|

市场调查报告书

商品编码

1906195

金属粉末:市场占有率分析、产业趋势与统计、成长预测(2026-2031)Metal Powder - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

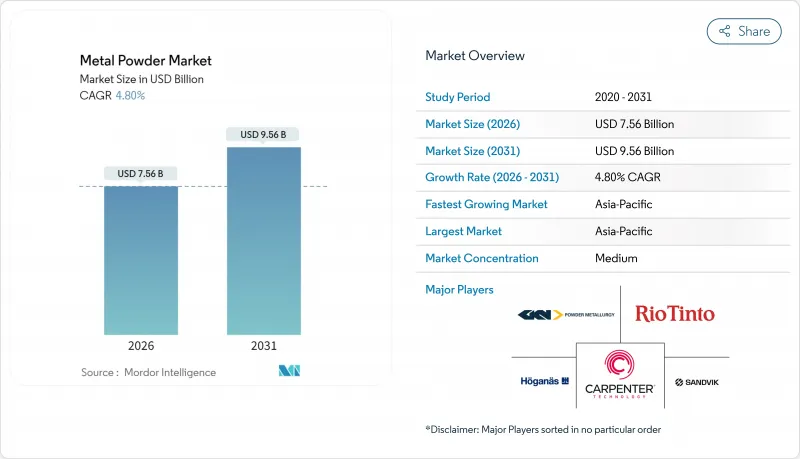

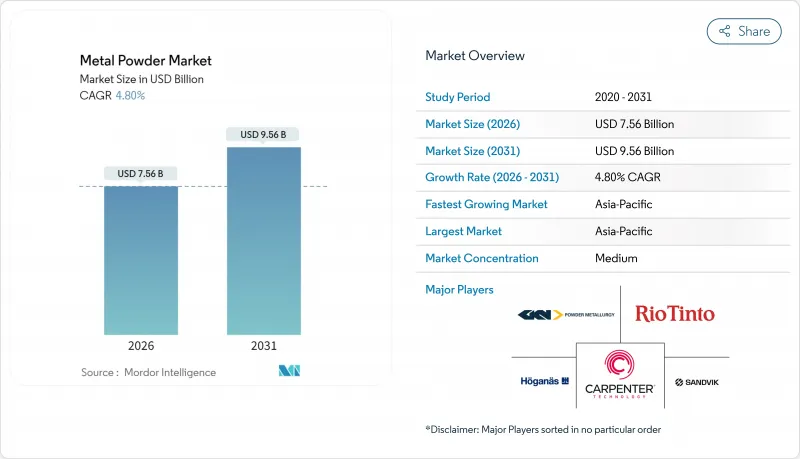

预计到 2026 年,金属粉末市值将达到 75.6 亿美元,高于 2025 年的 72.1 亿美元,预计到 2031 年将达到 95.6 亿美元。

预计从 2026 年到 2031 年,其复合年增长率将达到 4.8%。

汽车电气化、航太业现代化以及增材製造技术的产业化推动了粉末需求的增长,这些因素共同催生了对各种粉末的需求,从低合金铁基粉末到定制的镍钛基粉末。车辆和飞机的轻量化计划、电动动力系统的日益普及以及3D列印结构件的应用,都进一步推动了消费量的成长趋势。同时,粉末生产商面临原材料价格波动和日益严格的环境法规,这不仅推高了合规成本,也促使他们投资于更清洁的喷涂技术。能够灵活应对大批量压制烧结合同和小批量、高利润积层製造订单的供应商,其竞争优势正在不断增强,这也进一步凸显了工艺多元化的必要性。

全球金属粉末市场趋势及展望

促进汽车和航空领域的减重

汽车製造商持续致力于减轻车身重量,以延长电动车的续航里程并符合欧盟7排放气体标准。这推动了专为软磁复合复合材料设计的高密度铁基和铝基粉末的广泛应用。安赛乐米塔尔新开发的钢粉旨在用于低排放煞车系统,而美国国家航空暨太空总署(NASA)和普兰西股份公司(Plansee AG)的TiAl薄板专案则标誌着航空业的转型,其目标是与传统的镍基高温合金相比减重25%至35%。北美地区的出货量也印证了这一趋势,70%的铁基粉末订单与汽车订单相关,儘管航太合金在涡轮盘和结构支架应用方面仍然价格昂贵。

积层製造技术的应用日益广泛

金属粉末市场日益受到积层製造技术的影响,这些技术对粉末的球形度和流动稳定性提出了更高的要求。 NanoDimension 收购 Desktop Metal 后,整合了其 2.46 亿美元的营收基础,该公司专注于粉末层熔融和黏着剂喷涂技术。 Tecna 正在将专为 60µm 和 90µm 层厚定制的粗粒Ti64 粉末商业化,以加速航太原型产品的生产。由美国能源局(DOE) 支持的 AMAZEMET rePowder 技术可将不规则的回收金属转化为球形原料,扩大了可用废料的范围。 Hoganas 的 CustomAM 平台结合了等离子体和氮气雾化技术,使医疗植入设计人员能够将定製粉末的生产规模从实验室规模扩大到吨级。 ASTM 和 ASME 的认证工作表明,安全关键型核能部件的粉末规范日趋成熟。

职业和环境危害

美国职业安全与健康管理局 (OSHA) 的《可燃粉尘指南》要求金属粉末加工场所配备完善的通风系统、对工人进行培训并做好相关文件记录,这增加了企业的资本成本和营运成本。美国消防协会 (NFPA) 正在将多项文件过渡到 NFPA 660,这是一项涵盖可燃金属处理、精加工和回收的统一标准。美国排放标准要求在过滤过程中进行过滤,并在研磨过程中减少粉尘,粉末涂装室必须配备持续运作的喷灌,以降低闪燃风险。这些法规限制了执法严格地区的产能扩张,并加速了向封闭回路型低排放雾化器的过渡。

细分市场分析

2025年,铁粉在金属粉末市场中占据43.46%的份额,这主要得益于其在汽车同步器、齿轮和结构件等领域的成熟应用。压制和铁基仍将主导生产,太平洋金属公司每月1.5万吨的不銹钢产能为其提供了有力支撑。然而,特种合金预计将以更快的速度成长,到2031年将维持5.55%的复合年增长率,这主要得益于航太、医疗和国防项目对钛、镍和耐火合金高强度重量比的需求。 IperionX公司与美国签订的价值4710万美元的合同,旨在实施氢辅助热还原技术,这凸显了美国致力于实现钛供应链本土化的决心。印度铝业投资 100 亿美元扩建铝业,其中包括将其位于奥里萨邦的冶炼厂的年产能扩大 20 万吨,这将确保产能能够满足电动车机壳和可再生能源电缆的需求。

钢材原料的经济性以及高价值合金的价格,正迫使粉末生产商重新调整其产品组合。供应商正在扩大预合金原料的牌号范围,并减少压制后的混合工序,以提高机械性能的一致性。这为下游用户提供了安全关键零件所需的重复性,金属粉末市场也持续向高利润产品转型。

到2025年,雾化製程仍将占总收入的69.10%,因为气体、水和等离子体製程各自满足不同的流动性和纯度要求。 VDM Metals公司新推出的真空惰性气体雾化器体现了该公司持续的资本投入,旨在确保为高温合金粉末层熔融提供航太级产品。湿式冶金製程虽然小规模,年复合成长率仅5.2%,但其能够回收含锌残渣及含镍污泥,符合循环经济的目标。

新兴技术缩小了颗粒尺寸分布范围并降低了能耗。金属粉末加工厂无需熔化即可将棒材转化为均匀的碎屑,从而降低了废品率和碳排放。电极诱导气体雾化技术比传统的真空感应方法能够生产出更细小、更球形的颗粒,为超薄印刷层开闢了新的前景。同时,电解和还原製程在用于硬面堆焊和硬焊焊膏的高纯度粉末领域仍然占据着一席之地。

区域分析

预计到2025年,亚太地区将占全球营收的44.05%,并在2031年之前维持5.3%的年复合成长率,成为成长最快的地区。中国阴极铜产量年增14.27%,铝产量增加2.6%,印证了其丰富的资源。印度正透过JSW钢铁公司投资78亿美元的奥里萨邦工厂以及与JFE合资投资6.6亿美元的电工钢项目扩大产能,创造了3万个就业机会。日本和韩国在电子和精密加工领域保持领先地位,同时区域政策鼓励基础设施投资和回收(例如,三井物产对MTC Business的投资)。

在北美,创新主导订单保持稳定。 IperionX的钛合约确保了策略自主性,而GE航空航太公司增材製造业务的扩张将使粉末需求集中在喷射发动机组装厂附近。加拿大供应镍和钴精矿,墨西哥仍然是美国OEM项目变速箱和传动装置粉末部件的重要供应商。

欧洲正努力平衡严格的排放法规与高价值製造业的发展。芬兰的一家氢化直接还原铁(DRI)工厂正在塑造低碳钢粉的未来。德国正在资助轻量化传动系统粉末的研究,法国则在推动涡轮叶片热等静压(HIP)计画。 Hoganas公司报告称,自2018年以来,其范围1+2碳排放减少了46%,并且已将其51%的原材料转向再生材料。中东欧正在成为汽车产业的二次烧结中心,而英国正在为航太制定积层製造标准。

