|

市场调查报告书

商品编码

1851900

条码印表机:市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)Barcode Printer - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

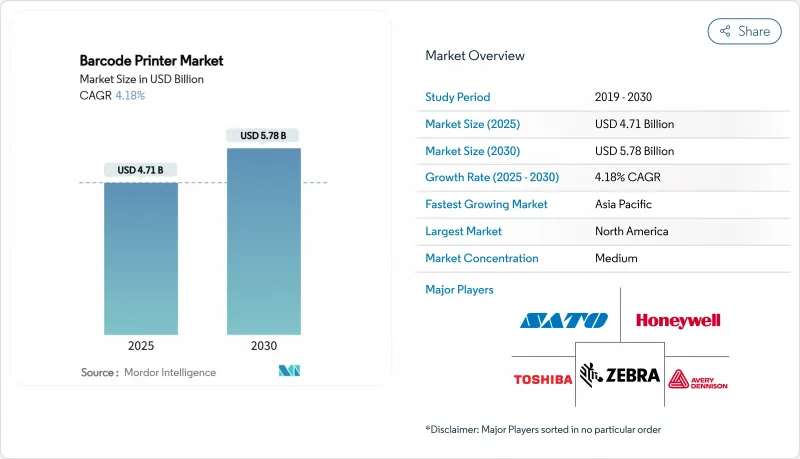

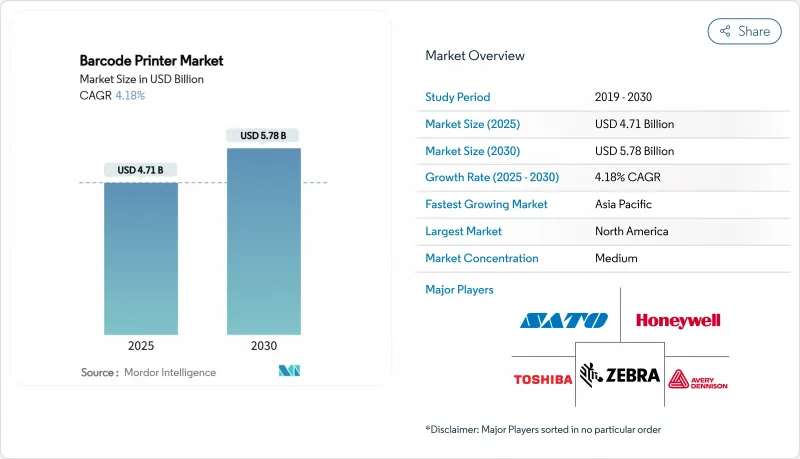

条码印表机市场预计到 2025 年将达到 47.1 亿美元,到 2030 年将达到 57.8 亿美元,年复合成长率为 4.18%。

这一成长反映了企业在自动化和供应链数位化的持续投入,即使该行业已步入成熟阶段,需求仍保持稳定。医疗保健和食品领域可追溯性要求的不断提高、全通路零售的加速发展以及智慧工厂对序列化生产数据的需求,都为采购预算提供了支撑。热转印技术持续推动条码印表机市场的发展,因为它能够为注重合规性的环境提供耐用标籤;而直接热感印表机则因其耗材成本更低、工作流程更简化而日益普及。儘管工业印表机仍然是全球製造业的标配,但随着末端配送网路和现场服务机构对即时标籤的需求不断增长,行动印表机如今已成为明显的成长引擎。随着中国製造商不断扩大规模并在价格上挑战现有企业,竞争日益激烈,迫使老牌企业加强对软体整合和专业服务的投入。

全球条码印表机市场趋势与洞察

全通路零售与电子商务物流的蓬勃发展

为了因应季节性需求波动,零售商在多个管道管理统一库存时,需要在履约中心即时列印标籤。 American Eagle Outfitters 在其位于宾州、占地 165 万平方英尺的物流中心实施了基于影像的解决方案,将纸箱读取准确率提升至 99%,这表明更高的扫描率能够带来更精准的列印效果。 Blue Sky Distribution 将客製印刷与路线规划软体同步,实现了 100% 的订单准确率,并将履约效率提高了 80%。为了消除固定瓶颈并提高仓库的灵活性,企业正在拣货车上部署固定式印表机。云端监控也越来越受欢迎,使 IT 团队能够远端管理韧体和安全性修补程式。这些需求正推动条码印表机市场向无线、坚固耐用型设备发展,这些设备可以透过集中式控制面板进行维护。

工业4.0主导的智慧工厂采用AIDC

智慧工厂依靠自动化识别和资料撷取,将生产资产与ERP和MES平台直接连接起来。斑马公司的FS42固定式扫描器整合了神经处理技术,用于检测条码并为AI模型提供数据,从而标记生产线上的缺陷。条码列印机将序号传输到工厂网络,支援基于组件ID的预测性维护程序。 Brady公司声称,基于列印条码的自动化资料输入可以消除高达90%的手动输入错误,同时将营运效率提高40%。因此,製造商正在指定支援工业通讯协定、边缘运算和高吞吐量的印表机。儘管各产业的资本支出大幅放缓,但硬体更新换代週期仍在持续。

热感印表机头的供应和价格波动

关税和不断上涨的原材料价格将导致热敏纸成本在2024年之前出现两位数的增长。印表机头生产集中在东亚少数几家专业工厂,替换用刷头% 。原始设备製造商(OEM)必须储备更多库存,这增加了营运成本热感,并推高了终端用户的价格。由于买家等待零件成本恢復正常,一些计划被迫停滞。从长远来看,製造商正在评估多供应商策略,但资金障碍限制了供应多样性。

细分市场分析

到2024年,工业印表机将占据条码印表机市场57.1%的份额,并创造最高的收入。这些设备支援宽幅介质、钢製底盘,并具备超过全天候运作的超长列印週期,因此对于製造商和物流中心而言,执行时间。 SATO的CL4NX Plus印表机列印速度高达14吋/秒,并配备基于韧体的印字头磨损追踪功能,可实现预测性零件更换。然而,到2030年,行动条码印表机的复合年增长率将达到6.2%,因为零工经济宅配业者、现场工程师和店内拣货员需要轻巧易携的设备。行动条码印表机市场预计将从2025年的10.2亿美元增长到2030年的13.9亿美元,这表明便携性正在重新定义客户的期望。桌上型印表机凭藉其可接受的列印週期和适中的初始投资,在小型企业中越来越受欢迎。将工业引擎安装在推车平台上的混合设计可能会模糊产品线,这表明未来的产品细分将更多地取决于工作流程而不是外形规格。

就出货量而言,工业印表机仍占最大份额。然而,中国OEM厂商的激进定价策略正在挤压中端市场的利润空间。随着买家更加重视电池续航时间、无线安全性和抗摔性能,行动印表机的平均售价表现更为稳定。展望未来,工业印表机产品可能会专注于乙太网路、蓝牙5和WPA3等连接方式的升级,而行动印表机产品则会在轻薄且麵向医疗保健的抗菌外壳方面展开竞争。工业领域根深蒂固的需求与行动领域的快速发展并存,凸显了市场区隔即使某个细分市场日益成熟,也能持续成长的潜力。

条码印表机市场按产品类型(桌上型印表机、行动印表机、工业印表机)、列印热感(热转印、直热式、雷射、喷墨等)、终端用户产业(製造业、零售业、运输物流业、医疗保健业及其他终端用户产业)及地区进行细分。市场预测以美元计价。

区域分析

到2024年,北美将占据条码印表机市场31.7%的份额。联邦政府的采购,例如美国邮政服务公司对数千台斑马(Zebra)设备的更新换代,推动了硬体需求的成长。药品供应链法规也要求医院和药局投资购买能够处理GS1 DataMatrix条码介质的印表机。加拿大零售业的现代化以及墨西哥加工厂的出口进一步提振了该地区的需求。预计北美条码印表机市场规模将在2025年达到14.9亿美元,并在2030年达到18.1亿美元。该地区的用户通常优先考虑整体拥有成本,因此他们倾向于采用远端设备管理套件,以便无需现场维护即可安排韧体更新。

亚太地区是成长最快的区域,预计到2030年复合年增长率将达到4.9%。中国和印度持续兴建家用电器和服装新工厂,这些工厂都需要在线上贴标以满足出口需求。 Gainsha拥有4万平方公尺的生产空间,并持有50项热感专利。其HPRT产品销往80多个国家,体现了中国品牌的全球影响力。日本汽车工厂正加速推动工业4.0的整合,而东南亚地区则出现了近岸外包现象,推动了南方地区对贴标设备的需求。预计到2025年,亚太地区条码印表机市场规模将达13.3亿美元,2030年将超过16.9亿美元。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 全通路零售与电子商务物流的蓬勃发展

