|

市场调查报告书

商品编码

1851483

生物分解性塑胶包装:市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)Biodegradable Plastic Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

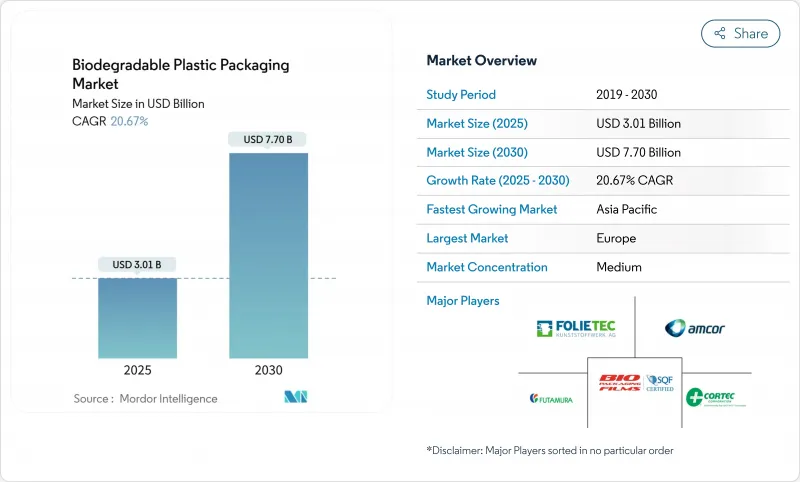

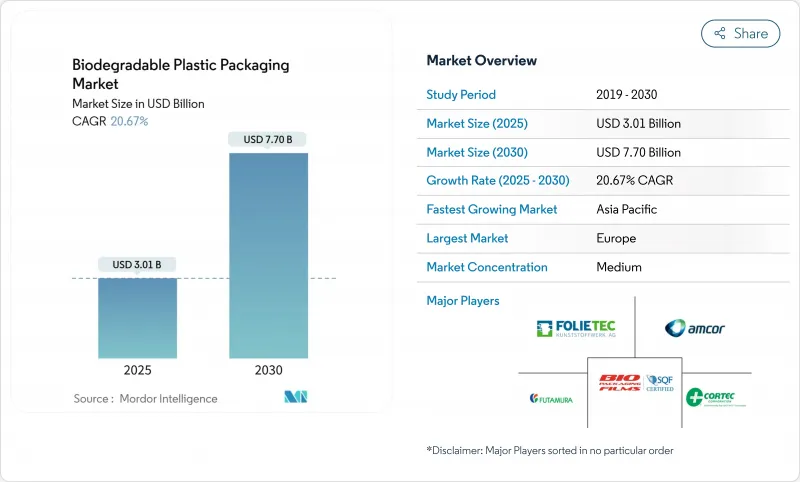

预计到 2025 年,生物分解性塑胶包装市场规模将达到 30.1 亿美元,到 2030 年将达到 77 亿美元,年复合成长率为 20.67%。

这一强劲的成长势头反映了监管要求、企业碳定价政策以及生物树脂加工技术的快速发展,所有这些因素都在提升可堆肥包装的经济效益。品牌所有者现在更倾向于采用全球通用的包装规范而非区域性规范,从而能够签订大批量合同,降低单位成本。海洋可降解的PHA和耐热的PBAT如今均能满足严格的阻隔性和耐温性要求。同时,市政废弃物减量目标正推动食品配送和零售业采用经认证的可堆肥解决方案,为树脂供应商创造了可预测的市场需求。因此,生物分解性塑胶包装市场拥有清晰的市场需求,有效抵消了农业原料价格波动带来的影响。

全球生物分解性塑胶包装市场趋势及洞察

欧盟和印度加速禁止使用一次性石油基塑胶包装

欧盟2024年一次性塑胶指令立即提振了对经认证的可堆肥食品接触包装的需求,取代了刀叉餐具和泡壳等难以回收的物品。印度的全邦禁令使超过18亿消费者面临同样的转变,迫使跨国公司在全球统一规范,并为树脂工厂释放规模经济效益。对生物基材料的惩罚性措施超过了溢价,进一步加速了其应用。澳洲2024年的禁令强化了政策的连锁效应,使生产者能更了解产量。

北美地区要求使用可堆肥包装的食品宅配应用程式的兴起

大型外送平台正强制要求大都会圈的高檔餐厅使用可堆肥的碗、杯子和刀叉餐具,此举符合市政垃圾回收目标以及2024年消费者偏好追踪数据。由于宅配结构掩盖了材料成本的额外支出,业者更关注品牌知名度和掩埋费的节省。连锁初步试验报告称,处理成本降低了15-20%,更容易遵守市政法规。这项要求正在推广到云端厨房网络,从而推动了对灵活包装酱料和配菜的需求。

西欧以外地区的工业堆肥基础建设十分困难。

在亚太和拉丁美洲,能够完全分解生物基树脂的高温堆肥厂建设正在快速前进。然而,市政资金筹措限制和授权障碍阻碍了这些设施的运作,而私营运营商则在等待有关接收废弃物食品和包装废弃物的更明确废弃物。在产能扩大之前,由于缺乏合适的消费后废弃物处理方案,向这些地区的销售将受到限制,从而抑制生物分解性塑胶包装市场的快速扩张。

细分市场分析

按材料类型划分,生物分解性塑胶包装市场规模主要由聚乳酸(PLA)占据,预计到2024年将占市场份额的66.45%,而聚羟基烷酯)预计将以25.34%的复合年增长率增长。 PHA在海洋环境中具有生物降解能力,加上沿海地区废弃物管理法规的加强,使其成为吸管、刀叉餐具以及面向岛屿和港口城市的阻隔性包装袋的理想选择。製造商正利用PHA宽广的熔融窗口来模塑PLA难以加工的厚管瓶和个人护理用品罐。此外,美国和泰国已宣布新增使用农业残渣而非食品级糖的PLA生产线,保护PLA免受原料价格波动的影响。

在实行工业堆肥的地区,PLA 仍保持着成本竞争力,并在西欧的烘焙薄膜和热成型沙拉管领域发挥重要作用。持续的研发催生了耐高温的 Ingeo 等级产品,可承受高达 105°C 的填充温度,从而缩小了以往的性能差距。 PBAT 和 PBS 则应用于一些特定的耐热和耐化学腐蚀应用领域,而淀粉混合物则在对价格极其敏感的食品包装袋市场中占据主导地位。整体材料格局展现出从第一代成本领先向第二代性能领先转变的趋势,进一步巩固了市场格局的长期多元化发展。

到2024年,柔性包装将占据生物分解性塑胶包装市场58.77%的份额,这主要得益于轻便的包装袋、包装膜和邮寄袋,它们能最大限度地降低电商和食材自煮包配送的运输成本。在改造生产线上加工的薄膜可实现适用于生鲜食品的氧气透过率,无需二次包装即可延长保质期。高端零食品牌青睐采用透明PLA的透明窗口,以展现产品的完整性,而添加PBAT的复合材料则能提高抗穿刺性。

硬质容器市场正以23.1%的复合年增长率加速成长,主要得益于咖啡胶囊、热饮杯内衬和微波炉托盘的普及。 NatureWorks与机械供应商IMA联合推出了承包胶囊系统,从而开拓了高销售饮料市场。为了提升业绩和品牌股权,连锁餐厅正逐步从聚苯乙烯泡壳转向使用PHA内衬纤维碗,这种纤维碗可与工业堆肥机相容。硬质容器市场的快速成长表明,功能性的提升正在削弱传统优势,并推动各细分市场整体收入的成长。

生物分解性塑胶包装市场报告材料类型(淀粉混合物、聚乳酸 (PLA) 及其他)、包装类型(软包装、硬包装)、终端用户行业(食品、食品饮料、食品服务及其他)、可堆肥性(家庭可堆肥、工业可堆肥)以及地区(北美、欧洲、亚太、中东和非洲、南美)进行细分。市场预测以美元计价。

区域分析

欧洲成熟的堆肥基础设施和完善的监管体系将确保其在2024年占据35.57%的生物分解性塑胶包装市场。区域树脂生产商受益于统一的EN标准和生产者延伸责任费所带来的可预测需求,而加工商则受益于巴黎、柏林和马德里等城市蓬勃发展的食品配送平台带来的便利。政府对有机废弃物分类收集的补贴将进一步促进包装的普及,巩固欧洲在短期内的领先地位。

亚太地区将以24.65%的复合年增长率领先,印度、中国和泰国正逐步淘汰难以回收的包装。中国针对一线城市「不可降解」塑胶的强制令,到2027年将扩大范围,从购物袋扩展到外带餐盒,这将催生以木薯和稻壳为原料的社区工厂。儘管印度的各邦法规仍不累积,但累积的人口覆盖率正促使跨国速食连锁店采用可堆肥涂层技术。澳洲和纽西兰也已全面禁止使用一次性塑胶製品,这即时推动了整个大洋洲对替代品的需求。

在北美,财富500强企业正利用食品配送强制规定和内部碳定价机制来推动工业堆肥的应用,但工业堆肥在各地区的普及程度仍不均衡。拉丁美洲的特大城市,如圣保罗和墨西哥城,正在试办建造堆肥中心,为更广泛的成长奠定基础。在中东和非洲,掩埋的短缺和旅游业主导的塑胶禁令正在创造新的市场机会,尤其是在波湾合作理事会成员国的旅馆业。总体而言,各地区的政策趋势和基础设施投资模式共同决定了生物分解性塑胶包装市场的区域成长。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 欧盟和印度加速禁止使用一次性石油基塑胶包装

- 北美地区要求使用可堆肥包装的食品配送应用程式的兴起

- 零售商(例如沃尔玛、家乐福)的「塑胶中和」承诺正在推动需求成长。

- 将现有吹膜生产线改造为生物树脂生产线(资本支出 15%)

- 品牌转向在包装上使用透明碳标籤。

- 引入企业层面的碳定价(高于 70 美元/吨)将有利于生物能源方案。

- 市场限制

- 西欧以外地区工业堆肥基础设施不堪负荷

- PLA原料价格(玉米、甘蔗)波动

- 消费者对「可堆肥」和「可生物降解」的说法感到困惑

- 美国和日本对机械回收污染行为的处罚规定。

- 供应链分析

- 监理与技术展望

- 波特五力分析

- 新进入者的威胁

- 供应商的议价能力

- 买方的议价能力

- 替代品的威胁

- 竞争对手之间的竞争

- 生态系分析

- 生物降解和生物基塑胶包装的创新

- 比较分析—石油基塑胶与生物降解包装

- 生质塑胶生产现状

- 生质塑胶生产统计数据

- 按树脂类型分割的产量

- 按地区分類的产量

- 食品服务/HoReCa产业的演进趋势

- 新兴产业趋势

第五章 市场规模与成长预测

- 依材料类型

- 淀粉混合物

- 聚乳酸(PLA)

- 聚己二酸丁二醇酯-对苯二甲酸丁二醇酯(PBAT)

- 聚丁二酸丁二醇酯(PBS)

- 聚羟基烷酯(PHAs)

- 其他成分

- 按包装类型

- 软包装

- 袋子和小袋

- 薄膜和包装

- 标籤和封套

- 硬包装

- 餐具

- 托盘和碗

- 食品容器

- 咖啡杯和咖啡胶囊

- 其他硬质包装

- 软包装

- 按最终用途行业划分

- 食物

- 饮料

- 食品服务

- 个人及居家护理

- 製药

- 其他终端用户产业

- 透过堆肥

- 家用可堆肥

- 工业可堆肥

- 按地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 其他欧洲地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 澳洲和纽西兰

- 亚太其他地区

- 中东和非洲

- 中东

- 阿拉伯聯合大公国

- 沙乌地阿拉伯

- 土耳其

- 其他中东地区

- 非洲

- 南非

- 奈及利亚

- 埃及

- 其他非洲地区

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 北美洲

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- Amcor plc

- BASF SE

- NatureWorks LLC

- Tetra Pak International SA

- Sealed Air Corporation

- Kuraray Co., Ltd.

- Taghleef Industries

- FKuR Kunststoff GmbH

- good natured Products Inc.

- Pactiv Evergreen Inc.

- ALPLA Werke Alwin Lehner GmbH

- Transcontinental Inc.

- Plascon Industries

- Futamura Group

- Cortec Corporation

- BioBag International AS

- Biome Bioplastics

- Bio Packaging Films

- Bio Futura

- Groupe Barbier

- VektoPack

- Singular Solutions Inc.

- Biogreen Biotech

- Plabottles.eu(Global Solutions BV)

第七章 市场机会与未来展望

The biodegradable plastic packaging market size stands at USD 3.01 billion in 2025 and is forecast to reach USD 7.70 billion by 2030, expanding at a 20.67% CAGR.

The strong trajectory reflects simultaneous regulatory mandates, corporate carbon-pricing policies, and rapid advances in bio-resin processing that together improve economic viability for compostable formats. Brand owners now prefer global rather than regional packaging specifications, allowing large volume contracts that lower per-unit costs. Material innovation continues to cut performance gaps with conventional polymers; marine-degradable PHA and heat-resistant PBAT variants now satisfy demanding barrier and temperature requirements. In parallel, municipal waste-diversion targets push food-delivery and retail sectors to adopt certified compost-ready solutions, creating predictable offtake for resin suppliers. The biodegradable plastic packaging market therefore enjoys clear line-of-sight demand that compensates for still-volatile agricultural feedstock pricing.

Global Biodegradable Plastic Packaging Market Trends and Insights

Accelerated bans on single-use petro-plastic packaging across EU and India

The European Union's 2024 Single-Use Plastic Directive immediately raised demand for certified compostable food-contact packs, replacing difficult-to-recycle items such as cutlery and clamshells. India's statewide prohibitions expose more than 1.8 billion consumers to the same shift, forcing multinationals to harmonize global specifications and unlocking scale economies for resin plants. Penalties that exceed the premium on bio-materials further accelerate adoption. Australia's 2024 bans reinforce a cascading policy effect that sustains volume visibility for producers.

Food-delivery app proliferation requiring compost-ready formats in North America

Leading aggregators mandate that restaurants use compostable bowls, cups, and cutlery in top metropolitan areas, aligning with municipal diversion goals and consumer preference tracking recorded in 2024. Delivery fee structures hide the material premium, so operators focus on brand perception and landfill fee savings. Chain pilots report 15-20% lower disposal costs and smoother compliance with city ordinances. The requirement has spilled into cloud kitchen networks, amplifying flexible-pack demand for sauces and sides.

Tight industrial-composting infrastructure outside Western Europe

Adoption in Asia-Pacific and Latin America recently outpaced the build-out of high-temperature composting plants capable of fully degrading bio-resins, risking landfill diversion and methane release that undermine environmental claims . Municipal funding limitations and permitting hurdles delay facility commissioning, while private operators await clearer acceptance rules for mixed food and packaging waste. Until capacity expands, sales into regions without adequate end-of-life options are capped, tempering the otherwise rapid uptake of the biodegradable plastic packaging market.

Other drivers and restraints analyzed in the detailed report include:

- Retailer "plastic-neutral" pledges boosting demand

- Re-tooling of existing film-blowing lines to run bio-resins

- Feedstock price volatility for PLA

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

The biodegradable plastic packaging market size for material types remained skewed toward Polylactic Acid, which held 66.45% share in 2024, yet Polyhydroxyalkanoates posted the strongest 25.34% CAGR outlook. PHA's ability to biodegrade in marine settings satisfies growing coastal-waste legislation, making it the preferred option for straws, cutlery, and high-barrier pouches targeting island and port cities. Manufacturers exploit its broad melt-flow window to mold thicker pharmaceutical vials and personal-care jars that PLA struggles to handle. The segment also benefits from fresh capacity announcements in the United States and Thailand that leverage agricultural residues instead of food-grade sugar sources, insulating it from feedstock swings.

PLA remains cost-competitive where industrial composting exists, supporting bakery films and thermoformed salad tubs in Western Europe. Continuous R&D produced higher-heat Ingeo grades that withstand 105 °C filling temperatures, narrowing earlier performance gaps. PBAT and PBS serve niche heat-resistant or chemical-contact applications, while starch blends dominate ultra-price-sensitive grocery bag programs. The overall material landscape shows a transition from first-generation cost leadership to second-generation performance leadership, reinforcing the long-term diversification of the biodegradable plastic packaging market.

Flexible formats commanded 58.77% of the biodegradable plastic packaging market share in 2024, underpinned by light-weighted pouches, wraps, and mailers that minimize freight costs for e-commerce and meal-kit delivery. Films processed on retrofitted lines achieve oxygen transmission rates suitable for fresh produce, extending shelf life without secondary wraps. Premium snack brands emphasize transparent windows made from clarified PLA to showcase product integrity, while laminates incorporating PBAT improve puncture resistance.

Rigid formats accelerate at 23.1% CAGR on the back of coffee pods, hot-cup linings, and microwave-ready trays. NatureWorks and machine supplier IMA released a turnkey pod system that meets Keurig and Nespresso specifications and composts in 90 days, opening high-volume beverage channels. Foodservice chains shift from polystyrene clamshells to PHA-lined fiber bowls compatible with industrial composters, satisfying performance and brand-equity goals. The fast-growing rigid segment illustrates how functionality gains erode legacy dominance and broaden total addressable revenue for the biodegradable plastic packaging market.

The Biodegradable Plastic Packaging Market Report is Segmented by Material Type (Starch Blends, Polylactic Acid (PLA), and More), Packaging Type (Flexible Packaging and Rigid Packaging), End-Use Industry (Food, Beverage, Foodservice, and More), Compostability (Home-Compostable and Industrial-Compostable), and Geography (North America, Europe, Asia-Pacific, MEA, South America). Market Forecasts are Provided in Value (USD).

Geography Analysis

Europe's mature composting infrastructure and comprehensive regulatory backdrop secured 35.57% biodegradable plastic packaging market share in 2024. Regional resin producers benefit from cohesive EN standards and predictable demand created by extended-producer-responsibility fees, while converters profit from proximity to high-growth food delivery platforms now ubiquitous in Paris, Berlin, and Madrid. Government subsidies for separate organic waste collection further aid pack adoption, cementing Europe's near-term leadership.

Asia-Pacific generates the strongest 24.65% CAGR as India, China, and Thailand enforce phased bans on difficult-to-recycle packaging formats. Chinese directives targeting "non-degradable" plastics in tier-one cities escalate from carrier bags to takeaway containers by 2027, spawning localized plants using cassava and rice-husk feedstocks. India's state regulations remain fragmented, yet cumulative population coverage draws multinational quick-service restaurants to standardize compostable coating technologies. Australia and New Zealand also adopted comprehensive single-use plastic prohibitions, driving immediate substitution demand throughout Oceania.

North America leverages food-delivery mandates and internal carbon-pricing at Fortune 500 corporations to propel adoption, although regional coverage of industrial composting remains uneven. Latin American megacities such as Sao Paulo and Mexico City deploy pilot composting hubs, setting the stage for broader growth. In the Middle East and Africa, landfill scarcity and tourism-driven plastic bans create niche opportunities, especially in Gulf Cooperation Council hospitality sectors. Overall, jurisdictional policy cadence and infrastructure investment patterns explain divergent regional growth in the biodegradable plastic packaging market.

- Amcor plc

- BASF SE

- NatureWorks LLC

- Tetra Pak International S.A.

- Sealed Air Corporation

- Kuraray Co., Ltd.

- Taghleef Industries

- FKuR Kunststoff GmbH

- good natured Products Inc.

- Pactiv Evergreen Inc.

- ALPLA Werke Alwin Lehner GmbH

- Transcontinental Inc.

- Plascon Industries

- Futamura Group

- Cortec Corporation

- BioBag International AS

- Biome Bioplastics

- Bio Packaging Films

- Bio Futura

- Groupe Barbier

- VektoPack

- Singular Solutions Inc.

- Biogreen Biotech

- Plabottles.eu (Global Solutions BV)

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Accelerated bans on single-use petro-plastic packaging across EU and India

- 4.2.2 Food-delivery app proliferation requiring compost-ready formats in North America

- 4.2.3 Retailer "plastic-neutral" pledges (e.g., Walmart, Carrefour) boosting demand

- 4.2.4 Re-tooling of existing film-blowing lines to run bio-resins (CAPEX ~15%)

- 4.2.5 Brand shift to transparent carbon-labelling on packs

- 4.2.6 Corporate-level internal carbon-price adoption (>US $70/t) favouring bio-options

- 4.3 Market Restraints

- 4.3.1 Tight industrial-composting infrastructure outside Western Europe

- 4.3.2 Feed-stock price volatility for PLA (corn, sugarcane)

- 4.3.3 Consumer confusion around "compostable" vs "biodegradable" claims

- 4.3.4 Mechanical-recycling stream contamination penalties in US and Japan

- 4.4 Supply-Chain Analysis

- 4.5 Regulatory and Technological Outlook

- 4.6 Porter's Five Forces Analysis

- 4.6.1 Threat of New Entrants

- 4.6.2 Bargaining Power of Suppliers

- 4.6.3 Bargaining Power of Buyers

- 4.6.4 Threat of Substitutes

- 4.6.5 Competitive Rivalry

- 4.7 Industry Ecosystem Analysis

- 4.8 Innovations in Biodegradable and Bio-based Plastic Packaging

- 4.9 Comparative Analysis - Petro-plastic vs Biodegradable Packaging

- 4.10 Bioplastics - Production Landscape

- 4.10.1 Production Statistics for Bioplastics

- 4.10.2 Production by Resin Type

- 4.10.3 Production by Region

- 4.11 Evolving Trends in the Foodservice/HoReCa Sector

- 4.12 Emerging Industry Trends

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Material Type

- 5.1.1 Starch Blends

- 5.1.2 Polylactic Acid (PLA)

- 5.1.3 Poly(Butylene Adipate-co-Terephthalate) (PBAT)

- 5.1.4 Polybutylene Succinate (PBS)

- 5.1.5 Polyhydroxyalkanoates (PHA)

- 5.1.6 Other Material Types

- 5.2 By Packaging Type

- 5.2.1 Flexible Packaging

- 5.2.1.1 Bags and Pouches

- 5.2.1.2 Films and Wraps

- 5.2.1.3 Labels and Sleeves

- 5.2.2 Rigid Packaging

- 5.2.2.1 Tableware

- 5.2.2.2 Trays and Bowls

- 5.2.2.3 Food Containers

- 5.2.2.4 Coffee Cups and Pods

- 5.2.2.5 Other Rigid Packaging

- 5.2.1 Flexible Packaging

- 5.3 By End-use Industry

- 5.3.1 Food

- 5.3.2 Beverage

- 5.3.3 Foodservice

- 5.3.4 Personal Care and Home Care

- 5.3.5 Pharmaceutical

- 5.3.6 Other End - Use Industry

- 5.4 By Compostability

- 5.4.1 Home-Compostable

- 5.4.2 Industrial-Compostable

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 Europe

- 5.5.2.1 Germany

- 5.5.2.2 United Kingdom

- 5.5.2.3 France

- 5.5.2.4 Italy

- 5.5.2.5 Spain

- 5.5.2.6 Russia

- 5.5.2.7 Rest of Europe

- 5.5.3 Asia-Pacific

- 5.5.3.1 China

- 5.5.3.2 India

- 5.5.3.3 Japan

- 5.5.3.4 South Korea

- 5.5.3.5 Australia and New Zealand

- 5.5.3.6 Rest of Asia-Pacific

- 5.5.4 Middle East and Africa

- 5.5.4.1 Middle East

- 5.5.4.1.1 United Arab Emirates

- 5.5.4.1.2 Saudi Arabia

- 5.5.4.1.3 Turkey

- 5.5.4.1.4 Rest of Middle East

- 5.5.4.2 Africa

- 5.5.4.2.1 South Africa

- 5.5.4.2.2 Nigeria

- 5.5.4.2.3 Egypt

- 5.5.4.2.4 Rest of Africa

- 5.5.5 South America

- 5.5.5.1 Brazil

- 5.5.5.2 Argentina

- 5.5.5.3 Rest of South America

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles {(includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)}

- 6.4.1 Amcor plc

- 6.4.2 BASF SE

- 6.4.3 NatureWorks LLC

- 6.4.4 Tetra Pak International S.A.

- 6.4.5 Sealed Air Corporation

- 6.4.6 Kuraray Co., Ltd.

- 6.4.7 Taghleef Industries

- 6.4.8 FKuR Kunststoff GmbH

- 6.4.9 good natured Products Inc.

- 6.4.10 Pactiv Evergreen Inc.

- 6.4.11 ALPLA Werke Alwin Lehner GmbH

- 6.4.12 Transcontinental Inc.

- 6.4.13 Plascon Industries

- 6.4.14 Futamura Group

- 6.4.15 Cortec Corporation

- 6.4.16 BioBag International AS

- 6.4.17 Biome Bioplastics

- 6.4.18 Bio Packaging Films

- 6.4.19 Bio Futura

- 6.4.20 Groupe Barbier

- 6.4.21 VektoPack

- 6.4.22 Singular Solutions Inc.

- 6.4.23 Biogreen Biotech

- 6.4.24 Plabottles.eu (Global Solutions BV)

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-need Assessment