|

市场调查报告书

商品编码

1851361

欧洲自动导引运输车(AGV):市场份额分析、产业趋势、统计和成长预测(2025-2030 年)Europe Automated Guided Vehicle (AGV) - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

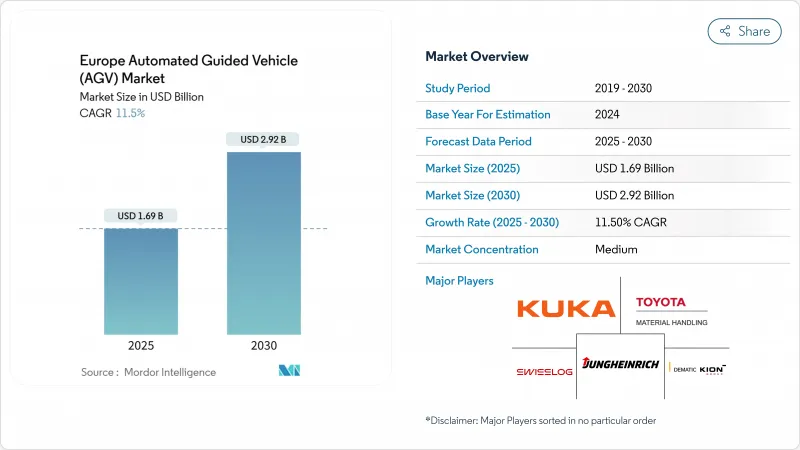

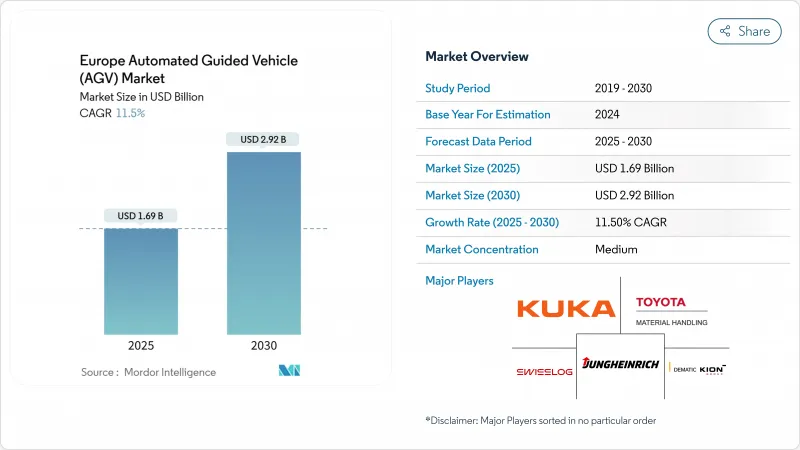

预计到 2025 年,欧洲 AGV 市场规模将达到 16.9 亿美元,到 2030 年将达到 29.2 亿美元,复合年增长率为 11.5%。

汽车产业的弹性製造措施、大规模港口自动化专案以及电子商务的持续扩张(需要高吞吐量的物流)是推动成长的主要动力。锂离子动力传动系统、5G赋能的车队编配以及基于人工智慧的交通管理平台正在融合,以提高各设施的生产效率,同时满足欧盟的脱碳目标。儘管德国在自动化领域的领先地位、荷兰的港口计划以及英国应对严重劳动力短缺的倡议都极大地促进了技术的普及,但射频频谱的分散和高昂的整合成本仍然阻碍着技术的普及速度。

欧洲自动导引运输车(AGV)市场趋势与洞察

欧洲都市区电子商务履约中心激增

都市区履约中心的快速成长正促使AGV(自动导引车)的设计重点转向紧凑型布局和全天候运作。 REWE集团位于马德堡、耗资2.5亿欧元的物流中心实现了50%的物流自动化,日处理包裹量达28.6万件,充分展现了以AGV为中心的布局所带来的规模经济效益。专业零售商也跟进:Dr. Max在义大利新建的仓库利用行动机器人来支援线上销售额55%的成长。随着物流地产供应趋于稳定,零售商们正积极洽谈能够支援AGV快速充电基础设施的自动化空间。

德国汽车工厂中面向工业4.0的弹性生产线

德国汽车製造商正在摒弃传统的输送机模式,转而采用由AGV车队协同运作的矩阵式生产方式。在宾士的白车身製造车间,约100辆库卡AGV能够即时自主地同步零件的流转。 BMW工厂则利用人工智慧车队控制软体,根据车型组合的变化灵活调整运输路线,从而避免停机。像杜尔的EcoProFleet这样的专用AGV系统,将这一理念延伸至喷漆车间,使多种车型能够共用资源运作。

中小企业系统整合和客製化的前期成本较高

许多中小企业安装两台自动导引车 (AGV) 的综合报价超过 49,000 欧元,这阻碍了其更广泛的市场渗透。虽然优化布局可以将投资回收期缩短至不到八个月,但由于企业内部专业知识有限以及对补贴计划了解不足,AGV 的普及程度并不均衡。经合组织的一项调查显示,72% 的欧洲中小企业了解数位化带来的好处,但由于缺乏技能和资金,只有 18% 的企业积极采用先进的自动化技术。

细分市场分析

自动化堆高机凭藉着与现有托盘工作流程的无缝相容性以及成熟的安全认证,预计到2024年将占据欧洲AGV市场38%的份额。牵引车和牵引车仍然是大型製造工厂的标配,而组装平台则支援汽车的准时制生产。受电子商务需求的推动,单元货载具预计将以13.2%的复合年增长率成长,并在2030年前为欧洲AGV市场规模做出更大贡献。

技术演进模糊了传统界线。凯傲(KION)的KAnIS计划展示了一款5G联网的室外堆高机与室内车队协同工作,将自动化覆盖范围扩展到了堆场区域。丰田与吉迪恩(Gideon)的合作则将堆高机传统技术与人工智慧驱动的自主移动机器人(AMR)结合,揭示了供应商如何重新定位自身,转向适应性强、用途广泛的平台。

由于雷射导引在结构化路径中展现出卓越的精度,预计到2024年,其市场份额将达到42%。视觉引导车辆正以14.6%的复合年增长率成长,它们利用SLAM和感测器融合技术,能够自主绘製复杂环境地图,并减少基础设施维修。磁力路径和雷射引导路径仍然是低温运输隧道等关键路径追踪应用场景中不可或缺的组成部分。弗劳恩霍夫IPA研究所的自由导航研究表明,混合视觉-雷射系统能够在保持毫米级精度的同时,无需固定反射器。 Innok Robotics公司将此模型扩展到户外,透过融合光达和运动追踪器来应对崎岖地形。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 欧洲都市区中履约中心如雨后春笋般出现

- 工业4.0使德国汽车工厂的弹性生产线成为可能。

- 人事费用上涨和西欧物流劳动力队伍中的比例偏低

- 欧盟绿色交易为低排放物流设备提供奖励措施

- 鹿特丹和安特卫普的港口自动化计划促进了船舶自动导引车(AGV)的普及应用。

- 欧洲地平线计画资助下一代群体导航演算法

- 市场限制

- 对于中小企业而言,系统整合和客製化的初始成本很高。

- 欧洲射频频谱碎片化导致高密度仓库网路延迟。

- CE标誌和ISO 3691-4安全认证的前置作业时间较长

- 熟练的AGV系统整合商数量有限

- 价值/供应链分析

- 监理与技术展望

- 波特五力分析

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争

- 产业价值链分析

第五章 市场规模与成长预测

- 按车辆类型

- 自动堆高机

- 拖车/牵引车/拖轮

- 单元载体

- 组装车辆

- 特殊用途/客製化

- 透过导航技术

- 雷射导

- 磁性/感应式

- 视觉指南

- 自然特征/SLAM

- 依电池类型

- 铅酸电池

- 锂离子

- 镍氢化物

- 超级电容/快速充电器

- 按操作模式

- 手动控制

- 混合/双模式

- 完全自主

- 透过使用

- 运输和配送

- 储存和搜寻

- 组装和套件

- 包装和托盘堆垛

- 按最终用户行业划分

- 车

- 饮食

- 零售与电子商务

- 电学

- 一般製造业

- 製药

- 航太/国防

- 按国家/地区

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 荷兰

- 其他欧洲地区

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- Swisslog Holding AG

- KUKA AG

- Jungheinrich AG

- Toyota Material Handling Europe AB

- Dematic(KION Group)

- SSI Schaefer AG

- Murata Machinery Ltd

- ABB Ltd

- Seegrid Corporation

- AGILOX Services GmbH

- Balyo SA

- Elettric 80 SpA

- Linde Material Handling GmbH

- STILL GmbH

- Mobile Industrial Robots(MiR)

- Fives Intralogistics SAS

- Euroimpianti SpA

- Oceaneering International(AGV Systems)

- Transbotics Corporation

- Amerden Inc.

第七章 市场机会与未来展望

The European AGV market size is valued at USD 1.69 billion in 2025 and is projected to reach USD 2.92 billion by 2030, reflecting an 11.5% CAGR.

Growth is driven by flexible manufacturing initiatives in the automotive sector, large-scale port automation programs, and sustained e-commerce expansion that demands high-throughput intralogistics. Lithium-ion powertrains, 5G-enabled fleet orchestration, and AI-based traffic management platforms are converging to raise overall equipment productivity while meeting EU decarbonization targets. Germany's automation leadership, the Netherlands' port projects, and the United Kingdom's response to acute labor shortages serve as powerful adoption catalysts, whereas fragmented RF spectrum and high integration costs still moderate deployment velocity.

Europe Automated Guided Vehicle (AGV) Market Trends and Insights

E-commerce fulfilment centres' surge across urban Europe

Rapid growth in urban fulfilment hubs is resetting AGV design priorities toward compact footprints and 24/7 availability. REWE Group's EUR 250 million logistics hub in Magdeburg automates 50% of intralogistics and handles 286,000 packages per day, proving the scale advantages of AGV-centric layouts. Specialty retailers follow suit; Dr. Max's new Italian warehouse uses mobile robots to sustain 55% online-sales growth. Combined with stabilizing logistics-real-estate vacancies, retailers now negotiate for automation-ready space that supports rapid AGV charging infrastructure.

Industry 4.0-enabled flexible manufacturing lines in German automotive plants

German automakers are dismantling rigid conveyor lines in favor of matrix production orchestrated by AGV fleets. Mercedes-Benz's body-in-white operations run nearly 100 KUKA vehicles that autonomously synchronize component flows in real time. BMW's factory implementations rely on AI fleet control software to adapt transport routes to model-mix changes without downtime. Purpose-built paint-shop AGVs such as Durr's EcoProFleet expand the concept to finishing lines, allowing multiple vehicle types to run on shared resources.

High up-front system integration & customisation costs for SMEs

Many SMEs confront integration quotations exceeding EUR 49,000 for a modest two-AGV installation, stalling broader market penetration. Although payback can arrive within eight months in optimized layouts, limited in-house expertise and low awareness of subsidy programs leave uptake uneven. OECD surveys show 72% of European SMEs understand digital benefits, yet only 18% actively deploy advanced automation due to skills and funding gaps.

Other drivers and restraints analyzed in the detailed report include:

- Labour-cost inflation & demographic shortages in Western Europe's logistics workforce

- EU Green Deal incentives for low-emission intralogistics equipment

- Fragmented European RF spectrum causing network latency in dense warehouses

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Automated forklifts captured 38% of the European AGV market share in 2024, underpinned by drop-in compatibility with existing pallet workflows and mature safety certifications. Tow tractors and tug vehicles remain staples in large manufacturing campuses, whereas assembly line platforms support just-in-time automotive sequencing. Unit-load carriers, propelled by e-commerce fulfilment needs, are forecast to grow at a 13.2% CAGR, increasing their contribution to the European AGV market size through 2030.

Technical evolution blurs legacy categories: KION's KAnIS project demonstrates 5G-linked outdoor forklifts that coordinate with indoor fleets, extending automated coverage to yard areas. Toyota's alliance with Gideon blends forklift heritage with AI-driven AMRs, revealing how suppliers reposition toward adaptable multi-purpose platforms.

Laser guidance commanded 42% share in 2024 thanks to proven precision in structured aisles. Vision-guided vehicles, growing at 14.6% CAGR, leverage SLAM and sensor fusion to self-map unpredictable environments, reducing infrastructure retrofits. Magnetic and inductive paths persist in critical path-following use cases such as cold-chain tunnels. Free-navigation research at Fraunhofer IPA shows how hybrid vision-laser stacks eliminate fixed reflectors while preserving millimetric accuracy. Innok Robotics extends this model outdoors with LiDAR plus motion-tracker fusion for rough terrain.

The European AGV Market Report is Segmented by Vehicle Type (Automated Forklift, Unit-Load Carrier, and More), Navigation Technology (Laser Guided, Magnetic/Inductive Guided, and More), Battery Type (Lead-Acid, Lithium-Ion, Nickel-Metal Hydride, and More), Mode of Operation (Manual Override, Hybrid/Dual-Mode, and More), Application, End-User Industry, and Geography. The Market Forecasts are Provided in Terms of Value (USD).

List of Companies Covered in this Report:

- Swisslog Holding AG

- KUKA AG

- Jungheinrich AG

- Toyota Material Handling Europe AB

- Dematic (KION Group)

- SSI Schaefer AG

- Murata Machinery Ltd

- ABB Ltd

- Seegrid Corporation

- AGILOX Services GmbH

- Balyo SA

- Elettric 80 SpA

- Linde Material Handling GmbH

- STILL GmbH

- Mobile Industrial Robots (MiR)

- Fives Intralogistics SAS

- Euroimpianti SpA

- Oceaneering International (AGV Systems)

- Transbotics Corporation

- Amerden Inc.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 E-commerce Fulfilment Centres Surge Across Urban Europe

- 4.2.2 Industry 4.0 Enabled Flexible Manufacturing Lines in German Automotive Plants

- 4.2.3 Labour-Cost Inflation and Demographic Shortages in Western Europes Logistics Workforce

- 4.2.4 EU Green Deal Incentives for Low-Emission Intralogistics Equipment

- 4.2.5 Port Automation Projects in Rotterdam and Antwerp Boosting Maritime AGV Adoption

- 4.2.6 Horizon Europe Funding for Next-Gen Swarm Navigation Algorithms

- 4.3 Market Restraints

- 4.3.1 High Up-front System Integration and Customisation Costs for SMEs

- 4.3.2 Fragmented European RF Spectrum Causing Network Latency in Dense Warehouses

- 4.3.3 Lengthy CE-Mark and ISO 3691-4 Safety Certification Lead-Times

- 4.3.4 Limited Availability of Skilled AGV Systems Integrators

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory and Technological Outlook

- 4.6 Porter's Five Forces Analysis

- 4.6.1 Bargaining Power of Suppliers

- 4.6.2 Bargaining Power of Buyers

- 4.6.3 Threat of New Entrants

- 4.6.4 Threat of Substitutes

- 4.6.5 Intensity of Competitive Rivalry

- 4.7 Industry Value-Chain Analysis

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Vehicle Type

- 5.1.1 Automated Forklift

- 5.1.2 Tow / Tractor / Tug

- 5.1.3 Unit-Load Carrier

- 5.1.4 Assembly Line Vehicle

- 5.1.5 Special-Purpose / Custom

- 5.2 By Navigation Technology

- 5.2.1 Laser Guided

- 5.2.2 Magnetic / Inductive Guided

- 5.2.3 Vision Guided

- 5.2.4 Natural Feature / SLAM

- 5.3 By Battery Type

- 5.3.1 Lead-acid

- 5.3.2 Lithium-ion

- 5.3.3 Nickel-Metal Hydride

- 5.3.4 Super-capacitor / Fast-Charge

- 5.4 By Mode of Operation

- 5.4.1 Manual Override

- 5.4.2 Hybrid / Dual-Mode

- 5.4.3 Fully Autonomous

- 5.5 By Application

- 5.5.1 Transportation and Distribution

- 5.5.2 Storage and Retrieval

- 5.5.3 Assembly and Kitting

- 5.5.4 Packaging and Palletising

- 5.6 By End-User Industry

- 5.6.1 Automotive

- 5.6.2 Food and Beverage

- 5.6.3 Retail and E-commerce

- 5.6.4 Electronics and Electrical

- 5.6.5 General Manufacturing

- 5.6.6 Pharmaceuticals

- 5.6.7 Aerospace and Defence

- 5.7 By Country

- 5.7.1 Germany

- 5.7.2 United Kingdom

- 5.7.3 France

- 5.7.4 Italy

- 5.7.5 Spain

- 5.7.6 Netherlands

- 5.7.7 Rest of Europe

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global Level Overview, Market Level Overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Swisslog Holding AG

- 6.4.2 KUKA AG

- 6.4.3 Jungheinrich AG

- 6.4.4 Toyota Material Handling Europe AB

- 6.4.5 Dematic (KION Group)

- 6.4.6 SSI Schaefer AG

- 6.4.7 Murata Machinery Ltd

- 6.4.8 ABB Ltd

- 6.4.9 Seegrid Corporation

- 6.4.10 AGILOX Services GmbH

- 6.4.11 Balyo SA

- 6.4.12 Elettric 80 SpA

- 6.4.13 Linde Material Handling GmbH

- 6.4.14 STILL GmbH

- 6.4.15 Mobile Industrial Robots (MiR)

- 6.4.16 Fives Intralogistics SAS

- 6.4.17 Euroimpianti SpA

- 6.4.18 Oceaneering International (AGV Systems)

- 6.4.19 Transbotics Corporation

- 6.4.20 Amerden Inc.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-Space and Unmet-Need Assessment