- 工业4.0主导的智慧工厂采用AIDC

- 医疗保健和食品产业对低温运输可追溯性的需求

- 行动和穿戴式条码印表机市场

- 云端原生远端列印管理和安全

- 采用无底纸标籤以符合ESG标准

- 市场限制

- 热感印表机头的供应和价格波动

- 向二维码/RFID技术的转变将降低对基础条码的需求。

- 更严格的电子垃圾处理指令将推高生命週期成本。

- 在严苛的工业应用中,转向直接零件标记和雷射蚀刻技术

- 供应链分析

- 监管环境

- 技术展望

- 波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 竞争对手之间的竞争

- 替代品的威胁

- 评估市场的宏观经济因素

第五章 市场规模与成长预测

- 依产品类型

- 桌上型印表机

- 行动印表机

- 工业印表机

- 透过印刷技术

- 热传递

- 直接热感

- 雷射

- 喷墨

- 其他的

- 按最终用户行业划分

- 製造业

- 车

- 电子学

- 食品/饮料

- 其他的

- 零售

- 运输与物流

- 卫生保健

- 其他终端用户产业

- 製造业

- 按地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 俄罗斯

- 其他欧洲地区

- 亚太地区

- 中国

- 日本

- 印度

- 韩国

- 亚太其他地区

- 中东和非洲

- 中东

- GCC

- 土耳其

- 以色列

- 其他中东地区

- 非洲

- 南非

- 奈及利亚

- 肯亚

- 其他非洲地区

- 北美洲

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- Zebra Technologies Corporation

- Sato Holdings Corporation

- Honeywell International Inc.

- Toshiba Tec Corporation

- Avery Dennison Corporation

- Seiko Epson Corporation

- TSC Auto ID Technology Co. Ltd.

- Brother Industries Ltd.

- Postek Electronics Co. Ltd.

- Primera Technology Inc.

- Bixolon Co. Ltd.

- Citizen Systems Japan Co. Ltd.

- Godex International Co. Ltd.

- Wasp Barcode Technologies

- Cab Produkttechnik GmbH and Co KG

- Printronix Auto ID Inc.

- Gainscha Technology Group Ltd.

- Domino Printing Sciences plc

- IDPRT(Xiamen Hanin Co. Ltd.)

- Datamax

第七章 市场机会与未来展望

The barcode printer market size is valued at USD 4.71 billion in 2025 and is forecast to reach USD 5.78 billion by 2030, advancing at a 4.18% CAGR.

This growth reflects steady corporate investment in automation and supply chain digitization that keeps demand resilient even as the sector enters a more mature phase. Expanding traceability mandates in healthcare and food, the acceleration of omnichannel retail, and the need for serialized production data inside smart factories all sustain procurement budgets. Thermal transfer technology continues to anchor the barcode printer market because it supports durable labels for compliance-critical environments, yet direct thermal printers are gaining ground because users prefer their lower consumable costs and simplified workflows. Industrial printers remain the workhorse of global manufacturing sites, but mobile units are now the clear growth engine as last-mile delivery networks and field service organizations pursue real-time labeling. Competitive intensity is rising as Chinese manufacturers scale up and challenge incumbents on price, forcing established brands to double down on software integration and specialized service offerings.

Global Barcode Printer Market Trends and Insights

Omnichannel retail and e-commerce logistics boom

Retailers that manage unified inventories across multiple channels need labels printed in real time at fulfillment sites to cope with seasonal demand swings. American Eagle Outfitters lifted carton reading accuracy to 99% after installing image-based solutions in its 1.65 million sq ft Pennsylvania distribution center, illustrating how higher scan rates feed back into precise print requirements. Blue Sky Distribution recorded 100% order accuracy and an 80% jump in fulfillment efficiency once it synchronized on-demand printing with routing software, which cut single-day delivery errors as orders rose 70%. Retailers now deploy mobile printers on picking carts to remove stationary bottlenecks, enhancing flexibility on warehouse floors. Demand for cloud oversight is also rising so that IT teams can manage firmware and security patches remotely. These needs push the barcode printer market toward devices that are wireless, rugged, and serviceable through centralized dashboards.

Industry 4.0-driven smart factories adopting AIDC

Smart factories rely on automated identification and data capture to link production assets directly with ERP and MES platforms. Zebra's FS42 fixed scanner integrates neural processing to inspect codes and feed AI models that flag defects on the line. When barcode printers relay serial numbers to plant networks, they enable predictive maintenance programs that rely on component IDs. Brady Corporation observed that automated data entry based on printed codes can eliminate up to 90% of manual typing errors while increasing lifting efficiency by 40%. Manufacturers therefore specify printers that support industrial protocols, edge computing, and high-volume throughput. The result is sustained hardware refresh cycles despite the broader slowdown in capital expenditure across sectors.

Supply volatility and price swings for thermal printheads

Tariffs and rising input prices pushed thermal paper costs up by double digits in 2024. Printhead fabrication is concentrated among a handful of specialist plants in East Asia, and replacement heads wear 25-50% faster in direct thermal modes than in thermal transfer settings. OEMs must stock larger buffers, elevating working capital needs and pushing end-user prices higher. Some projects have slipped because buyers wait for component costs to normalize. Longer term, manufacturers are evaluating multi-supplier strategies, yet the capital barrier keeps supply diversity modest.

Other drivers and restraints analyzed in the detailed report include:

- Cold-chain traceability demand in healthcare and food

- Mobile and wearable barcode printers enhancing field productivity

- Migration toward QR / RFID reducing basic barcode demand

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Industrial printers produced the highest revenue in 2024 by securing 57.1% of the barcode printer market. These devices deliver wide media widths, steel chassis, and duty cycles that exceed 24-hour operation, which manufacturers and logistics hubs value for uptime. SATO's CL4NX Plus prints at 14 ips while tracking head wear in firmware, ensuring predictive part replacement. Nonetheless, mobile units record a 6.2% CAGR to 2030 as gig-economy couriers, field engineers, and in-store pickers seek lightweight devices that roam with workers. The barcode printer market size for mobile models is projected to expand from USD 1.02 billion in 2025 to USD 1.39 billion by 2030, indicating that portability is redefining customer expectations. Desktop printers keep traction among small firms because they blend acceptable duty cycles with modest capex. Hybrid designs that mount industrial engines on cart platforms may blur product lines, suggesting future segmentation will hinge on workflow rather than form factor.

In volume terms, industrial printers still ship the largest absolute unit count because multi-line factories employ fleets for work-in-process tickets. However, price aggression by Chinese OEMs is compressing margins in the mid-tier. Mobile printer ASPs have proven more resilient because buyers prioritize battery life, wireless security, and drop resistance. Over the forecast, industrial SKU turnover will center on connectivity upgrades-Ethernet, Bluetooth 5, and WPA3-while mobile SKUs will compete on weight reductions and antimicrobial casings for healthcare. The coexistence of entrenched industrial demand with agile mobile adoption underscores how the barcode printer market can grow even as one segment matures.

Barcode Printer Market is Segmented by Product Type (Desktop Printers, Mobile Printers, Industrial Printers), Printing Technology (Thermal Transfer, Direct Thermal, Laser, Inkjet, Others), End-User Industry (Manufacturing, Retail, Transportation and Logistics, Healthcare, Other End-User Industries), and by Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

North America retained 31.7% of the barcode printer market in 2024. Federal procurement, such as the United States Postal Service's refresh of thousands of Zebra devices, anchors hardware volumes. Drug supply chain laws also oblige hospitals and pharmacies to invest in printers that handle GS1 DataMatrix media. Canada's retail modernization and Mexico's maquiladora exports further reinforce regional demand. The barcode printer market size for North America is estimated at USD 1.49 billion in 2025 and will edge toward USD 1.81 billion by 2030. Users in the region typically prioritize total cost of ownership, driving adoption of remote fleet management suites that schedule firmware updates without site visits.

Asia-Pacific is the fastest-expanding arena with a 4.9% CAGR to 2030. China and India keep building new factories for consumer electronics and apparel, each requiring inline labeling for export. Gainscha operates over 40,000 sqm of manufacturing space and holds 50 thermal patents, underscoring indigenous capability gains. HPRT reports distribution in more than 80 countries, reflecting the global reach of Chinese brands. Japan advances Industry 4.0 integration in automotive plants, while Southeast Asia wins near-shoring that moves labeling equipment demand southward. The barcode printer market size in Asia-Pacific is projected at USD 1.33 billion in 2025 and should exceed USD 1.69 billion by 2030.

- Zebra Technologies Corporation

- Sato Holdings Corporation

- Honeywell International Inc.

- Toshiba Tec Corporation

- Avery Dennison Corporation

- Seiko Epson Corporation

- TSC Auto ID Technology Co. Ltd.

- Brother Industries Ltd.

- Postek Electronics Co. Ltd.

- Primera Technology Inc.

- Bixolon Co. Ltd.

- Citizen Systems Japan Co. Ltd.

- Godex International Co. Ltd.

- Wasp Barcode Technologies

- Cab Produkttechnik GmbH and Co KG

- Printronix Auto ID Inc.

- Gainscha Technology Group Ltd.

- Domino Printing Sciences plc

- IDPRT (Xiamen Hanin Co. Ltd.)

- Datamax

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Omnichannel retail and e-commerce logistics boom

- 4.2.2 Industry 4.0-driven smart factories adopting AIDC

- 4.2.3 Cold-chain traceability demand in healthcare and food

- 4.2.4 Mobile and wearable barcode printer

- 4.2.5 Cloud-native remote print management and security

- 4.2.6 Adoption of linerless labeling for ESG compliance

- 4.3 Market Restraints

- 4.3.1 Supply volatility and price swings for thermal printheads

- 4.3.2 Migration toward QR/RFID reducing basic barcode demand

- 4.3.3 Tightening e-waste directives inflating lifecycle costs

- 4.3.4 Shift to direct-part marking and laser etching in harsh industrial use

- 4.4 Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Consumers

- 4.7.3 Threat of New Entrants

- 4.7.4 Intensity of Competitive Rivalry

- 4.7.5 Threat of Substitute Products

- 4.8 Assessment of the Macroeconomic Factors on the Market

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Product Type

- 5.1.1 Desktop Printers

- 5.1.2 Mobile Printers

- 5.1.3 Industrial Printers

- 5.2 By Printing Technology

- 5.2.1 Thermal Transfer

- 5.2.2 Direct Thermal

- 5.2.3 Laser

- 5.2.4 Inkjet

- 5.2.5 Others

- 5.3 By End-user Industry

- 5.3.1 Manufacturing

- 5.3.1.1 Automotive

- 5.3.1.2 Electronics

- 5.3.1.3 Food and Beverage

- 5.3.1.4 Others

- 5.3.2 Retail

- 5.3.3 Transportation and Logistics

- 5.3.4 Healthcare

- 5.3.5 Other End-user Industries

- 5.3.1 Manufacturing

- 5.4 By Geography

- 5.4.1 North America

- 5.4.1.1 United States

- 5.4.1.2 Canada

- 5.4.1.3 Mexico

- 5.4.2 South America

- 5.4.2.1 Brazil

- 5.4.2.2 Argentina

- 5.4.2.3 Rest of South America

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Russia

- 5.4.3.6 Rest of Europe

- 5.4.4 Asia-Pacific

- 5.4.4.1 China

- 5.4.4.2 Japan

- 5.4.4.3 India

- 5.4.4.4 South Korea

- 5.4.4.5 Rest of Asia-Pacific

- 5.4.5 Middle East and Africa

- 5.4.5.1 Middle East

- 5.4.5.1.1 GCC

- 5.4.5.1.2 Turkey

- 5.4.5.1.3 Israel

- 5.4.5.1.4 Rest of Middle East

- 5.4.5.2 Africa

- 5.4.5.2.1 South Africa

- 5.4.5.2.2 Nigeria

- 5.4.5.2.3 Kenya

- 5.4.5.2.4 Rest of Africa

- 5.4.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Zebra Technologies Corporation

- 6.4.2 Sato Holdings Corporation

- 6.4.3 Honeywell International Inc.

- 6.4.4 Toshiba Tec Corporation

- 6.4.5 Avery Dennison Corporation

- 6.4.6 Seiko Epson Corporation

- 6.4.7 TSC Auto ID Technology Co. Ltd.

- 6.4.8 Brother Industries Ltd.

- 6.4.9 Postek Electronics Co. Ltd.

- 6.4.10 Primera Technology Inc.

- 6.4.11 Bixolon Co. Ltd.

- 6.4.12 Citizen Systems Japan Co. Ltd.

- 6.4.13 Godex International Co. Ltd.

- 6.4.14 Wasp Barcode Technologies

- 6.4.15 Cab Produkttechnik GmbH and Co KG

- 6.4.16 Printronix Auto ID Inc.

- 6.4.17 Gainscha Technology Group Ltd.

- 6.4.18 Domino Printing Sciences plc

- 6.4.19 IDPRT (Xiamen Hanin Co. Ltd.)

- 6.4.20 Datamax

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment