|

市场调查报告书

商品编码

1851911

无底纸标籤:市场占有率分析、产业趋势、统计数据和成长预测(2025-2030 年)Linerless Labels - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

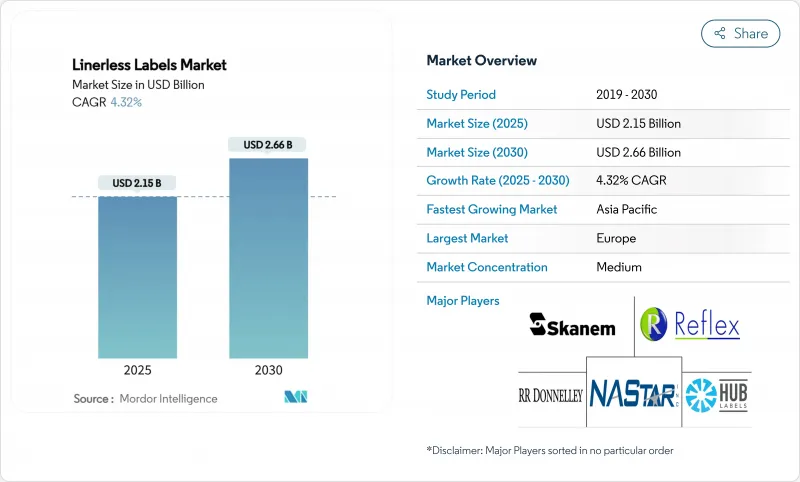

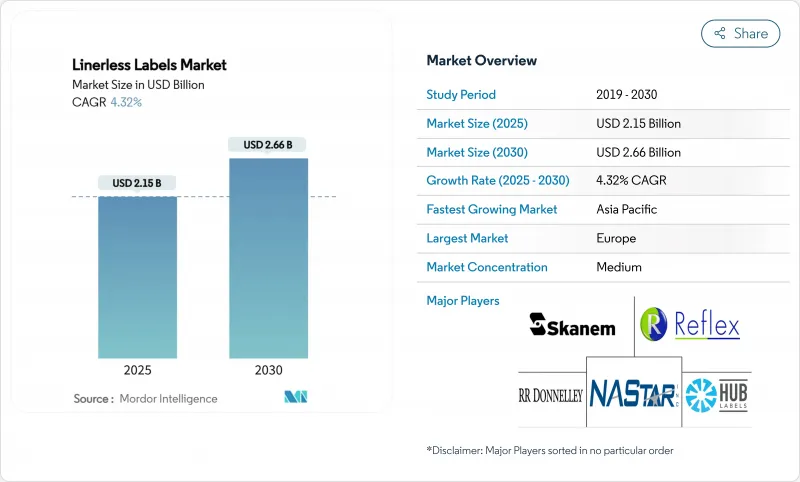

无底纸标籤市场预计到 2025 年将达到 21.5 亿美元,到 2030 年将达到 26.6 亿美元,年复合成长率为 4.32%。

该法规要求所有包装在2030年前必须可回收,并争取2040年将人均包装废弃物减少15%。柔版印刷继续占据40.32%的市场份额,而以喷墨和热感技术为主导的数位印刷系统正以7.43%的复合年增长率快速增长,这主要得益于电子商务推动了对可变长度、客製印刷的需求。薄膜基材占48.23%的市场份额,其中特种基材和再生基材的复合年增长率最高,达到8.11%,符合企业的循环经济目标。水性丙烯酸胶黏剂保持其主导地位,市占率为42.32%,而紫外光固化胶合剂正以7.84%的复合年增长率快速成长,以弥补低温运输性能方面的不足。欧洲以34.62%的市占率领先,而亚太地区则在製造规模扩大和电子商务成长的推动下,以8.53%的复合年增长率快速成长。

