|

市场调查报告书

商品编码

1851457

汽车轮胎:市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)Automotive Tires - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

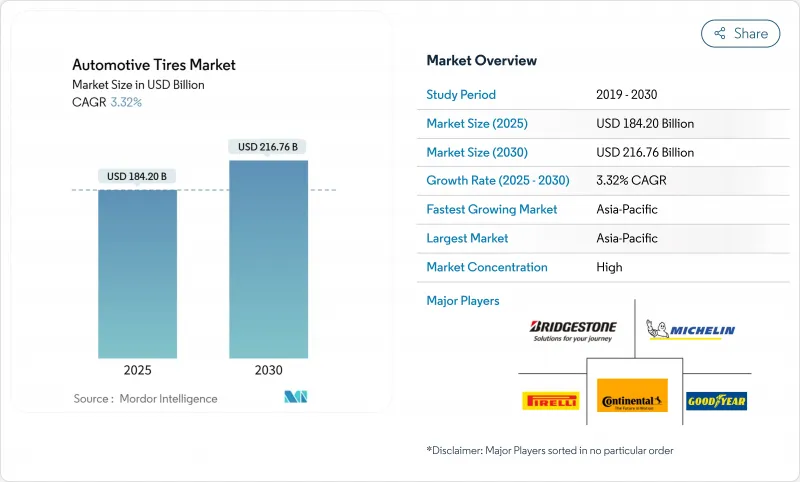

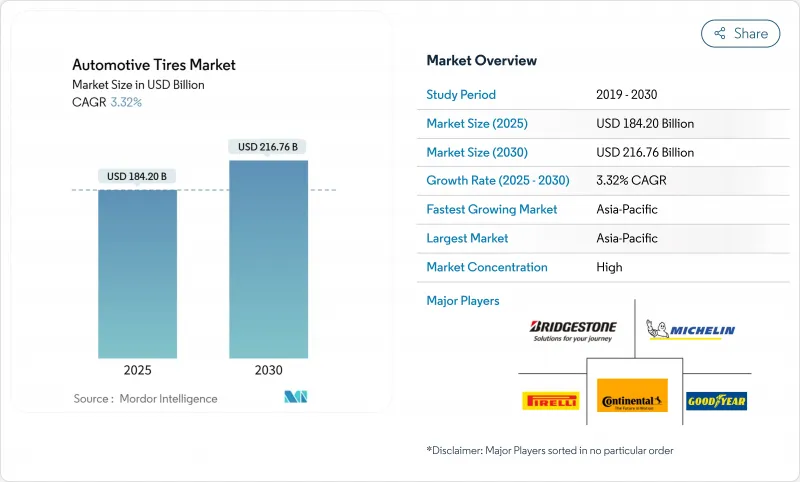

预计到 2025 年,汽车轮胎市场规模将达到 1,842 亿美元,到 2030 年将达到 2,167.6 亿美元,年复合成长率为 3.32%。

电动车的兴起推动了对超低噪音和低滚动阻力产品的需求,永续性政策促进了国内合成橡胶投资,而消费者对更大尺寸轮毂的偏好则推高了平均售价。北美和欧洲在互联性和高性能轮胎领域不断创新,而亚洲凭藉其深厚的製造实力和不断增长的汽车保有量,将继续保持其地理优势。东南亚橡胶叶病和欧洲炭黑物流带来的供应压力凸显了供应链韧性的重要性。然而,随着车队现代化和数据驱动的智慧轮胎合约开闢新的收入来源,整体汽车轮胎市场仍在持续扩张。

全球汽车轮胎市场趋势与洞察

电气化带来了对超低噪音轮胎的需求

电动动力系统消除了遮罩噪音,使轮胎与路面的相互作用成为声学设计的重中之重。欧盟日益严格的外部噪音法规进一步强化了这一趋势,主流汽车轮胎市场也要求采用类似的技术以满足合规性和舒适性要求。供应商能够在原物料成本上涨的情况下,满足性能和法规要求,确保获得梦寐以求的原厂配套标准,并保持价格稳定。

中国强制使用低滚动阻力轮胎

第六阶段燃油经济法规要求消费量降低15%,滚动阻力问题特别突出。国内外品牌纷纷推出富含二氧化硅的轮胎配方,可将研发週期缩短至18个月,并将燃油经济性提升8%。透过中国认证所取得的成果可以迅速推广至整个亚洲的生产,从而在不重复研发成本的情况下,提升整个汽车轮胎市场的基准技术水准。

橡胶叶病对东南亚的影响

印尼的橡胶树害虫(Pestalotiopsis)导致橡胶乳胶产量下降,天然橡胶现货价格较去年同期上涨33%,全球轮胎工厂的利润空间也因此受到挤压。由于受害橡胶树需要10年才能达到割胶成熟期,因此恢復过程将会十分缓慢。种植者正转向种植银胶菊和俄罗斯蒲公英等本地品种,但距离商业性规模种植仍需数个种植季,中期内成本压力仍将持续。

细分市场分析

到2024年,全季轮胎将继续保持在汽车轮胎市场的领先地位,市占率将达到62.28%。儘管冬季轮胎尺寸较小,但由于欧洲安全法规的实施,其市场需求预计将会成长,并在2025年至2030年间以4.24%的复合年增长率成为成长最快的轮胎类型。夏季轮胎在气温持续较高的地区仍然很受欢迎,而全地形/泥地轮胎则更受注重越野性能的SUV车主青睐。目前,製造商正在将高硅配方与自我调整胎纹相结合,使一种胎面即可应对高温和轻度积雪路面,从而降低经销商的库存管理难度。

研发投入也正着力满足电动车的需求。高端冬季轮胎产品对电动车买家越来越有吸引力,因为发泡衬垫可以降低车厢噪音,橡胶化学品在零下温度下仍能保持柔韧性。越来越多的车队开始为送货车指定三峰雪花认证,这表明相关法规的范围正在扩大。同时,数据主导的轮胎换位服务正在延长轮胎寿命,并将收入转向增值冬季更换套餐。这些相互关联的趋势正在推动季节性产品线的发展,使其不再局限于简单的温度范围。

到2024年,子午线轮胎将占据汽车轮胎市场86.24%的份额,这主要得益于其燃油效率高、操控稳定和胎面寿命长等优势。斜交轮胎在低速、高负荷应用领域仍占有一席之地,但其影响力逐渐缩小。最具颠覆性的发展是无气轮胎领域,预计到2030年,该领域将以每年5.67%的速度增长,因为工程车辆、军用车辆和场地维护车辆对防刺穿轮胎的需求运作。热塑性辐条和复合材料胎体正在缩小与传统子午线轮胎在滚动阻力方面的差距。

试点计画表明,考虑到补胎和停机时间,无气轮胎在整个生命週期内可节省成本,这促使原始设备製造商(OEM)在下一个开发週期中对乘用车进行测试。子午线轮胎供应商则透过增强轮胎边缘填充物和采用轻薄钢丝带束层来减轻重量而不牺牲强度,旨在随着电动车整备质量的增加而保护市场份额。可回收性法规进一步推动了人们对单一材料、无气轮胎设计的兴趣,因为这种设计简化了报废处理流程。最终呈现的是一种双管齐下的创新竞赛,而非完全的替代方案。

到2024年,乘用车将占汽车轮胎总销量的57.18%,巩固其作为汽车轮胎市场核心的主导地位。 SUV和跨界车的持续成长正推动轮胎製造商研发更高载重指数和更大直径的轮胎。专为纯电动车设计的轮胎市场表现尤为突出,随着全球电动车註册量的激增,预计其复合年增长率将达到10.92%。电池品质的增加和瞬时扭力的提升将推动对更坚固的胎体、富含二氧化硅的胎面以及隔音减震器的需求。

在早期平台工程阶段,高端汽车製造商越来越多地与合作伙伴共同开发客製化的纯电动车轮胎,并融入品牌专属尺寸以确保替换需求。在更换通路,续航里程优化行销正说服注重成本的消费者接受15%至30%的溢价,以换取每次充电行驶里程的增加。同时,轻型商用车的电气化催生了用于宅配。

区域分析

到2024年,亚洲将占全球汽车轮胎市场份额的54.66%,并在2030年之前保持最高的复合年增长率(CAGR),达到6.51%。中国凭藉其庞大的整车製造商(OEM)群体将继续保持区域主导地位,而印度SUV市场的蓬勃发展正在推动对18-20英寸轮胎和高端进口轮胎的需求。东南亚橡胶叶病导致天然橡胶供应受限,促使企业转向合成橡胶和银胶菊等替代作物。

北美位居第二,这得益于成熟的替换轮胎市场以及商用车智慧轮胎平台的快速普及。美国关係法案(IRA)促进了国内合成橡胶产能的提升,从而降低了供应链风险;电动车的普及也推动了以续航里程和降噪为重点的特种轮胎产品线的发展。

欧洲持续优先发展优质、永续产品。 2024年的标籤改革将引导消费者选择高等级替代品,并奖励那些拥有丰富科技产品的品牌。然而,炭黑的物流挑战导致前置作业时间延长、库存成本上升,促使人们关注再生炭黑,并加强与供应商的合作。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场驱动因素

- 欧盟乘用车电气化主导了对超低噪音轮胎的需求。

- 为符合中国第六阶段燃油标准,强制使用低迴油轮胎

- 北美最后一公里配送车队的物联网智慧轮胎合约

- 美国IRA相关合成橡胶产能将提升当地供应稳定性。

- 印度SUV车型18吋超大轮毂的流行推高了每辆车的平均售价。

- 欧盟2024年轮胎标籤改革将提升A级更换需求。

- 市场限制

- 东南亚橡胶叶病导致原料成本上涨

- 电动车整备品质过高会引发保固索赔

- 欧洲炭黑运输瓶颈

- 美国禁止在织布机上使用含氟脱模剂

- 价值/供应链分析

- 监管和技术展望

- 波特五力模型

- 新进入者的威胁

- 买方/消费者的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争

第五章 市场规模及成长预测(价值及数量)

- 按轮胎类型

- 夏天

- 冬天

- 四季

- 全地形/泥地

- 透过轮胎设计

- 径向

- 偏见

- 非气动/无气式

- 按车辆类型

- 搭乘用车

- SUV 与跨界车

- 轻型商用车

- 大型商用卡车和巴士

- 摩托车

- 非公路及特殊车辆(OTR、农业、矿业、赛车)

- 透过使用

- 公路

- 非公路用途(建筑、矿业、农业)

- 最终用户

- OEM

- 售后市场(替换件和翻新件)

- 按轮圈尺寸

- 15吋或更小

- 15到20英寸

- 20吋或以上

- 透过推进力

- 内燃机汽车

- 电池电动车

- 混合动力汽车和燃料电池汽车

- 地区

- 北美洲

- 美国

- 加拿大

- 北美其他地区

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 其他欧洲地区

- 亚太地区

- 中国

- 日本

- 印度

- 韩国

- 亚太其他地区

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中东

- GCC

- 土耳其

- 其他中东地区

- 非洲

- 南非

- 奈及利亚

- 其他非洲地区

- 北美洲

第六章 竞争情势

- 策略趋势

- 市占率分析

- 公司简介

- Bridgestone Corporation

- Michelin Group

- Goodyear Tire & Rubber Company

- Continental AG

- Pirelli & C. SpA

- Hankook Tire & Technology

- Yokohama Rubber Co., Ltd.

- Sumitomo Rubber Industries

- MRF Ltd.

- Apollo Tyres

- JK Tyre & Industries

- Kumho Tire

- Toyo Tire Corporation

- Nexen Tire

- Zhongce Rubber Group

- Linglong Tire

- CEAT Ltd.

- Sailun Group

- Nokian Tyres

- Triangle Tire

第七章 市场机会与未来展望

The Automotive Tire Market stands at USD 184.20 billion in 2025 and is forecast to reach USD 216.76 billion by 2030, expanding at a 3.32% CAGR.

Multiple dynamics shape this trajectory: electric-vehicle adoption raises demand for ultra-low-noise and low-rolling-resistance products; sustainability policies encourage domestic synthetic-rubber investment; and consumer preference for larger rim diameters lifts average selling prices. Asia's manufacturing depth and rising vehicle ownership keep it the geographic anchor, while North America and Europe innovate around connectivity and premium performance. Supply-side pressures from Southeast-Asian rubber-leaf disease and European carbon-black logistics highlight the need for supply-chain resilience. Yet, the overall automotive tire market continues to expand as fleets modernize and data-rich smart-tire contracts unlock new revenue streams.

Global Automotive Tires Market Trends and Insights

Electrification-Led Demand for Ultra-Low-Noise Tires

Electric drivetrains remove engine masking noise, placing tire-road interaction at the acoustic forefront. Premium EV makers pay more premiums for noise-canceling foam products and tuned tread patterns that cut in-cabin decibels by up to 20%.The European Union's stricter exterior-noise limits reinforce this trend, and the automotive tire market now sees mainstream segments requesting similar technology for compliance and comfort. Suppliers can meet performance and regulation, secure coveted OE fitments, and maintain price discipline despite higher raw-material costs.

Mandatory low-RRR Rire Adoption in China

Phase-6 fuel-efficiency rules mandate a 15% consumption improvement, spotlighting rolling resistance. Domestic and global brands are compressing R&D cycles to 18 months to deliver silica-rich compounds capable of 8% fuel-economy gains. Gains achieved for Chinese homologation rapidly cascade into broader Asian production, elevating baseline technology across the automotive tire market without duplicative R&D spend.

Southeast-Asian Rubber-Leaf Disease Impact

Pestalotiopsis infestation has cut latex yields in Indonesia, pushing natural-rubber spot prices up 33% year-on-year and squeezing margins for tire plants worldwide. Recovery is slow because affected trees need up to 10 years to reach tapping maturity. Producers diversify toward guayule and Russian dandelion sources, yet commercial scale remains several seasons away, sustaining cost pressure through the medium term.

Other drivers and restraints analyzed in the detailed report include:

- 18-inch-plus Rim Boom in Indian SUVs

- EU-2024 Tire-Label Revamp

- Excess EV Curb-Weight Accelerating Warranty Claims

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

All-season products maintained leadership in 2024 with 62.28% of the automotive tire market share, helped by their year-round convenience in varied climates. Winter tires, although smaller, are projected to post the fastest 4.24% CAGR between 2025 and 2030 as safety mandates in Europe widen adoption. Summer lines remain popular in regions with consistently high temperatures, while all-terrain/mud-terrain patterns capture SUV owners who value off-road capability. Manufacturers now blend high-silica compounds with adaptive sipes so a single tread can tolerate both heat and light snow, lowering inventory complexity for dealers.

R&D spending also targets electric-vehicle needs: foam inserts reduce cabin noise and rubber chemistries hold flexibility below freezing, making premium winter SKUs attractive to EV buyers. More fleets specify three-peak-mountain-snowflake certification on delivery vans, underscoring growing regulatory reach. Meanwhile, data-driven tire rotation services lengthen tread life, shifting revenue toward value-added winter-changeover packages. These interplay trends ensure seasonal lines evolve well beyond simple temperature bands.

Radial construction captured 86.24% of the automotive tire market share in 2024, due to fuel efficiency, stable handling, and long tread life. Bias ply endures in low-speed, heavy-load niches, yet its influence keeps shrinking. The most disruptive advance is the non-pneumatic/airless segment, which is forecast to grow 5.67% annually through 2030 as construction, military, and grounds-maintenance fleets seek puncture-proof uptime. Thermoplastic spokes and composite webs are narrowing the rolling-resistance gap with conventional radials.

