|

市场调查报告书

商品编码

1851790

区块链在製造业的应用:市场占有率分析、产业趋势、统计数据和成长预测(2025-2030 年)Blockchain In Manufacturing - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

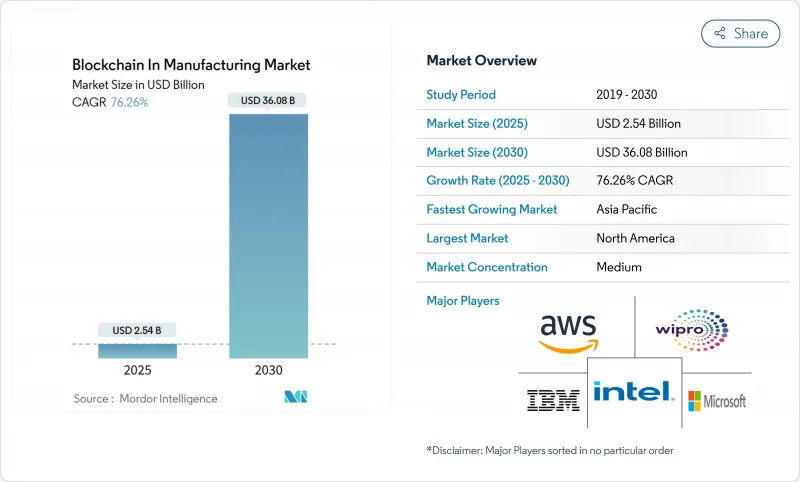

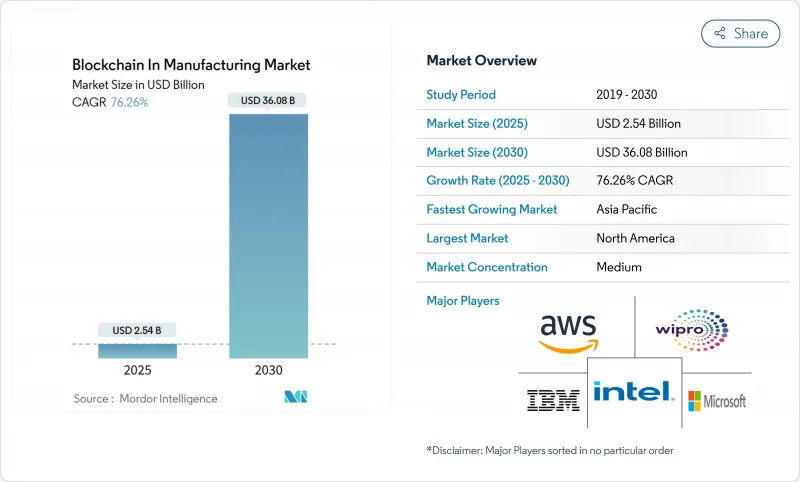

预计到 2025 年,製造业区块链市场规模将达到 25.4 亿美元,到 2030 年将达到 360.8 亿美元,预测期(2025-2030 年)复合年增长率为 76.26%。

采用不可篡改的帐本进行批量认证、防伪和设备代币化的应用日益普及,加速了从先导计画向企业级部署的过渡。日益严格的监管审查,尤其是在《药品供应链安全法案》的推动下,迫使製造商采用分散式帐本来实现序列化和召回管理的自动化。云端基础的区块链即服务 (BaaS) 平台也降低了中小型工厂的进入门槛。儘管标准分散和精通区块链的操作技术短缺阻碍了短期内的应用,但云端超大规模资料中心业者云端服务商和工业原始设备製造商 (OEM) 之间的战略伙伴关係正在弥合能力差距。

全球製造业区块链市场趋势与洞察

离散製造业中BaaS(后端即服务)的日益普及

目前,云端交付的区块链即服务 (BaaS) 在离散製造业的采用率已达 61.8%,这主要得益于其承包的环境,无需专门的节点管理。将区块链遥测数据整合到微软 Fabric 分析套件中,用户可以查询生产线事件以及企业数据,从而将系统整合时间缩短 35%。这种成本节约和简化 DevOps 的组合,必将使 BaaS 成为汽车、电子和工业设备工厂的热门选择,因为这些工厂需要快速上线和严格的执行时间。

强制性供应链认证和可追溯性

美国食品药物管理局 (FDA) 延长了食品可追溯性规则的最后期限,但重申区块链非常适合满足批次级不可篡改的报告要求。欧盟的同期数位产品护照法规也强调了在产品生命週期的每个阶段建立分散式记录的必要性。製药、航太和消费性电子产品製造商将序列资料嵌入共用帐本,用于自动召回,从而将人工审核成本降低了 28%。

标准碎片化和互通性差距

由于缺乏通用资料模型,供应商必须为每个交易对象建造成本高昂的中间件桥接器。 GS1 和 ISO工作小组正在起草通用模式,但其应用进度落后于快速推进的实施期限。汽车和化学工业正在进行基于联盟的试点项目,但这些项目规模仍然较小,远未达到标准水准。

细分市场分析

预计到2030年,品管和合规工具的复合年增长率将达到77.4%,超过物流管理。物流管理在2024年占据了製造业区块链市场份额的46%。进行FDA序列化测试的製药公司报告称,当批次历史记录储存在分散式帐本上时,偏差解决速度提高了30%。自动签发审核证书的智慧合约工作流程取代了纸本记录,将合规时间缩短了40%。第二波应用程式包括预测性维修日誌和保固裁决,其中不可篡改的历史记录降低了争议率。仿冒品检测仍然至关重要,因为高级化学标籤会将真伪杂凑值输入公共帐本,从而增强消费者信心。随着应用案例的不断增加,区块链在製造业市场,无论是在待开发区还是棕地工厂,都获得了显着的关注。

品质体係也构成了积层製造领域新型智慧财产权保护方案的基石,它利用零知识证明来验证设计合规性,同时又不洩漏商业机密。电子元件製造商正在将设备上的加密签章整合到帐本中,以提高召回的准确性。品质、合规性和防伪的融合正在加速企业对互通平台的兴趣,并强化区块链在製造业市场成长中的作用。

汽车工厂在2024年的收入中占据主导地位,占比31.2%,这反映了零部件可追溯性的广泛要求和成熟的工业4.0投资。然而,随着全球医疗保健法规强制要求序列化、低温运输追踪和患者级验证,生命科学製造商预计将扩大该领域区块链在製造业的市场规模,到2030年将以78.06%的复合年增长率成长。与IBM和默克合作的製药製造商报告称,在模拟审核中,召回执行速度提高了25%。航太和国防整合商正在采用安全的3D列印零件系谱帐本来降低篡改风险。消费电子品牌正在产品中嵌入保固令牌以简化售后服务,而食品和饮料加工商正在实施从农场到餐桌的追踪,以满足永续性审核。这些垂直领域的多元化发展正在推动区块链在製造业领域超越其早期开拓者的地位。

製造业区块链市场报告按应用(物流和供应链管理、仿冒品控制、品管和合规性等)、最终用户产业(汽车、航太和国防、製药和生命科学等)、部署模式(本地部署、云端/区块链即服务、混合/边缘部署)、区块链类型(公共区块链、私有地区/区块链等)和私人地区进行细分。

区域分析

北美地区占2024年总收入的44.3%,这主要得益于FDA的强制规定、成熟的云端基础设施以及创业投资对帐本新兴企业的大力支持。药品序列化和航太零件溯源认证的要求推动了早期示范应用,随后扩展到多工厂部署。各州政府的奖励进一步促进了中小企业采用该技术。

亚太地区预计在2025年至2030年间将实现78.34%的最高复合年增长率,这主要得益于数位化倡议,例如中国的工业区块链试点计画和日本的「社会5.0」智慧工厂蓝图。亚洲开发银行的「十三边形计画」反映了该地区致力于在製造业出口信贷领域实现银行间去中心化结算的决心。印度的电子产业丛集和韩国的电池供应链协定正在加速发展,推动了二级供应商的采用。

欧洲正崛起为以永续性发展为核心的领导者,利用数位产品护照记录碳足迹和循环经济指标。德国汽车製造商采用联合帐本追踪再生钢材含量,法国航太巨头则利用区块链管理积层製造粉末。北欧製造商透过水力和风力发电为许可型网路供电,满足了环境、社会和治理(ESG)方面的期望。跨境资料计划正在促进互通性,这表明随着区块链在全球製造业市场的成熟,区域性实施方案将在通用管治下趋于一致。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 离散製造业中BaaS(后端即服务)的日益普及

- 供应链中原产地和可追溯性的强制性认证

- 针对昂贵零件的防伪措施需求

- 利用令牌化实现设备即服务模型

- 与积层製造集成,实现安全的零件谱系

- 「保护隐私的零知识证明在智慧财产权保护中的应用」试点项目

- 市场限制

- 标准碎片化和互通性差距

- 区块链人才在营运技术环境中的局限性

- 人们越来越关注链上可追溯性的能源消耗问题

- 后量子时代安全要求的不确定性

- 价值/供应链分析

- 监管环境

- 技术展望

- 波特五力分析

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争

- 疫情与地缘政治影响评估

第五章 市场规模与成长预测

- 透过使用

- 物流供应链管理

- 仿冒品管理

- 品管与合规性

- 预测性维护和资产跟踪

- 采购智能合约

- 其他用途

- 按最终用户行业划分

- 车

- 航太/国防

- 製药和生命科学

- 消费性电子产品

- 工业机械

- 饮食

- 其他行业

- 透过部署模式

- 本地部署

- 云端/区块链即服务 (BaaS)

- 混合/边缘

- 按区块链类型

- 公共

- 私人/许可

- 联盟

- 按地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲国家

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 其他欧洲地区

- 亚太地区

- 中国

- 日本

- 印度

- 韩国

- 亚太其他地区

- 中东和非洲

- 中东

- 沙乌地阿拉伯

- 阿拉伯聯合大公国

- 土耳其

- 其他中东地区

- 非洲

- 南非

- 奈及利亚

- 肯亚

- 其他非洲地区

- 北美洲

第六章 竞争情势

- 市场集中度

- 策略倡议和伙伴关係

- 市占率分析

- 公司简介

- IBM Corporation

- Microsoft Corporation

- SAP SE

- Oracle Corporation

- Amazon Web Services Inc.

- Accenture PLC

- Wipro Limited

- Infosys Ltd

- Intel Corporation

- Advanced Micro Devices Inc.

- VeChain Technology

- Chronicled Inc.

- SyncFab

- Siemens AG

- Honeywell International Inc.

- General Electric

- R3 LLC

- ConsenSys

- Kaleido

- BlockApps Inc.

第七章 市场机会与未来展望

The Blockchain In Manufacturing Market size is estimated at USD 2.54 billion in 2025, and is expected to reach USD 36.08 billion by 2030, at a CAGR of 76.26% during the forecast period (2025-2030).

Rising deployment of immutable ledgers for batch provenance, anti-counterfeiting, and equipment tokenization is accelerating the transition from pilot projects to enterprise-wide rollouts. Heightened regulatory scrutiny, especially under the Drug Supply Chain Security Act, is compelling manufacturers to adopt distributed ledgers that automate serialization and recall management. Equipment-as-a-service initiatives are unlocking new revenue streams, while cloud-based Blockchain-as-a-Service (BaaS) platforms lower entry barriers for small and mid-sized factories. Although fragmentation in standards and shortages of blockchain-skilled operational-technology talent temper near-term adoption, strategic partnerships between cloud hyperscalers and industrial OEMs are closing capability gaps.

Global Blockchain In Manufacturing Market Trends and Insights

Escalating Adoption of BaaS Across Discrete Manufacturing

Cloud-delivered BaaS now represents 61.8% of implementation preferences among discrete manufacturers, a share propelled by turnkey environments that eliminate the need for specialized node management. Microsoft's integration of blockchain telemetry into its Fabric analytics suite allows users to query production-line events alongside enterprise data, reducing system-integration time by 35%. Cost savings combine with simplified DevOps to ensure that BaaS gains traction in automotive, electronics, and industrial equipment factories that require rapid onboarding yet stringent uptime.

Supply-Chain Provenance and Traceability Mandates

The FDA extended its Food Traceability Rule deadline yet reaffirmed blockchain's suitability for immutable lot-level reporting requirements. Parallel EU Digital Product Passport rules reinforce the need for distributed records across every product lifecycle phase. Pharmaceutical, aerospace, and consumer electronics producers are embedding serialization data onto shared ledgers to automate recall, thereby trimming manual audit costs by 28%.

Fragmented Standards and Interoperability Gaps

The absence of universal data models forces suppliers to build costly middleware bridges for each trading partner. GS1 and ISO working groups are drafting common schemas, yet adoption lags fast-moving implementation deadlines. Consortium-based pilots in automotive and chemicals signal progress but remain pockets rather than norms.

Other drivers and restraints analyzed in the detailed report include:

- Demand for Counterfeit Mitigation in High-Value Components

- Tokenization Enabling Equipment-as-a-Service Models

- Limited Blockchain Talent in OT Environments

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Quality control and compliance tools are projected to post a 77.4% CAGR to 2030, outpacing logistics management despite the latter's 46% hold on the blockchain in manufacturing market share in 2024. Pharmaceutical firms running FDA serialization pilots report 30% faster deviation resolution when batch histories sit on a distributed ledger. Smart-contract workflows that auto-issue audit certificates replace paper record-keeping, cutting compliance hours by 40%. Second-wave applications include predictive maintenance logs and warranty adjudication, where immutable histories lower dispute rates. Counterfeit detection remains central as luxury-grade chemical tags feed authenticity hashes into public ledgers, enhancing consumer trust. As use cases multiply, the blockchain in the manufacturing market registers significant traction across both greenfield and brownfield plants.

Quality systems also form the backbone for emerging intellectual-property protection schemes in additive manufacturing, where zero-knowledge proofs confirm design compliance without revealing trade secrets. Electronic-component makers integrate on-device cryptographic signatures with the ledger, strengthening recall precision. This convergence of quality, compliance, and anti-counterfeiting accelerates enterprise interest in interoperable platforms, reinforcing the blockchain in the manufacturing market growth narrative.

Automotive factories dominated revenue with 31.2% in 2024, reflecting extensive part traceability obligations and mature Industry 4.0 investments. Nonetheless, life-sciences producers will expand the blockchain in the manufacturing market size for their segment at a 78.06% CAGR through 2030 as serialization, cold-chain tracking, and patient-level provenance become mandatory under global health regulations. Drug makers collaborating with IBM and Merck reported 25% faster recall execution during simulated audits. Aerospace and defense integrators adopt secure part genealogy ledgers for 3D-printed components, mitigating tampering risks. Consumer-electronics brands embed warranty tokens into products to streamline after-sales service, while food and beverage processors deploy farm-to-fork tracking to satisfy sustainability audits. Collectively, vertical diversification broadens the blockchain in the manufacturing industry footprint beyond early movers.

The Blockchain in Manufacturing Market Report is Segmented by Application (Logistics and Supply Chain Management, Counterfeit Management, Quality Control and Compliance, and More), End-User Vertical (Automotive, Aerospace and Defense, Pharmaceutical and Life Sciences, and More), Deployment Mode (On-Premises, Cloud/Blockchain-as-a-Service, and Hybrid/Edge), Blockchain Type (Public, Private/Permissioned, and More), and Geography.

Geography Analysis

North America held 44.3% of 2024 revenue owing to FDA mandates, established cloud infrastructure, and strong venture capital backing for ledger startups. Pharmaceutical serialization and aerospace part pedigree requirements drove early proofs that have since scaled to multi-plant deployments. State-level incentives further supported SME adoption.

Asia Pacific registers the highest 78.34% CAGR forecast between 2025 and 2030, reflecting sweeping digitization initiatives such as China's industrial blockchain pilots and Japan's Society 5.0 smart-factory roadmap. The Asian Development Bank's Project Tridecagon showcases regional commitment to inter-bank distributed settlements that align with manufacturing export-credit flows. India's electronics clusters and South Korea's battery-supply chain agreements add momentum, catalyzing adoption by Tier-2 suppliers.

Europe emerges as a sustainability-centric adopter, leveraging Digital Product Passports to document carbon footprints and circular-economy metrics. Germany's automotive OEMs employ joint ledgers to track recycled steel content, while France's aerospace primes adopt blockchain to manage additive-manufacturing powders. Nordic manufacturers power permissioned networks with hydro and wind energy, addressing ESG expectations. Cross-border data-spaces projects promote interoperability, suggesting that regional implementations will converge under common governance as the blockchain in the manufacturing market matures globally.

- IBM Corporation

- Microsoft Corporation

- SAP SE

- Oracle Corporation

- Amazon Web Services Inc.

- Accenture PLC

- Wipro Limited

- Infosys Ltd

- Intel Corporation

- Advanced Micro Devices Inc.

- VeChain Technology

- Chronicled Inc.

- SyncFab

- Siemens AG

- Honeywell International Inc.

- General Electric

- R3 LLC

- ConsenSys

- Kaleido

- BlockApps Inc.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Escalating adoption of BaaS across discrete manufacturing

- 4.2.2 Supply-chain provenance and traceability mandates

- 4.2.3 Demand for counterfeit mitigation in high-value components

- 4.2.4 Tokenisation enabling equipment-as-a-service models

- 4.2.5 Integration with additive manufacturing for secure part genealogy

- 4.2.6 Privacy-preserving zero-knowledge-proof pilots for IP protection

- 4.3 Market Restraints

- 4.3.1 Fragmented standards and interoperability gaps

- 4.3.2 Limited blockchain talent in OT environments

- 4.3.3 Rising energy-use concerns for on-chain traceability

- 4.3.4 Uncertainty around post-quantum security requirements

- 4.4 Value/Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Pandemic and Geopolitical Impact Assessment

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Application

- 5.1.1 Logistics and Supply Chain Management

- 5.1.2 Counterfeit Management

- 5.1.3 Quality Control and Compliance

- 5.1.4 Predictive Maintenance and Asset Tracking

- 5.1.5 Smart Contracts for Procurement

- 5.1.6 Other Applications

- 5.2 By End-user Vertical

- 5.2.1 Automotive

- 5.2.2 Aerospace and Defense

- 5.2.3 Pharmaceutical and Life Sciences

- 5.2.4 Consumer Electronics

- 5.2.5 Industrial Machinery

- 5.2.6 Food and Beverage

- 5.2.7 Other Verticals

- 5.3 By Deployment Mode

- 5.3.1 On-premises

- 5.3.2 Cloud/Blockchain-as-a-Service (BaaS)

- 5.3.3 Hybrid/Edge

- 5.4 By Blockchain Type

- 5.4.1 Public

- 5.4.2 Private/Permissioned

- 5.4.3 Consortium

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 Japan

- 5.5.4.3 India

- 5.5.4.4 South Korea

- 5.5.4.5 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 Middle East

- 5.5.5.1.1 Saudi Arabia

- 5.5.5.1.2 United Arab Emirates

- 5.5.5.1.3 Turkey

- 5.5.5.1.4 Rest of Middle East

- 5.5.5.2 Africa

- 5.5.5.2.1 South Africa

- 5.5.5.2.2 Nigeria

- 5.5.5.2.3 Kenya

- 5.5.5.2.4 Rest of Africa

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves and Partnerships

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, Recent Developments)

- 6.4.1 IBM Corporation

- 6.4.2 Microsoft Corporation

- 6.4.3 SAP SE

- 6.4.4 Oracle Corporation

- 6.4.5 Amazon Web Services Inc.

- 6.4.6 Accenture PLC

- 6.4.7 Wipro Limited

- 6.4.8 Infosys Ltd

- 6.4.9 Intel Corporation

- 6.4.10 Advanced Micro Devices Inc.

- 6.4.11 VeChain Technology

- 6.4.12 Chronicled Inc.

- 6.4.13 SyncFab

- 6.4.14 Siemens AG

- 6.4.15 Honeywell International Inc.

- 6.4.16 General Electric

- 6.4.17 R3 LLC

- 6.4.18 ConsenSys

- 6.4.19 Kaleido

- 6.4.20 BlockApps Inc.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-need Assessment