|

市场调查报告书

商品编码

1851490

六亚甲基二胺:市场占有率分析、产业趋势、统计数据、成长预测(2025-2030)Hexamethylenediamine - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

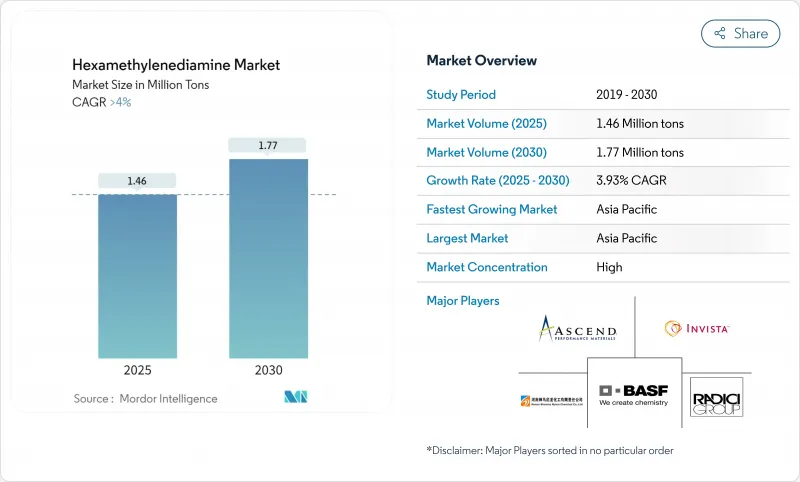

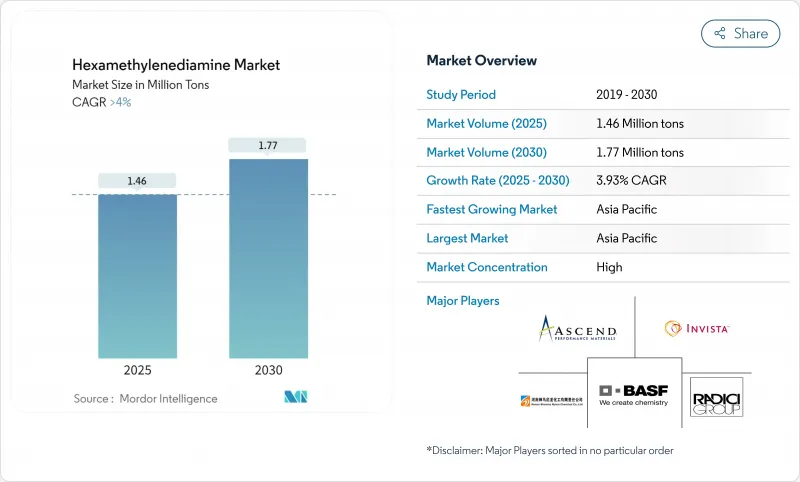

预计到 2025 年,六亚甲基二胺市场规模将达到 146 万吨,到 2030 年将达到 177 万吨,在预测期(2025-2030 年)内,复合年增长率将超过 4%。

儘管强劲的需求源自于尼龙6,6的生产,但己二腈至六亚甲基二胺产业链的产能限制正促使亚太、北美和欧洲地区进行新的投资。对轻量化汽车零件的策略性关注、疫情后技术纺织品的復苏以及环氧树脂固化剂等特种应用的稳定成长,都支撑着生产扩张。为应对近期的供应衝击,生产商加快了垂直整合步伐,并试行使用生物基原料,以期降低成本和减少排放。同时,原油价格波动导致的原料供应不稳定、REACH主导胺类物质排放的限制以及生物基路线规模化生产的风险,都对前景构成了压力。

全球六亚甲基二胺市场趋势与洞察

尼龙66在汽车轻量化零件的应用日益广泛

汽车轻量化目标正在加速尼龙6,6的应用,而下游渗透率的提升则推动了六亚甲基二胺市场的发展。汽车製造商重视聚酰胺的强度重量比、耐热性和可回收性,尤其是在电池电动车领域,因为重量直接影响续航里程。亚太地区的汽车製造商正在扩大尼龙进气歧管和结构件的使用,同时聚酰胺产能也在扩张,这增强了区域平衡,并为一体化供应商带来了回报。在北美,一级供应商正在围绕尼龙6,6重新设计引擎室零件,以适应涡轮增压带来的热负荷。因此,材料替代趋势正在推动结构性而非週期性的需求成长。

从己二腈到HMD的产能快速扩张

2024年的供应衝击暴露了对少数己二腈装置的依赖。生产商的应对措施包括消除瓶颈,并在中国、墨西哥湾沿岸和西欧等地新建生产线,以增加己二腈-己二胺的产能。英威达运作梅特兰工厂以及Ascend在阿拉巴马州扩建90吨/年产能,正是这一趋势的典型体现。虽然这波扩张缓解了原料供应紧张的局面,但也可能导致短期供应过剩和区域价格波动加剧。儘管如此,大多数业者仍然认为,为了保障下游尼龙的经济效益,并在以亚洲为中心的终端用户丛集中获得地理优势,这些资本投资是合理的。

原油衍生己二腈价格波动

由于己二腈的价格与原油和石脑油之间的价差密切相关,上游价格波动会迅速传导至己二胺合约结算,给非一体化企业带来压力。 2015年中国炼油厂事故凸显了集中风险,随后炼油厂停产加剧了现货溢价。进口量庞大的欧洲对价格波动最为敏感,增加了专业尼龙纺丝生产商的利润压力。欧元疲软推高了以美元计价的原物料价格,进一步降低了竞争力。这些因素正在推动反向一体化计划,并促使企业更加关註生物基路线,以期将成本与原油价格波动脱钩。

细分市场分析

至2024年,尼龙产量将占六亚甲基二胺市场的78.19%。该细分市场产量将达到114万吨,主要由汽车引擎室零件和地毯纤维驱动。在预测期内,该细分市场将支撑最大的绝对需求成长,但复合年增长率仅为3.68%。相较之下,环氧树脂固化剂和除生物剂中间体等特种应用将以5.05%的速度成长,使其在六亚甲基二胺市场的份额从2025年的25万吨增长到2030年的32万吨。

多元化发展至利润率更高的细分市场可降低收入受尼龙价格週期波动的影响。透过供应可配製的尼龙等级,生产商可以缩短客户认证时间并降低转换成本。这种方法也能充分利用现有的精炼生产线,使新增资本支出相对于收入维持在较低水准。因此,预计在所有地区,特种尼龙等级的采用率将继续超过基础聚合物的成长速度。

六亚甲基二胺市场报告按应用(尼龙生产、涂料中间体、除生物剂、其他应用(固化剂、润滑剂等))、终端用户行业(纺织、塑胶、汽车、其他终端用户行业(油漆和涂料、石油化工等))和地区(亚太地区、北美、欧洲、南美、中东和非洲)进行细分。

区域分析

亚太地区占据六亚甲基二胺市场52.06%的份额,反映了中国从炼油到尼龙的完整产业链以及该地区汽车和纺织业的蓬勃发展。预计该地区的需求将以4.96%的复合年增长率增长,从2025年的76万吨增长到2030年的近97万吨。各国政府正大力推动先进材料丛集建设,而邻近己二酸原料产地也缩短了供应链。例如,英威达在上海投资17.5亿元人民币,产能翻倍,这样的投资项目强化了当地的供应链,提升了竞争力。

北美市占率主要得益于页岩油原料和汽车树脂的需求。然而,与进口产品的成本竞争以及近期主要生产商的破产程序凸显了其对价格週期的脆弱性。生产商正专注于高纯度和生物基树脂的生产,以确保利润率并吸引电子和医疗设备原始设备製造商的收购。

欧洲专注于永续性和特色细分市场。BASF在法国新建的年产260公斤的工厂整合了先进的精炼技术和节能反应器,以满足日益严格的脱碳要求。法国关于胺类排放的REACH法规比其他地区更为严格,这增加了合规成本,但也为本地生产提供了价格竞争力优势。

南美洲和中东及非洲地区都在利用天然气经济的优势,扩大下游塑胶需求。巴西汽车製造业的復苏和沙乌地阿拉伯的化工多元化倡议,为该地区的HMD企业创造了机会,儘管基数较小。跨境合资企业正在开拓这些新兴市场,但政治和物流风险意味着其成长速度将低于亚太地区。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 尼龙66在轻量化汽车零件的应用日益广泛

- 从己二腈到六甲基二甲胺的快速产能积累

- 转向生物基己二腈原料

- 六亚甲基二胺基环氧固化剂的出现。

- 纺织业对六亚甲基二胺的需求不断增长

- 市场限制

- 原油衍生己二腈价格波动

- 生物基六亚甲基二胺技术的规模化风险

- REACH法规对胺类排放有严格的规定

- 价值链分析

- 波特五力模型

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章 市场规模与成长预测

- 透过使用

- 尼龙生产

- 涂料中间体

- 除生物剂

- 其他用途(硬化剂、润滑剂等)

- 按年级

- 标准工业级

- 高纯度

- 生物基级

- 按最终用途行业划分

- 车

- 纺织品

- 塑胶

- 其他终端用户产业(油漆涂料、电子产品等)

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 泰国

- 印尼

- 越南

- 马来西亚

- 菲律宾

- 亚太其他地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 北欧国家

- 土耳其

- 其他欧洲地区

- 南美洲

- 巴西

- 阿根廷

- 哥伦比亚

- 南美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 阿拉伯聯合大公国

- 卡达

- 南非

- 奈及利亚

- 埃及

- 其他中东和非洲地区

- 亚太地区

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率(%)/排名分析

- 公司简介

- Ascend Performance Materials

- BASF

- Cathay Biotech Inc.

- Dow

- DOMO Chemicals

- Evonik Industries AG

- Genomatica Inc.

- INVISTA

- Radici Partecipazioni SpA

- Solvay

- Shenma Industrial Co. Ltd

- Spectrum Chemical

- Thermo Fisher Scientific Inc.

第七章 市场机会与未来展望

The Hexamethylenediamine Market size is estimated at 1.46 million tons in 2025, and is expected to reach 1.77 million tons by 2030, at a CAGR of greater than 4% during the forecast period (2025-2030).

Demand strength is rooted in nylon 6,6 production, while capacity constraints in the adiponitrile-to-hexamethylenediamine chain are triggering fresh investment across Asia-Pacific, North America and Europe. Strategic focus on lightweight vehicle parts, the post-pandemic revival of technical textiles and the steady uptake of specialty applications such as epoxy curing agents underpin volume expansion. Producers have responded to recent supply shocks by accelerating vertical integration and by piloting bio-based feedstocks that promise lower cost and reduced emissions. At the same time, crude-linked feedstock volatility, REACH-driven amine-emission limits and scale-up risk for bio routes temper the outlook.

Global Hexamethylenediamine Market Trends and Insights

Increasing Consumption of Nylon 6,6 in Lightweight Vehicle Parts

Automotive light-weighting targets are accelerating nylon 6,6 adoption, and the downstream pull-through is boosting the hexamethylenediamine market. Vehicle makers value polyamide's strength-to-weight ratio, heat resistance and recyclability, particularly for battery-electric models where mass directly affects range. Asia-Pacific OEMs are ramping nylon intake manifold and structural-member usage alongside regional polyamide capacity additions, tightening regional balances and rewarding integrated suppliers. In North America, Tier-1 suppliers are redesigning engine-bay components around nylon 6,6 to cope with turbo-charging heat loads. The material substitution trend is therefore driving a structural, rather than merely cyclical, uplift in hexamethylenediamine demand.

Rapid Capacity Additions for Adiponitrile-to-HMD

Supply shocks in 2024 exposed reliance on a handful of adiponitrile units. Producers reacted by green-lighting de-bottlenecks and grass-roots lines that push integrated adiponitrile-hexamethylenediamine capacities higher in China, the Gulf Coast and Western Europe. INVISTA's Maitland restart and Ascend's 90 kt/y Alabama build-out epitomize the trend. While the wave will ease feedstock tightness, it also risks short-term oversupply and sharper regional price swings. Still, most operators deem the capex justified to safeguard downstream nylon economics and capture proximity advantages in Asia-centric end-use clusters.

Volatility in Crude-Derived Adiponitrile Prices

Because adiponitrile tracks crude-naphtha spreads, upstream price shifts transmit quickly to hexamethylenediamine contract settlements, squeezing unintegrated players. The 2015 China plant accident underscored concentration risk, and subsequent refinery outages kept spot premiums wide. Import-heavy Europe feels swings most acutely, amplifying margin pressure on captive nylon spinners. Currency movement adds another layer: a weak euro inflates dollar-indexed feedstocks, further eroding competitiveness. These factors spur back-integration projects and intensify interest in bio-routes that decouple cost from oil volatility.

Other drivers and restraints analyzed in the detailed report include:

- Shift Toward Bio-Based Adiponitrile Feedstocks

- Emergence of HMD-Based Epoxy Curing Agents

- Scale-Up Risk for Bio-Based HMD Technologies

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Nylon production retained a commanding 78.19% slice of the hexamethylenediamine market in 2024. The segment's volume translates to 1.14 million tons, supported by automotive under-the-hood parts and carpet fibers. This pool underpins the largest absolute demand increment over the forecast horizon, but its CAGR trails at 3.68%. In contrast, specialty uses such as epoxy curing agents and biocide intermediates are expanding at a 5.05% pace, lifting their share of the hexamethylenediamine market size from 0.25 million tons in 2025 toward 0.32 million tons in 2030.

Diversification into higher-margin niches mitigates revenue exposure to nylon price cycles. Producers supply formulation-ready grades that shorten customer qualification time, reinforcing switching costs. The approach also leverages existing purification trains, so incremental capex stays low relative to returns. As a result, specialty penetration is expected to continue outpacing base-polymer growth across all regions.

The Hexamethylenediamine Market Report is Segmented by the Application (Nylon Production, Intermediate for Coatings, Biocides, and Other Applications (Curing Agents, Lubricants, Etc. )), End-User Industry (Textile, Plastics, Automotive, and Other End-User Industries (Paints and Coatings, Petrochemicals, Etc. )), and Geography (Asia-Pacific, North America, Europe, South America, and Middle-East and Africa).

Geography Analysis

Asia-Pacific's 52.06% stake in the hexamethylenediamine market reflects China's integrated refinery-to-nylon ecosystem and the region's outsized automotive and textile sectors. Regional demand rises at a 4.96% CAGR, lifting volume from 0.76 million tons in 2025 to nearly 0.97 million tons by 2030. Governments promote advanced materials clusters, and proximity to adipic-acid feedstock shortens supply lines. Investments such as INVISTA's RMB 1.75 billion capacity doubling in Shanghai anchor the local supply chain and strengthen competitiveness.

North America's share is underpinned by shale-advantaged feedstocks and captive automotive resin demand. Yet, cost competition from imports and recent bankruptcy proceedings at a major producer underscore vulnerability to price cycles. Producers emphasize high-purity and bio-based grades to defend margins and secure offtake from electronics and medical OEMs.

Europe is focusing on sustainability and specialty niches. BASF's new 260 kt/y French plant integrates advanced purification and energy-efficient reactors that align with tightening decarbonization directives. REACH restrictions on amine emissions are stricter than other regions, raising compliance costs yet providing a non-price competitive moat for local output.

South America plus the Middle East and Africa both regions leverage competitive gas economics and expanding downstream plastics demand. Brazil's automotive-production rebound and Saudi Arabia's chemicals diversification initiatives open windows for regional HMD units, albeit from a small base. Political and logistical risk keeps growth moderate compared with Asia-Pacific, but cross-border joint ventures are positioning to tap these frontier volumes.

- Ascend Performance Materials

- BASF

- Cathay Biotech Inc.

- Dow

- DOMO Chemicals

- Evonik Industries AG

- Genomatica Inc.

- INVISTA

- Radici Partecipazioni SpA

- Solvay

- Shenma Industrial Co. Ltd

- Spectrum Chemical

- Thermo Fisher Scientific Inc.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Increasing Consumption of Nylon 6,6 in Lightweight Vehicle Parts

- 4.2.2 Rapid Capacity Additions for Adiponitrile-to-HMDA

- 4.2.3 Shift towards Bio-based Adiponitrile Feedstocks

- 4.2.4 Emergence of Hexamethylenediamine -based Epoxy Curing Agents

- 4.2.5 Growing Demand for Hexamethylenediamine from Textile Industry

- 4.3 Market Restraints

- 4.3.1 Volatility in Crude-Derived Adiponitrile Prices

- 4.3.2 Scale-up Risk for Bio-based Hexamethylenediamine Technologies

- 4.3.3 Stringent REACH Restrictions on Amine Emissions

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitute Products and Services

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Volume)

- 5.1 By Application

- 5.1.1 Nylon Production

- 5.1.2 Intermediates of Coating

- 5.1.3 Biocides

- 5.1.4 Other Applications (Curing Agents, Lubricants, etc.)

- 5.2 By Grade

- 5.2.1 Standard Industrial Grade

- 5.2.2 High-Purity Grade

- 5.2.3 Bio-based Grade

- 5.3 By End-use Industry

- 5.3.1 Automotive

- 5.3.2 Textiles

- 5.3.3 Plastics

- 5.3.4 Other End-user Industries (Paints and Coatings, Electronics, etc.)

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 Thailand

- 5.4.1.6 Indonesia

- 5.4.1.7 Vietnam

- 5.4.1.8 Malaysia

- 5.4.1.9 Philippines

- 5.4.1.10 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Spain

- 5.4.3.6 Russia

- 5.4.3.7 NORDIC Countries

- 5.4.3.8 Turkey

- 5.4.3.9 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Colombia

- 5.4.4.4 Rest of South America

- 5.4.5 Middle-East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 United Arab Emirates

- 5.4.5.3 Qatar

- 5.4.5.4 South Africa

- 5.4.5.5 Nigeria

- 5.4.5.6 Egypt

- 5.4.5.7 Rest of Middle-East and Africa

- 5.4.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, and Recent Developments)

- 6.4.1 Ascend Performance Materials

- 6.4.2 BASF

- 6.4.3 Cathay Biotech Inc.

- 6.4.4 Dow

- 6.4.5 DOMO Chemicals

- 6.4.6 Evonik Industries AG

- 6.4.7 Genomatica Inc.

- 6.4.8 INVISTA

- 6.4.9 Radici Partecipazioni SpA

- 6.4.10 Solvay

- 6.4.11 Shenma Industrial Co. Ltd

- 6.4.12 Spectrum Chemical

- 6.4.13 Thermo Fisher Scientific Inc.

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-need Assessment