南美洲和中东/非洲仍是新兴市场。巴西的铁矿石蕴藏量为烧结矿粉末提供了支撑,但基础设施的匮乏将减缓高附加价值产品的普及。海湾国家正在考虑投资氢能和太阳能,这可能会带动对特种合金粉末的需求。非洲国家正在探索电池金属的开采,但物流和政策稳定性将决定投资的时间表。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 调查先决条件

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 促进汽车和航空领域的减重

- 积层製造技术的应用激增

- 对小型化电子设备的需求不断增长

- 对可再生能源组件的需求不断增长

- 对高超音速防御合金的需求不断增长

- 市场限制

- 职业和环境危害

- 原物料价格波动

- 关键部件中粉末均匀性的局限性

- 价值链分析

- 波特五力模型

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章 市场规模与成长预测

- 类型

- 铁

- 青铜

- 铝

- 硅

- 镍

- 其他类型(钛等)

- 过程

- 原子化

- 化合物还原

- 电解

- 其他製程(例如湿式冶金)

- 製造方法

- 压制烧结(传统粉末冶金)

- 金属射出成型

- 积层製造/3D列印

- 其他方法(热等向性静压等)

- 终端用户产业

- 运输

- 电气和电子设备

- 医疗保健

- 化学/冶金

- 防御

- 建造

- 其他终端用户产业(例如,积层製造服务机构)

- 地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 泰国

- 印尼

- 越南

- 马来西亚

- 菲律宾

- 亚太其他地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 北欧国家

- 土耳其

- 其他欧洲地区

- 南美洲

- 巴西

- 阿根廷

- 哥伦比亚

- 其他南美洲

- 中东和非洲

- 沙乌地阿拉伯

- 阿拉伯聯合大公国

- 卡达

- 南非

- 奈及利亚

- 埃及

- 其他中东和非洲地区

- 亚太地区

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率(%)/排名分析

- 公司简介

- Advanced Technology & Materials Co., Ltd.

- Alcoa Corporation

- ATI

- Aubert & Duval

- BASF

- CNPC Powder

- CRS Holdings, LLC.

- Erasteel

- GKN Powder Metallurgy

- HC Starck Tungsten GmbH

- Hitachi High-Tech India Private Limited

- Hoganas AB

- JFE Steel Corporation

- Kymera International

- Metalysis Ltd.

- Polema

- Linde Plc

- Outokumpu

- Rio Tinto Metal Powders

- Sandvik AB

- Seiko Epson Corporation

- Tekna

- Valimet

第七章 市场机会与未来展望

Metal Powder Market size in 2026 is estimated at USD 7.56 billion, growing from 2025 value of USD 7.21 billion with 2031 projections showing USD 9.56 billion, growing at 4.8% CAGR over 2026-2031.

Demand is anchored in automotive electrification, aerospace modernization, and the industrialization of additive manufacturing, which together create a broad pull for powders ranging from low-alloy iron grades to bespoke nickel- and titanium-based compositions. Light-weighting programs in vehicles and aircraft, the proliferation of electric drive trains, and the rising adoption of 3D-printed structural parts keep consumption on an upward track. At the same time, powder makers face raw-material price swings and tightening environmental rules that boost compliance costs yet also spur investments in cleaner atomization technologies. Competitive momentum is tilting toward suppliers that can flex between high-volume press-and-sinter contracts and low-volume, high-margin additive jobs, reinforcing the need for process diversity.

Global Metal Powder Market Trends and Insights

Light-weighting Push in Auto & Aero Sectors

Automotive OEMs continue to cut vehicle mass to extend electric-vehicle range and meet Euro 7 brake-emission norms, prompting broader uptake of high-density ferrous and aluminum powders designed for soft-magnetic composites. ArcelorMittal's newly developed steel powders target low-emission braking systems, while NASA and Plansee AG's TiAl sheet program shows aviation's pivot toward 25-35% weight savings over legacy Ni-base superalloys. North American shipments underscore the trend, with 70% of ferrous powder tonnage tied to automotive orders, even as aerospace alloys command premium pricing in turbine disk and structural bracket applications.

