|

市场调查报告书

商品编码

1851190

汽车电池管理系统:市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)Automotive Battery Management Systems - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

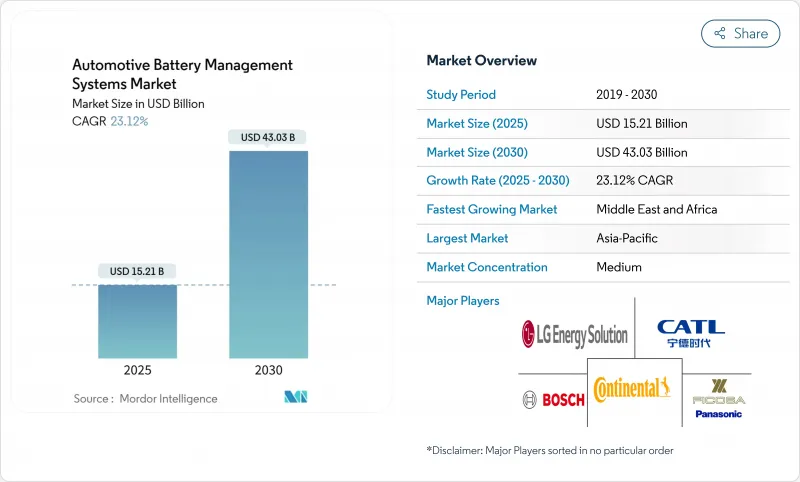

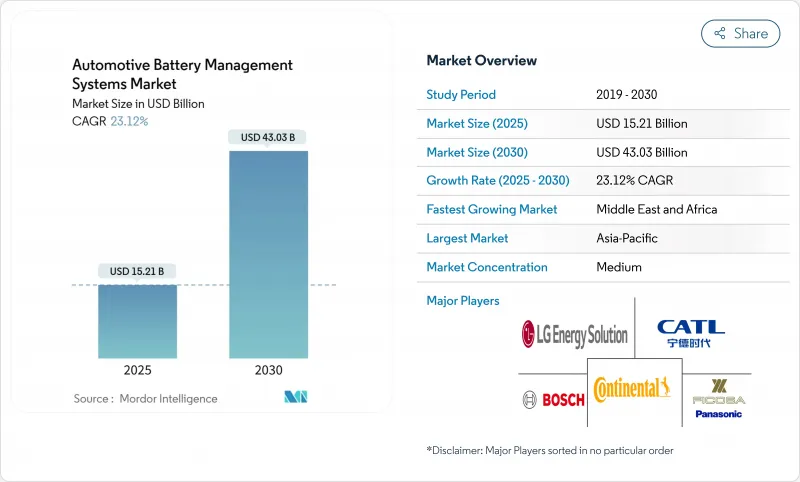

预计到 2025 年,汽车电池管理系统市场规模将达到 152.1 亿美元,到 2030 年将达到 430.3 亿美元。

这一成长反映了全球动力系统从内燃机向电动推进的转变,电池管理系统 (BMS) 扮演着车辆中枢神经系统的角色。监管压力,例如将于 2024 年应用于新款车型的 ISO 21434 网路安全标准,正在加速推动网路安全设计的需求。同时,从硬布线向模组化和无线拓扑结构的快速过渡,正在减轻线束重量、提高能量密度并缩短组装时间。例如,NXP 的超宽频 BMS 等无线解决方案(将于 2025 年发布供 OEM 测试)展示了下一代架构如何兼顾安全性、效率和成本目标。不断增长的电动车 (EV) 销售目标、不断下降的电池组成本以及磷酸铁锂 (LFP) 化学技术的广泛应用,持续推动着设计升级,使电芯和模组层面的智能化程度更高,从而巩固了汽车电池管理系统市场的强劲增长势头。

全球汽车电池管理系统市场趋势与洞察

全球扩大电动车销售义务

零排放汽车(ZEV)政策正在欧盟和加州等地区实施,这提高了电池的耐用性、续航里程维持率和健康透明度的基准值。欧盟7排放标准将于2026年生效,而加州的「先进清洁汽车II」(Advanced Clean Car II)标准要求电池在行驶15万英里后仍能维持80%的续航里程,这将迫使电池管理系统(BMS)供应商采用更复杂的健康分析和劣化建模技术。规则的统一将促使全球平台采用符合标准的单一架构,使原始设备製造商(OEM)能够避免针对特定地区的客製化设计,从而推动汽车电池管理系统市场的发展。已经采用自适应演算法的供应商将获得先发优势,而传统供应商则将面临更长的检验週期和更高的成本。

