|

市场调查报告书

商品编码

1851598

木塑复合材料(WPC):市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)Wood Plastic Composites (WPC) - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

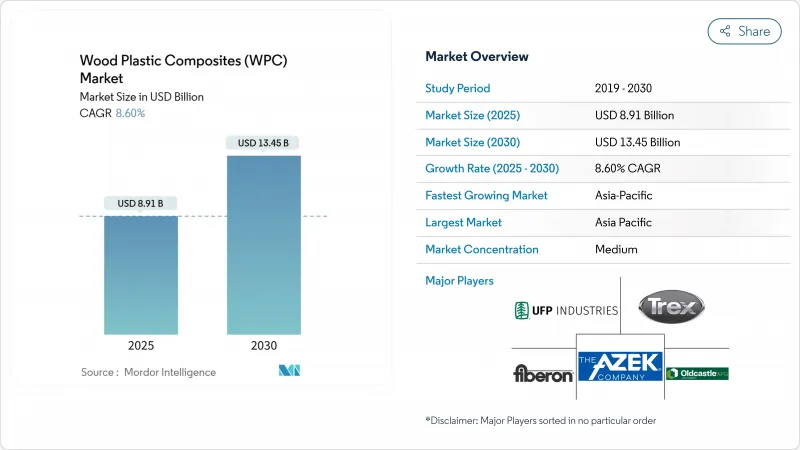

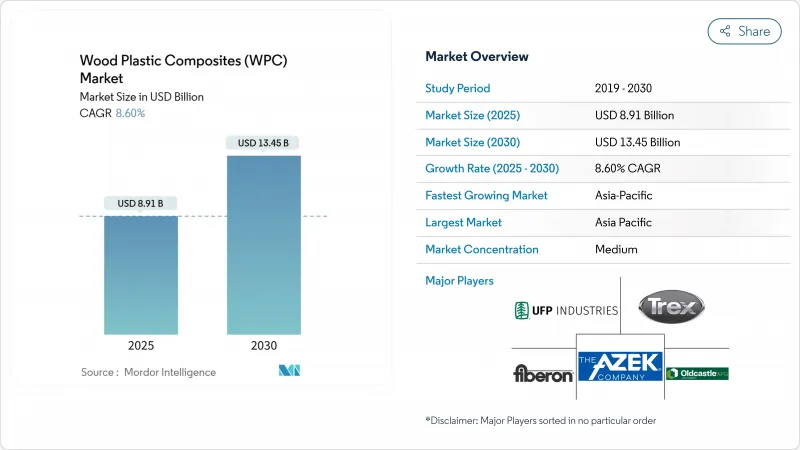

预计到 2025 年,木塑复合材料 (WPC) 市场规模将达到 89.1 亿美元,到 2030 年将达到 134.5 亿美元,预测期(2025-2030 年)复合年增长率为 8.60%。

推动需求成长的因素包括亚洲建设活动的活性化、北美DIY装修热潮的兴起以及欧洲日益严格的再生材料含量法规。产品开发商正致力于使用相容剂和提高木纤维含量以增强强度,而欧洲汽车製造商则指定使用更轻的非结构性部件以延长电动车的续航里程。供应商也正在推广包覆型材,以保护色彩并减少吸湿,从而提升零售吸引力。亚太地区预计在2024年将占全球销售额的55%,并将成为成长最快的地区,到2030年将以9.50%的复合年增长率成长。这主要得益于当地製造商不断提升生产能力,并致力于生产无铅PVC室内板材以符合当地日益严格的卫生法规。

全球木塑复合材料(WPC)市场趋势与洞察

DIY居家维修的趋势日益增长

房主们越来越倾向于选择安装快速、防污且无需每年重新密封的露台板材。零售商也积极回应,开始销售卡扣式板材,这种板材不仅安装简便,还能满足消费者对永续性。目前,碳负排放的木塑复合材料(WPC)露台板材原型产品所储存的二氧化碳量已超过其生产过程中的排放量,如果大规模推广,每年可储存25万吨二氧化碳。美国大型连锁超市正在扩大其销售的封闭式型材产品范围,从而增强了稳定的现金流,帮助生产商抵御建设产业不景气。数位教学和网红内容的传播正在推动DIY的普及,使塑木复合材料逐渐进入郊区家庭的装修预算。这一趋势也带动了与板材颜色相匹配的售后栏桿和照明套件的销售,从而创造了额外的收入来源。

欧盟循环经济行动计画中的强制性木纤维回收目标

欧盟的目标是到2030年将其再生材料含量翻一番,达到23.2%,并要求板材和甲板工厂更多地使用消费后木粉。各公司正在安装光学分类机和化学清洗线,以提高再生材料含量,同时不影响机械性能。同时,包装和包装废弃物法规强制要求所有形式的包装都必须是可回收包装,这进一步增强了对生物复合材料替代品的需求。在绿色建筑标籤的推动下,德国和法国的建筑商正在製定更高的回收率标准,以缩短先进分类设备的投资回收期。因此,再生材料供应合约的谈判期限已延长至多年,从而降低了原材料价格的不确定性。随着合规性转变成为结构性需求驱动因素,这些政策因素共同推动了塑木复合材料市场的扩张。

温度敏感性和磨损等技术问题

某些配方材料在持续高温下会发生蠕变,因此限制了其在引擎室等温度超过 120°C 的应用中的使用。众所周知,高人流的地板材料在经过数百万次踩踏后会失去光泽,因此常被设施管理人员弃用。奈米颗粒增强材料的研究显示出提高表面耐磨性的潜力,但会增加成本,而中型建筑商往往对此有所顾虑。高温尖峰时段的尺寸漂移也会增加施工公差,并延长承包商的工作时间。这些问题限制了它们在金属和工程木材已被证明有效的应用中的替代潜力。

细分市场分析

聚乙烯木塑复合材料(WPC)已在木塑复合材料市场占据主导地位,预计2024年将占据55%的市场。聚乙烯WPC的优点在于其易于挤出、填料相容性强以及原材料价格实惠。製造商可添加高达60%的木粉而不会显着增加黏度,使板材保持成本竞争力。聚丙烯级产品将最快成长,复合年增长率(CAGR)达9.20%,这主要得益于其更高的热变形率和刚度,使其适用于汽车内装板,并已证实可实现30%的减重。无铅PVC板材将在室内地板材料占据日益增长的市场份额,尤其是在亚洲。 PLA等相容剂正被应用于实验性甲板砖中,随着成本差距的缩小,其未来发展潜力巨大。顺丁烯二酸酐接枝等相容剂创新技术可增强界面结合力,使生产商能够使用更多木材和更少树脂。这项措施同时提高了永续性评分和利润率。

市场参与企业正在拓展其树脂产品组合,以对冲聚合物价格波动带来的风险。 2024年,聚合物价格波动幅度达到了两位数。这项策略也能确保在计画内的裂解装置停产导致聚乙烯供应受限的情况下,原料供应的连续性。因此,丰富的产品组合有助于企业获得长期销售合约,进而提升竞争优势。这种转变将材料科学与应用需求结合,进一步巩固了塑木复合材料市场的发展动能。

挤出生产线是甲板和围栏生产的支柱,预计到2024年将占全球产量的70%。配备重力式餵料器的双螺桿挤出机目前可以以800公斤/小时的速度运行,同时将水分含量保持在0.5%以下,从而最大限度地减少空隙。生产线自动化系统即时追踪型材温度,使废品率低于2%。射出成型虽然规模仍然较小,但随着汽车製造商对三维形状和严格公差的需求不断增长,其复合年增长率(CAGR)已达到9.10%。多材料包覆成型将木塑复合材料(WPC)芯材与触感柔软的热塑性弹性体(TPE)表层粘合在一起,在提升汽车内饰质感的同时,减少了组装步骤。拉挤成型在桥樑人行道的高模量梁领域找到了独特的应用前景,它利用连续玻璃粗纱来实现高弯曲刚度。

製程创新透过机器原始设备製造商 (OEM) 与本地加工商之间的授权合约进行推广,从而降低了学习难度。近红外线光谱线上监测能够快速回馈水分含量,而过去则需要实验室干燥测试。这些升级提高了产量,降低了每公斤产品的能耗,从而扩大了市场规模,并减少了塑木复合材料的碳足迹。与木塑复合材料相容的 3D 列印耗材正陆续进入设计工作室,使建筑师无需进行完整的工业运作即可自由测试定制的格栅地板,这标誌着新一轮应用浪潮的到来。

木塑复合材料市场报告按塑胶材料(聚乙烯、聚丙烯、其他)、加工技术(挤出、射出成型、其他)、产品形式(带盖(共挤出)WPC、不带盖(传统)WPC)、应用(建筑和施工产品、汽车零件、其他)和地区(亚太地区、北美、欧洲、南美、中东和非洲)进行细分。

区域分析

到2024年,亚太地区将占全球木塑复合材料市场55%的份额,对该产业贡献巨大。强劲的都市化、对绿色建筑规范的支持以及丰富的生物质资源,都支撑着该地区的领先地位。随着工厂优化卷材生产线并获得美国联邦住房管理局(FHA)的认可,中国对北美的甲板出口正在成长。日本是低挥发性有机化合物(VOC)室内板材的先驱者,这得益于政府对健康住宅的补贴。印度的基础建设正在推广使用木塑复合材料(WPC)人行天桥,以避免热带地区常见的白蚁问题。

北美拥有浓厚的DIY文化,而高端品牌策略正在推动市场成长。 Trex和AZEK向超过6,700家零售商供应产品,并正将销售通路拓展至二线城市。家居装潢连锁店发现,每米售价4美元的封层板销售量优于传统的防腐木材,进一步推动了市场扩张。加拿大受益于丰富的国内木材资源,这缩短了供应链,并促进了分散式板材生产,从而更好地服务偏远社区。

随着强制性再利用目标的推进,欧洲的政策框架正在重组木材采购和回收途径。德国加工商正在试行高达80%的再生木材,并因此获得了让大型开发人员印象深刻的生态标章。汽车原始设备製造商的需求正将中欧打造成为射出成型材料(WPC)组件的中心,并将供应与附近的组装厂整合起来。儘管气候寒冷,北欧市场仍在度假屋中广泛采用帽式甲板,因为其维护成本低于初始投资。

在中东,尤其是海湾合作委员会(GCC)国家,耐沙漠复合材料凉棚越来越受欢迎。这种凉棚采用紫外线防护和耐热颜料配製而成,即使在高达摄氏45度的温度下也能保持色彩鲜艳。杜拜的城市美化计画带动了步行道订单,凸显了木塑复合材料(WPC)相比热带硬木在生命週期成本方面的优势。虽然非洲的户外家具市场仍处于起步阶段,但南非的零售商报告称,采用耐盐雾且不易开裂的复合材料板条製成的高端户外家具销量实现了两位数的增长。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- DIY居家维修的趋势日益增长

- 欧盟循环经济行动计画中强制木纤维回收目标

- 亚洲室内装潢材料转向无铅PVC基木塑复合材料的转变正在加速。

- 欧洲汽车製造商努力减轻非结构性汽车零件的重量

- 海湾合作委员会国家对低维护成本的城市户外景观产品的需求激增

- 市场限制

- 技术问题,例如温度敏感性和佩戴舒适性

- 价格波动

- 高层建筑防火认证面临的障碍

- 价值链分析

- 波特五力模型

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章 市场规模与成长预测

- 透过塑胶材料

- 聚乙烯(PE)

- 聚丙烯(PP)

- 聚氯乙烯(PVC)

- 聚苯乙烯(PS)

- 其他材料(ABS、PLA 等)

- 透过加工技术

- 挤压

- 射出成型

- 压缩和提取

- 按产品形式

- 带盖共挤出木塑复合材料

- 无上限(传统)WPC

- 透过使用

- 建筑及施工产品

- 甲板

- 击剑

- 塑形和修剪

- 景观设计与户外

- 汽车零件

- 产业

- 消费品

- 家具

- 其他的

- 建筑及施工产品

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- ASEAN

- 亚太其他地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 法国

- 英国

- 义大利

- 北欧国家

- 其他欧洲地区

- 中东和非洲

- 沙乌地阿拉伯

- 土耳其

- 南非

- 奈及利亚

- 其他中东和非洲地区

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 亚太地区

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- Anhui Sentai WPC Group Share Co., Ltd.

- Axion Structural Innovations LLC

- Beologic

- Fiberon(Fortune Brands Innovations)

- FKuR

- Geolam AG

- Green Bay Decking LLC

- Guangzhou Kindwood Co., Ltd.

- JELU-WERK J. Ehrler GmbH & Co. KG

- Oldcastle APG(CRH)

- PolyPlank Solutions AB

- Resysta International

- Saint-Gobain

- TAMKO Building Products LLC

- The AZEK Company Inc.

- Trex Company Inc.

- UFP Industries, Inc.

第七章 市场机会与未来展望

The Wood Plastic Composites Market size is estimated at USD 8.91 billion in 2025, and is expected to reach USD 13.45 billion by 2030, at a CAGR of 8.60% during the forecast period (2025-2030).

Demand accelerators include growing construction activity in Asia, DIY renovation in North America, and regulatory pushes for recycled content in Europe. Product developers are blending higher wood-fiber loads with compatibilizers that improve strength, while automakers in Europe specify lighter non-structural parts to extend electric-vehicle range. Suppliers are also scaling capped profiles that protect colour and curb moisture uptake, which widens retail appeal. Asia-Pacific commands 55% of 2024 revenue and will remain the fastest-expanding geography at a 9.50% CAGR through 2030 as local manufacturers upgrade capacity and pursue lead-free PVC indoor panels that meet tightening regional health rules.

Global Wood Plastic Composites (WPC) Market Trends and Insights

Rise in DIY Home Improvement Trends

Home-owners are spending more on decks that install quickly, resist staining, and avoid yearly re-sealing. Retailers respond by stocking click-fit boards that save labor and tap into the wider sustainability preference of consumers. Carbon-negative WPC decking prototypes now store more CO2 than production emits, potentially locking away 250,000 tons annually if adopted at scale. Big-box chains in the United States dedicate additional aisle space to capped profiles, reinforcing steady cash sales that cushion producers from construction cyclicality. Digital tutorials and influencer content widen do-it-yourself reach, pushing the wood plastic composite market into suburban remodel budgets. The trend also lifts aftermarket railing and lighting kits that match board colours, creating incremental revenue streams.

Mandatory Wood-Fiber Reuse Targets in EU Circular Economy Action Plan

The EU seeks to double its circular material-use rate to 23.2% by 2030, which obliges panel and decking factories to integrate more post-consumer wood flour. Companies deploy optical sorters and chemical cleaning lines that raise recycled-content ratios without hurting mechanical properties. Simultaneously, the Packaging and Packaging Waste Regulation compels every packaging format to be recyclable, reinforcing demand for biocomposite alternatives. German and French builders, backed by green-building labels, specify higher recycled fractions that shorten payback for advanced sorting plants. Consequently, recyclate supply contracts are now negotiated over multi-year tenors, reducing feedstock-price uncertainty. These policy levers collectively expand the wood plastic composite market as compliance shifts become structural demand drivers.

Technical Issues Like Temperature Sensitivity and Wearability

Some formulations creep under sustained heat, limiting under-hood use where temperatures breach 120 °C. High-traffic flooring reveals surface gloss loss after millions of footfalls, which deters facility managers. Nanoparticle fortification studies show promise for tougher surfaces yet add cost overheads that mid-tier builders resist. Dimensional drift at temperature peaks also raises installation tolerances, lengthening job times for contractors. These concerns lower substitution rates in applications where metal or engineered wood remain proven.

Other drivers and restraints analyzed in the detailed report include:

- Accelerated Shift Toward Lead-Free PVC-Based WPC for Indoor Applications in Asia

- Light-weighting Push by European OEMs for Non-Structural Automotive Parts

- Fire-Resistance Certification Hurdles in High-Rise Construction

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Polyethylene WPC held 55% of the wood plastic composite market share in 2024, establishing its dominant position in the market. Its dominance stems from easy extrusion, broad filler tolerance, and attractive raw-material pricing. Manufacturers mix up to 60% wood flour without severe viscosity spikes, which keeps board costs competitive. Polypropylene grades expand fastest at a 9.20% CAGR, lifted by higher heat-deflection and stiffness that suit automotive interior panels where 30% weight savings are proven. Lead-free PVC boards, especially in Asian indoor flooring, fill a growing health-conscious niche. Biopolymers such as PLA appear in pilot deck tiles, signalling future openings once cost gaps narrow. Compatibilizer innovation, notably maleic-anhydride grafts, lifts interfacial bonding so producers can raise wood loadings and shrink resin usage. That step enhances sustainability scores and margins simultaneously.

Market participants broaden their resin slate to hedge against polymer price swings that reached double-digit volatility in 2024. The strategy also secures feedstock continuity when planned cracker shutdowns tighten PE supply. Consequently, portfolio breadth becomes a competitive credential in winning long-term distributor contracts. These shifts reinforce the wood plastic composite market trajectory by aligning material science with application-specific needs.

Extrusion lines produced 70% of 2024 global volume, making the method the backbone of deck and fence output. Twin-screw extruders with gravimetric feeders can now run 800 kg/hr while keeping moisture below 0.5%, which minimises void formation. Line automation tracks profile temperature in real time, trimming scrap rates below 2%. Injection molding, though smaller, climbs at 9.10% CAGR because automakers require three-dimensional geometries and tight tolerances. Multi-material over-molding joins WPC cores with soft-touch TPE skins, enhancing vehicle interior feel while cutting assembly steps. Pultrusion holds niche appeal for high-modulus beams in bridge walkways, leveraging continuous glass rovings for strong bending stiffness.

Process innovation spreads through licencing deals between machinery OEMs and regional processors, flattening the learning curve. Inline monitoring with near-infrared spectroscopy provides rapid moisture feedback that once required laboratory drying tests. These upgrades raise throughput and shrink energy per kilogram, boosting the wood plastic composite market size and trimming carbon footprints. WPC-ready 3D-printing filaments emerge in design studios, giving architects freedom to test customised lattice decks without full industrial runs, foreshadowing another adoption wave.

The Wood Plastic Composite Market Report is Segmented by Plastic Material (Polyethylene, Polypropylene, and More), Processing Technology (Extrusion, Injection Molding, and More), Product Form (Capped (Co-Extruded) WPC and Un-Capped (Conventional) WPC), Application (Building and Construction Products, Automotive Parts, and More), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa).

Geography Analysis

In 2024, the Asia-Pacific region accounted for 55% of the global wood plastic composite market, demonstrating its significant contribution to the industry. Strong urbanisation, supportive green-building norms, and abundant biomass supply anchor the region's leadership. Chinese decking exports to North America climb as factories optimise capstock lines and secure FHA acceptance. Japan pioneers low-VOC indoor boards, aided by government subsidies for healthier housing. India's infrastructure push sees WPC pedestrian bridges that avoid termite issues common in tropical settings.

North America benefits from a strong DIY culture and premium brand strategies, driving its market growth. Trex and AZEK supply more than 6,700 retail outlets, extending reach into secondary cities. Capped boards priced at USD 4.00 per linear foot outsell traditional pressure-treated lumber at home-centre chains, reinforcing market expansion. Canada benefits from domestic wood-fiber availability that shortens supply chains and boosts decentralised board production to serve remote communities.

Europe's policy framework reshapes sourcing and recycling routes as mandatory reuse targets near. German processors trial up to 80% recycled wood content to gain environment labels that sway large developers. Automotive OEM demand positions Central Europe as a hub for injection-molded WPC parts, integrating supply with nearby assembly plants. Nordic markets, despite cold climates, adopt capped decking for holiday cottages where low maintenance outweighs initial spend.

The Middle East, specifically GCC nations, records brisk uptake of desert-resistant composite pergolas. Formulations embed UV blockers and heat-stable pigments that preserve colour at 45 °C ambient conditions. Municipal beautification in Dubai triggers boardwalk orders that underscore WPC lifecycle cost benefits compared with tropical hardwood. Africa remains early stage but South African retailers report double-digit growth in premium outdoor furniture made from composite slats that weather salt air without cracking.

- Anhui Sentai WPC Group Share Co., Ltd.

- Axion Structural Innovations LLC

- Beologic

- Fiberon (Fortune Brands Innovations)

- FKuR

- Geolam AG

- Green Bay Decking LLC

- Guangzhou Kindwood Co., Ltd.

- JELU-WERK J. Ehrler GmbH & Co. KG

- Oldcastle APG (CRH)

- PolyPlank Solutions AB

- Resysta International

- Saint-Gobain

- TAMKO Building Products LLC

- The AZEK Company Inc.

- Trex Company Inc.

- UFP Industries, Inc.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rise in DIY Home Improvement Trends

- 4.2.2 Mandatory Wood-Fiber Reuse Targets in EU Circular Economy Action Plan

- 4.2.3 Accelerated Shift Toward Lead-Free PVC-Based WPC for Indoor Applications in Asia

- 4.2.4 Light-weighting Push by European OEMs for Non-Structural Automotive Parts

- 4.2.5 Surge in Demand for Low-Maintenance Urban Outdoor Landscaping Products in GCC

- 4.3 Market Restraints

- 4.3.1 Technical Issues Like Temperature Sensitivity, Wearability, etc

- 4.3.2 Volatility in Prices

- 4.3.3 Fire-Resistance Certification Hurdles in High-Rise Construction

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitute Products and Services

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Plastic Material

- 5.1.1 Polyethylene (PE)

- 5.1.2 Polypropylene (PP)

- 5.1.3 Polyvinyl Chloride (PVC)

- 5.1.4 Polystyrene (PS)

- 5.1.5 Others (ABS, PLA, etc.)

- 5.2 By Processing Technology

- 5.2.1 Extrusion

- 5.2.2 Injection Molding

- 5.2.3 Compression and Pultrusion

- 5.3 By Product Form

- 5.3.1 Capped (Co-extruded) WPC

- 5.3.2 Un-capped (Conventional) WPC

- 5.4 By Application

- 5.4.1 Building and Construction Products

- 5.4.1.1 Decking

- 5.4.1.2 Fencing

- 5.4.1.3 Molding and Trimming

- 5.4.1.4 Landscaping and Outdoor

- 5.4.2 Automotive Parts

- 5.4.3 Industrial

- 5.4.4 Consumer Goods

- 5.4.5 Furniture

- 5.4.6 Others

- 5.4.1 Building and Construction Products

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 ASEAN

- 5.5.1.6 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 France

- 5.5.3.3 United Kingdom

- 5.5.3.4 Italy

- 5.5.3.5 Nordics

- 5.5.3.6 Rest of Europe

- 5.5.4 Middle East and Africa

- 5.5.4.1 Saudi Arabia

- 5.5.4.2 Turkey

- 5.5.4.3 South Africa

- 5.5.4.4 Nigeria

- 5.5.4.5 Rest of Middle East and Africa

- 5.5.5 South America

- 5.5.5.1 Brazil

- 5.5.5.2 Argentina

- 5.5.5.3 Rest of South America

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Anhui Sentai WPC Group Share Co., Ltd.

- 6.4.2 Axion Structural Innovations LLC

- 6.4.3 Beologic

- 6.4.4 Fiberon (Fortune Brands Innovations)

- 6.4.5 FKuR

- 6.4.6 Geolam AG

- 6.4.7 Green Bay Decking LLC

- 6.4.8 Guangzhou Kindwood Co., Ltd.

- 6.4.9 JELU-WERK J. Ehrler GmbH & Co. KG

- 6.4.10 Oldcastle APG (CRH)

- 6.4.11 PolyPlank Solutions AB

- 6.4.12 Resysta International

- 6.4.13 Saint-Gobain

- 6.4.14 TAMKO Building Products LLC

- 6.4.15 The AZEK Company Inc.

- 6.4.16 Trex Company Inc.

- 6.4.17 UFP Industries, Inc.

7 Market Opportunities and Future Outlook

- 7.1 Emerging Bio-based WPCs

- 7.2 White-space and Unmet-need Assessment