Surge in Additive Manufacturing Adoption

The metal powder market is increasingly shaped by additive manufacturing, which demands highly spherical, flow-stable powders. Nano Dimension's agreement to acquire Desktop Metal consolidates a USD 246 million revenue base devoted to powder-bed fusion and binder-jet technologies. Tekna has commercialized coarse Ti64 fractions tailored for 60 µm and 90 µm layers to cut build times in aerospace prototypes. DOE-backed AMAZEMET rePowder converts irregular reclaimed metal into spherical feedstock, widening the usable scrap pool. Hoganas' CustomAM platform, combining plasma and nitrogen atomization, lets medical-implant designers scale bespoke powders from lab batches to tons. ASTM and ASME qualification workstream signals the maturing of powder specifications for safety-critical nuclear parts.

Occupational & Environmental Hazards

OSHA combustible-dust guidelines mandate extensive ventilation, worker training, and documentation for metal-powder sites, lifting both capital and operating spend. NFPA is transitioning multiple documents into the unified NFPA 660 standard to cover handling, finishing, and recycling of combustible metals. EPA effluent limits now require filtration on abrasive blasting plus dust minimization during grinding, while powder-coating booths must install continuous-duty sprinklers to address flash-fire risk. Collectively, these rules constrain capacity expansions in regions with stringent enforcement and speed the shift toward closed-loop, low-emission atomizers.

Other drivers and restraints analyzed in the detailed report include:

- Increasing Demand for Electronics Miniaturization

- Growing Demand for Renewable-Energy Components

- Raw-Material Price Volatility

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Iron powders carried 43.46% of metal powder market share in 2025, aided by entrenched use in automotive synchronizers, gears, and structural parts. Volumetric heft still stems from press-and-sinter ferrous grades, supported by Pacific Metals' 15,000 t/month stainless capacity. Specialty alloys, however, claim faster growth at 5.55% CAGR through 2031 as aerospace, medical, and defense programs specify titanium, nickel, and refractory blends for elevated strength-to-weight ratios. IperionX's USD 47.1 million DoD contract to deploy Hydrogen-Assisted Metallothermic Reduction validates US ambitions for a native titanium supply chain. Hindalco's USD 10 billion aluminum build-out, including a 200,000 TPA Odisha smelter step-up, ensures capacity for electric-vehicle housings and renewable-energy cabling.

The interplay of commodity iron economics and premium alloy pricing encourages powder makers to balance output portfolios. Suppliers widen grade catalogs with pre-alloyed feeds that reduce post-press blending, improving mechanical consistency. In turn, downstream users gain repeatability essential for safety-critical parts, keeping the metal powder market in structural transition toward higher-margin mix.

Atomization retained 69.10% revenue in 2025, as gas, water, and plasma routes satisfy divergent flowability and purity demands. VDM Metals' new vacuum inert gas atomizer demonstrates ongoing capital deployment to secure aerospace-grade outputs for superalloy powder-bed fusion. Hydrometallurgical processing, while only a 5.2% CAGR pocket, recovers zinc-rich residues and nickel-bearing sludges, dovetailing with circular-economy targets.

Emergent techniques tighten particle-size bands and cut energy use. Metal Powder Works converts barstock into uniform chips without melting, trimming scrap rates and carbon footprints. Electrode-induction gas atomization yields finer spheres than legacy vacuum induction, opening new territories for ultra-thin printable layers. Meanwhile, electrolysis and reduction processes keep niche footholds for high-purity powders required in hard-facing and brazing pastes.

The Metal Powder Market Report is Segmented by Type (Iron, Bronze, Aluminum, and More), Process (Atomization, Reduction of Compounds, and More), Manufacturing Method (Press and Sinter, and More), End-User Industry (Transportation, Electrical and Electronics, and More), and Geography (Asia-Pacific, North America, Europe, South America, Middle East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific led with 44.05% revenue in 2025 and is projected to post the fastest 5.3% CAGR to 2031. China's copper-cathode output grew 14.27% year on year, and aluminum production rose 2.6%, underscoring resource depth. India widens capacity through JSW Steel's USD 7.8 billion Odisha complex plus a USD 660 million electrical-steel joint venture with JFE that adds 30,000 jobs. Japan and South Korea sustain electronics and precision machining leadership, while regional policy favors infrastructure investment and recycling ventures exemplified by Mitsui's stake in MTC Business.

North America shows steady, innovation-driven orders. IperionX's titanium contract secures strategic autonomy, while GE Aerospace's additive build-out clusters powder demand near jet-engine assembly hubs. Canada supplies nickel and cobalt concentrates, and Mexico remains integral for gearbox and transmission powder parts shipped into US OEM programs.