降低电池组成本

锂离子电池组价格的快速下降正在重塑成本结构。到2024年,主流磷酸铁锂电池组的平均价格将达到75美元/千瓦时,而钠离子电池的试验表明,其成本可低至10美元/千瓦时。随着电芯价格的降低,原始设备製造商(OEM)可以将更大比例的电池预算分配给更智慧的电池管理系统(BMS)功能,例如预测分析和无线连接,而不是仅仅关注硬体成本的降低。这种向更高单包价值的转变正在增强汽车电池管理系统市场对先进电池管理解决方案的需求。

因热失控召回事件导致保固条款增加

备受瞩目的火灾事故导致了大规模召回,迫使汽车製造商增加保固准备金并采用保守的电池组设计。三星SDI的多品牌召回以及现代摩比斯开发的自熄模组凸显了产业的紧迫性。绝缘、灭火和冗余感测器的额外成本可能会减缓实验性电池管理系统(BMS)功能的部署,并抑制汽车电池管理系统市场近期的成长。

细分市场分析

到2024年,电池感测器将占据汽车电池管理系统35.41%的市场份额,并在2030年之前以24.66%的复合年增长率成长。涵盖温度、压力、气体排放和湿度等多物理场感测技术的广泛应用,正助力原始设备製造商(OEM)从被动保护转向即时预测诊断。随着监管机构强制要求加强热失控检测,以及车队营运商寻求更精细的数据以优化工作週期和保固范围,电池感测器的应用将加速发展。将二氧化碳和氢气感测器整合到模组级基板,可提升预警能力,有助于避免代价高昂的召回和停机。随着电动车电池组电压超过800V,高解析度分流器和霍尔效应感测器对于精确估算电池荷电状态和健康状态至关重要,这将确保该领域的长期成长。

电池级电压精度现已达到±2mV,从而实现更精确的电荷均衡并延长电池组寿命,使得积体电路精度成为关键的采购标准。领先的晶片製造商正在将测量、均衡和通讯模组整合到单一晶粒上,从而缩小基板尺寸并简化车辆认证流程。 「其他电子元件和材料」类别(包括导热间隙填充材料、气凝胶片和相变复合材料)随着能量密度的提高而不断扩大,对卓越的散热和绝缘解决方案提出了更高的要求。

到2024年,模组化汽车电池管理系统市占率将达到48.95%。在电池组层面分离感测和执行功能,可显着提升系统可靠性,满足商用车队和高运转率叫车的需求。此外,增量式硬体模组还支援快速的现场更换,从而提高车辆的运作。

随着天线小型化、安全网状通讯协定和认证射频协定栈在生产中的成熟,无线电设计正迅速发展,预计从2025年到2030年将以35.17%的复合年增长率成长。取消菊链连接线束可减轻电池组重量,并释放宝贵的空间以主动冷却板和额外的电芯。同时,针对特定领域的分散式架构可满足赛车运动和航太跨界专案中对极高冗余度的需求,从而减少汽车电池管理系统市场的产品多样性。

区域分析

亚太地区将继续保持汽车电池管理系统市场的主导地位,预计到2024年将占据61.33%的市场份额。中国从上游提炼到整车组装的垂直整合电池价值链降低了成本结构,并加快了设计迭代速度。政府的采购补贴、主要城市的优惠车牌政策以及成熟的充电生态系统将推动电动车的普及,并增加电池管理系统的出货量。随着中国电芯和模组供应商在波兰、匈牙利和内华达州等地建厂,供应链优势也正扩展到欧洲和北美,从而确保了免税准入并缩短了物流运输路线。

中东和非洲地区虽然基数较低,但仍是成长最快的地区,预计到2030年复合年增长率将达到27.55%。杜拜、利雅德和开罗正在推广电动公车走廊,并制定了最后一公里配送的电气化目标,这需要耐热的电池管理系统(BMS)设计。公私合作将推动併网电池的投资,并带动二手车辆电池组和二手BMS软体的销售。