Pilot programs show airless tires delivering lifecycle cost savings once puncture repairs and downtime are factored in, persuading OEMs to schedule passenger-car trials in the next development cycle. Radial suppliers answer with reinforced bead fillers and slimmer steel belts that trim mass without sacrificing strength, aiming to defend share while EV curb weights climb. Regulations on recyclability further elevate interest in single-material airless designs that simplify end-of-life processing. The outcome is a two-track innovation race rather than an outright substitution.

Passenger cars accounted for 57.18% of the 2024 volume, cementing their place at the core of automotive tire market size. SUVs and crossovers continue encroaching, nudging tire makers toward higher load indices and taller diameters. The standout growth story is BEV-specific tires, slated for a robust 10.92% CAGR as global electric-vehicle registrations soar. Added battery mass and instant torque drive demand for stronger casings, silica-rich treads, and acoustic dampers.

During early platform engineering, premium automakers increasingly co-develop bespoke BEV tires, embedding brand-exclusive dimensions that lock in replacement revenue. In the replacement channel, range-optimization marketing persuades cost-sensitive buyers to accept 15-30% price premiums when they can verify extra miles per charge. Meanwhile, light-commercial-vehicle electrification sparks new SKUs with reinforced sidewalls for parcel-delivery duty. This vehicle-mix evolution accelerates product complexity throughout the supply chain.

The Automotive Tire Market Report is Segmented by Tire Type (Summer, Winter, and More), Tire Design (Radial, Bias, and More), Vehicle Type (Passenger Cars and More), Application (On-Road and Off-Road), End User (OEM and Aftermarket) Rim-Size (Less Than 15 Inches and More), Propulsion (ICE, BEV, and More) and Geography. The Market Forecasts are Provided in Terms of Value (USD) and Volume (Units).

Geography Analysis

Asia held 54.66% of the automotive tire market in 2024 and sustained the highest 6.51% CAGR to 2030. China anchors regional dominance through its vast OEM base, while India's SUV boom fuels demand for 18-20-inch sizes and premium imports. Rubber-leaf disease in Southeast Asia constrains natural rubber supply, encouraging synthetic rubber diversification and alternative crops such as guayule.

North America ranks second, supported by mature replacement sales and rapid adoption of smart-tire platforms in commercial fleets. Domestic synthetic-rubber capacity fostered by the U.S. IRA reduces supply-chain risk, while rising EV penetration spurs specialized tire lines that prioritize range and noise reduction.

Europe continues to prioritize premium and sustainable products. The 2024 label overhaul guides consumers toward high-grade replacements, rewarding brands with technology-rich portfolios. Carbon-black logistics challenges, however, lengthen lead times and boost inventory costs, prompting interest in recovered carbon black and tighter supplier collaboration.

- Bridgestone Corporation

- Michelin Group

- Goodyear Tire & Rubber Company

- Continental AG

- Pirelli & C. SpA

- Hankook Tire & Technology

- Yokohama Rubber Co., Ltd.

- Sumitomo Rubber Industries

- MRF Ltd.

- Apollo Tyres

- JK Tyre & Industries

- Kumho Tire

- Toyo Tire Corporation

- Nexen Tire

- Zhongce Rubber Group

- Linglong Tire

- CEAT Ltd.

- Sailun Group

- Nokian Tyres

- Triangle Tire

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Drivers

- 4.1.1 Electrification-led demand for ultra-low-noise tires in EU passenger cars

- 4.1.2 Mandatory low-RRR tire adoption to meet China Phase-6 fuel norms

- 4.1.3 IoT-enabled smart-tire contracts in North-American last-mile fleets

- 4.1.4 On-shored synthetic-rubber capacity under U.S. IRA boosting local supply security

- 4.1.5 18-inch-plus rim boom in Indian SUVs lifting ASP per unit

- 4.1.6 EU-2024 tyre-labelling revamp pushing A-rated replacement demand

- 4.2 Market Restraints

- 4.2.1 Southeast-Asian rubber-leaf disease inflating raw-material costs

- 4.2.2 Excess EV curb-weight accelerating warranty claims

- 4.2.3 Carbon-black shipping bottlenecks in Europe

- 4.2.4 Impending US PFAS ban on fluorinated mould-release agents

- 4.3 Value / Supply-Chain Analysis

- 4.4 Regulatory or Technological Outlook

- 4.5 Porter's Five Forces

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Buyers / Consumers

- 4.5.3 Bargaining Power of Suppliers

- 4.5.4 Threat of Substitute Products

- 4.5.5 Intensity of Competitive Rivalry

5 Market Size & Growth Forecasts (Value & Volume)

- 5.1 By Tire Type

- 5.1.1 Summer

- 5.1.2 Winter

- 5.1.3 All-Season

- 5.1.4 All-Terrain / Mud-Terrain

- 5.2 By Tire Design

- 5.2.1 Radial

- 5.2.2 Bias

- 5.2.3 Non-pneumatic / Airless

- 5.3 By Vehicle Type

- 5.3.1 Passenger Cars

- 5.3.2 SUVs & Crossovers

- 5.3.3 Light Commercial Vehicles

- 5.3.4 Heavy Commercial Trucks & Buses

- 5.3.5 Two-Wheelers

- 5.3.6 Off-the-Road & Specialty (OTR, Agriculture, Mining, Racing)

- 5.4 By Application

- 5.4.1 On-Road

- 5.4.2 Off-Road (Construction, Mining, Agriculture)

- 5.5 By End User

- 5.5.1 OEM

- 5.5.2 Aftermarket (Replacement & Retread)

- 5.6 By Rim Size

- 5.6.1 Below 15 inches

- 5.6.2 15 - 20 inches

- 5.6.3 Above 20 inches

- 5.7 By Propulsion

- 5.7.1 Internal-Combustion Vehicles

- 5.7.2 Battery-Electric Vehicles

- 5.7.3 Hybrid & Fuel-Cell Vehicles

- 5.8 Geography

- 5.8.1 North America

- 5.8.1.1 United States

- 5.8.1.2 Canada

- 5.8.1.3 Rest of North America

- 5.8.2 Europe

- 5.8.2.1 Germany

- 5.8.2.2 United Kingdom

- 5.8.2.3 France

- 5.8.2.4 Italy

- 5.8.2.5 Rest of Europe

- 5.8.3 Asia-pacific

- 5.8.3.1 China

- 5.8.3.2 Japan

- 5.8.3.3 India

- 5.8.3.4 South Korea

- 5.8.3.5 Rest of Asia-Pacific

- 5.8.4 South America

- 5.8.4.1 Brazil

- 5.8.4.2 Argentina

- 5.8.4.3 Rest of South America

- 5.8.5 Middle East

- 5.8.5.1 GCC

- 5.8.5.2 Turkey

- 5.8.5.3 Rest of Middle East

- 5.8.6 Africa

- 5.8.6.1 South Africa

- 5.8.6.2 Nigeria

- 5.8.6.3 Rest of Africa

- 5.8.1 North America

6 Competitive Landscape

- 6.1 Strategic Moves

- 6.2 Market Share Analysis

- 6.3 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank / Share for key companies, Products & Services, and Recent Developments)

- 6.3.1 Bridgestone Corporation

- 6.3.2 Michelin Group

- 6.3.3 Goodyear Tire & Rubber Company

- 6.3.4 Continental AG

- 6.3.5 Pirelli & C. SpA

- 6.3.6 Hankook Tire & Technology

- 6.3.7 Yokohama Rubber Co., Ltd.

- 6.3.8 Sumitomo Rubber Industries

- 6.3.9 MRF Ltd.

- 6.3.10 Apollo Tyres

- 6.3.11 JK Tyre & Industries

- 6.3.12 Kumho Tire

- 6.3.13 Toyo Tire Corporation

- 6.3.14 Nexen Tire

- 6.3.15 Zhongce Rubber Group

- 6.3.16 Linglong Tire

- 6.3.17 CEAT Ltd.

- 6.3.18 Sailun Group

- 6.3.19 Nokian Tyres

- 6.3.20 Triangle Tire

7 Market Opportunities & Future Outlook

- 7.1 White-space & Unmet-Need Assessment