Europe balances stringent emissions rules with high-value manufacturing. Finland's hydrogen-DRI plant signals a low-carbon future for steel powders. Germany funds lightweight drivetrain powder research; France pushes turbine-blade HIP programs. Hoganas documents a 46% drop in scope 1+2 carbon since 2018, shifting 51% of feedstock to secondary streams. Central and Eastern Europe host automotive tier-2 sintering hubs, while the UK advances aerospace additive standards.

South America, the Middle East, and Africa remain emergent. Brazil's iron-ore reserves support sinter-base powders, yet infrastructure gaps slow additive uptake. Gulf nations eye hydrogen and solar investments that may translate into demand for specialty alloy powders. African states explore battery-metal mining, though logistics and policy stability condition investment timelines.

- Advanced Technology & Materials Co., Ltd.

- Alcoa Corporation

- ATI

- Aubert & Duval

- BASF

- CNPC Powder

- CRS Holdings, LLC.

- Erasteel

- GKN Powder Metallurgy

- H.C. Starck Tungsten GmbH

- Hitachi High-Tech India Private Limited

- Hoganas AB

- JFE Steel Corporation

- Kymera International

- Metalysis Ltd.

- Polema

- Linde Plc

- Outokumpu

- Rio Tinto Metal Powders

- Sandvik AB

- Seiko Epson Corporation

- Tekna

- Valimet

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Light-weighting push in auto & aero sectors

- 4.2.2 Surge in additive manufacturing adoption

- 4.2.3 Increasing demand for electronics miniaturization

- 4.2.4 Growing demand for renewable-energy components

- 4.2.5 Increasing requirement for defense hypersonics alloy demand

- 4.3 Market Restraints

- 4.3.1 Occupational & environmental hazards

- 4.3.2 Raw-material price volatility

- 4.3.3 Powder consistency limits in critical parts

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size & Growth Forecasts (Value)

- 5.1 Type

- 5.1.1 Iron

- 5.1.2 Bronze

- 5.1.3 Aluminum

- 5.1.4 Silicon

- 5.1.5 Nickel

- 5.1.6 Other Types (Titanium, etc.)

- 5.2 Process

- 5.2.1 Atomization

- 5.2.2 Reduction of Compounds

- 5.2.3 Electrolysis

- 5.2.4 Other Processes (Hydrometallurgical Routes, etc.)

- 5.3 Manufacturing Method

- 5.3.1 Press and Sinter (Conventional PM)

- 5.3.2 Metal Injection Molding

- 5.3.3 Additive Manufacturing / 3D Printing

- 5.3.4 Other Methods (Hot Isostatic Pressing, etc.)

- 5.4 End-User Industry

- 5.4.1 Transportation

- 5.4.2 Electrical and Electronics

- 5.4.3 Medical

- 5.4.4 Chemical and Metallurgical

- 5.4.5 Defense

- 5.4.6 Construction

- 5.4.7 Other End-User Industries (Additive Manufacturing Service Bureaus, etc.)

- 5.5 Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 Thailand

- 5.5.1.6 Indonesia

- 5.5.1.7 Vietnam

- 5.5.1.8 Malaysia

- 5.5.1.9 Philippines

- 5.5.1.10 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Russia

- 5.5.3.7 NORDIC Countries

- 5.5.3.8 Turkey

- 5.5.3.9 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Colombia

- 5.5.4.4 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 United Arab Emirates

- 5.5.5.3 Qatar

- 5.5.5.4 South Africa

- 5.5.5.5 Nigeria

- 5.5.5.6 Egypt

- 5.5.5.7 Rest of Middle East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products & Services, Recent Developments)

- 6.4.1 Advanced Technology & Materials Co., Ltd.

- 6.4.2 Alcoa Corporation

- 6.4.3 ATI

- 6.4.4 Aubert & Duval

- 6.4.5 BASF

- 6.4.6 CNPC Powder

- 6.4.7 CRS Holdings, LLC.

- 6.4.8 Erasteel

- 6.4.9 GKN Powder Metallurgy

- 6.4.10 H.C. Starck Tungsten GmbH

- 6.4.11 Hitachi High-Tech India Private Limited

- 6.4.12 Hoganas AB

- 6.4.13 JFE Steel Corporation

- 6.4.14 Kymera International

- 6.4.15 Metalysis Ltd.

- 6.4.16 Polema

- 6.4.17 Linde Plc

- 6.4.18 Outokumpu

- 6.4.19 Rio Tinto Metal Powders

- 6.4.20 Sandvik AB

- 6.4.21 Seiko Epson Corporation

- 6.4.22 Tekna

- 6.4.23 Valimet

7 Market Opportunities & Future Outlook

- 7.1 White-space & Unmet-Need Assessment

- 7.2 Increasing Developments in Healthcare Industries