|

市场调查报告书

商品编码

1851404

醋酸:市场占有率分析、产业趋势、统计数据、成长预测(2025-2030)Acetic Acid - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

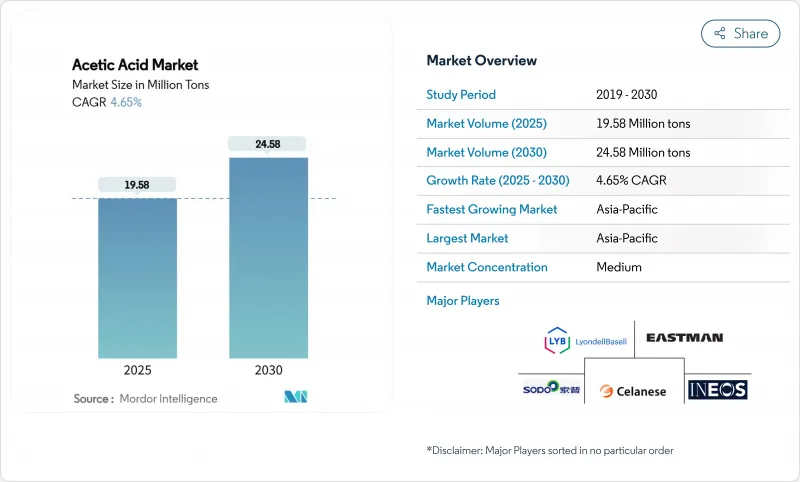

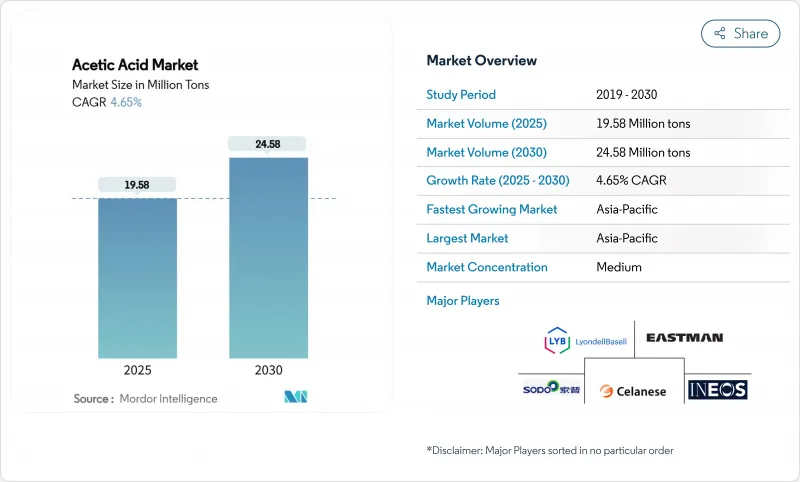

预计到 2025 年,醋酸市场规模将达到 1,958 万吨,到 2030 年将达到 2,458 万吨,在预测期(2025-2030 年)内复合年增长率为 4.65%。

对醋酸乙烯单体、高纯度对苯二甲酸和新兴电池级电解的强劲需求将支撑市场成长。规模化带来的成本效益、永续性要求以及下游一体化将提升生产商的利润率。由于聚酯、黏合剂和溶剂的消费量持续高企,亚太地区将继续占据主导地位。日益严格的监管正在加速对低碳生产技术和碳捕获计划的投资,进一步塑造市场竞争动态。

全球醋酸市场趋势与洞察

对醋酸乙烯单体的需求不断增长

水性黏合剂和被覆剂配方依赖于醋酸乙烯单体,因为它具有优异的黏合强度和柔韧性。这些特性符合日益严格的溶剂排放环保法规,尤其是在建筑和汽车製造领域。亚太地区占全球醋酸乙烯酯单体消费量的60%以上,促使企业在靠近需求中心的乙酰基产业链上进行投资。塞拉尼斯在南京新建了一套醋酸乙烯酯乙烯装置,新增产能7万吨。

精对苯二甲酸的消耗量增加

纺织品和包装用聚酯的增长带动了精对苯二甲酸产量的增加,同时乙酸仍作为溶剂和反应介质继续使用。中石化位于江苏省的年产300万吨的单套PTA装置已成为亚太地区典型的生产规模。规模较大的装置不断推高总需求,同时也提高了乙酸的利用效率。区域供应不平衡,例如印度PTA价格高企,使得弹性的供应商能够从中获得套利利润。

与羰基化反应相关的二氧化碳/挥发性有机化合物排放法规

北美和欧洲的监管机构目前正着力控制羰基化反应器和蒸馏製程的排放。美国环保署的监管指南和美国的《环境保护法》都收紧了排放标准。遵守这些法规需要投资碳捕获和先进的洗涤器,这有利于规模更大、资金更雄厚的生产商。塞拉尼斯公司对克利尔湖工厂的维修捕获了甲醇合成过程中产生的二氧化碳,为综合减排树立了标竿。

细分市场分析

2024年,醋酸乙烯单体占醋酸市占率的27.97%。聚醋酸乙烯酯和乙烯-醋酸乙烯酯共聚物将透过取代不符合新排放法规的溶剂型体系,确保市场成长。塞拉尼斯和英力士利用后向整合降低成本,服务下游产业。

精对苯二甲酸将以5.06%的复合年增长率成长,受益于聚酯在服装和瓶装树脂领域应用的扩大。乙酸乙酯在医药和涂料溶剂领域保持稳定应用,而乙酸酐儘管在香烟过滤嘴领域有所下降,但在医药乙酰化领域仍展现出韧性。衍生性商品需求模式反映了生产者在乙酰化产业链中获取价值的策略。一体化业者正将大宗乙酸转化为利润较高的下游产品,以在原物料价格波动期间保障其利润。

乙酸报告按衍生物(醋酸乙烯单体、精对苯二甲酸、乙酸乙酯等)、生产路线(甲醇羰基化、乙醛氧化等)、应用(塑料和聚合物、食品和饮料、粘合剂和涂料、纺织品、医疗等)和地区(亚太地区、北美、欧洲、南美、中东和非洲)进行细分。

区域分析

亚太地区将在2024年占据全球醋酸市场68.50%的份额,预计到2030年将以5.26%的复合年增长率成长。光是中国就控制全球约55%的醋酸产能,使其拥有规模经济优势与区域定价权。该地区庞大的聚酯和黏合剂产业也有助于在外部经济波动期间稳定需求。

儘管北美消费市场日趋成熟,但对低碳生产的投资仍十分可观。塞拉尼斯公司位于克利尔湖的130万吨级升级计画整合了碳捕获和原料保障机制,以确保其竞争力。强调减排的法规正在推动美国和加拿大的生物基计划发展,并有可能将部分进口产品转向国内供应。

在欧洲,循环经济原则和严格的生命週期评估被优先考虑。经认证的低碳足迹製造商将成为汽车和包装客户的首选供应商。中东和非洲新兴的生产能力旨在利用具有竞争力的原料成本,但基础设施和法律规范仍在发展中。拉丁美洲的醋酸市场正稳定成长,其应用领域涵盖聚酯瓶树脂和食品防腐剂,但与亚太地区的产量相比,规模有限。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 对醋酸乙烯单体(VAM)的需求不断增长

- 精对苯二甲酸(PTA)消费量增加

- 高固态涂料中醋酸盐和酯类溶剂的应用扩展

- 在净零生物基乙酸强制令下的介绍

- 锂离子电池电解液添加剂的新应用

- 市场限制

- 波动性甲醇原料价格

- 与羰基化反应相关的二氧化碳/挥发性排放法规

- 针对中国出口产品的反倾销措施

- 价值链分析

- 波特五力模型

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章 市场规模与成长预测

- 导数

- 醋酸乙烯单体(VAM)

- 精对苯二甲酸(PTA)

- 乙酸乙酯

- 乙酸酐

- 其他衍生性商品

- 透过生产路线

- 甲醇羰基化

- 乙醛氧化

- 环氧乙烷

- 生物基发酵

- 透过使用

- 塑胶和聚合物

- 饮食

- 黏合剂、油漆、被覆剂

- 纺织品

- 医疗保健

- 其他用途

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 亚太其他地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 义大利

- 法国

- 其他欧洲地区

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率(%)/排名分析

- 公司简介

- Celanese Corporation

- Daicel Corporation

- Eastman Chemical Company

- Gujarat Narmada Valley Fertilizers & Chemicals Limited

- INEOS

- Jiangsu SOPO(Group)Co., Ltd.

- Kingboard Holdings Ltd.

- LyondellBasell Industries Holdings BV

- Mitsubishi Chemical Group Corporation

- PetroChina Company Limited

- SABIC

- Sekab

- Shandong Hualu Hengsheng Group Co., Ltd.

- Shanghai Huayi Fine Chemical Co., Ltd

- Sipchem Company

- Tanfac Industries Ltd

- Wacker Chemie AG

- Yankuang Energy Group Company Limited

第七章 市场机会与未来展望

The Acetic Acid Market size is estimated at 19.58 Million tons in 2025, and is expected to reach 24.58 Million tons by 2030, at a CAGR of 4.65% during the forecast period (2025-2030).

Robust demand across vinyl acetate monomer, purified terephthalic acid, and emerging battery-grade electrolytes anchors growth. Scale-based cost efficiency, rising sustainability mandates, and downstream integration strengthen producer margins. Asia-Pacific dominance persists as polyester, adhesive, and solvent consumption remains high. Investment in low-carbon production technologies and carbon-capture projects is accelerating as regulatory scrutiny tightens, further shaping competitive dynamics in the acetic acid market.

Global Acetic Acid Market Trends and Insights

Increasing Demand for Vinyl Acetate Monomer

Water-based adhesive and coating formulations rely on vinyl acetate monomer for superior bonding strength and flexibility. These attributes meet stricter environmental rules on solvent emissions, especially in construction and automotive production. Asia-Pacific accounts for more than 60% of global VAM consumption, encouraging integrated acetyl chain investments near demand hubs. Celanese started a new vinyl acetate ethylene unit in Nanjing that adds 70,000 tons of capacity, illustrating the proximity advantage.

Rising Consumption of Purified Terephthalic Acid

Polyester growth in textiles and packaging drives higher purified terephthalic acid volumes, sustaining acetic acid usage as solvent and reaction medium. Sinopec's single-train PTA plant in Jiangsu, with 3 million tons annual capacity, shows the scale now typical in Asia-Pacific production. Larger units improve acetic acid utilization efficiency yet keep total demand rising. Regional supply imbalances, such as India's premium PTA pricing, allow flexible suppliers to capture arbitrage gains.

Carbonylation-Related CO2/VOC Emission Regulations

North American and European regulators now target emissions from carbonylation reactors and distillation steps. The EPA's control guidelines and Canada's Environmental Protection Act both tighten emission thresholds. Compliance requires investments in carbon capture and advanced scrubbers, favoring larger producers with available capital. Celanese's Clear Lake retrofit captures CO2 for methanol synthesis, setting a benchmark for integrated abatement.

Other drivers and restraints analyzed in the detailed report include:

- Expansion of Acetate-Ester Solvents in High-Solids Coatings

- Emerging Use in Li-Ion Battery Electrolyte Additives

- Anti-Dumping Actions Against Chinese Exports

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Vinyl acetate monomer held 27.97% acetic acid market share in 2024 as construction and automotive sectors favored water-based adhesives. Polyvinyl acetate and ethylene-vinyl acetate copolymers secure growth by replacing solvent-borne systems that fail new emission norms. Celanese and INEOS leverage backward integration to keep costs low and service captive downstream units.

Purified terephthalic acid, growing at a 5.06% CAGR, benefits from polyester expansion in apparel and bottle resin. Ethyl acetate maintains steady use in pharmaceutical and coating solvents, while acetic anhydride demonstrates resilience in pharmaceutical acetylation despite cigarette filter decline. Derivative demand patterns reflect producer strategies that capture value along the acetyl chain. Integrated operators convert commodity acetic acid volumes into higher-margin downstream products, protecting earnings during feedstock price swings.

The Acetic Acid Report is Segmented by Derivative (Vinyl Acetate Monomer, Purified Terephthalic Acid, Ethyl Acetate, and More), Production Route (Methanol Carbonylation, Acetaldehyde Oxidation, and More), Application (Plastics and Polymers, Food and Beverage, Adhesives Paints and Coatings, Textile, Medical, and Other Applications), and Geography (Asia-Pacific, North America, Europe, South America, and Middle-East and Africa).

Geography Analysis

Asia-Pacific dominated with 68.50% acetic acid market share in 2024 and is forecast to grow at 5.26% CAGR through 2030. China alone controls about 55% of global capacity, granting scale economies and regional pricing influence. The region's large polyester and adhesive industries stabilize volume demand even during external economic swings.

North America exhibits mature consumption yet notable investment in low-carbon production. Celanese's 1.3 million ton Clear Lake upgrade integrates carbon capture and feedstock security to ensure competitiveness. Regulatory focus on emission reduction promotes bio-based projects across the United States and Canada, potentially shifting a portion of import volumes to domestic supply.

Europe prioritizes circular economy principles and stringent lifecycle assessments. Producers with verified low-carbon footprints gain procurement preference among automotive and packaging customers. Emerging Middle East and Africa capacity aims to leverage competitive feedstock costs, yet infrastructure and regulatory frameworks remain in development. Latin America experiences steady acetic acid market growth tied to polyester bottle resin and food preservative applications, but scale is limited compared with Asia-Pacific production.

- Celanese Corporation

- Daicel Corporation

- Eastman Chemical Company

- Gujarat Narmada Valley Fertilizers & Chemicals Limited

- INEOS

- Jiangsu SOPO (Group) Co., Ltd.

- Kingboard Holdings Ltd.

- LyondellBasell Industries Holdings B.V.

- Mitsubishi Chemical Group Corporation

- PetroChina Company Limited

- SABIC

- Sekab

- Shandong Hualu Hengsheng Group Co., Ltd.

- Shanghai Huayi Fine Chemical Co., Ltd

- Sipchem Company

- Tanfac Industries Ltd

- Wacker Chemie AG

- Yankuang Energy Group Company Limited

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Increasing Demand for Vinyl Acetate Monomer (VAM)

- 4.2.2 Rising Consumption of Purified Terephthalic Acid (PTA)

- 4.2.3 Expansion of Acetate-Ester Solvents in High-Solids Coatings

- 4.2.4 Bio-Based Acetic Acid Adoption Under Net-Zero Mandates

- 4.2.5 Emerging Use in Li-Ion Battery Electrolyte Additives

- 4.3 Market Restraints

- 4.3.1 Volatile Methanol Feedstock Pricing

- 4.3.2 Carbonylation-Related CO2/VOC Emission Regulations

- 4.3.3 Anti-Dumping Actions Against Chinese Exports

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Volume)

- 5.1 By Derivative

- 5.1.1 Vinyl Acetate Monomer (VAM)

- 5.1.2 Purified Terephthalic Acid (PTA)

- 5.1.3 Ethyl Acetate

- 5.1.4 Acetic Anhydride

- 5.1.5 Other Derivatives

- 5.2 By Production Route

- 5.2.1 Methanol Carbonylation

- 5.2.2 Acetaldehyde Oxidation

- 5.2.3 Ethylene Oxidation

- 5.2.4 Bio-based Fermentation

- 5.3 By Application

- 5.3.1 Plastics and Polymers

- 5.3.2 Food and Beverage

- 5.3.3 Adhesives, Paints and Coatings

- 5.3.4 Textile

- 5.3.5 Medical

- 5.3.6 Other Applications

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 Italy

- 5.4.3.4 France

- 5.4.3.5 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle-East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle-East and Africa

- 5.4.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%)/ Ranking Analysis

- 6.4 Company Profiles (includes Global Overview, Market Overview, Core Segments, Financials, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 Celanese Corporation

- 6.4.2 Daicel Corporation

- 6.4.3 Eastman Chemical Company

- 6.4.4 Gujarat Narmada Valley Fertilizers & Chemicals Limited

- 6.4.5 INEOS

- 6.4.6 Jiangsu SOPO (Group) Co., Ltd.

- 6.4.7 Kingboard Holdings Ltd.

- 6.4.8 LyondellBasell Industries Holdings B.V.

- 6.4.9 Mitsubishi Chemical Group Corporation

- 6.4.10 PetroChina Company Limited

- 6.4.11 SABIC

- 6.4.12 Sekab

- 6.4.13 Shandong Hualu Hengsheng Group Co., Ltd.

- 6.4.14 Shanghai Huayi Fine Chemical Co., Ltd

- 6.4.15 Sipchem Company

- 6.4.16 Tanfac Industries Ltd

- 6.4.17 Wacker Chemie AG

- 6.4.18 Yankuang Energy Group Company Limited

7 Market Opportunities and Future Outlook

- 7.1 White-space and unmet-need assessment