北美地区随着抑制通膨的立法推动本土电池和组件製造的发展而势头强劲。 BMW、丰田和现代在卡罗来纳州、乔治亚和安大略省的投资支持了电池管理系统(BMS)基板的在地采购,从而减少了对亚洲进口的依赖。欧洲在监管方面仍处于领先地位,即将推出的电池护照制度将推动可追溯性功能的实施,这将增加系统的复杂性和软体内容。这些要求将提高单车收入,并使拥有安全云端管道的供应商脱颖而出,从而维持汽车电池管理系统市场的整体健康前景。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 全球扩大电动车销售义务

- 降低电池组成本

- 从集中式拓扑结构过渡到模组化和无线拓扑结构

- 对磷酸铁锂化学品的激增需求需要先进的活性平衡技术。

- ISO 21434主导了对「网路安全型楼宇管理系统」的需求

- OEM厂商纷纷转向内部设计BMS ASIC晶片,以降低智慧财产权授权费。

- 市场限制

- 热召回事件增加保固条款

- 功率半导体严重短缺

- 2027 年后欧盟「电池护照」可追溯性负担

- 基于人工智慧的预测性电池管理系统仍缺乏功能安全认证。

- 价值/供应链分析

- 监管环境

- 技术展望

- 波特五力模型

- 新进入者的威胁

- 买方的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争

第五章 市场规模与成长预测

- 按组件

- 电池积体电路

- 电池感应器

- 其他电子产品和材料

- 按拓扑学

- 集中

- 模组化的

- 去中心化

- 无线的

- 依推进类型

- 混合动力电动车(HEV)

- 插电式混合动力汽车(PHEV)

- 电池电动车(BEV)

- 燃料电池电动车(FCEV)

- 按车辆类型

- 搭乘用车

- 轻型商用车

- 中型和大型商用车辆

- 两轮车和三轮车

- 非公路及特种车辆

- 按地区

- 北美洲

- 美国

- 加拿大

- 北美其他地区

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 欧洲

- 德国

- 英国

- 法国

- 西班牙

- 义大利

- 俄罗斯

- 其他欧洲地区

- 亚太地区

- 中国

- 日本

- 印度

- 韩国

- 澳洲

- 亚太其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 阿拉伯聯合大公国

- 土耳其

- 埃及

- 南非

- 其他中东和非洲地区

- 北美洲

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- LG Energy Solution

- CATL

- Panasonic(Ficosa)

- Robert Bosch GmbH

- Continental AG

- Texas Instruments

- Analog Devices

- Infineon Technologies

- NXP Semiconductors

- Renesas Electronics

- Hitachi Astemo

- Mitsubishi Electric

- Denso Corporation

- Preh GmbH

- Eaton Mobility(Eatron)

- Lithium Balance

- Sensata Technologies

- Eberspacher Vecture

- Rimac Technology

第七章 市场机会与未来展望

The automotive battery management system market size is valued at USD 15.21 billion in 2025 and is forecast to climb to USD 43.03 billion in 2030, reflecting a vigorous 23.12% CAGR.

This expansion mirrors the global pivot from internal-combustion engines toward electrified propulsion, where a battery management system (BMS) functions as the vehicle's central nervous system. Regulatory pressure, notably ISO 21434 cybersecurity rules that came into force for new vehicle models in 2024, is accelerating demand for cyber-secure designs. At the same time, rapid migration from hard-wired to modular and wireless topologies is trimming harness weight, boosting energy density, and shortening assembly time. Wireless solutions such as NXP's ultra-wideband BMS, released for OEM trials in 2025, exemplify how next-generation architectures can align safety, efficiency, and cost goals. Heightened electric-vehicle (EV) sales targets, falling battery pack cost, and mainstream adoption of lithium-iron-phosphate (LFP) chemistries continue to stimulate design upgrades that place more intelligence at the cell and module level, reinforcing a robust growth path for the automotive battery management system market.

Global Automotive Battery Management Systems Market Trends and Insights

EV sales mandates widening globally

Binding ZEV policies in regions such as the EU and California raise the baseline for durability, range retention, and transparency of battery health. Euro 7 rules will be effective in 2026, and California's Advanced Clean Cars II demands 80% range retention for 150,000 miles, compelling BMS suppliers to incorporate more refined state-of-health analytics and degradation modeling. Harmonizing rules incentivize global platforms to adopt one compliance-ready architecture, elevating the automotive battery management system market as OEMs avoid region-specific designs. Suppliers that already embed adaptive algorithms gain a head start, whereas legacy providers face added validation cycles and cost.

Falling cost of battery packs

Rapid declines in lithium-ion battery-pack prices are reshaping cost structures. Mainstream LFP packs averaged USD 75 per kWh in 2024, and pilot sodium-ion runs have demonstrated costs as low as USD 10 per kWh. As cells get cheaper, OEMs can allocate larger portions of the battery budget to smarter BMS functions, such as predictive analytics and wireless connectivity, rather than focusing solely on hardware cost reduction. This shift toward higher value content per pack reinforces demand for advanced battery management solutions across the automotive battery management system market.

Thermal-runaway recalls raising warranty reserves

High-profile fire events have led to sizable recalls, forcing automakers to boost warranty accruals and adopt conservative pack design. Samsung SDI's multi-brand recall and Hyundai Mobis' development of self-extinguishing modules underscore industry urgency. Added cost for insulation, fire suppression, and redundant sensors can slow deployment of experimental BMS functions, tempering near-term growth in the automotive battery management system market.

Other drivers and restraints analyzed in the detailed report include:

- Shift from centralized to modular and wireless topologies

- Soaring demand for LFP chemistry requiring advanced active balancing

- Acute power-semiconductor shortages

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Battery Sensors captured 35.41% of the automotive battery management system market share in 2024, and the segment is forecast to post a 24.66% CAGR through 2030. Wider deployment of multi-physics sensing, covering temperature, pressure, off-gas, and humidity, allows OEMs to move from passive protection toward real-time predictive diagnostics. Adoption accelerates as regulators demand enhanced thermal-runaway detection and as fleet operators seek granular data to optimize duty cycles and warranty coverage. Integrating CO2 and H2 sensors into module-level boards improves early-warning capabilities, helping avoid costly recalls and downtime. As EV packs scale above 800 V, high-resolution shunt and Hall-effect sensors become indispensable for accurate state-of-charge and state-of-health estimation, cementing the segment's long-term expansion path.

Tight cell-level voltage accuracy, now reaching +-2 mV, enables finer charge balancing and extended pack life, making IC precision a decisive purchase criterion. Leading chipmakers have fused measurement, balancing, and communication blocks onto single dies, shrinking board footprints and simplifying automotive qualifications. The residual "Other electronics and materials" bucket, encompassing thermally conductive gap fillers, aerogel sheets, and phase-change composites, continues to broaden as energy density rises, calling for superior heat-spreading and insulation solutions.

In 2024, Modular arrangements accounted for 48.95% of the automotive battery management system market share, reflecting OEM preference for scalable sub-battery modules that can be rearranged without wholesale redesign. Box-level isolation of sensing and actuation delivers fault tolerance suited to commercial fleets and high-utilization ride-hailing vehicles. Incremental hardware blocks also facilitate rapid line-side replacement, lifting vehicle uptime.

Wireless designs are scaling rapidly, showing a 35.17% CAGR across 2025-2030 as antenna miniaturization, secure mesh protocols, and certified RF stacks reach production maturity. Eliminating daisy-chain harnesses cuts pack weight and opens valuable cubic centimeters for active cooling plates or extra cells. Centralized topologies continue in entry-price passenger cars, where minimal components trump expandability, whereas niche distributed architectures meet extreme redundancy mandates in motorsports and aerospace crossover programs, cushioning product diversity inside the automotive battery management system market.

The Automotive Battery Management System Market Report is Segmented by Component (Battery IC, Battery Sensors, and More), Topology (Centralized, Modular, and More), Propulsion Type (Hybrid Electric Vehicle (HEV), Battery Electric Vehicle (BEV), and More), Vehicle Type (Passenger Cars, Light Commercial Vehicles, and More), and Geography (North America, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific retained a commanding 61.33% share of the automotive battery management system market in 2024. China's vertically integrated battery value chain-from upstream refining to final vehicle assembly-compresses cost structures and quickens design iterations. Government purchase incentives, favorable license-plate policies in megacities, and a mature charging ecosystem lift EV penetration and reinforce BMS unit shipments. Supply-chain leverage even extends to Europe and North America, as Chinese cell and module suppliers open factories in Poland, Hungary, and Nevada to secure tariff-free access and shorten logistics lanes.

The Middle East and Africa region, although emerging from a low base, is the fastest-growing region with a 27.55% CAGR through 2030. Dubai, Riyadh, and Cairo are rolling out e-bus corridors and last-mile delivery electrification targets that demand heat-tolerant BMS designs. Public-private alliances channel investment into grid-tied battery storage, creating adjacent sales for repurposed vehicle packs and second-life BMS software.

North America gains momentum as the Inflation Reduction Act galvanizes domestic cell and module manufacturing. Investments by BMW, Toyota, and Hyundai in the Carolinas, Georgia, and Ontario shrink reliance on Asian imports and underpin local sourcing of BMS boards. Europe remains a regulatory trailblazer, with the upcoming battery passport pushing traceability features that increase system complexity and software content. Such requirements elevate per-vehicle revenue and differentiate suppliers ready with secure cloud pipelines, sustaining a healthy overall outlook for the automotive battery management system market.

- LG Energy Solution

- CATL

- Panasonic (Ficosa)

- Robert Bosch GmbH

- Continental AG

- Texas Instruments

- Analog Devices

- Infineon Technologies

- NXP Semiconductors

- Renesas Electronics

- Hitachi Astemo

- Mitsubishi Electric

- Denso Corporation

- Preh GmbH

- Eaton Mobility (Eatron)

- Lithium Balance

- Sensata Technologies

- Eberspacher Vecture

- Rimac Technology

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 EV sales mandates widening globally

- 4.2.2 Falling cost of battery packs

- 4.2.3 Shift from centralized to modular and wireless topologies

- 4.2.4 Soaring demand for LFP chemistry requiring advanced active balancing

- 4.2.5 ISO 21434-driven "cyber-secure BMS" demand

- 4.2.6 OEM move to in-house BMS ASIC design to cut IP royalty cost

- 4.3 Market Restraints

- 4.3.1 Thermal-runaway recalls raising warranty reserves

- 4.3.2 Acute power-semiconductor shortages

- 4.3.3 Post-2027 EU "battery-passport" traceability overheads

- 4.3.4 AI-based predictive BMS still lacks functional-safety certification

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitutes

- 4.7.5 Competitive Rivalry

5 Market Size & Growth Forecasts (Value in USD)

- 5.1 By Component

- 5.1.1 Battery IC

- 5.1.2 Battery Sensors

- 5.1.3 Other Electronics and Materials

- 5.2 By Topology

- 5.2.1 Centralized

- 5.2.2 Modular

- 5.2.3 Distributed

- 5.2.4 Wireless

- 5.3 By Propulsion Type

- 5.3.1 Hybrid Electric Vehicle (HEV)

- 5.3.2 Plug-in Hybrid Electric Vehicle (PHEV)

- 5.3.3 Battery Electric Vehicle (BEV)

- 5.3.4 Fuel-Cell Electric Vehicle (FCEV)

- 5.4 By Vehicle Type

- 5.4.1 Passenger Cars

- 5.4.2 Light Commercial Vehicles

- 5.4.3 Medium and Heavy Commercial Vehicles

- 5.4.4 Two and Three-Wheelers

- 5.4.5 Off-Highway and Specialty Vehicles

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Rest of North America

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Spain

- 5.5.3.5 Italy

- 5.5.3.6 Russia

- 5.5.3.7 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 Japan

- 5.5.4.3 India

- 5.5.4.4 South Korea

- 5.5.4.5 Australia

- 5.5.4.6 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 United Arab Emirates

- 5.5.5.3 Turkey

- 5.5.5.4 Egypt

- 5.5.5.5 South Africa

- 5.5.5.6 Rest of Middle East and Africa

- 5.5.1 North America

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (Includes Global Level Overview, Market Level Overview, Core Segments, Financials as Available, Strategic Information, Market Rank/Share for Key Companies, Products and Services, SWOT Analysis, and Recent Developments)

- 6.4.1 LG Energy Solution

- 6.4.2 CATL

- 6.4.3 Panasonic (Ficosa)

- 6.4.4 Robert Bosch GmbH

- 6.4.5 Continental AG

- 6.4.6 Texas Instruments

- 6.4.7 Analog Devices

- 6.4.8 Infineon Technologies

- 6.4.9 NXP Semiconductors

- 6.4.10 Renesas Electronics

- 6.4.11 Hitachi Astemo

- 6.4.12 Mitsubishi Electric

- 6.4.13 Denso Corporation

- 6.4.14 Preh GmbH

- 6.4.15 Eaton Mobility (Eatron)

- 6.4.16 Lithium Balance

- 6.4.17 Sensata Technologies

- 6.4.18 Eberspacher Vecture

- 6.4.19 Rimac Technology

7 Market Opportunities & Future Outlook

- 7.1 White-space & Unmet-Need Assessment