全球无底纸标籤市场趋势与洞察

对永续食品和饮料包装的需求激增

为了满足监管要求和消费者对低环境影响包装的期望,食品品牌正在采用无底纸标籤。艾利丹尼森公司报告称,其智慧标籤部门到2024年将实现15%的有机销售额成长,其中大部分成长归功于食品应用。与预衬纸产品相比,食品应用可减少30%的材料用量和49%的碳排放。生鲜食品供应商越来越多地指定使用无底纸解决方案,以减少掩埋的废弃物并提高可追溯性。自动化包装生产线正在利用动态标籤尺寸调整技术,将材料用量减少高达40%。这些因素共同加速了冷藏、冷冻和常温产品类型的市场普及。随着大型加工商制定供应商强制性要求并逐步推广至整个区域价值链,其影响将更加显着。对可回收面板和食品级UV固化黏合剂的投资将进一步推动已调理食品产业的应用。

物流的蓬勃发展需要可变长度的运输标籤。

小包裹数量的快速增长迫使履约中心优化标籤库存并减少浪费。东芝的DL1024工业印表机将运输标籤和装箱单整合到单一的可变长度格式中,从而降低40%的列印成本并消除衬纸浪费。美国邮政服务修订后的小包裹标籤指南强调采用精简设计以加快自动化扫描速度,间接支持了无衬纸包装。高吞吐量设施报告称,每卷标籤数量增加了50%,减少了换卷次数并提高了吞吐量。微型履约中心透过无衬纸包装节省空间,提高了拣货效率。零售商严格的永续发展评分标准正促使供应商转向无衬纸系统,以避免因过度包装而受到处罚。

改造旧式贴标生产线的成本

改用无底纸贴标机通常需要每条生产线投入 5 万至 20 万美元的资本升级,这对规模较小的加工商来说是一笔不小的开支,会将投资回收期延长至约两年。 FoxJet 的全电动贴标机现在提供模组化改造套件,无需压缩空气,从而降低营业成本并简化安装。然而,员工培训和改进的维护流程仍然会增加间接成本。许多生产商正在采用混合工作流程,使用无底纸贴标机生产新的 SKU,而使用传统设备处理长期生产的产品。提供融资方案或订阅模式的设备供应商可以透过减轻领先资金压力来加快转换速度。

细分市场分析

到2024年,弹性凸版印刷将维持40.32%的无底纸标籤市场份额,而数位印刷市场将以7.43%的复合年增长率成长。随着电商企业对可变数据和即时客製化的需求日益增长,中短版数位印刷的无底纸标籤市场规模将迅速扩大。结合柔版底涂和喷墨底漆的混合印刷机可减少浪费并加快换版速度。热感直印系统具有物流优势,即使标籤需要承受物料输送过程中的磨损,也能维持成本效益。数位工作流程还能减少水和溶剂的使用,进而实现永续性目标。对线上完工和云端色彩管理的投资提高了输出一致性,使数位印刷能够在中等版次的印刷量上与传统柔版印刷展开正面竞争。

与RFID嵌体插入技术的兼容性进一步增强了数位技术的作用,实现了智慧标籤的一次性生产。利用网路标籤入口网站的加工商正从需要个人化设计且无最低订购量限制的小型经销商中获得新的收入。基材製造商正在推出无需底涂的薄膜,从而提高油墨附着力并降低耗材成本。摘要,印刷技术组合正在快速变化,柔版印刷更适合大宗商品SKU,而数位印刷更适合无底纸标籤市场中快速变化、数据丰富的应用。

由于其耐湿性和较长的保质期,以PP和PET为主的薄膜面材占据了无底纸标籤市场48.23%的份额。然而,在买家对循环经济的承诺和监管机构对再生材料含量配额的推动下,特种材料和再生材料替代品的市场成长速度正在超过它们,复合年增长率高达8.11%。预计到2030年,用于食品和个人护理包装的再生材料薄膜无底纸标籤市场规模将稳定成长。 UPM Raflatac的碳行动产品组合采用ISCC认证的材料,旨在减少从摇篮到大门的排放,并吸引那些寻求范围3减排的品牌。

纸面材料填补了可堆肥性和触感优先于耐用性的市场空白。混合结构将薄型聚丙烯(PP)表层与再生牛皮纸基材结合,在优化强度的同时降低了原生塑胶的用量。可水洗薄膜可在碱性溶液中剥离,实现PET的闭合迴路回收,这对于寻求瓶到瓶回收系统的饮料供应商至关重要。供应商现在能够提供与传统复合标籤相媲美的更丰富的颜色和表面处理选择,从而消除了特种标籤应用的一大障碍。对双向拉伸线和解解聚合回收工厂的持续投资将扩大原材料供给能力,以满足不断增长的需求。

区域分析

2024年,欧洲将占全球销售额的34.62%,这得益于其较早的监管政策、完善的零售网络和成熟的加工商基础。 UPM Raflatac和HERMA等区域领导者率先推出了可清洗和再生材料包装,从而带动了自有品牌的需求成长。政府采购标准中对可回收包装的明确规定进一步巩固了欧洲的领先地位。北美也紧随其后,这主要得益于电子商务的快速发展以及各州推行的生产者延伸责任制立法,该立法将包装供应商的废弃物成本内部化。该地区的加工商正在投资建造高速紫外线消毒生产线,以服务冷藏食品和小包裹配送中心,而CCL Industries则透过策略性收购扩大产能。

亚太地区将以8.53%的复合年增长率成为成长最快的地区,这主要得益于中国庞大的製造业规模和印度电子商务的快速发展。随着本地加工商增加数位印刷机,以及国际品牌对美观、永续包装的需求不断增长,该地区的无底纸标籤市场份额预计将会上升。日本Lintec Corporation公司正在投资扩大耐寒黏合剂的产能和研发,以巩固其在该地区的技术领先地位。越南和印尼等新兴市场正在采用无底纸标籤,以满足西方零售商制定的出口认证标准。南美洲也呈现出选择性成长,一家巴西大型饮料製造商正在宝特瓶回收计划中试用可清洗薄膜。在中东和非洲,阿联酋和南非处于领先地位,跨国快速消费品工厂正在采用全球标准。

监管协调、跨境电子商务以及对生产能力的投资都表明,该地区的需求将持续轮动。随着资本流入亚太地区的生产能力,原料供应链也将随之调整,进一步降低单价并加速生产线库存的更新换代。欧洲仍然是监管领域的标桿,其政策创新正日益在全球范围内得到效仿,巩固了无内衬生产能力作为出口型製造商基本要求的地位。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 对永续食品和饮料包装的需求激增

- 电子商务物流的蓬勃发展需要可变长度的运输标籤。

- 欧洲和北美减少废弃物的监管要求

- 按需无底纸印刷促进快餐店厨房自动化

- 采用RFID互联包装及微型履约

- 市场限制

- 传统标籤生产线维修成本

- 原料价格波动(黏合剂和被覆剂);

- 低温运输环境中的黏合剂累积问题

- 供应链分析

- 监管环境

- 技术展望

- 波特五力分析

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争

第五章 市场规模与成长预测

- 透过印刷技术

- 数码(喷墨和热感)

- 柔版印刷

- 凹版印刷

- 胶印和凸版印刷

- 透过面材

- 纸

- 薄膜(PP、PET、PE)

- 特种和再生基材

- 按黏合剂类型

- 水性丙烯酸

- 热熔胶

- 紫外线固化型

- 溶剂型

- 按最终用户行业划分

- 食物

- 饮料

- 医疗保健和製药

- 化妆品和个人护理

- 家用化学品

- 物流与电子商务

- 其他终端用户产业

- 按地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 其他欧洲地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 澳洲、纽西兰

- 亚太其他地区

- 中东和非洲

- 中东

- 阿拉伯聯合大公国

- 沙乌地阿拉伯

- 土耳其

- 其他中东地区

- 非洲

- 南非

- 奈及利亚

- 埃及

- 其他非洲地区

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 北美洲

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- Avery Dennison Corporation

- CCL Industries(Inc. & Innovia Films)

- 3M Company

- Beontag

- UPM Raflatac

- Coveris

- Hub Labels Inc.

- Reflex Labels Ltd

- Skanem AS

- NAStar Inc.

- Optimum Group

- SATO Europe GmbH

- ProPrint Group

- Lexit Group AS

- RR Donnelley & Sons Co.

- Gipako UAB

- Lintec Corporation

- HERMA GmbH

- Zebra Technologies

- Multi-Color Corporation

第七章 市场机会与未来展望

The linerless labels market size is valued at USD 2.15 billion in 2025 and is forecast to reach USD 2.66 billion by 2030, advancing at a 4.32% CAGR.

Growth is anchored in stricter global packaging regulations, particularly the European Union's Packaging and Packaging Waste Regulation, which requires all packaging to be recyclable by 2030 and targets a 15% cut in per-capita packaging waste by 2040. Flexography continues to hold a 40.32% share, yet digital systems led by inkjet and thermal technologies are expanding at a 7.43% CAGR as e-commerce drives demand for variable-length, on-demand printing. Film facestocks account for 48.23% share, while specialty and recycled substrates post the strongest 8.11% CAGR amid corporate circular-economy goals. Water-based acrylic adhesives remain dominant at 42.32% share; UV-curable chemistries grow the fastest at 7.84% CAGR, solving cold-chain performance gaps. Europe leads with 34.62% share; however, Asia-Pacific rises at an 8.53% CAGR on the back of manufacturing scale-up and e-commerce expansion.

Global Linerless Labels Market Trends and Insights

Surge in Sustainable Food and Beverage Packaging Demand

Food brands are embedding linerless labels to meet both regulatory compliance and consumer expectations for lower-impact packaging. Avery Dennison reported 15% organic sales growth in its Intelligent Labels division during 2024, attributing much of the increase to food applications that cut material use by 30% and carbon footprint by 49% versus linered products. Fresh produce suppliers increasingly specify linerless solutions to slash landfill waste and enhance traceability, while automated packaging lines leverage dynamic label sizing to trim material usage by up to 40%. Combined, these factors accelerate market uptake across chilled, frozen and ambient product categories. The effect compounds as large processors set supplier mandates that cascade through regional value chains. Investments in recyclable facestocks and food-grade UV-curable adhesives further propel adoption in prepared-meal sectors.

E-commerce Logistics Boom Requiring Variable-Length Shipping Labels

Soaring parcel volumes force fulfillment centers to optimize label inventory and waste. Toshiba's DL1024 industrial printer merges shipping labels and packing slips into one variable-length format, lowering printing costs by 40% and eliminating liner waste. The United States Postal Service's revised parcel-labeling guide emphasizes streamlined designs that speed automated scanning, indirectly supporting linerless migration. High-volume facilities report 50% more labels per roll, translating into fewer roll changes and faster throughput. In micro-fulfillment hubs, space savings from liner elimination unlock additional picking capacity. Retailers' stricter sustainability scorecards are pushing suppliers toward linerless systems to avoid penalties linked to excess packaging.

Retrofit Costs for Legacy Labeling Lines

Switching to linerless often demands capital upgrades of USD 50,000 - 200,000 per line, a hurdle for smaller converters that extends payback periods to roughly two years. FoxJet's all-electric labelers now offer modular retrofit kits that remove compressed-air requirements, lowering operating costs and easing installation. Still, personnel training and revised maintenance routines add indirect expense. Many producers adopt hybrid workflows: linerless on new SKUs while legacy gear handles long-running products. Equipment vendors that bundle finance packages or subscription models can accelerate conversion by alleviating upfront cash pressure.

Other drivers and restraints analyzed in the detailed report include:

- Regulatory Waste-Reduction Mandates in Europe and North America

- QSR Kitchen Automation Uptake of On-Demand Linerless Printing

- Raw-Material Price Volatility Affecting Adhesives and Release Coatings

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Flexography maintained a 40.32% slice of the linerless labels market in 2024, but the digital segment is expanding at a 7.43% CAGR. The linerless labels market size for digital presses serving short and mid runs is set to widen quickly as e-commerce brands demand variable data and real-time customization. Hybrid presses that merge flexo priming with inkjet finishing lower waste and speed changeovers, an advantage for converters chasing small batch jobs. Thermal direct systems flourish in logistics because labels must survive material-handling abrasion yet remain cost-effective. Digital workflows also reduce water and solvent use, aligning with sustainability scorecards. Investments in inline finishing and cloud-connected color management lift output consistency, helping digital formats compete head-on with conventional flexo for medium runs.

Compatibility with RFID inlay insertion further elevates digital's role, enabling one-pass production of smart labels. Converters leveraging web-to-label portals capture new revenue from small sellers needing personalized designs without minimum-order hurdles. As substrate manufacturers release primer-free films, ink adhesion improves and reduces consumable costs. In summary, the printing-technology mix is shifting rapidly, with flexo staying relevant for commoditized SKUs while digital becomes the default for fast-moving, data-rich applications across the linerless labels market.

Film-based facestocks-largely PP and PET-retain a 48.23% grip on the linerless labels market share thanks to moisture resistance and shelf appeal. Yet specialty and recycled alternatives outpace at an 8.11% CAGR, propelled by buyers' circular-economy pledges and regulatory recycled-content quotas. The linerless labels market size for recycled-content films covering food and personal-care packages is forecast to climb steadily through 2030. UPM Raflatac's Carbon Action portfolio uses ISCC-certified feedstocks to cut cradle-to-gate emissions and appeal to brands chasing Scope-3 reductions.

Paper facestocks defend niches where compostability or tactile branding trumps durability. Hybrid structures pairing thin PP overcell with recycled-kraft bases optimize strength while shrinking virgin-plastic content. Wash-off films that delaminate in alkaline baths permit closed-loop PET recycling, crucial for beverage suppliers seeking bottle-to-bottle systems. Suppliers broaden color and finish ranges to rival conventional laminated labels, removing one more barrier to specialty adoption. Continuous investment in biax-stretch lines and depolymerization recycling plants indicates that feed-stock availability will scale to meet rising demand.

The Linerless Labels Market Report is Segmented by Printing Technology (Digital, Flexography, Gravure, Offset and Letterpress), Facestock Material (Paper, Film, Specialty and Recycled Substrates), Adhesive Type (Water-Based Acrylic, Hot-Melt, UV-Curable, Solvent-Based), End-User Industry (Food, Beverage, Healthcare and Pharmaceuticals, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Europe commanded 34.62% of 2024 revenue on the strength of early regulatory adoption, dense retail networks and established converter bases. Regional majors such as UPM Raflatac and HERMA pioneer wash-off and recycled-content formats, creating spill-over demand among private-label brands. Government procurement criteria specifying recyclable packaging further cement Europe's lead. North America follows, buoyed by e-commerce acceleration and statewide extended-producer-responsibility bills that internalize disposal costs for packaging suppliers. Converters here invest in high-speed UV lines to serve chilled-food and parcel hubs, while CCL Industries expands capacity via strategic acquisitions.

Asia-Pacific registers the fastest 8.53% CAGR, driven by China's manufacturing scale and India's rapid e-commerce penetration. The linerless labels market share in the region is poised to climb as local converters add digital presses and overseas brands demand harmonized sustainable packaging. Japan's Lintec Corporation invests in capacity upgrades and R&D for cold-resistant adhesives, reinforcing regional technology leadership. Emerging markets such as Vietnam and Indonesia adopt linerless to meet export certification standards set by Western retailers. South America sees selective growth as Brazil's beverage giants trial wash-off films in PET bottle recycling projects. In the Middle East & Africa, uptake centers on United Arab Emirates and South Africa where multinational FMCG plants deploy global specifications.

Collectively, regulatory harmonization, cross-border e-commerce and capacity investments suggest sustained regional demand rotation. As capital flows into Asia-Pacific capacity, raw-material supply chains adapt, further lowering unit costs and accelerating substitution away from linered stock. Europe remains the regulatory bellwether; its policy innovations are increasingly mirrored worldwide, embedding linerless capability as a baseline requirement for export-oriented manufacturers.

- Avery Dennison Corporation

- CCL Industries (Inc. & Innovia Films)

- 3M Company

- Beontag

- UPM Raflatac

- Coveris

- Hub Labels Inc.

- Reflex Labels Ltd

- Skanem AS

- NAStar Inc.

- Optimum Group

- SATO Europe GmbH

- ProPrint Group

- Lexit Group AS

- R.R. Donnelley & Sons Co.

- Gipako UAB

- Lintec Corporation

- HERMA GmbH

- Zebra Technologies

- Multi-Color Corporation

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Surge in sustainable food and beverage packaging demand

- 4.2.2 E-commerce logistics boom requiring variable-length shipping labels

- 4.2.3 Regulatory waste-reduction mandates in Europe and North America

- 4.2.4 QSR kitchen automation uptake of on-demand linerless printing

- 4.2.5 RFID-enabled connected packaging and micro-fulfillment adoption

- 4.3 Market Restraints

- 4.3.1 Retrofit costs for legacy labeling lines

- 4.3.2 Raw-material price volatility (adhesives and release coating)

- 4.3.3 Adhesive build-up issues in cold-chain environments

- 4.4 Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Printing Technology

- 5.1.1 Digital (Inkjet and Thermal)

- 5.1.2 Flexography

- 5.1.3 Gravure

- 5.1.4 Offset and Letterpress

- 5.2 By Facestock Material

- 5.2.1 Paper

- 5.2.2 Film (PP, PET, PE)

- 5.2.3 Specialty and Recycled Substrates

- 5.3 By Adhesive Type

- 5.3.1 Water-based Acrylic

- 5.3.2 Hot-Melt

- 5.3.3 UV-Curable

- 5.3.4 Solvent-based

- 5.4 By End-user Industry

- 5.4.1 Food

- 5.4.2 Beverage

- 5.4.3 Healthcare and Pharmaceuticals

- 5.4.4 Cosmetics and Personal Care

- 5.4.5 Household Chemicals

- 5.4.6 Logistics and E-commerce

- 5.4.7 Other End-User Industry

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 Europe

- 5.5.2.1 Germany

- 5.5.2.2 United Kingdom

- 5.5.2.3 France

- 5.5.2.4 Italy

- 5.5.2.5 Spain

- 5.5.2.6 Russia

- 5.5.2.7 Rest of Europe

- 5.5.3 Asia-Pacific

- 5.5.3.1 China

- 5.5.3.2 India

- 5.5.3.3 Japan

- 5.5.3.4 South Korea

- 5.5.3.5 Australia and New Zealand

- 5.5.3.6 Rest of Asia-Pacific

- 5.5.4 Middle East and Africa

- 5.5.4.1 Middle East

- 5.5.4.1.1 United Arab Emirates

- 5.5.4.1.2 Saudi Arabia

- 5.5.4.1.3 Turkey

- 5.5.4.1.4 Rest of Middle East

- 5.5.4.2 Africa

- 5.5.4.2.1 South Africa

- 5.5.4.2.2 Nigeria

- 5.5.4.2.3 Egypt

- 5.5.4.2.4 Rest of Africa

- 5.5.5 South America

- 5.5.5.1 Brazil

- 5.5.5.2 Argentina

- 5.5.5.3 Rest of South America

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global-level Overview, Market-level Overview, Core Segments, Financials, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 Avery Dennison Corporation

- 6.4.2 CCL Industries (Inc. & Innovia Films)

- 6.4.3 3M Company

- 6.4.4 Beontag

- 6.4.5 UPM Raflatac

- 6.4.6 Coveris

- 6.4.7 Hub Labels Inc.

- 6.4.8 Reflex Labels Ltd

- 6.4.9 Skanem AS

- 6.4.10 NAStar Inc.

- 6.4.11 Optimum Group

- 6.4.12 SATO Europe GmbH

- 6.4.13 ProPrint Group

- 6.4.14 Lexit Group AS

- 6.4.15 R.R. Donnelley & Sons Co.

- 6.4.16 Gipako UAB

- 6.4.17 Lintec Corporation

- 6.4.18 HERMA GmbH

- 6.4.19 Zebra Technologies

- 6.4.20 Multi-Color Corporation

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment