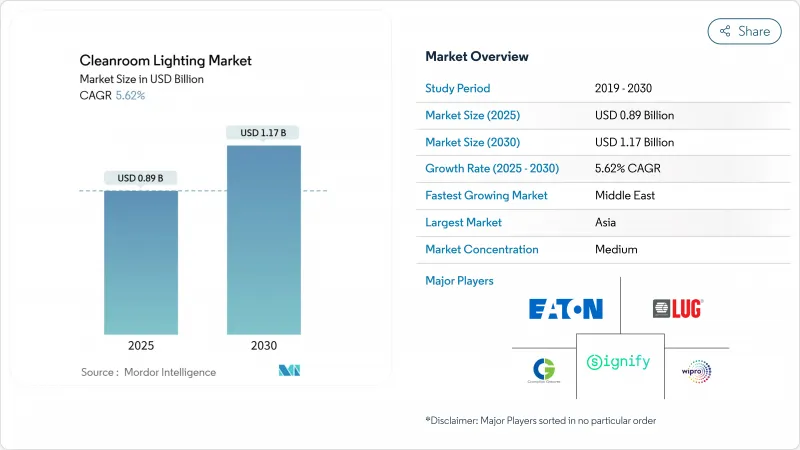

预计无尘室照明市场规模将在 2025 年达到 8.9 亿美元,在 2030 年达到 11.7 亿美元,年复合成长率为 5.62%。

半导体製造厂、生物製药车间和先进实验室日益严格的污染控制要求支撑了当前的市场需求,而欧盟生态设计法规和北美萤光禁令推动的LED维修则进一步巩固了未来五年的市场前景。儘管半导体製造商仍然是最大的买家,生技药品和细胞治疗运营商正在缩小与半导体製造商的差距,因为他们正在为精细的细胞培养采用无闪烁、密封的灯具。整合UV-C的LED灯具在医院和製药隔离器的应用也日益普及,这反映了后疫情时代感染控制的重要性。在供应方面,成熟照明品牌之间的垂直整合有助于抵消原材料的波动性和认证成本,同时,一些专注于危险场所和远UV-C领域的专业公司也正在出现。

全球无尘室照明市场趋势与洞察

欧洲製药厂面临越来越大的GMP和ISO 14644合规压力

欧盟GMP附件1修订后的要求,收紧了无菌製药生产实验室的颗粒物排放法规,迫使操作人员用IP65防护等级的LED面板灯取代传统的萤光,以最大限度地减少颗粒物脱落并能耐受强效消毒剂。契约製造、疫苗生产商和新兴基因治疗公司都在经历设备更新换代,以确保在欧盟市场进入。

东亚地区300毫米晶圆厂扩建需要ISO 1级照明灯具

台湾、日本和中国当地对极紫外光微影术线的创纪录投资,推动了对配备超低损耗光刻(ULPA)滤光片、可在ISO 1级环境下运行的EUV兼容灯具的需求。南亚耗资96亿美元的双层工厂便是此类计划的典型代表,其照明方案在早期就已确定,以满足严格的频谱和天花板标准。

铝和聚碳酸酯价格波动

低挥发性铝合金和无尘室级聚碳酸酯等大宗商品价格的快速波动推高了材料成本,并给固定价格计划合约带来了压力。供应商数量有限加剧了成本敏感性,迫使垂直整合的照明品牌提前采购原材料并重新设计外壳。

细分市场分析

到2024年,LED将占总收入的80.4%,显着超越萤光和无电极LED技术。目前规模较小的紫外线(UV)细分市场预计将成长8.7%,这主要得益于远紫外线(远UVC)和杀菌LED将照明和消毒功能相结合。能源效率需求、即时调光功能和卓越的色彩稳定性都促使LED成为市场首选,而智慧感测器封装则为ISO级空间中的预测性维护提供了可能。

第二代LED灯具在密封的石英窗口后方整合了222nm波长的发送器,无需通风即可持续消毒。这种双重功能既提高了灯具的平均售价,也减少了天花板龙骨的拥挤程度。由于欧盟生态设计禁令将于2025年生效,萤光正逐步被淘汰,仅用于改装设备。随着高阶UV-C产品的普及,预计到2030年,基于LED的无尘室照明市场规模将超过10亿美元。

到2024年,面板式和储油式照明灯具将占总销售额的45.1%,其中嵌入式安装方式更受欢迎,因为它可以最大限度地减少层架和颗粒物滞留。采用快速拆卸齿轮托盘的模组化面板系统可以缩短检验週期并简化垫圈更换,从而满足精益设施管理的目标。

目前,危险场所照明灯具的市占率仅占个位数,但正以6.5%的复合年增长率快速成长。製药溶剂室和锂电池生产线均指定使用符合ATEX、IECEx和NEC认证的1区/1类LED灯具。认证产品的供应紧张推高了现有供应商的利润率,同时也提升了提供防爆灯具的供应商在无尘室照明市场的份额。

区域分析

亚太地区仍将是最大的市场,预计到2024年将占全球收入的27.8%,这主要得益于台湾、日本、韩国和中国沿海地区半导体产业的集中。台积电在熊本的合资项目以及南亚新北市的巨型晶圆厂等计划,确保了未来多年的照明封装产品供应。太阳能製造商也将ISO 7电池标准应用于异质结太阳能组件,扩大了对可再生能源供应链的需求。印度正在崛起为一个分散且价格敏感的细分市场,与当地原始设备製造商(OEM)的合作有望加速该技术的普及。

到2030年,中东地区将以6.7%的复合年增长率引领成长,这主要得益于医疗私有化和疫苗自给自足计划推动了大型医院和製药企业的蓬勃发展。利雅德和阿布达比部署远紫外线消毒设备,印证了该地区有能力为高端感染控制解决方案提供资金。沙乌地阿拉伯一家生物製药厂的溶剂处理相关危险场所订单进一步提振了该地区的收入,但认证产品的短缺可能会延误计划进度。

北美受益于强劲的生技药品研发管线以及《晶片与科学法案》推动的晶圆厂建设復苏。FUJIFILM在北卡罗来纳州的扩建项目体现了新建生物製造园区对高规格照明的需求。合格电工的短缺构成短期瓶颈,但模组化面板系统安装时间仅为传统安装方式的一半,有效缓解了工期风险。受生态设计法规的推动,欧洲掀起了一波改装,该法规规定将于2025年逐步淘汰T8萤光。即便宏观经济的不确定性抑制了待开发区案的支出,这些改造项目仍能带来稳定的收入。北欧国家、德国和法国在合规方面仍处于领先地位,要求ISO和GMP可追溯性,并优先考虑已获得认证的成熟拥有者。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 欧洲製药公司面临越来越大的压力,需要遵守GMP和ISO 14644标准。

- 东亚地区300毫米半导体工厂扩建需要ISO 1级照明灯具

- 北美生技药品和细胞治疗设施的成长对无闪烁密封LED的需求日益增长

- 波湾合作理事会成员国医院中用于感染控制的UV-C整合照明装置的普及情况

- 欧盟生态设计-2023和强制改装加速了以LED灯具取代传统萤光具的进程。

- 南美洲一条高速食品饮料包装生产线需要IP65+防碎照明设备。

- 市场限制

- 铝和聚碳酸酯价格波动影响照明灯具物料清单

- ATEX/IECEx认证照明设备短缺导致中东製药计划延误

- ISO 3级环境下高流明LED的温度控管极限

- 非洲封闭式电网照明灯具熟练安装人员短缺

- 生态系分析

- 技术展望

- 波特五力分析

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争

第五章 市场规模与成长预测数据

- 透过光源

- LED

- 萤光

- 就职

- 紫外线

- 按固定装置设计/外形规格

- 控制板

- 环绕式/条状

- 下照灯

- 危险场所设备

- 按安装类型

- 凹

- 表面

- 吊坠/吊挂

- 按最终用户行业划分

- 半导体和电子学

- 医疗保健和生命科学

- 食品和饮料加工

- 研究和学术实验室

- 航太/国防

- 汽车涂料和电池製造

- 其他行业

- 按销售管道

- 直接 OEM

- 系统整合商

- 经销商

- 按地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 北欧国家

- 其他欧洲地区

- 南美洲

- 巴西

- 其他南美洲

- 亚太地区

- 中国

- 日本

- 印度

- 东南亚

- 亚太其他地区

- 中东和非洲

- 中东

- GCC

- 土耳其

- 其他中东地区

- 非洲

- 南非

- 其他非洲地区

- 北美洲

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- Signify Holding

- Cooper Lighting Solutions

- Wipro Lighting

- Eaton Lighting

- LUG Light Factory

- Terra Universal

- Solite Europe

- Paramount Industries

- Kenall Manufacturing

- AB Fagerhult

- Waldmann Lighting

- Glamox AS

- Hubbell Lighting

- Cree Lighting

- Philips Cleanroom Lighting

- HE Williams Inc.

- Clean Air Lighting LLC

- Admiral Lighting

- Boyd Cleanroom Lighting

- Hefei Kejia Purification

- Shenzhen Sansi Lighting

- Beghelli SpA

第七章 市场机会与未来展望

The cleanroom lighting market size stood at USD 0.89 billion in 2025 and is forecast to reach USD 1.17 billion by 2030, advancing at a 5.62% CAGR.

Heightened contamination-control requirements in semiconductor fabs, biopharmaceutical suites, and advanced research labs anchor current demand, while aggressive LED retrofits driven by EU EcoDesign rules and North American fluorescent bans reinforce the five-year outlook. Semiconductor manufacturers remain the single largest buyers, yet biologics and cell-therapy operators are closing the gap as they standardize flicker-free, sealed luminaires for sensitive cell cultures. Uptake of UV-C-integrated LED fixtures is gaining momentum in hospitals and pharmaceutical isolators, reflecting post-pandemic infection-control priorities. On the supply side, vertical integration among established lighting brands is helping offset raw-material volatility and certification costs, whereas niche specialists are finding headroom in hazardous-location and Far-UVC segments.

Global Cleanroom Lighting Market Trends and Insights

Increasing GMP and ISO 14644 compliance pressure on European pharma plants

Revised EU GMP Annex 1 requirements tighten particulate limits across sterile drug-manufacturing suites, forcing operators to swap legacy fluorescents for sealed IP65 LED panels that minimize shedding and withstand aggressive sanitizing agents. Contract manufacturers, vaccine producers, and emerging gene-therapy firms are all advancing replacement cycles to safeguard market access in the European Union.

300 mm fab expansion in East Asia needing ISO Class 1 luminaires

Record capital outlays for extreme-ultraviolet lithography lines in Taiwan, Japan, and mainland China are driving demand for ULPA-filtered, EUV-compatible luminaires able to operate in ISO Class 1 environments. Nanya Technology's USD 9.6 billion double-deck fab typifies these projects, with lighting packages specified early to meet rigorous spectral and sealing criteria.

Volatile aluminum & polycarbonate pricing

Rapid swings in commodity prices for low-outgassing aluminum alloys and cleanroom-grade polycarbonates inflate bills of material and strain fixed-price project contracts. Limited supplier pools amplify cost sensitivity, compelling vertically integrated lighting brands to forward-buy raw materials or redesign housings.

Other drivers and restraints analyzed in the detailed report include:

- Biologics and cell-therapy build-out in North America

- UV-C-integrated hospital fixtures in Gulf Cooperation Council states

- Scarcity of ATEX/IECEx-certified lights

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

LEDs anchored 80.4% of 2024 revenue within the cleanroom lighting market, far outstripping fluorescent and induction technologies. UV sub-segments, although modest today, are growing at an 8.7% clip as Far-UVC and germicidal LEDs merge illumination and disinfection. Energy-efficiency mandates, instant-dimming capability, and superior color stability underpin LED preference, with smart-sensor packages enabling predictive maintenance for ISO-classified spaces.

Second-generation LEDs integrate 222 nm emitters behind sealed quartz windows, allowing continuous sterilization without room evacuation. This dual-functionality increases fixture ASPs while shrinking ceiling-grid congestion. Fluorescents, constrained by EU EcoDesign bans taking force in 2025, are relegated to retrofit niches set for phased retirement. As premium UV-C products scale, the cleanroom lighting market size for LED-based solutions is forecast to exceed USD 1 billion by 2030.

Panel and troffer luminaires represented 45.1% of 2024 revenue, favored for flush mounting that minimizes ledges and particle traps. Modular panel systems with quick-disconnect gear trays shorten validation cycles and simplify gasket replacement, aligning with lean facility-management goals.

Hazardous-location fixtures, though only a mid-single-digit share today, are advancing at 6.5% CAGR. Pharmaceutical solvent suites and lithium-battery lines specify Zone 1/Division 1 LEDs certified under ATEX, IECEx, or NEC. Supply tightness in certified products raises margins for incumbents, boosting the cleanroom lighting market share of vendors offering explosion-proof lines.

The Clean Room Lighting Market Report is Segmented by Light Source (LED, Fluorescent, and More), Fixture Design/Form Factor (Panel/Troffer, Wrap-around/Strip, and More), Mounting Type (Recessed, Surface, and Pendant/Suspended), End-User Industry (Semiconductor and Electronics, Healthcare and Life Sciences, and More), Sales Channel (Direct OEM, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific remained the largest territory, holding 27.8% of 2024 revenue thanks to dense semiconductor clustering in Taiwan, Japan, Korea, and coastal China. Projects such as TSMC's Kumamoto joint venture and Nanya's New Taipei City megafab secure multi-year lighting-package pipelines. Photovoltaic manufacturers are also standardizing ISO 7 cells for heterojunction solar modules, extending addressable demand into renewable-energy supply chains. India is emerging as a fragmented, price-sensitive sub-market where local OEM alliances can accelerate penetration.

The Middle East leads growth at 6.7% CAGR through 2030 as healthcare privatization and vaccine self-sufficiency programs drive large hospital and pharma complexes. Far-UVC deployments in Riyadh and Abu Dhabi underscore the region's readiness to fund premium infection-control solutions. Hazardous-location orders tied to solvent handling in Saudi biopharma plants further buoy regional revenue, though scarcity of certified products can delay project milestones.

North America benefits from a robust biologics pipeline and resurgent wafer-fab construction under the CHIPS and Science Act. Fujifilm's North Carolina expansion exemplifies high-spec lighting demand in new biomanufacturing campuses. Labor shortages among certified electricians present a short-term bottleneck, yet modular panel systems that install in half the time of legacy housings mitigate schedule risk. Europe's retrofit wave, catalyzed by EcoDesign rules that shutter T8 fluorescents in 2025, provides steady replacement revenue even as macro uncertainty tempers greenfield spending. Nordic countries, Germany, and France remain compliance leaders, requiring ISO and GMP traceability that favors established certificate holders.

- Signify Holding

- Cooper Lighting Solutions

- Wipro Lighting

- Eaton Lighting

- LUG Light Factory

- Terra Universal

- Solite Europe

- Paramount Industries

- Kenall Manufacturing

- AB Fagerhult

- Waldmann Lighting

- Glamox AS

- Hubbell Lighting

- Cree Lighting

- Philips Cleanroom Lighting

- H.E. Williams Inc.

- Clean Air Lighting LLC

- Admiral Lighting

- Boyd Cleanroom Lighting

- Hefei Kejia Purification

- Shenzhen Sansi Lighting

- Beghelli S.p.A.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Increasing GMP and ISO 14644 compliance pressure on European pharma manufacturers

- 4.2.2 Expansion of 300 mm semiconductor fabs in East Asia requiring ISO Class 1 luminaires

- 4.2.3 Growth of biologics and cell-therapy facilities in North America demanding flicker-free sealed LEDs

- 4.2.4 Uptake of UV-C-integrated luminaires for infection control in Gulf Cooperation Council Countries hospitals

- 4.2.5 EU EcoDesign-2023 retrofit mandates accelerating LED replacement of legacy fluorescent fixtures

- 4.2.6 High-speed F&B packaging lines in South America needing IP65+ shatter-proof lighting

- 4.3 Market Restraints

- 4.3.1 Volatile aluminium and polycarbonate prices inflating fixture BOMs

- 4.3.2 Scarcity of ATEX/IECEx-certified lights delaying Middle-East pharma projects

- 4.3.3 Thermal-management limits of high-lumen LEDs in ISO Class 3 environments

- 4.3.4 Shortage of skilled installers for sealed grid luminaires in Africa

- 4.4 Industry Ecosystem Analysis

- 4.5 Technological Outlook

- 4.6 Porter's Five Forces Analysis

- 4.6.1 Bargaining Power of Suppliers

- 4.6.2 Bargaining Power of Buyers

- 4.6.3 Threat of New Entrants

- 4.6.4 Threat of Substitute Products

- 4.6.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUES)

- 5.1 By Light Source

- 5.1.1 LED

- 5.1.2 Fluorescent

- 5.1.3 Induction

- 5.1.4 UV

- 5.2 By Fixture Design/Form Factor

- 5.2.1 Panel/Troffer

- 5.2.2 Wrap-around/Strip

- 5.2.3 Downlights

- 5.2.4 Hazardous-Location Fixtures

- 5.3 By Mounting Type

- 5.3.1 Recessed

- 5.3.2 Surface

- 5.3.3 Pendant/Suspended

- 5.4 By End-User Industry

- 5.4.1 Semiconductor and Electronics

- 5.4.2 Healthcare and Life Sciences

- 5.4.3 Food and Beverage Processing

- 5.4.4 Research and Academic Laboratories

- 5.4.5 Aerospace and Defense

- 5.4.6 Automotive Paint and Battery Manufacturing

- 5.4.7 Other Industries

- 5.5 By Sales Channel

- 5.5.1 Direct OEM

- 5.5.2 System Integrators

- 5.5.3 Distributors

- 5.6 By Geography

- 5.6.1 North America

- 5.6.1.1 United States

- 5.6.1.2 Canada

- 5.6.1.3 Mexico

- 5.6.2 Europe

- 5.6.2.1 Germany

- 5.6.2.2 United Kingdom

- 5.6.2.3 France

- 5.6.2.4 Nordics

- 5.6.2.5 Rest of Europe

- 5.6.3 South America

- 5.6.3.1 Brazil

- 5.6.3.2 Rest of South America

- 5.6.4 Asia-Pacific

- 5.6.4.1 China

- 5.6.4.2 Japan

- 5.6.4.3 India

- 5.6.4.4 South-East Asia

- 5.6.4.5 Rest of Asia-Pacific

- 5.6.5 Middle East and Africa

- 5.6.5.1 Middle East

- 5.6.5.1.1 Gulf Cooperation Council Countries

- 5.6.5.1.2 Turkey

- 5.6.5.1.3 Rest of Middle East

- 5.6.5.2 Africa

- 5.6.5.2.1 South Africa

- 5.6.5.2.2 Rest of Africa

- 5.6.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Signify Holding

- 6.4.2 Cooper Lighting Solutions

- 6.4.3 Wipro Lighting

- 6.4.4 Eaton Lighting

- 6.4.5 LUG Light Factory

- 6.4.6 Terra Universal

- 6.4.7 Solite Europe

- 6.4.8 Paramount Industries

- 6.4.9 Kenall Manufacturing

- 6.4.10 AB Fagerhult

- 6.4.11 Waldmann Lighting

- 6.4.12 Glamox AS

- 6.4.13 Hubbell Lighting

- 6.4.14 Cree Lighting

- 6.4.15 Philips Cleanroom Lighting

- 6.4.16 H.E. Williams Inc.

- 6.4.17 Clean Air Lighting LLC

- 6.4.18 Admiral Lighting

- 6.4.19 Boyd Cleanroom Lighting

- 6.4.20 Hefei Kejia Purification

- 6.4.21 Shenzhen Sansi Lighting

- 6.4.22 Beghelli S.p.A.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment