|

市场调查报告书

商品编码

1851808

医药玻璃包装:市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)Pharmaceutical Glass Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

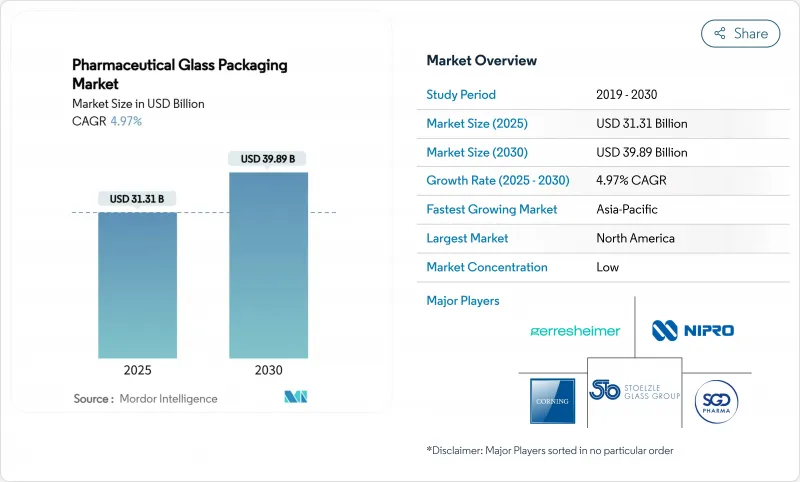

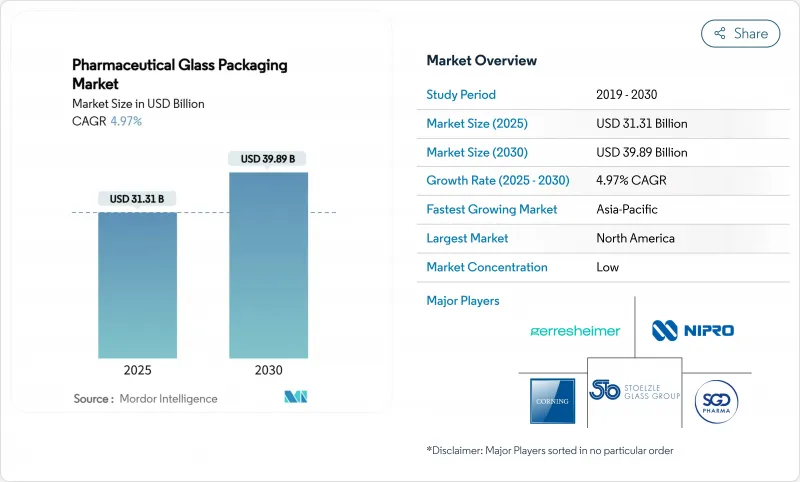

预计到 2025 年,医药玻璃包装市场规模将达到 313.1 亿美元,到 2030 年将达到 398.9 亿美元,年复合成长率为 4.97%。

这一趋势反映出市场正稳步转向高价值容器系统,这些系统既能满足严格的无菌和洗脱标准,又能支持生物製剂的快速规模化生产、分散式疫苗生产以及自行注射的偏好。美国食品药物管理局 (FDA) 和生技药品管理局 (EMA) 不断收紧的指导方针持续推动对 I 型硼硅酸玻璃的需求,而人工智慧检测技术则可在降低缺陷风险的同时提高生产效率。同时,熔炉现代化和回收率的提高使生产商能够在不影响监管合规性的前提下实现永续性。因此,儘管原料成本波动和来自先进聚合物日益激烈的竞争有所限制,但医药玻璃包装市场仍蕴藏着稳健的成长机会。

全球医药玻璃包装市场趋势与洞察

扩大生技药品和注射产品线

监管数据显示,2024年FDA核准的55种新药中,将有17种为生技药品,凸显了生技药品的持续成长动能。因此,製造商正在加速升级其i型包装能力,以确保蛋白质稳定性并降低分层风险。 Stevanart集团的营收飙升至11.04亿欧元,其中38%来自高价值解决方案,凸显了高端包装容器如何抓住这一机会。肿瘤和自体免疫疗法越来越倾向于使用可进行皮下注射的大容量药筒,这进一步强化了医药玻璃包装市场在支持以患者为中心的给药方式方面的关键作用。基因疗法的持续突破将推动对能够在整个冷冻供应链中保持无菌状态的包装容器的更大依赖。这些趋势共同为生技药品提供了结构性利好,并将显着提升2030年后的基准需求。

新冠疫情后扩大疫苗填充及包装产能

随着各国政府持续建立战略疫苗储备,全球管瓶消费量依然居高不下。 Shots公司已生产超过10亿支新冠疫苗管瓶,展现了基准的永续性。欧洲药品管理局(EMA)为缓解GLP-1促效剂短缺而做出的调整,进一步凸显了建构韧性供应链的重要性。在北美,Bormioli Pharma公司新增的FDA核准的储存能力提振了需求,推动区域销售额成长了47%。此外,印度和东南亚的工厂扩建也促进了对当地加工商的销售量,并巩固了新兴枢纽地区的医药玻璃包装市场。这些投资在支持广泛疫苗接种目标的同时,也缓解了疫情初期出现的订单波动。

COP/COC聚合物注射器的快速普及

格雷斯海默公司的ClearJect聚合物注射器采用防碎、无黏合剂的设计,非常适合自行注射治疗。肖特製药公司的TOPPAC Freeze注射器则是针对需要深度冷冻保存的mRNA药物,凸显了聚合物的多功能性。由于患者对家用玻璃注射器安全性的担忧,聚合物在高价值细分市场的应用正在加速普及。虽然玻璃注射器在传统注射剂领域仍占据主导地位,但聚合物注射器在黏稠生技药品和大容量自动注射器领域正逐渐获得市场份额。这种竞争格局的转变可能会在中期内阻碍市场竞争。

细分市场分析

由于在疫苗、冷冻干燥生技药品和临床批次製剂方面的灵活性,管瓶预计在2024年将维持35.42%的销售额。稳定的需求使得SGD Pharma能够在五家工厂每天生产超过800万支管瓶,确保全球供应的连续性。随着库存调整的结束和肿瘤药物研发管线补充商业库存,管瓶的医药玻璃包装市场预计将会扩大。预灌封注射器和药筒预计将以7.53%的复合年增长率快速成长,主要受皮下注射生技药品和GLP-1受体拮抗剂的推动。 BD最新推出的8毫米针头适用于高黏度製剂,消除了推广应用的一大障碍。瓶装製剂在口服混悬液和儿科电解质溶液领域表现良好,而安瓿则在耐热麻醉剂领域中保持着一定的市场需求。包括双腔系统在内的特殊规格包装以及复杂的联合治疗的需求正在增长。在医药玻璃包装市场,人工智慧侦测持续降低产品报废率,保护利润率。

以病人为中心的医疗保健模式促使药物研发人员优先考虑用药的便利性、依从性和减少就诊次数。注射笔可容纳多剂量,而自动注射器则无需专业人员指导即可实现精准给药。为了保持竞争力,管瓶生产商正转向模组化填充生产线,提供可在透明瓶和琥珀色瓶之间快速切换的混合批次填充方案,以最大限度地减少停机时间。可减少颗粒生成并促进硅化的涂层技术正在拓展玻璃的性能范围。因此,如今每个产品类型都在监管合规性、加工性能和整体拥有成本方面竞争,进一步加剧了医药玻璃包装市场的差异化。

2024年,I型硼硼硅酸玻璃的销售额将占总销售额的55.32%,这主要得益于其优异的耐化学性和全球药典的认可。随着高浓度生技药品和抗体药物复合体对惰性表面的需求日益增长,I型硼硅酸盐玻璃的市场主导地位将持续维持。此外,I型玻璃容器的医药玻璃包装市场也将受益于新型配方,例如不含硼的Valor玻璃,它几乎完全消除了分层风险。同时,II型钠钙玻璃的复合年增长率将达到6.86%,这主要得益于表面涂层的改进,使其能够以低成本的方式适用于弱酸性注射剂,从而在性能和预算之间取得理想的平衡。 Gerresheimer公司最新推出的II型玻璃为那些无法承受硼硅酸玻璃高价的中檔治疗药物提供了更多选择。

III型玻璃因其优异的pH中性性能(而非水解应力),常用于口服液、止咳糖浆和滴瓶的包装。同时,琥珀色玻璃则用于保护渗透性药物和眼科抗病毒药物的延长管线。 SGD Pharma目前在部分产品中采用20%的消费后玻璃屑,且不影响监管合规性。在预测期内,永续性评分将有助于采购决策,而生命週期分析将成为医药玻璃包装市场中所有类型玻璃的综合价值提案。

区域分析

北美地区将占2024年销售额的38.98%,这主要得益于活跃的研发开发平臺、强劲的创业投资资金以及严格的合规文化。肖特製药在北卡罗来纳州投资3.71亿美元,预计到2030年将使美国即用型注射器(RTU注射器)的国内产量增加两倍,这将进一步巩固其在该地区的领先地位。联邦政府对先进製造业的诱因也将加速炉窑向电混合动力汽车炉的转型,从而符合二氧化碳减量目标。对GLP-1疗法和生物製药的强劲需求将促使主要製剂生产商运作多班制生产,并为学名药的销售波动做好准备。

在严格的法规环境和早期永续性指令的支持下,欧洲保持着均衡成长。儘管欧盟新的《包装和包装废弃物条例2025/40》将关键的医药玻璃排除在回收配额之外,但品牌所有者正自愿承诺将碎玻璃纳入玻璃屑利用,以实现其公司的净零排放目标。对后疫情时代战略药品储备的政治支持正在推动区域管瓶和药筒的生产能力。然而,能源成本仍然是竞争的一大障碍,除非绿色电力价格趋于稳定,否则一些生产商会将产能转移到成本较低的地区。

亚太地区将以8.12%的复合年增长率成为成长最快的地区,主要得益于中国和印度不断扩大的产能。预计2023年生物製药市场规模将达6,506亿元人民币,到2029年将翻倍。政府的奖励策略将鼓励高端玻璃的进口,同时,国内企业也加紧改造熔炉。跨国合约研发生产企业(CDMO)正在新加坡和韩国建立灌装包装工厂,将区域标准提升至美国和欧盟水平,从而扩大潜在的医药玻璃包装市场。东南亚的疫苗企业正在利用优惠资金建造灌装包装生产线,进一步刺激了对管瓶的需求。

儘管南美洲和中东及非洲在绝对数量上落后于其他地区,但随着当地学名药生产商扩大生产规模以减少对进口的依赖,这些地区的成长势头正在增强。巴西面临巴西国家卫生监督局(ANVISA)的严格监管,这迫使其升级包装;而海湾国家则将医疗保健投资纳入其经济多元化计画。值得注意的是,区域内碱灰和液化石油气能源的输送缓解了人们对炉灶燃料的担忧,并使某些新兴市场成为医药玻璃包装市场中面向出口的生产中心。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 扩大生技药品和注射产品线

- 新冠疫情后扩大疫苗填充及包装产能

- 改用即用型(RTU)管瓶和注射器

- 高附加价值i型硼硅酸玻璃的需求不断增长

- 医药永续性指令提高了玻璃的可回收性

- 人工智慧驱动的线上品质控制降低了玻璃缺陷率(漏报率)

- 市场限制

- COP/COC聚合物注射器的快速普及

- 碱灰和能源价格的波动会推高玻璃成本。

- 超强效药物的分层与断裂问题

- 区域容器玻璃熔炉产能短缺(未充分报告)

- 供应链分析

- 监理展望

- 技术展望

- 波特五力分析

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争

第五章 市场规模与成长预测

- 副产品

- 瓶子

- 管瓶

- 安瓿

- 药筒和预灌封注射器

- 其他产品

- 按玻璃类型

- i型硼硅酸

- II 型处理钠石灰

- 第三型钠石灰

- 其他玻璃

- 按剂型

- 注射

- 口服液

- 眼科/鼻科

- 话题

- 最终用户

- 製药创新公司

- 学名药和合约生产商

- 生技公司

- 配药药房

- 动物用药品

- 按地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 其他欧洲地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 澳洲、纽西兰

- 亚太其他地区

- 中东和非洲

- 中东

- 阿拉伯聯合大公国

- 沙乌地阿拉伯

- 土耳其

- 其他中东地区

- 非洲

- 南非

- 奈及利亚

- 埃及

- 其他非洲地区

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 北美洲

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- Gerresheimer AG

- Schott AG

- SGD Pharma

- Stevanato Group

- Corning Inc.

- Nipro Corp.

- West Pharmaceutical Services

- Bormioli Pharma

- Owens-Illinois(Ardagh Glass Pharma)

- Stolzle Glass Group

- Beatson Clark

- Shandong Medicinal Glass

- Arab Pharmaceutical Glass

- Piramal Glass

- Sisecam Group

- Baxter BioPharma Solutions

- Kindeva Drug Delivery

- Origin Pharma Packaging

- DWK Life Sciences

- GerroMed(under-reported niche)

第七章 市场机会与未来展望

The pharmaceutical glass packaging market size reached USD 31.31 billion in 2025 and is forecast to climb to USD 39.89 billion by 2030, expanding at a 4.97% CAGR.

This outlook reflects a steady pivot toward high-value container systems that can meet rigorous sterility and leachables limits while supporting rapid biologics scale-up, decentralized vaccine production and growing self-injection preferences. Tightened guidelines from the FDA and the European Medicines Agency continue to elevate demand for Type I borosilicate formats, while AI-enabled inspection unlocks higher throughput with lower defect risk. At the same time, furnace modernization and greater recycled content help producers manage sustainability mandates without compromising regulatory compliance. As a result, the pharmaceutical glass packaging market continues to offer reliable growth opportunities, tempered only by raw-material cost swings and rising competition from advanced polymers.

Global Pharmaceutical Glass Packaging Market Trends and Insights

Expansion of Biologics and Injectable Drugs Pipeline

Regulatory data show 17 biologics approvals among 55 new FDA drugs in 2024, underscoring sustained biologics momentum. Manufacturers therefore accelerate Type I capacity upgrades that ensure protein stability and mitigate delamination risk. A revenue jump to EUR 1,104 million at Stevanato Group, with 38% from high-value solutions, highlights how premium containers capture this wave. Oncology and autoimmune therapies increasingly favor large-volume cartridges that enable subcutaneous dosing, reinforcing the critical role of the pharmaceutical glass packaging market in supporting patient-centric delivery. Continued gene-therapy breakthroughs will deepen reliance on containers that maintain sterility across frozen supply chains. Together these trends give biologics a structural tailwind that raises baseline demand well beyond 2030.

Mounting Vaccine Fill-Finish Capacity Post-COVID

Global vial consumption remains elevated as governments keep strategic vaccine reserves. SCHOTT produced enough vials for more than 1 billion COVID-19 doses, illustrating the sustained baseline. EMA coordination to ease GLP-1 agonist shortages further spotlights the drive for resilient supply chains. North American demand strengthened when Bormioli Pharma lifted regional sales 47% after adding FDA-approved storage capacity. Facility expansions across India and Southeast Asia also push incremental volume to local converters, reinforcing the pharmaceutical glass packaging market across emerging hubs. These investments support broad immunization goals while smoothing order volatility seen during the initial pandemic surge.

Rapid Adoption of COP/COC Polymer Syringes

ClearJect polymer syringes from Gerresheimer deliver break-resistant, glue-free formats that appeal to self-injection therapies. SCHOTT Pharma's TOPPAC Freeze targets mRNA drugs that need deep-cold durability, underscoring polymer versatility. Patient safety concerns for fragile glass in at-home settings accelerate polymer acceptance in high-value niches. While glass maintains dominance for conventional injectables, polymers now capture incremental share in viscous biologics and high-volume autoinjectors. This competitive encroachment creates a modest drag on the pharmaceutical glass packaging market over the medium term.

Other drivers and restraints analyzed in the detailed report include:

- Shift to Ready-to-Use (RTU) Vials and Syringes

- Rising Demand for High-Value Borosilicate Type I Glass

- Volatile Soda-Ash and Energy Prices Inflating Glass Cost

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Vials retained 35.42% revenue in 2024 as their flexibility spans vaccines, lyophilized biologics and clinical batches. Steady demand lets SGD Pharma run more than 8 million vials daily across five plants, safeguarding global supply continuity. The pharmaceutical glass packaging market size for vials is projected to grow as destocking subsides and oncology pipelines refill commercial inventories. Prefillable syringes and cartridges expand fastest at a 7.53% CAGR, propelled by subcutaneous biologics and GLP-1 antagonists that favor ready-to-inject formats. BD's latest eight-millimeter needles address higher viscosity formulations, removing one adoption hurdle. Bottles hold steady in oral suspensions and pediatric electrolytes, whereas ampoules preserve niche demand for heat-stable anesthetics. Specialty formats, including dual-chamber systems, rise alongside complex combination therapies. Across products, AI inspection continues to trim scrap rates, protecting margins within the pharmaceutical glass packaging market.

The shift toward patient-centric care pushes drug developers to prioritize convenience, adherence and reduced clinic visits. Cartridge-based pens accommodate multi-dose regimes, while autoinjectors ensure accurate dose delivery without professional oversight. Vial makers lean on modular filling lines to remain competitive, offering hybrid batches that switch between clear and amber containers with minimal downtime. Coating technologies that reduce particle generation and ease siliconization broaden the performance envelope for glass. Consequently, every product category now competes on a mix of regulatory robustness, machinability and total cost of ownership, heightening differentiation within the pharmaceutical glass packaging market.

Type I borosilicate captured 55.32% revenue in 2024 thanks to sterling chemical resistance and global pharmacopeia acceptance. Its dominance will persist as high-concentration biologics and antibody-drug conjugates demand inert surfaces. The pharmaceutical glass packaging market size for Type I containers benefits further from new compositions like boron-free Valor that virtually eliminate delamination risk. Treated Type II soda-lime glass, however, posts a 6.86% CAGR as surface coatings extend suitability to mildly acidic injectables at lower cost, offering an attractive balance between performance and budget. Gerresheimer's latest Type II lines broaden options for mid-tier therapies that cannot justify premium borosilicate pricing.

Type III glass remains common for oral liquids, cough syrups and dropper bottles where pH neutrality dominates over hydrolytic stress. Meanwhile, colored amber variants shield photolabile drugs and line extensions of ophthalmic antivirals. Recycled content climbs as large pharma institutes Scope 3 emission targets; SGD Pharma now offers 20% post-consumer cullet in selected ranges without compromising regulatory compliance. Over the forecast horizon, sustainability scoring will intensify procurement decisions, making life-cycle analysis an embedded value proposition across all glass types of the pharmaceutical glass packaging market.

The Pharmaceutical Glass Packaging Market Report is Segmented by Product (Bottles, Vials, Ampoules, and More), Glass Type (Type I Borosilicate, Type II Treated Soda-Lime, and More), Drug Formulation (Injectables, Oral Liquids, Ophthalmic/Nasal, Topical), End-User (Pharma Innovator Companies, Generic and CMOs, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

North America generated 38.98% of 2024 revenue, fueled by intense R&D pipelines, strong venture funding and strict compliance culture. SCHOTT Pharma's USD 371 million investment in North Carolina is slated to triple domestic output of RTU syringes by 2030, further cementing regional leadership. Federal incentives for advanced manufacturing also speed furnace rebuilds into electric hybrids, aligning with carbon-reduction targets. Robust demand for GLP-1 therapeutics and oncology biologics sustains multi-shift operations at major converters, guarding against volume swings in legacy generics.

Europe maintains balanced growth, underpinned by its stringent regulatory environment and early sustainability mandates. The new EU Packaging and Packaging Waste Regulation 2025/40 exempts critical pharma glass from some recycling quotas, yet brand owners voluntarily pledge to integrate cullet to meet corporate net-zero goals. Political support for strategic drug reserves post-COVID fosters local vial and cartridge capacity. However, energy costs remain a competitive thorn, pushing some producers to relocate capacity to lower-cost regions unless green power tariffs stabilize.

Asia-Pacific records the fastest 8.12% CAGR, powered by manufacturing scale-ups in China and India where the 2023 biopharma market stood at 650.6 billion yuan and is forecast to double by 2029. Government stimulus packages encourage high-end glass imports even as domestic players ramp furnace rebuilds. Multinational CDMOs establish fill-finish sites in Singapore and South Korea, raising regional specifications to US and EU levels and enlarging the addressable pharmaceutical glass packaging market. Southeast Asian vaccine institutes leverage concessional funding to build fill-finish lines, further lifting vial demand.

South America and the Middle East & Africa trail in absolute numbers but gain momentum as local generics houses expand facility footprints to cut import reliance. Brazil's stringent ANVISA rules compel packaging upgrades, and Gulf states pursue health-care investment drives as part of economic diversification plans. Importantly, regional arteries for soda ash and LPG energy ease furnace-fuel concerns, positioning select emerging markets as secondary hubs for export-oriented production within the pharmaceutical glass packaging market.

- Gerresheimer AG

- Schott AG

- SGD Pharma

- Stevanato Group

- Corning Inc.

- Nipro Corp.

- West Pharmaceutical Services

- Bormioli Pharma

- Owens-Illinois (Ardagh Glass Pharma)

- Stolzle Glass Group

- Beatson Clark

- Shandong Medicinal Glass

- Arab Pharmaceutical Glass

- Piramal Glass

- Sisecam Group

- Baxter BioPharma Solutions

- Kindeva Drug Delivery

- Origin Pharma Packaging

- DWK Life Sciences

- GerroMed (under-reported niche)

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Expansion of biologics and injectable drugs pipeline

- 4.2.2 Mounting vaccine fill-finish capacity post-COVID

- 4.2.3 Shift to ready-to-use (RTU) vials and syringes

- 4.2.4 Rising demand for high-value borosilicate Type-I glass

- 4.2.5 Pharma sustainability mandates boosting glass recyclability

- 4.2.6 AI-enabled inline QC reducing glass defect rates (under-reported)

- 4.3 Market Restraints

- 4.3.1 Rapid adoption of COP/COC polymer syringes

- 4.3.2 Volatile soda-ash and energy prices inflating glass cost

- 4.3.3 Delamination and breakage concerns in ultra-potent drugs

- 4.3.4 Regional container-glass furnace capacity shortages (under-reported)

- 4.4 Supply-Chain Analysis

- 4.5 Regulatory Outlook

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Product

- 5.1.1 Bottles

- 5.1.2 Vials

- 5.1.3 Ampoules

- 5.1.4 Cartridges and Prefillable Syringes

- 5.1.5 Other Product

- 5.2 By Glass Type

- 5.2.1 Type I Borosilicate

- 5.2.2 Type II Treated Soda-Lime

- 5.2.3 Type III Soda-Lime

- 5.2.4 Other Glass Type

- 5.3 By Drug Formulation

- 5.3.1 Injectables

- 5.3.2 Oral Liquids

- 5.3.3 Ophthalmic / Nasal

- 5.3.4 Topical

- 5.4 By End-User

- 5.4.1 Pharma Innovator Companies

- 5.4.2 Generic and CMOs

- 5.4.3 Biotech Firms

- 5.4.4 Compounding Pharmacies

- 5.4.5 Veterinary Pharma

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 Europe

- 5.5.2.1 Germany

- 5.5.2.2 United Kingdom

- 5.5.2.3 France

- 5.5.2.4 Italy

- 5.5.2.5 Spain

- 5.5.2.6 Russia

- 5.5.2.7 Rest of Europe

- 5.5.3 Asia-Pacific

- 5.5.3.1 China

- 5.5.3.2 India

- 5.5.3.3 Japan

- 5.5.3.4 South Korea

- 5.5.3.5 Australia and New Zealand

- 5.5.3.6 Rest of Asia-Pacific

- 5.5.4 Middle East and Africa

- 5.5.4.1 Middle East

- 5.5.4.1.1 United Arab Emirates

- 5.5.4.1.2 Saudi Arabia

- 5.5.4.1.3 Turkey

- 5.5.4.1.4 Rest of Middle East

- 5.5.4.2 Africa

- 5.5.4.2.1 South Africa

- 5.5.4.2.2 Nigeria

- 5.5.4.2.3 Egypt

- 5.5.4.2.4 Rest of Africa

- 5.5.5 South America

- 5.5.5.1 Brazil

- 5.5.5.2 Argentina

- 5.5.5.3 Rest of South America

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (Includes Global level Overview, Market level overview, and others)

- 6.4.1 Gerresheimer AG

- 6.4.2 Schott AG

- 6.4.3 SGD Pharma

- 6.4.4 Stevanato Group

- 6.4.5 Corning Inc.

- 6.4.6 Nipro Corp.

- 6.4.7 West Pharmaceutical Services

- 6.4.8 Bormioli Pharma

- 6.4.9 Owens-Illinois (Ardagh Glass Pharma)

- 6.4.10 Stolzle Glass Group

- 6.4.11 Beatson Clark

- 6.4.12 Shandong Medicinal Glass

- 6.4.13 Arab Pharmaceutical Glass

- 6.4.14 Piramal Glass

- 6.4.15 Sisecam Group

- 6.4.16 Baxter BioPharma Solutions

- 6.4.17 Kindeva Drug Delivery

- 6.4.18 Origin Pharma Packaging

- 6.4.19 DWK Life Sciences

- 6.4.20 GerroMed (under-reported niche)

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-need Assessment