|

市场调查报告书

商品编码

1851239

机器人技术:市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)Robotics - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

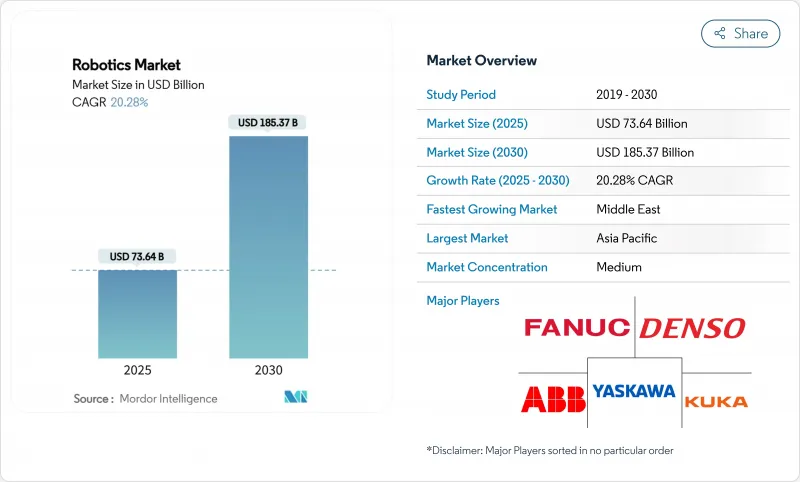

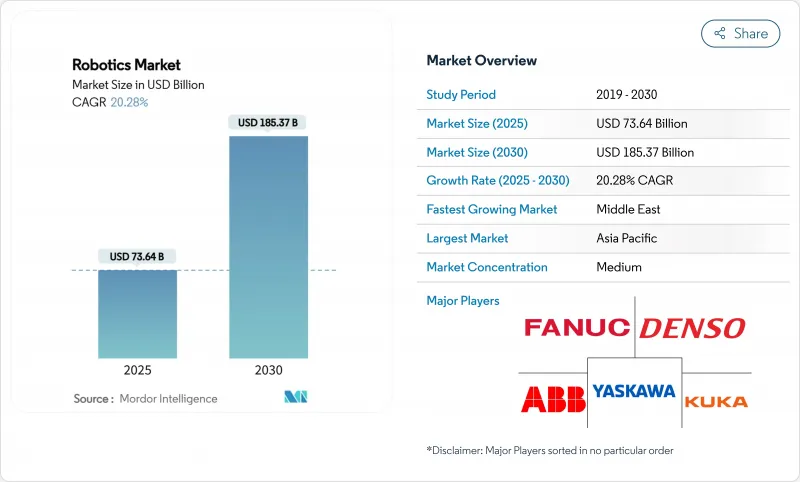

全球机器人市场预计到 2025 年将达到 736.4 亿美元,到 2030 年将扩大到 1853.7 亿美元。

这种成长轨迹反映了已开发国家结构性劳动力短缺、自动化硬体成本的系统性下降,以及政府支持的将机器人视为战略基础设施而非可有可无的资本财的回流计划。大型企业正在加速采用机器人以在薪资上涨压力下稳定生产,而中小企业则透过协作系统和RAS合约获得机器人。区域趋势正在转变:亚太地区在机器人销售方面继续领先,但中东地区成长最快,因为主权财富基金正在寻求技术主导的多元化发展。在供应方面,零件成本下降和低程式码程式设计平台正在重塑价值链,使其朝着软体智慧方向发展,从而为专注于人工智慧控制的供应商创造了经常性收入来源。网路安全漏洞、出口管制摩擦以及小型用户技能不足仍然是障碍,但同时也为专业服务,特别是安全部署和生命週期支持,创造了市场空间。

全球机器人市场趋势与洞察

劳动力短缺增加了对自动化的需求

人口结构变化带来的不利影响正促使日本、美国和西欧大部分地区的自动化发展方向从降低成本转向产能保护。到2024年,七国集团(G7)製造业的工厂空缺职位将超过200万个,日本的机器人密度将达到创纪录的每万名员工399台机器人。像Stellantis这样的汽车製造商正在悄悄推进协作式部署,采用以人性化的机器人单元,既能维持员工数量,又能减少重复性劳损。全球机器人市场受益于这些结构性缺口在经济週期中持续存在,为供应商提供了一个不受GDP波动影响的可预测需求基础。

每功能小时机器人平均价格下降

从2024年起,零件的商品化和大规模生产将使协作机器人的价格每年下降约15%,而软体升级将使效能价格比翻倍。中国供应商目前销售的入门级人形机器人售价为人民币19.9万元(约27,512美元),这使得小型工厂能够负担得起。随着硬体成本的下降,小型和新兴市场製造商的采用率将迅速提高,从而扩大全球机器人市场的潜在用户群。

中小企业持续存在的整合技能差距

68%的中小企业缺乏实施机器人技术所需的工程人才,导致投资报酬週期长、采用率低。整合商集中在都市区,农村企业服务不足。如果缺乏加速技能培养和承包服务模式,全球机器人市场仍是一个巨大的未开发潜力。

细分市场分析

到2024年,工业机器人将占据全球机器人市场71.4%的份额,这主要得益于汽车和电子产业高产能组装的持续需求。然而,协作机器人到2030年将以26.71%的复合年增长率成长,这主要得益于其安全认证的力感应技术以及低于3万美元的定价,使其符合中小企业的预算。这种转变表明,灵活的、由人工监督的单元,而非封闭的围栏,将推动全球机器人市场下一波发展浪潮。

中国协作机器人製造商的快速扩张将使其国内市场份额在2017年至2024年间从35%增长至73%,加剧价格竞争并加速全球销售成长。到2024年,外科手术系统市场规模将超过39.2亿美元,再次巩固医疗保健作为成长最快终端应用领域的地位。这种多元化发展将缓解全球机器人市场的周期性波动,并使硬体供应商能够更好地应对任何单一行业的低迷时期。

儘管硬体支出在2024年将占总支出的63.8%,但随着人工智慧成为关键价值驱动因素,软体收入将以每年23.62%的速度成长。 ABB的OmniCore平台将云端分析和强化学习整合到更先进的控制系统中,进而将循环时间缩短25%,能耗降低20%。随着客户从资本支出模式转向营运支出模式,预计到2030年,全球基于订阅的机器人即服务(Robot-as-a-Service)市场规模将成长两倍。

涵盖整合、远端监控和预测性维护的业务收益进一步巩固了供应商锁定。这模糊了软体和服务之间的界限,更新权和网路安全性修补程式被捆绑在多年合约中。这一趋势正在重塑全球机器人市场的利润格局,并提高了纯粹以硬体为中心的厂商的准入门槛。

区域分析

到2024年,亚太地区将占据全球机器人市场38.1%的份额,主要得益于中国每年新增43万台工业机器人以及全球三分之二的机器人专利。中国工厂将把机器人整合到锂离子电池和家电生产线中,本土品牌也将扩大出口,从而巩固该地区在全球机器人市场的成本竞争力。受中国市场需求復苏和国内人口结构压力的推动,发那科(FANUC)预计2024年累计1802亿日圆(约16.4亿美元)的利润。韩国一项耗资26亿美元的公私合作计画将把其人形机器人技术应用于电池工厂自动化,这明确了韩国的战略重点。

到2030年,中东地区的复合年增长率将达到21.84%,位居全球之首,这主要得益于主权财富基金将油气盈余投入工业数位化、物流和医疗保健领域。阿联酋的自由贸易区正在试行仓库型自主移动机器人(AMR),以满足该地区电子商务的需求,并减少对季节性外籍劳工的过度依赖。此外,各国政府也资助先进製造中心,吸引全球整合商,进而扩大全球机器人市场的潜在用户群。

北美市场需求仍然强劲,这得益于《晶片製造法案》(CHIPS Act)支持的晶圆厂以及安杜瑞尔公司(Anduril)价值6.422亿美元的海军反无人机订单等国防合约。欧洲则专注于安全的人机协作标准和永续性目标,德国每年6,900万欧元(约7,500万美元)的人工智慧整合资金为此订单了有力支撑。这两个地区都在投资高价值软体和集成,同时越来越多地将通用子次组件外包给亚洲,这反映了全球机器人市场的一种「槓铃式」策略。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 劳动力短缺推动了对自动化的需求

- 每功能小时机器人平均价格下降

- 低程式码机器人程式设计平台的兴起

- 七国集团鼓励製造业回流的财政奖励

- 电商第三方物流公司在仓库部署自主移动机器人(AMR)

- 国家级人形机器人研发任务(例如中国2025计画)

- 市场限制

- 中小企业持续存在的整合技能差距

- 对先进伺服的地缘政治出口管制

- 稀土磁铁价格波动

- ROS部署中的网路安全漏洞

- 价值链分析

- 监管环境

- 技术展望

- 波特五力分析

- 新进入者的威胁

- 供应商的议价能力

- 买方的议价能力

- 替代品的威胁

- 竞争对手之间的竞争

- 评估市场宏观经济趋势

第五章 市场规模与成长预测

- 按机器人类型

- 工业机器人

- 服务机器人

- 协作工作(协作机器人)

- 移动/AMR

- 按组件

- 硬体

- 软体

- 服务(整合、RaaS)

- 透过使用

- 製造和组装

- 物流/仓储

- 医学与外科

- 国防与安全

- 检查和维护

- 清洁和卫生

- 按最终用户行业划分

- 车

- 电子和半导体

- 饮食

- 医疗保健提供者

- 军事/国防

- 其他终端用户产业

- 按地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 其他欧洲地区

- 亚太地区

- 中国

- 印度

- 日本

- 亚太其他地区

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中东

- 阿拉伯聯合大公国

- 沙乌地阿拉伯

- 其他中东地区

- 非洲

- 南非

- 奈及利亚

- 其他非洲地区

- 北美洲

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- ABB Ltd.

- Fanuc Corporation

- Yaskawa Electric Corporation

- KUKA AG

- Kawasaki Heavy Industries Ltd

- Universal Robots A/S(Teradyne)

- Denso Corporation

- Mitsubishi Electric Corporation

- Omron Corporation

- Staubli International AG

- Epson Robots(Seiko Epson)

- Comau SpA

- Nachi-Fujikoshi Corp.

- Toshiba Corporation

- Intuitive Surgical Inc.

- Stryker Corporation

- iRobot Corporation

- Boston Dynamics Inc.

- Locus Robotics Corp.

- DJI Technology Co. Ltd

第七章 市场机会与未来展望

The global robotics market reached USD 73.64 billion in 2025 and is forecast to expand to USD 185.37 billion by 2030, translating into a healthy 20.28% CAGR.

This growth trajectory reflects structural labor shortages in advanced economies, systematic cost deflation in automation hardware, and government-backed reshoring programs that treat robots as strategic infrastructure rather than optional capital goods. Large enterprises accelerate adoption to stabilise production amid wage pressure, while small and medium firms now gain access through collaborative systems and Robot-as-a-Service contracts. Regional momentum is shifting: Asia-Pacific retains volume leadership, but the Middle East shows the quickest pace as sovereign funds pursue technology-driven diversification. On the supply side, declining component costs and low-code programming platforms reshape the value chain toward software intelligence, setting up recurring revenue streams for vendors that master artificial-intelligence-based control. Cyber-security weaknesses, export-control friction, and skill gaps among smaller users remain braking forces, yet they also open specialist service niches, especially around secure deployment and lifecycle support.

Global Robotics Market Trends and Insights

Rising Labour-Shortage Led Automation Demand

Demographic headwinds in Japan, the United States, and much of Western Europe have shifted automation from cost-saving to capacity-assurance mode. Unfilled factory vacancies topped 2 million roles across G-7 manufacturing in 2024, while Japan's robot density reached 399 units per 10,000 employees, the highest on record. Automakers such as Stellantis adopted human-centric robotic cells that trim repetitive strain injuries yet safeguard headcount, signalling a nuanced push toward collaborative deployment. The global robotics market benefits because these structural gaps persist through economic cycles, giving vendors a predictable demand base that decouples from GDP volatility.

Declining Average Robot Price Per Functional Hour

Component commoditisation and scale production cut collaborative robot prices by roughly 15% a year post-2024, while software upgrades doubled performance relative to price. Chinese suppliers even marketed entry-level humanoids at CNY 199,000 (USD 27,512), placing robots within small-factory capital budgets. As hardware costs slide, adoption curves steepen among small and emerging-market manufacturers, thereby widening the addressable pool for the global robotics market.

Persistent SME Integration Skill-Gap

Sixty-eight percent of SMEs still lack engineering talent for robotics deployment, prolonging payback periods and dampening utilisation rates. Integrators cluster in urban hubs, leaving regional firms underserved. Without accelerated skills development or turnkey service models, the global robotics market leaves considerable latent demand untapped.

Other drivers and restraints analyzed in the detailed report include:

- Proliferation of Low-Code Robot-Programming Platforms

- Fiscal Incentives for Reshoring Manufacturing in G-7

- Geopolitical Export-Control on Advanced Servos

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Industrial robots accounted for 71.4% of the global robotics market in 2024, riding sustained demand from high-throughput automotive and electronics assembly lines. Yet collaborative robots expand at a 26.71% CAGR to 2030, underpinned by safety-certified force-sensing and sub-USD 30,000 price tags that place them within SME budgets. This pivot signals that flexible, human-supervised cells, rather than fenced-off lines, will drive the next deployment wave of the global robotics market.

A surge in Chinese cobot makers lifted their domestic share from 35% to 73% between 2017 and 2024, heightening price competition and accelerating worldwide unit growth. Service-robot niches also flourish: surgical systems surpassed USD 3.92 billion in 2024, reaffirming healthcare as the fastest-rising end-use. This diversification reduces cyclicality for the global robotics market and cushions hardware vendors against single-sector downturns.

Hardware still represented 63.8% of 2024 spending, but software revenue is set to grow 23.62% annually as artificial intelligence becomes the primary value driver. Higher-level control stacks now incorporate cloud analytics and reinforcement learning that deliver 25% faster cycle times with 20% lower electricity use on ABB's OmniCore platform. The global robotics market size for subscription-based Robot-as-a-Service is projected to treble by 2030 as customers migrate from capital expenditure toward operating expenditure models.

Service revenues, covering integration, remote monitoring, and predictive maintenance, further solidify vendor lock-in. As a result, software and services blur, embedding update rights and cyber-security patches into multi-year contracts. This trend rewires profit pools and raises entry barriers for purely hardware-centric challengers within the global robotics market.

The Robotics Market Report is Segmented by Robot Type (Industrial Robots, Service Robots, and More), Component (Hardware, Software, and Services), Application (Manufacturing and Assembly, Logistics and Warehousing, Medical and Surgical, and More), End-User Industry (Automotive, Electronics and Semiconductor, Food and Beverage, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific secured 38.1% of global robotics market share in 2024, anchored by China's 430,000 annual industrial-robot installations and two-thirds of worldwide robotics patent grants. Chinese factories integrate robots into lithium-ion battery and consumer-electronics lines, while domestic brands escalate exports, embedding regional cost competitiveness into the global robotics market. Japan posted JPY 180.2 billion (USD 1.64 billion) profit at Fanuc in 2024 on revived Chinese demand and domestic demographic pressure. South Korea's USD 2.6 billion public-private programme channels humanoid expertise toward battery-plant automation, underscoring strategic prioritisation.

The Middle East registers the highest 21.84% CAGR to 2030 as sovereign wealth vehicles divert hydrocarbons surplus into industrial digitalisation, logistics, and healthcare robotics. Free-trade zones in the United Arab Emirates trial warehouse AMRs to service regional e-commerce flows, reducing over-reliance on seasonal migrant labour. National programmes additionally fund advanced manufacturing hubs that attract global integrators, amplifying the addressable base for the global robotics market.

North American demand remains resilient, propelled by CHIPS-Act-backed fabs and defence contracts such as the USD 642.2 million Navy counter-drone award to Anduril. Europe focuses on safe human-robot collaboration standards and sustainability targets, helped by EUR 69 million (USD 75 million) in annual German funding for artificial-intelligence integration. Both regions increasingly outsource commodity sub-assemblies to Asia while investing in high-value software and integration, reflecting a barbell strategy within the global robotics market.

- ABB Ltd.

- Fanuc Corporation

- Yaskawa Electric Corporation

- KUKA AG

- Kawasaki Heavy Industries Ltd

- Universal Robots A/S (Teradyne)

- Denso Corporation

- Mitsubishi Electric Corporation

- Omron Corporation

- Staubli International AG

- Epson Robots (Seiko Epson)

- Comau SpA

- Nachi-Fujikoshi Corp.

- Toshiba Corporation

- Intuitive Surgical Inc.

- Stryker Corporation

- iRobot Corporation

- Boston Dynamics Inc.

- Locus Robotics Corp.

- DJI Technology Co. Ltd

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rising labour-shortage led automation demand

- 4.2.2 Declining average robot price per functional hour

- 4.2.3 Proliferation of low-code robot-programming platforms

- 4.2.4 Fiscal incentives for reshoring manufacturing in G-7

- 4.2.5 Warehouse AMR roll-outs by e-commerce 3PLs

- 4.2.6 Nation-level humanoid RandD missions (e.g., China 2025)

- 4.3 Market Restraints

- 4.3.1 Persistent SME integration skill-gap

- 4.3.2 Geopolitical export-control on advanced servos

- 4.3.3 Rare-earth magnet price volatility

- 4.3.4 Cyber-security vulnerabilities in ROS deployments

- 4.4 Value Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Suppliers

- 4.7.3 Bargaining Power of Buyers

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Assessment of Macro Economic Trends on the Market

5 MARKET SIZE AND GROWTH FORECASTS (VALUES)

- 5.1 By Robot Type

- 5.1.1 Industrial Robots

- 5.1.2 Service Robots

- 5.1.3 Collaborative (Cobots)

- 5.1.4 Mobile/AMR

- 5.2 By Component

- 5.2.1 Hardware

- 5.2.2 Software

- 5.2.3 Services (Integration, RaaS)

- 5.3 By Application

- 5.3.1 Manufacturing and Assembly

- 5.3.2 Logistics and Warehousing

- 5.3.3 Medical and Surgical

- 5.3.4 Defense and Security

- 5.3.5 Inspection and Maintenance

- 5.3.6 Cleaning and Sanitation

- 5.4 By End-User Industry

- 5.4.1 Automotive

- 5.4.2 Electronics and Semiconductor

- 5.4.3 Food and Beverage

- 5.4.4 Healthcare Providers

- 5.4.5 Military and Defense

- 5.4.6 Other End-user Industries

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 Europe

- 5.5.2.1 Germany

- 5.5.2.2 United Kingdom

- 5.5.2.3 France

- 5.5.2.4 Rest of Europe

- 5.5.3 Asia-Pacific

- 5.5.3.1 China

- 5.5.3.2 India

- 5.5.3.3 Japan

- 5.5.3.4 Rest of Asia-Pacific

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle East

- 5.5.5.1 United Arab Emirates

- 5.5.5.2 Saudi Arabia

- 5.5.5.3 Rest of Middle East

- 5.5.6 Africa

- 5.5.6.1 South Africa

- 5.5.6.2 Nigeria

- 5.5.6.3 Rest of Africa

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 ABB Ltd.

- 6.4.2 Fanuc Corporation

- 6.4.3 Yaskawa Electric Corporation

- 6.4.4 KUKA AG

- 6.4.5 Kawasaki Heavy Industries Ltd

- 6.4.6 Universal Robots A/S (Teradyne)

- 6.4.7 Denso Corporation

- 6.4.8 Mitsubishi Electric Corporation

- 6.4.9 Omron Corporation

- 6.4.10 Staubli International AG

- 6.4.11 Epson Robots (Seiko Epson)

- 6.4.12 Comau SpA

- 6.4.13 Nachi-Fujikoshi Corp.

- 6.4.14 Toshiba Corporation

- 6.4.15 Intuitive Surgical Inc.

- 6.4.16 Stryker Corporation

- 6.4.17 iRobot Corporation

- 6.4.18 Boston Dynamics Inc.

- 6.4.19 Locus Robotics Corp.

- 6.4.20 DJI Technology Co. Ltd

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-Space and Unmet-Need Assessment